Patent details

Status

Spanish patent filed

Inventors

Jon Molina, Oscar Roberto Contreras, Mónica Echeverry, Muzi Li, Jesús Ordoño, Andrés Díaz Lantada, Carlos Aguilar Vega, Rodrigo Zapata Martínez

Application number

P202530946

Applicant

IMDEA Materials Institute and Technical University of Madrid

Priority date

15/10/2025

Transfer opportunity

Technology License

Summary

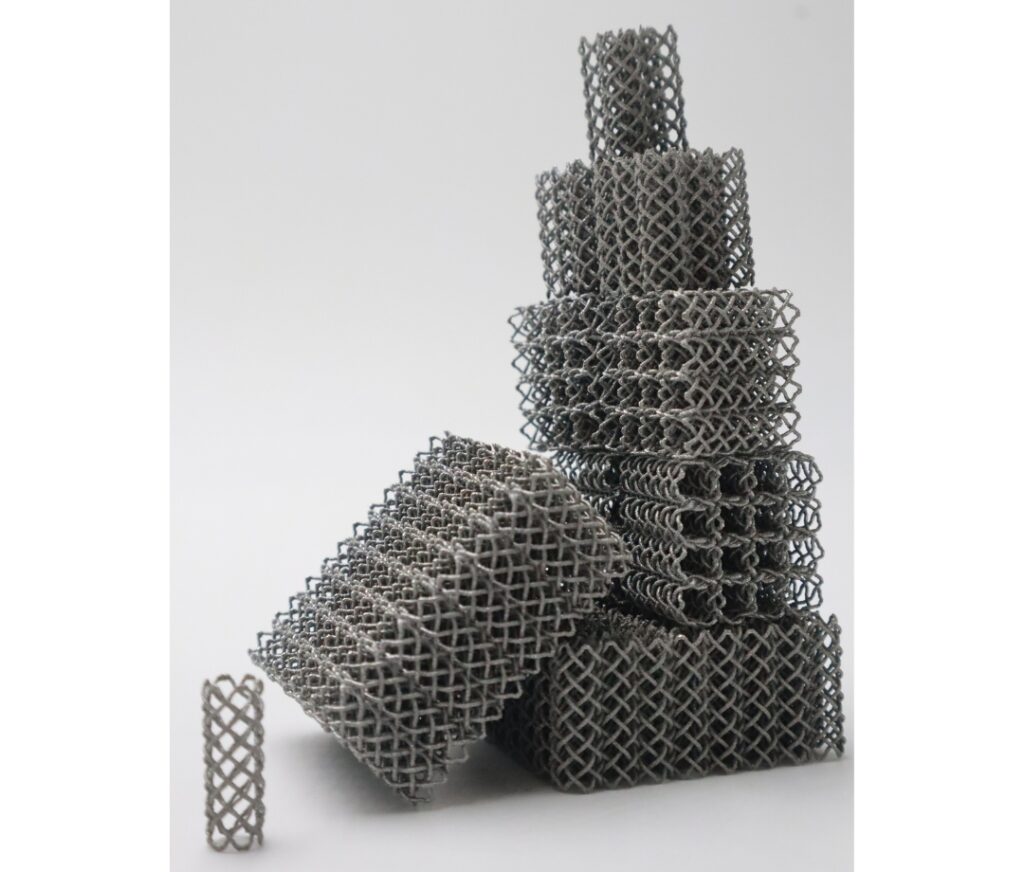

A computational design and additive manufacturing methodology for creating Nitinol personalised, functionally graded braided textile-based architectures (see figures below) for next-generation biomedical implants and engineering devices. Utilising advanced algorithms, the approach enables the 3D printing of complex, interlaced fiber structures from smart alloys (Nitinol) that exhibit superelastic and shape-memory properties, allowing the fabricated actuators to undergo large deformations (>50%) while maintaining minimal hysteresis and returning to their original configuration with exceptional precision, enabling engineer structures and devices with simultaneous high strength, large-scale reversible deformability, superior energy absorption, and patient-adaptive geometry.

Description

The technology enables the 3D printing of personalised braided Nitinol actuators with controlled sinusoidal fiber geometry, spacing, and variable cross-sectional thickness. Through an integrated computational algorithm that incorporates topological optimisation and mathematical modelling, the methodology generates continuous, interlaced, closed-fibre architectures capable of accommodating complex anatomical geometries and vascular bifurcations, even in the presence of predefined discontinuities or functional voids. The resulting metamaterials merge the mechanical advantages of textile-based architectures with the precision and customisation of additive manufacturing, as well as the smart thermomechanical properties of Nitinol.

Advantages

- Complex anatomical customisation: Non-circular, patient-specific geometries including vascular bifurcations and intricate three-dimensional topologies.

- Smart material integration: use of Nitinol (NiTi) for shape-memory and superelastic behaviour.

- Optimised mechanical performance: low hysteresis, high energy absorption, and fatigue resistance.

- Design automation: computational control of fiber orientation, spacing, and cross-section.

- Multi-functional potential: same design logic applicable to implants (stents, valves), lightweight structures for aerospace and energy-absorbing devices.

Contact

Technology Transfer and Innovation Office, IMDEA Materials Institute

Email: techtransfer@imdeamaterials.org

Telephone: +34 91 5493422