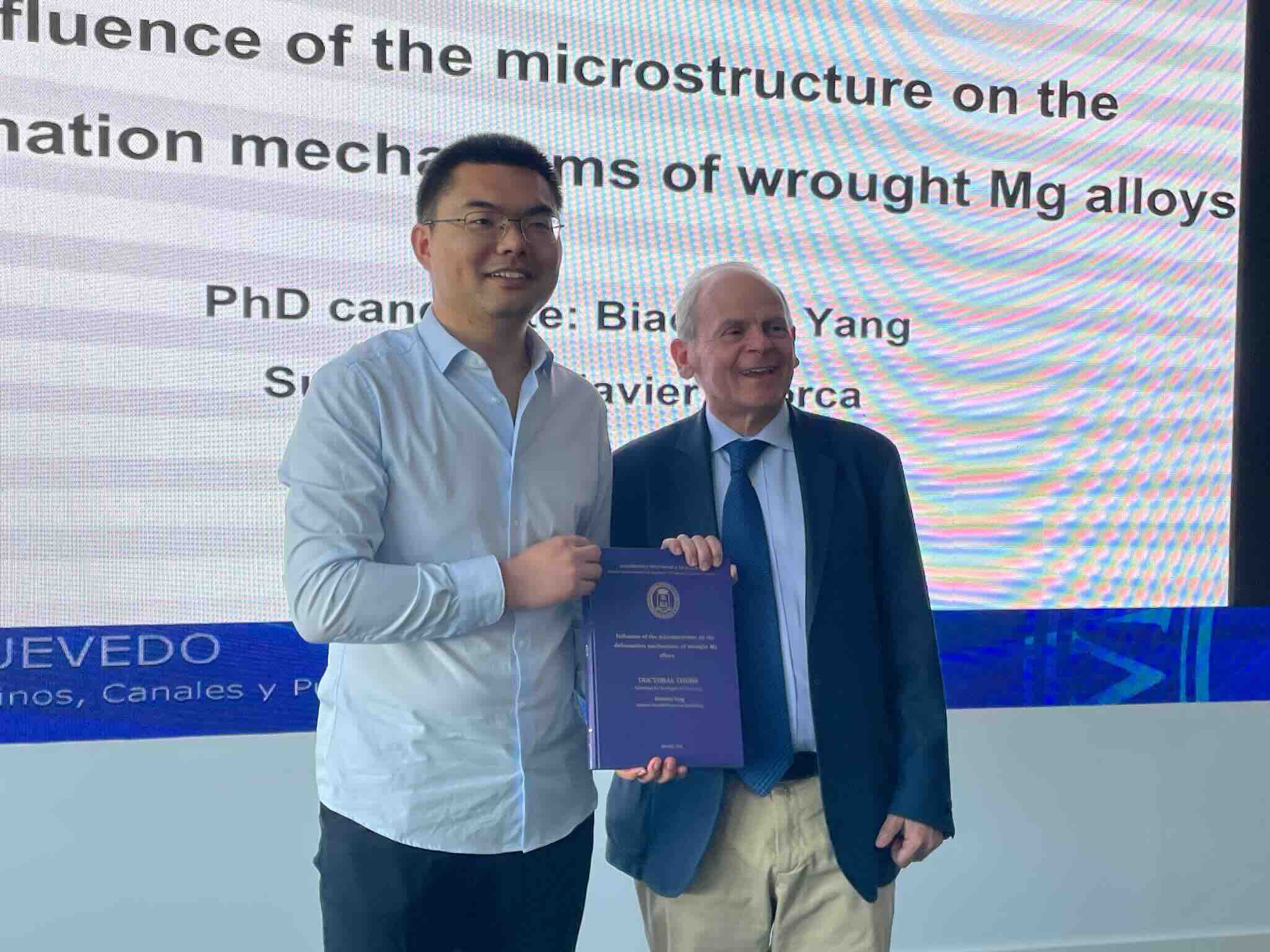

Maral Sarebanzdeh receives the Acta Student Award

Maral sarebanzadeh has received the Acta Student Award for his primary contribution to the paper: M. Sarebanzadeh, A. Orozco-Caballero, E. Nieto-Valeiras, J. LLorca – Twin nucleation at grain boundaries in