💜🔬✨ International Day of Women and Girls in Science ✨🔬💜

Today, we celebrate the International Day of Women and Girls in Science, a day to recognize the talent, dedication, and impact of the many women who contribute every day to

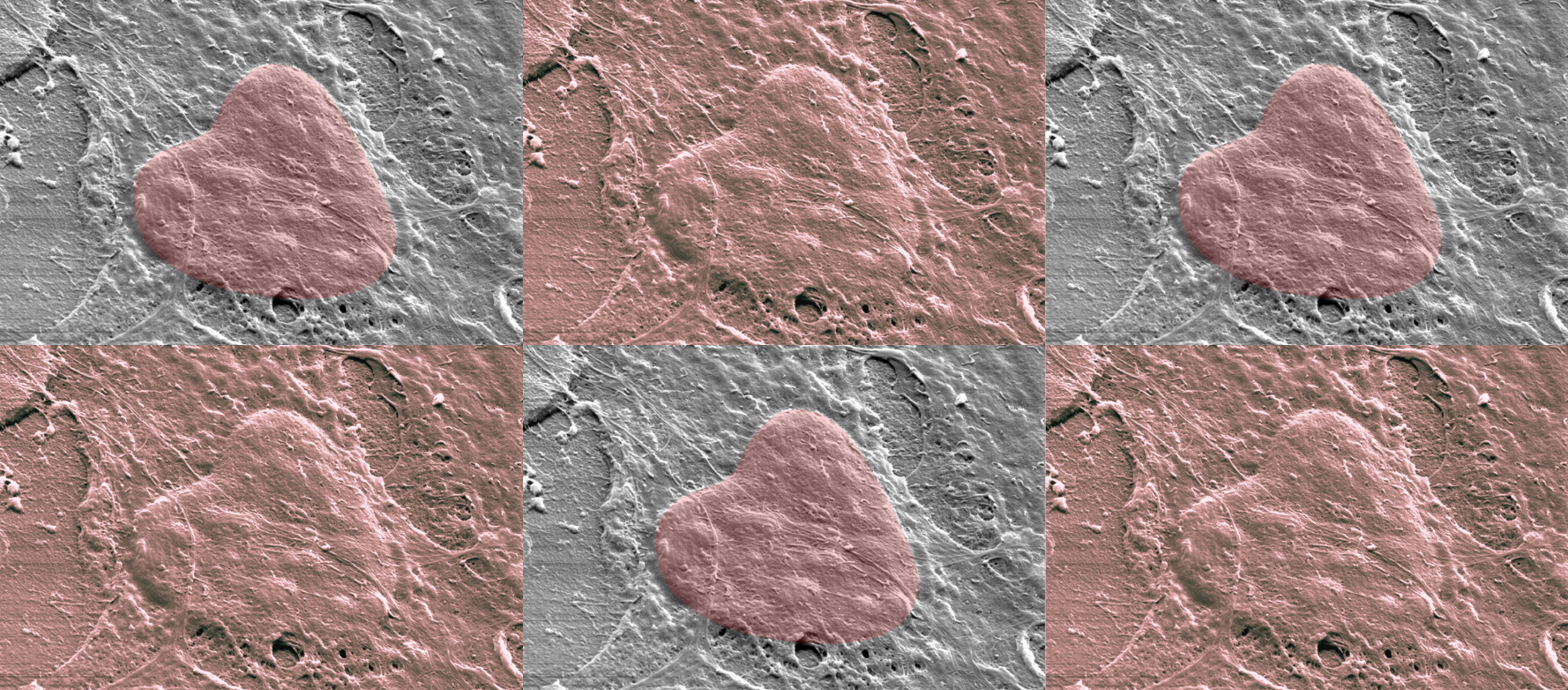

Image: Dr. Monsur Islam

Image editing and Text: Ángela García de la Camacha Díaz

As February arrives, streets, shops and everyday life begin to fill with roses, petals, chocolates, teddy bears, and heart-shaped decorations. The atmosphere itself seems to change, becoming lighter and more romantic. Wherever we look, it feels as if Cupid has been very busy, sending his arrows everywhere. As the famous song says, “love is in the air”. And perhaps it truly is present in more places than we can imagine. Spanish poet José Ángel Valente once wrote that love is found in everything we reach for, everything we lift up, everything we fight for, and everything we gather and seed… And it was precisely there, in that idea, where we found our greatest surprise.

In the lab, we were carrying out cell differentiation experiments using 3D pyrolytic carbon scaffolds. On these structures, pre-osteoblast MC3T3-E1 cells were cultured for 21 days in a osteogenic differentiation medium. When we observed the samples under a scanning electron microscope, we noticed something unexpected: one of the cells had adopted a shape strikingly similar to a heart. It was hard not to think that Cupid’s arrow had also found its way into our experiment. As if the poet had anticipated it, love seemed to be seeded there too! Reminding us once again that love is everywhere, even in science.

From the BCD Group, we wish you a happy month of love, love in all its forms. And in our case, a very special one: an endless love for biomaterial science.

MC3T3-E1 cells were cultured for 21 days in a osteogenic differentiation medium.

Biometals, Coatings, and Devices Alumni.

Biometals, Coatings, and Devices PhD Student.

Don’t forget to follow us on Linkedin to keep updated of all the relevant information from the BCD group!

Today, we celebrate the International Day of Women and Girls in Science, a day to recognize the talent, dedication, and impact of the many women who contribute every day to

We are very happy to welcome Dr. Patricia González Jiménez as a new postdoctoral researcher in the BCD Group. Her work aims to bridge experimental models and predictive tools to

Last week, from January 22nd to 24th, members of the BCD Group attended the II Workshop on Additive Biofabrication, held in Santiago de Compostela. The event brought together researchers working

Today, we celebrate the International Day of Women and Girls in Science, a day to recognize the talent, dedication, and impact of the many women who contribute every day to

We are very happy to welcome Dr. Patricia González Jiménez as a new postdoctoral researcher in the BCD Group. Her work aims to bridge experimental models and predictive tools to

Last week, from January 22nd to 24th, members of the BCD Group attended the II Workshop on Additive Biofabrication, held in Santiago de Compostela. The event brought together researchers working

Vanessa Hernández-Montes, J.F. Santa-Marín, R. Buitrago-Sierra, Javier Llorca, Mónica Echeverry-Rendón, Surfaces and Interfaces, 2025

Yu-Yao Liu, Marko Dobricic, Claudio Intini, ergal J. O’Brien, Javier LLorca, Mónica Echeverry-Rendón, Colloids and Surfaces B: Biointerfaces, 2025

Guillermo Domínguez López, Paul Luis Williams, Javier LLorca, Mónica Echeverry-Rendón, Journal of Bio- and Tribo-Corrosion, 2025