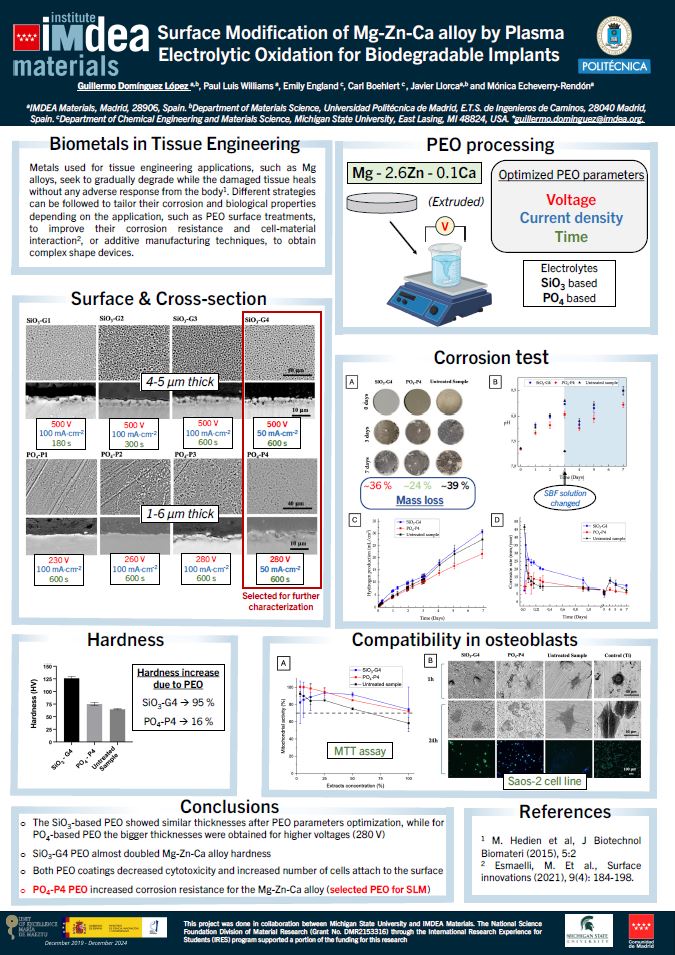

New publication in Surface & Coatings Technology

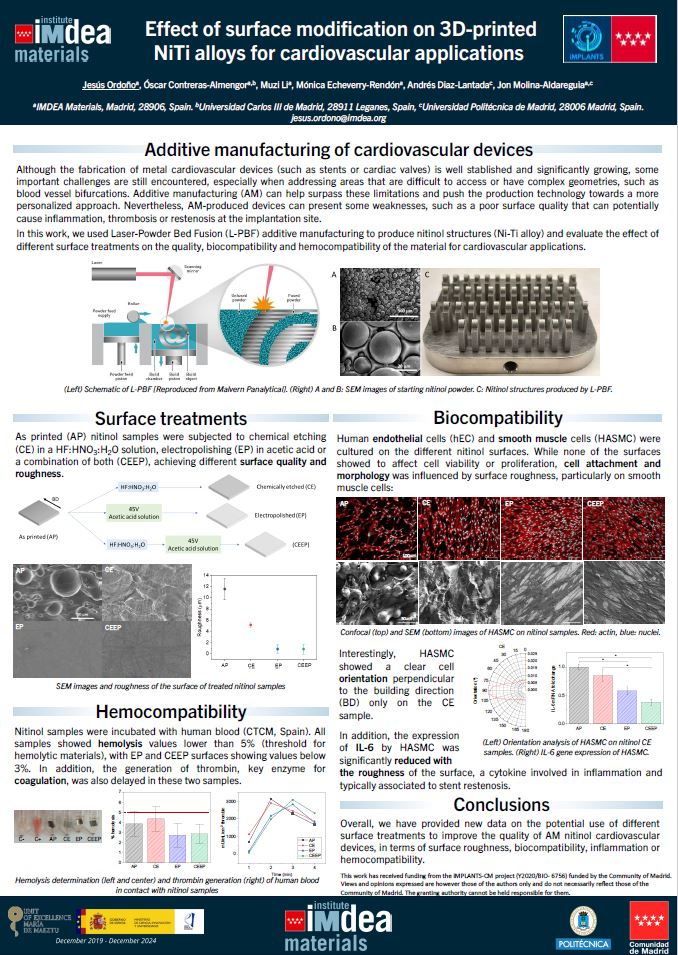

The BCD Group is proud to share our latest publication in Surface & Coatings Technology! Congratulations to our colleagues Guillermo Domínguez López, Javier LLorca and Mónica Echeverry-Rendón for this great