Synthesis, processing and integration of materials

Metallic alloys

• Bulk processing techniques: casting by induction and arc

melting, GLEEBLE 3800 thermo-mechanical simulator equipped with tools for physical simulation of casting, rolling, forging, welding, sintering, and controlled heat treatments.

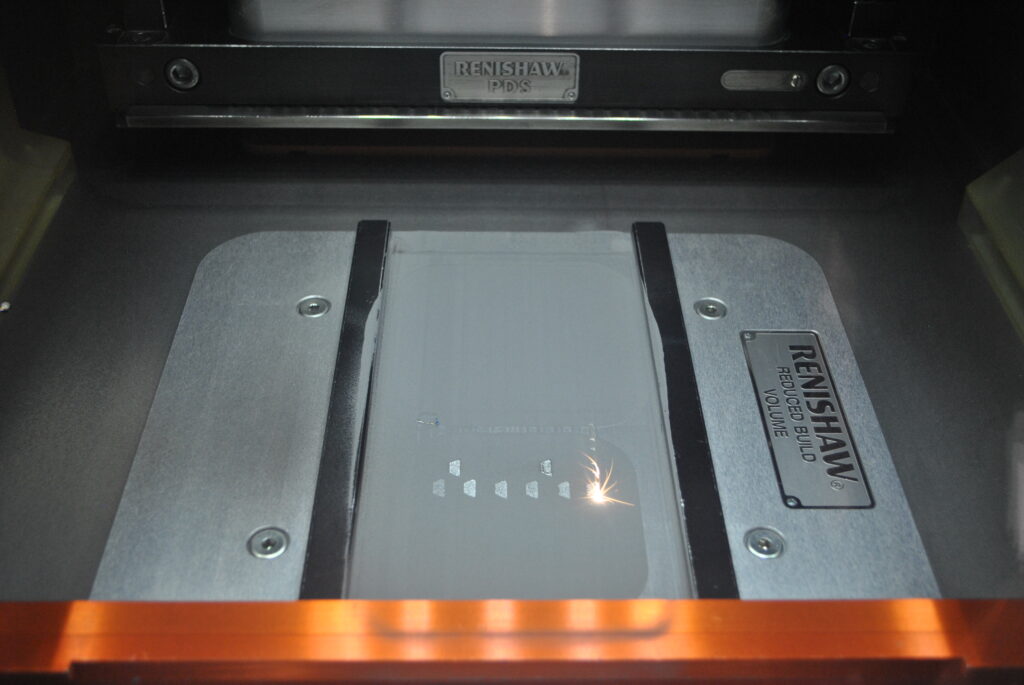

• Powders manufactured by gas atomisation and mechanical milling. Selective laser melting technology for additive manufacturing of metals.

Polymer based composites and nanocomposites

• Liquid moulding processing: RTM resin transfer moulding, VI vacuum infusion, RFI resin film infusion and pultrusion.

• Prepreg lamination using vacuum bagging of autoclave and out-of-autoclave prepregs (OoA) or laminate hot-press moulding (<400°C).

• Semi-industrial equipment for compounding and injection moulding of thermoplastics.

• Integration of advanced nano-fillers.

• Filament maker for 3D printing (3dvo).

• Melt flow index.

Nanomaterials

• Synthesis and chemical modification of nanocarbons, inorganic materials, nanoporous semiconductors, thin films, zeolites and other nanomaterials.

• Evaporation equipment in controlled atmospheres, high-pressure reactors and in-house chemical vapour deposition systems.

Energy storage and conversion devices

• Synthesis and characterisation of nanostructured electrode materials for energy storage applications. Fabrication of

composite electrodes and integration in various types of rechargeable batteries (Li-ion, Li-S, Li-O2, Na-ion, and hybrid batteries, etc.).

• Fabrication and testing of nanocarbon-based electrodes and their integration with liquid and solid electrolytes to form large-area (> 100 cm2) flexible supercapacitors.

• Integration of energy-storage functions in structural composites.

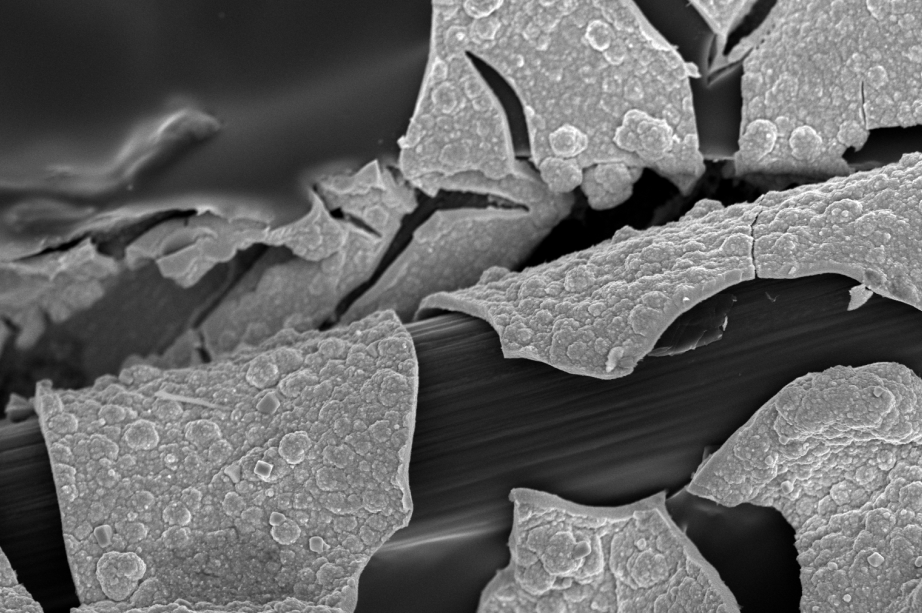

Microstructural and chemical characterisation

• 3D microscopy at different length-scales, including X-ray tomography, X-ray diffraction, 3D-SEM, 3D-EDS and 3D-EBSD in the FIB and 3D-TEM and 3D-EDS in the TEM.

• In-situ thermo-mechanical testing of mininaturised samples in the X-ray tomography system, as well as in the SEM and TEM.

• In-situ processing studies in the X-ray tomography system, such as casting, infiltration and curing of polymer based materials.

• Raman spectrophotometer.

• Gel permeation chromatography.

• Particle size analyser.

• Freeze dryer.

• In-situ thermal studies of polymers in the X-ray diffractometer.

Mechanical properties

• Mechanical testing of a wide range of materials, using electromechanical and hydraulic machines (quasi-static, dynamic, fracture and fatigue testing in a wide range of temperatures).

• Characterisation of mechanical properties at multiple length scales, including nanoindentation, micropillar compression, microtensile testing and fracture micromechanics.

• Tests can be carried out both ex-situ and in-situ in SEM, TEM and X-ray tomography, including measurements at elevated temperature.

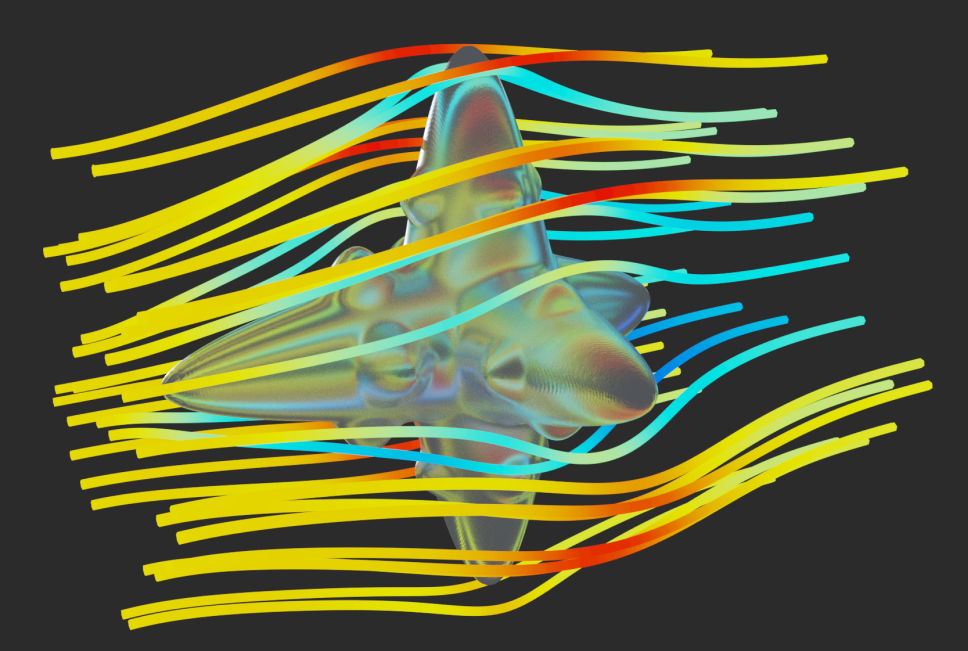

Simulation

• Simulation techniques at different scales (electronic, atomistic, mesoscopic and continuum) to design or improve materials and components by means of virtual testing and virtual processing.

• High-performance computer cluster (1000 Intel Xeon CPU cores and NVIDIA GPU acceleration leading to a computational power of 120 Tflops).

• In-house developed simulation tools.

• Commercial and open source software tools for modelling and simulation in Materials Science and Enginnering (CALPHAD, DICTRA, Micress, Abaqus, LSDyna, PamCrash, LAMMPS, VASP, etc.).

Functional properties

Fire resistance

• Rapid laboratory scale tests for screening (micro-scale combustion calorimetry and oxygen index).

• Dual cone calorimetry and UL94 Horizonal/Vertical Flame Chamber.

Thermal

• DSC, TGA and Hot Disk Thermal Conductivity analyser. Thermal behaviour of mechanical properties, DMA and rheology.

• Pushrod Dilatomer for the measurement of dimensional changes.

Electrochemical

• Electrochemical characterisation of energy storage devices (Li-ion, Li-S, Li-O2, Na-ion, and hybrid batteries). Simultaneous testing of 100 batteries can be performed using a multichannel battery tester.

• Galvanostatic/potentiostatic cycling at various current densities.

• Single channel Zive SP1 electrochemical workstation is used for cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) study of batteries.

• LCR equipment to quantify dielectric properties in composites.

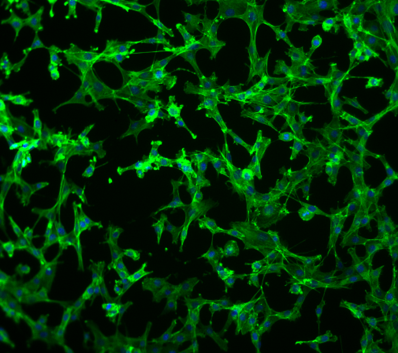

Biomaterials and cell culture

• Confocal, fluorescence and inverted microscopes.

• PCR instrument.

• Multi-mode plate reader (absorbance, fluorescence, luminescence).

• Ultrasonic processor.

• Autoclave.

• Protein gel electrophoresis and blotting system.

• Liquid nitrogen tank for cell storage and 80ºC freezer.

• Prusa mini 3D printer.

• Biosafety cabinets.

• Benchtop and CO2 incubators.

• Centrifuge and microcentrifuge, vortex mixers, hot plate stirrer, dry block heater, UV lamp, and thermostatic water baths.