4D tomography

In-situ XCT infiltration of fibers by vacuum assisted resin transfer molding process

Fibre-reinforced polymers are extensively used in the automotive, aerospace and energy industries for structural applications. The interest in Liquid Composite Moulding (LCM) processes, for the production of composite materials has grown in the last years, especially in the vacuum assisted resin transfer moulding (VARTM) process due to its relative low cost and the possibility to process large panels, for example for wind turbine blades. However, the large amount of physical variables that control the infusion process impacts on the quality of the panels and the physical process is not well understood.

The liquid flow in the panel exhibits a dual scale behaviour in which the fibre tows saturate at a much slower rate (microflow) than the bulk preform, i.e. between the tows (macroflow). These two flows exist due to the different permeability between the fibre tows and the bulk, being the former one several orders of magnitude lower than the later one. Under certain conditions some regions might remain partially saturated, due e.g. to trapped air or differences between capillarity and resin pressures which leads to low quality panels.

The resin flow process through the fiber fabric is very complex and understanding the parameters that control the nucleation, growth and coalescence of pores during infusion the key to improve the VARTM process. Therefore an in-situ infiltration device was developed at IMDEA to investigate the infusion process and the first results will be published soon.

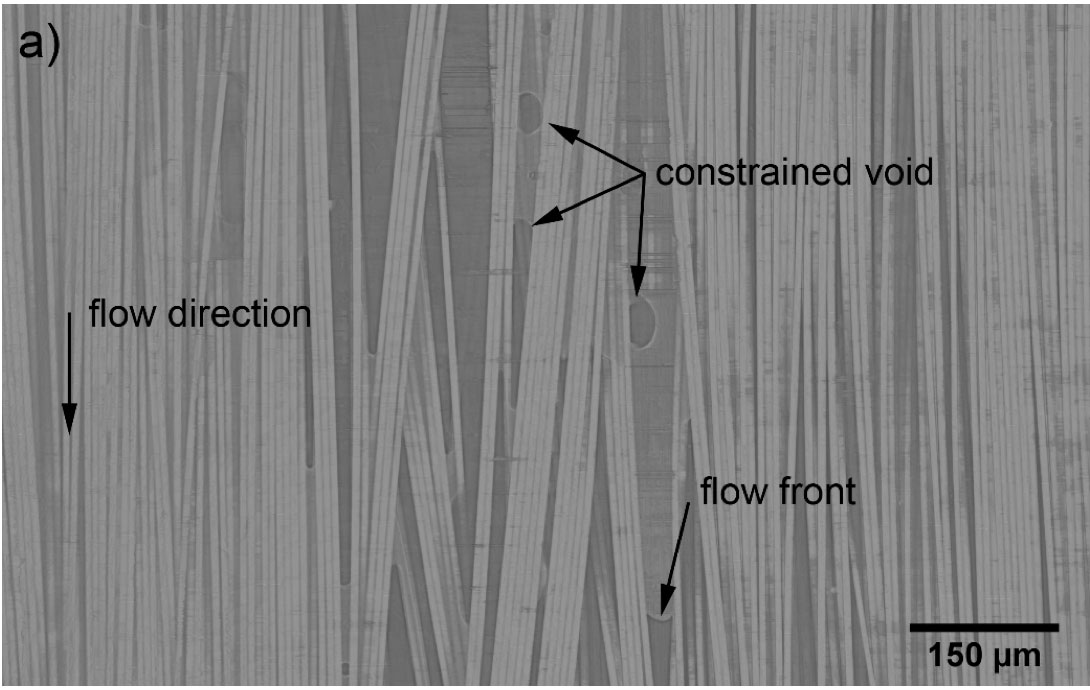

During tow impregnation, microvoids and macrovoids can be followed by XCT. Microvoids are generated by small inhomogeneities in the flow velocity in the tow cross section resulting in zones/channels where the fluid propagates faster. These differences in the velocity of the flow at the tow level are shown in Fig. 1. Elongated voids are formed as a result of the differences in the longitudinal flow within the tows. The migration of the void along the tow is sometimes constrained by presence of two fibers with convergent trajectories that can trap the void and arrest the propagation. These voids can escape from this trap in the longitudinal direction if the pressure gradient is large enough to push them throughout the constrained capillary channel. Otherwise, they will try to move along the transverse direction and the final transportation path depends on the different constraints, longitudinal and transverse, experience by the void towards the outlet gate.

Fig. 1: Longitudinal cross section of the impregnated tow showing trapped voids and the flow front meniscus. Local fiber misalignments with convergent/divergent trajectories are also visible.

[1] J. Vilà, F. Sket, F. Wilde, G. Requena, C- González, J. Llorca. An in situ investigation of microscopic infusión and void transport during vacuum-assisted infiltration by means of X-ray computed tomography. Compos. Sci. and Tech. 119 (2015) 12-19.

DOI: http://dx.doi.org/10.1016/j.compscitech.2015.09.016