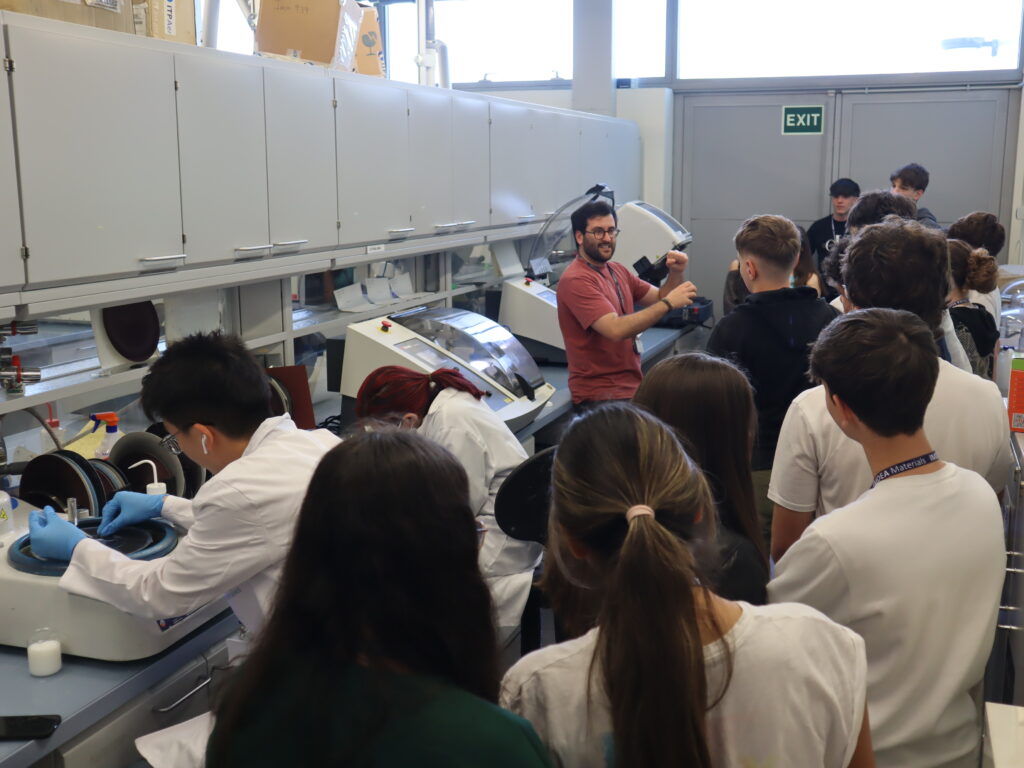

Materials science in focus in IMDEA Materials’ 14th annual imaging contest

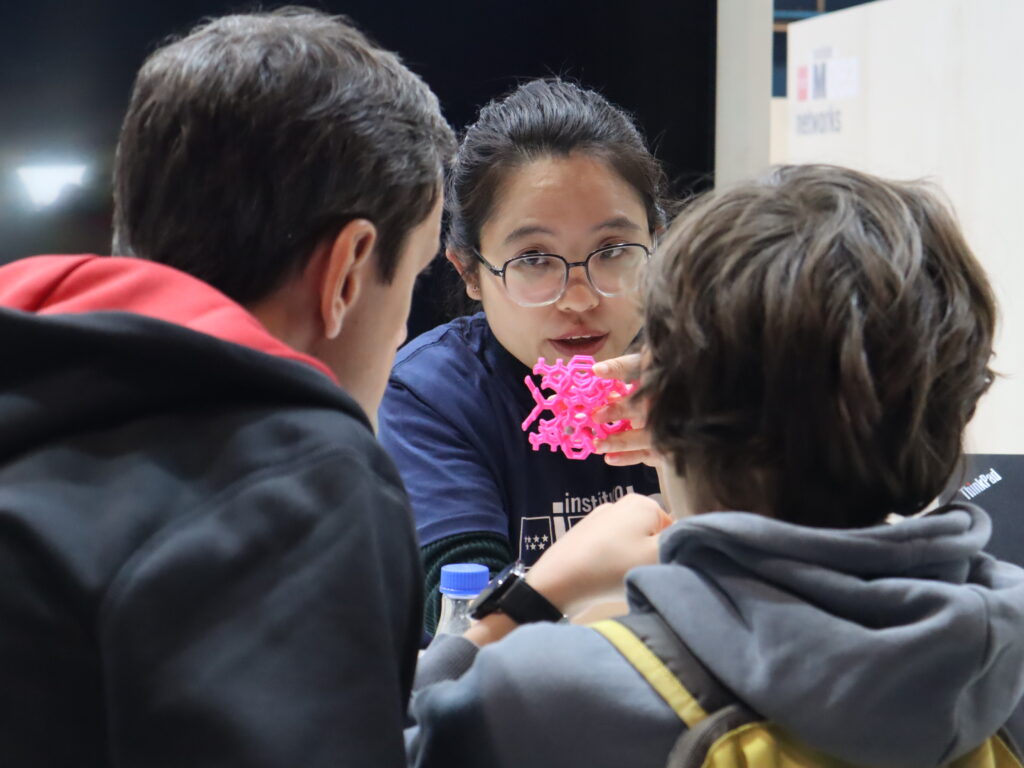

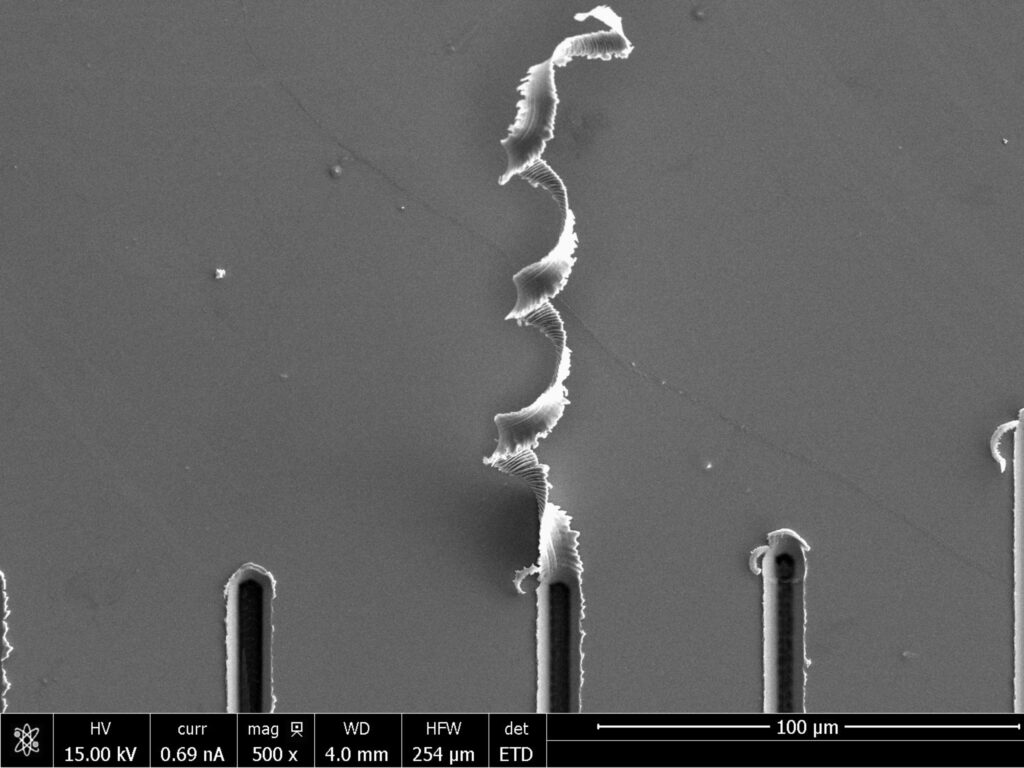

IMDEA Materials recently celebrated our 14th annual Scientific Imaging Contest, featuring images related to materials characterisation, processing, simulation, as well as daily life at the Institute.