Thin-Film and Multilayers

Nanoscale multilayers have been the subject of extensive studies for more than one decade due to their tremendous possibilities for developing new generations of multifunctional materials. Multilayers with excellent electrical, magnetic, optical and mechanical properties have been developed by proper selection and optimization of layered material. Metal/metal, metal/ceramic and ceramic/ceramic multilayers in this case have been investigated for different applications. In particular, metal/ceramic multilayers, with their unique ductile/brittle layer structure, possess an optimum combination of high hardness, toughness and damage tolerance, which makes them very attractive as protective coatings, packaging coatings, and more recently optical absorbing coatings.

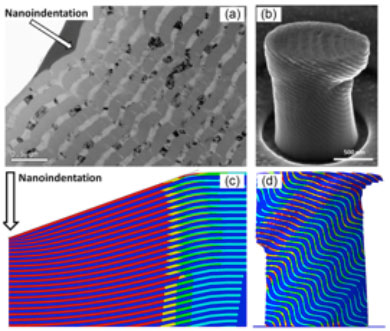

The deformation mechanisms of metal/ceramic multilayers are quite different from those observed in bulk systems or even other layered systems, due to the high interfacial area and dramatically small length scale. As a result, exploring the deformation mechanisms of metal/ceramic multilayers is still challenging but crucial not only from the engineering viewpoint, but also from the fundamental perspective. For the present study, instrumented nanoindentation, micropillar compression as well as the finite element modeling is employed to explore the deformation mechanisms of Al/SiC multilayers. The main objective of this study is to quantify the role of the individual layer thickness, temperature and/or Al-SiC interface (interface property, waviness) on the strength of Al/SiC multilayers.

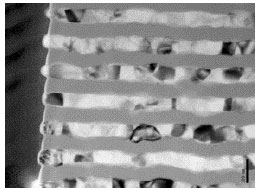

(a) Al/SiC multilayers cross-sectional morphology after nanoindentation; (b) deformed Al/SiC micropillars with 45° interface orientation; (c, d) Von Mises Contours of the Al/SiC multilayers after nanoindentation and micropillar compression