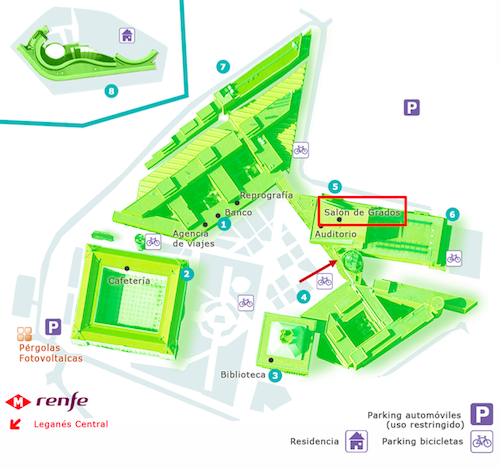

The PhD Defense will take place next Friday, April 21st, at 11:30 am, in the “Aula

de Grados” of the “Padre Soler” building, at the Carlos III University (Leganés Campus).

Abstract

Carbon nanotube fibre is an interesting new material due to its unusual combination of bulk properties (mechanical, electrical and thermal) and its complex hierarchical structure. Individual CNT is defined as a basic structural block, thus, CNT fibre combines the properties of a high-performance material but coexists with mesoporous structure, providing a high surface area (260m2/g). Kilometres of continuous macroscopic fibre of control number of layers are synthesised, tailored by the addition of sulphur as a catalyst promoter during chemical vapour deposition (CVD) in the direct spinning process. This control enables a first study on the chiral angle distribution of CNTs in SWCNT fibre sample. The experimental distribution of chiral angles matches theoretical predictions for CNTs produced with a molten catalyst. This work also shows control over the assembly of CNTs in the gas phase. It is presented a method to spin highly oriented fibre by lowering the concentration of CNTs in the gas phase. Through reduction of the precursor feed rate or increase in carrier gas flow rate, the density of entanglements is reduced and the CNT aerogel can thus be drawn up to 170 draw ratio. The resulting fibre has specific strength and Young´s modulus in the range 1.1 ± 0.2 GPa and 60 ± 16 GPa, with toughness reaching over 80J/g. Similar, electrical conductivity of highly oriented fibre reached 3.5 x 105 S/m. The complex hierarchical structure is analysed. Internal porous structures and the building block interactions are discussed in detail by BET, BJH and XRD techniques. Next, examples of device produced with the CNT fibre produced and critical parameters of the synthesis for scaling-up the process are presented.