X-Ray Tomography

The understanding of materials has gradually increased aided by the development of methods that provide as complete and unbiased description of microstructure as possible. X-ray computed tomography (XCT) is a non-destructive imaging technique that provides information on the three-dimensional (3D) structure of a material. It is based on the collection of a series of radiographies on an X-ray detector at different angular positions. Absorption contrast X-ray computed tomography is probably the most well-known 3D X-ray imaging method. In this mode it is possible to detect differences between x-ray absorption coefficients of different phases, inclusions, defects, damage, etc. provided they are different enough. This technique has been traditionally used in medicine, but it became increasingly interesting for material science application with the improvement in spatial and temporal resolution for laboratory devices.

Our research lines are:

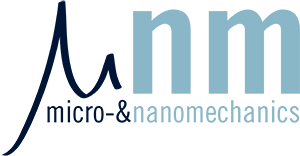

- 4D tomography: damage development and evolution in structural materials, e.g. fiber reinforced composites, light metal alloys, steels, etc. by means of in-situ or sequential testing at room and high temperature. Some examples are tensile, fatigue, three point bending, creep

- Optimization of Out-of-Autoclave Processing of Composites (AROOA & DEFCOM project).

- Effect of the casting defects in Mg alloys and Ni-based superalloys (XMART project).

- Correlation between 3D microstructure and mechanical properties of materials.

- In-situ XCT infiltration of fibers by vacuum assisted resin transfer molding process