Liu, Yun; Zhang, Chuan-Jie; Zhao, Jin-Chao; Guo, Yi; Zhu, Ping; Wang, De-Yi

Effect of anisotropic microstructure of a 12Cr-ODS steel on the fracture behaviour in the small punch test

Altstadt, E.; Serrano, M.; Houska, M.; Garcia-Junceda, A.

In silico design and screening of hypothetical MOF-74 analogs and their experimental synthesis

Witman, Matthew; Ling, Sanliang; Anderson, Samantha; Tong, Lianheng; Stylianou, Kyriakos C.; Slater, Ben; Smit, Berend; Haranczyk, Maciej

Effect of manganese and cobalt ions on flame retardancy and thermal degradation of bio-based alginate films

Liu, Yun; Zhao, Jin-Chao; Zhang, Chuan-Jie; Guo, Yi; Zhu, Ping; Wang, De-Yi

High temperature deformation mechanisms in pure magnesium studied by nanoindentation

Sanchez-Martin, R.; Zambaldi, C.; Perez-Prado, M. T.; Molina-Aldareguia, J. M.

Comparative study on synergistic effect of LDH and zirconium phosphate with aluminum trihydroxide on flame retardancy of EVA composites

Kalali, Ehsan Naderi; De Juan, Sergio; Wang, Xin; Nie, Shibin; Wang, Rui; Wang, De-Yi

The influence of high grain boundary density on helium retention in tungsten

Valles, G.; Gonzalez, C.; Martin-Bragado, I.; Iglesias, R.; Perlado, J. M.; Rivera, A.

Finite element modeling of fretting wear scars in the thin steel wires: Application in crossed cylinder arrangements

Cruzado, A.; Urchegui, M. A.; Gomez, X.

An experimental study on the mechanism of texture evolution during hot-rolling process in a beta titanium alloy

Kou, Hongchao; Chen, Yi; Tang, Bin; Cui, Yuwen; Sun, Feng; Li, Jinshan; Xue, Xiangyi

Real time monitoring of click chemistry self-healing in polymer composites

Yue, H. -B.; Fernandez-Blazquez, J. P.; Beneito, D. F.; Vilatela, J. J.

Molecular dynamics modeling and simulation of void growth in two dimensions

Chang, H-J; Segurado, J.; Rodriguez de la Fuente, O.; Pabon, B. M.; Lorca, J. L.

Bounds for nonlinear composites via iterated homogenization

Ponte Castaneda, P.

Microstructure and thermostability of a W-Cu nanocomposite produced via high-pressure torsion

Edwards, D.; Sabirov, I.; Sigle, W.; Pippan, R.

Microtomographic investigation of damage in E911 steel after long term creep

Sket, F.; Dzieciol, K.; Borbely, A.; Kaysser-Pyzalla, A. R.; Maile, K.; Scheck, R.

Fire response of polyamide 6 with layered and fibrillar nanofillers

Cai, Guipeng; Dasari, Aravind; Yu, Zhong-Zhen; Du, Xusheng; Dai, Shaocong; Mai, Yiu-Wing; Wang, Jiyang

Structural composites for multifunctional applications: Current challenges and future trends

Gonzalez, C.; Vilatela, J. J.; Molina-Aldareguia, J. M.; Lopes, C. S.; LLorca, J.

Interfacial crystallization of isotactic polypropylene surrounding macroscopic carbon nanotube and graphene fibers

Abdou, John P.; Reynolds, Karina J.; Pfau, Michaela R.; van Staden, Justin; Braggin, Gregory A.; Tajaddod, Navid; Minus, Marilyn; Reguero, Victor; Vilatela, Juan J.; Zhang, Shanju

Temperature and stain rate effect on the deformation of nanostructured pure titanium

Rodriguez-Galan, D.; Sabirov, I.; Segurado, J.

Comparative study of the synergistic effect of binary and ternary LDH with intumescent flame retardant on the properties of polypropylene composites

Wang, Xin; Spoerer, Yvonne; Leuteritz, Andreas; Kuehnert, Ines; Wagenknecht, Udo; Heinrich, Gert; Wang, De-Yi

Bio-based nickel alginate and copper alginate films with excellent flame retardancy: preparation, flammability and thermal degradation behavior

Liu, Yun; Zhao, Jin-Chao; Zhang, Chuan-Jie; Guo, Yi; Cui, Li; Zhu, Ping; Wang, De-Yi

Effect of layer thickness on the high temperature mechanical properties of Al/SiC nanolaminates

Lotfian, S.; Mayer, C.; Chawla, N.; Llorca, J.; Misra, A.; Baldwin, J. K.; Molina-Aldareguia, J. M.

Anisotropy of uni-axial and bi-axial deformation behavior of pure Titanium after hydrostatic extrusion

Moreno-Valle, E. C.; Pachla, W.; Kulczyk, M.; Savoini, B.; Monge, M. A.; Ballesteros, C.; Sabirov, I.

Effect of a binder system on the low-pressure powder injection moulding of water-soluble zircon feedstocks

Hidalgo, J.; Abajo, C.; Jimenez-Morales, A.; Torralba, J. M.

Microstructure and hardness evolution in MAR-M247 Ni-based superalloy processed by controlled cooling and double heat treatment

Rahimian, Mehdi; Milenkovic, Srdjan; Sabirov, Ilchat

Texture evolution and dynamic recrystallization in a beta titanium alloy during hot-rolling process

Chen, Yi; Li, Jinshan; Tang, Bin; Kou, Hongchao; Xue, Xiangyi; Cui, Yuwen

Understanding size effects on the strength of single crystals through high-temperature micropillar compression

Soler, Rafael; Wheeler, Jeffrey M.; Chang, Hyung-Jun; Segurado, Javier; Michler, Johann; Llorca, Javier; Molina-Aldareguia, Jon M.

Bio-based semi-aromatic polyamide/functional clay nanocomposites: preparation and properties

Shabanian, Meisam; Kang, Nianjun; Liu, Jianwen; Wagenknecht, Udo; Heinrich, Gert; Wang, De-Yi

Latent hardening size effect in small-scale plasticity

Bardella, Lorenzo; Segurado, Javier; Panteghini, Andrea; Llorca, Javier

Mechanical Characterization of Lead-Free Sn-Ag-Cu Solder Joints by High-Temperature Nanoindentation

Lotfian, S.; Molina-Aldareguia, J. M.; Yazzie, K. E.; Llorca, J.; Chawla, N.

Lean alloys in PM: from design to sintering performance

Oro, R.; Campos, M.; Torralba, J. M.; Capdevila, C.

Effect of Cu-doped graphene on the flammability and thermal properties of epoxy composites

Liu, Yun; Babu, Heeralal Vignesh; Zhao, Jianqing; Goni-Urtiaga, Asier; Sainz, Raquel; Ferritto, Rafael; Pita, Marcos; Wang, De-Yi

Thermal oxidative degradation kinetics of novel intumescent flame-retardant polypropylene composites

Nie, Shibin; Zhou, Can; Peng, Chao; Liu, Lei; Zhang, Chi; Dong, Xiang; Wang, De-yi

Transverse cracking of cross-ply laminates: A computational micromechanics perspective

Herraez, Miguel; Mora, Diego; Naya, Fernando; Lopes, Claudio S.; Gonzalez, Carlos; LLorca, Javier

Microstructure and mechanical properties of physical vapor deposited Cu/W nanoscale multilayers: Influence of layer thickness and temperature

Monclus, M. A.; Karlik, M.; Callisti, M.; Frutos, E.; LLorca, J.; Polcar, T.; Molina-Aldareguia, J. M.

Creep behaviour of injection moulded polyamide 6/organoclay nanocomposites by nanoindentation and cantilever-bending

Seltzer, Rocio; Mai, Yiu-Wing; Frontini, Patricia M.

Hierarchical TiO2 nanofibres as photocatalyst for CO2 reduction: Influence of morphology and phase composition on catalytic activity

Renones, Patricia; Moya, Alicia; Fresno, Fernando; Collado, Laura; Vilatela, Juan J.; de la Pena O'Shea, Victor A.

Deformation and energy dissipation mechanisms of needle-punched nonwoven fabrics: A multiscale experimental analysis

Martinez-Hergueta, F.; Ridruejo, A.; Gonzalez, C.; LLorca, J.

Effect of Nd Additions on Extrusion Texture Development and on Slip Activity in a Mg-Mn Alloy

Hidalgo-Manrique, Paloma; Yi, S. B.; Bohlen, J.; Letzig, D.; Perez-Prado, M. T.

Effect of Misorientation on the Compression of Highly Anisotropic Single-Crystal Micropillars

Soler, Rafael; Mikel Molina-Aldareguia, Jon; Segurado, Javier; LLorca, Javier

Mechanical properties of tungsten alloys with Y2O3 and titanium additions

Aguirre, M. V.; Martin, A.; Pastor, J. Y.; LLorca, J.; Monge, M. A.; Pareja, R.

Effect of the grain refinement via severe plastic deformation on strength properties and deformation behavior of an A16061 alloy at room and cryogenic temperatures

Moreno-Valle, E. C.; Sabirov, I.; Perez-Prado, M. T.; Murashkin, M. Yu.; Bobruk, E. V.; Valiev, R. Z.

Interdiffusion and Atomic Mobility for Face-Centered-Cubic Co-Al Alloys

Cui, Y. -W.; Tang, B.; Kato, R.; Kainuma, R.; Ishida, K.

Physically-sound simulation of low-velocity impact on fiber reinforced laminates

Lopes, C. S.; Sadaba, S.; Gonzalez, C.; Llorca, J.; Camanho, P. P.

Computational identification of organic porous molecular crystals

Evans, Jack D.; Huang, David M.; Haranczyk, Maciej; Thornton, Aaron W.; Sumby, Christopher J.; Doonan, Christian J.

Precipitation strengthening and reversed yield stress asymmetry in Mg alloys containing rare-earth elements: A quantitative study

Hidalgo-Manrique, P.; Robson, J. D.; Perez-Prado, M. T.

Effect of lamellar orientation on the strength and operating deformation mechanisms of fully lamellar TiAl alloys determined by micropillar compression

Jesus Palomares-Garcia, Alberto; Teresa Perez-Prado, Maria; Mikel Molina-Aldareguia, Jon

Global and local deformation behavior and mechanical properties of individual phases in a quenched and partitioned steel

de Diego-Calderon, I.; De Knijf, D.; Monclus, M. A.; Molina-Aldareguia, J. M.; Sabirov, I.; Foejer, C.; Petrov, R. H.

Prominent role of basal slip during high-temperature deformation of pure Mg polycrystals

Cepeda-Jimenez, C. M.; Molina-Aldareguia, J. M.; Carreno, F.; Perez-Prado, M. T.

Modeling Lightning Impact Thermo-Mechanical Damage on Composite Materials

Munoz, Raul; Delgado, Sofia; Gonzalez, Carlos; Lopez-Romano, Bernardo; Wang, De-Yi; LLorca, Javier

Iterated linear comparison bounds for viscoplastic porous materials with ellipsoidal microstructures

Agoras, M.; Ponte Castaneda, P.

Numerical investigation to prevent crack jumping in Double Cantilever Beam tests of multidirectional composite laminates

Sebaey, T. A.; Blanco, N.; Lopes, C. S.; Costa, J.

Billion-atom synchronous parallel kinetic Monte Carlo simulations of critical 3D Ising systems

Martinez, E.; Monasterio, P. R.; Marian, J.

Void growth in copper during high-temperature power-law creep

Dzieciol, K.; Borbely, A.; Sket, F.; Isaac, A.; Di Michiel, M.; Cloetens, P.; Buslaps, Th; Pyzalla, A. R.

Hierarchical nanoporous silica doped with tin as novel multifunctional hybrid material to flexible poly(vinyl chloride) with greatly improved flame retardancy and mechanical properties

Pan, Ye-Tang; Trempont, Cedric; Wang, De-Yi

Impact of halogen-free flame retardant with varied phosphorus chemical surrounding on the properties of diglycidyl ether of bisphenol-A type epoxy resin: synthesis, fire behaviour, flame-retardant mechanism and mechanical properties

Zhao, Xiaomin; Babu, Heeralal Vignesh; Llorca, Javier; Wang, De-Yi

Effect of indentation size on the nucleation and propagation of tensile twinning in pure magnesium

Sanchez-Martin, R.; Perez-Prado, M. T.; Segurado, J.; Molina-Aldareguia, J. M.

A computational model coupling mechanics and electrophysiology in spinal cord injury

Jerusalem, Antoine; Garcia-Grajales, Julian A.; Merchan-Perez, Angel; Pena, Jose M.

Diffusion Research in BCC Ti-Al-Mo Ternary Alloys

Chen, Yi; Tang, Bin; Xu, Guanglong; Wang, Chuanyun; Kou, Hongchao; Li, Jinshan; Cui, Yuwen

Microstructural and mechanical characterisation of 7075 aluminium alloy consolidated from a premixed powder by cold compaction and hot extrusion

Jabbari Taleghani, M. A.; Ruiz Navas, E. M.; Torralba, J. M.

Damage resistance and damage tolerance of dispersed CFRP laminates: Effect of ply clustering

Sebaey, T. A.; Gonzalez, E. V.; Lopes, C. S.; Blanco, N.; Costa, J.

Continuum modeling of a neuronal cell under blast loading

Jerusalem, Antoine; Dao, Ming

The Influence of Intrinsic Framework Flexibility on Adsorption in Nanoporous Materials

Witman, Matthew; Ling, Sanliang; Jawahery, Sudi; Boyd, Peter G.; Haranczyk, Maciej; Slater, Ben; Smit, Berend

Enhancing the fracture resistance of carbon fiber reinforced SiC matrix composites by interface modification through a simple fiber heat-treatment process

Liu, H. T.; Yang, L. W.; Sun, X.; Cheng, H. F.; Wang, C. Y.; Mao, W. G.; Molina-Aldareguia, J. M.

Simultaneous synthesis of vertically aligned carbon nanotubes and amorphous carbon thin films on stainless steel

Romero, Pablo; Oro, Raquel; Campos, Monica; Torralba, Jose M.; Guzman de Villoria, Roberto

Computational micromechanics of the transverse and shear behavior of unidirectional fiber reinforced polymers including environmental effects

Naya, F.; Gonzalez, C.; Lopes, C. S.; Van der Veen, S.; Pons, F.

Synergistic Effect of Carbon Nanotube and Polyethersulfone on Flame Retardancy of Carbon Fiber Reinforced Epoxy Composites

Li, Cheng; Kang, Nian-Jun; Delgado Labrandero, Sofia; Wan, Jintao; Gonzalez, Carlos; Wane, De-Yi

High-temperature nanoindentation behavior of Al/SiC multilayers

Lotfian, S.; Molina-Aldareguia, J. M.; Yazzie, K. E.; Llorca, J.; Chawla, N.

Mechanical and electrical properties of an ultrafine grained Al-8.5 wt. % RE (RE=5.4 wt.% Ce, 3.1wt.% La) alloy processed by severe plastic deformation

Murashkin, M. Yu.; Sabirov, I.; Medvedev, A. E.; Enikeev, N. A.; Lefebvre, W.; Valiev, R. Z.; Sauvage, X.

Structure-property relationships of nanocornposites based on polylactide and MgAl layered double hydroxides

Leng, Jing; Purohit, Purv J.; Kang, Nianjun; Wang, De-Yi; Falkenhagen, Jana; Emmerling, Franziska; Thueneman, Andreas F.; Schoenhals, Andreas

One-step hydrothermal synthesis of nano zinc carbonate and its use as a promising substitute for antimony trioxide in flame retardant flexible poly(vinyl chloride)

Pan, Ye-Tang; Wang, De-Yi

A numerical study of the influence of microvoids in the transverse mechanical response of unidirectional composites

Vajari, Danial Ashouri; Gonzalez, Carlos; Llorca, Javier; Legarth, Brian Nyvang

An eco-friendly way to fire retardant flexible polyurethane foam: layer-by-layer assembly of fully bio-based substances

Wang, Xin; Pan, Ye-Tang; Wan, Jin-Tao; Wang, De-Yi

Interfacial load transfer in carbon nanotube/ceramic microfiber hybrid polymer composites

Lachman, Noa; Wiesel, Erica; Guzman de Villoria, Roberto; Wardle, Brian L.; Wagner, H. Daniel

Shape Dynamics and Rheology of Soft Elastic Particles in a Shear Flow

Gao, Tong; Hu, Howard H.; Ponte Castaneda, Pedro

Influence of the high pressure torsion die geometry on the allotropic phase transformations in pure Zr

Zhilyaev, A. P.; Galvez, F.; Sharafutdinov, A.; Perez-Prado, M. T.

Effect of interface fracture on the tensile deformation of fiber-reinforced elastomers

Moraleda, Joaquin; Segurado, Javier; Llorca, Javier

Effect of phosphorus-containing inorganic-organic hybrid coating on the flammability of cotton fabrics: Synthesis, characterization and flammability

Liu, Yun; Pan, Ye-Tang; Wang, Xin; Acuna, Pablo; Zhu, Ping; Wagenknecht, Udo; Heinrich, Gert; Zhang, Xiu-Qin; Wang, Rui; Wang, De-Yi

Development of constitutive relationship and processing map for Al-6. 65Si-0.44Mg alloy and its composite with B4C particulates

Gangolu, S.; Rao, A. Gourav; Sabirov, I.; Kashyap, B. P.; Prabhu, N.; Deshmukh, V. P.

Three-dimensional dislocation dynamics analysis of size effects on void growth

Chang, Hyung-Jun; Segurado, Javier; LLorca, Javier

Variable-stiffness composite panels: As-manufactured modeling and its influence on the failure behavior

Falco, O.; Mayugo, J. A.; Lopes, C. S.; Gascons, N.; Turon, A.; Costa, J.

Simulation of the deformation of polycrystalline nanostructured Ti by computational homogenization

Segurado, Javier; Llorca, Javier

Effect of the cooling rate on microstructure and hardness of MAR-M247 Ni-based superalloy

Milenkovic, Srdjan; Sabirov, Ilchat; LLorca, Javier

Preparation and characterisation of bioplastics made from cottonseed protein

Yue, H. -B.; Cui, Y. -D.; Shuttleworth, P. S.; Clark, James H.

An experimental and numerical study of the influence of local effects on the application of the fibre push-in test

Molina-Aldareguia, Jon M.; Rodriguez, M.; Gonzalez, C.; LLorca, J.

Optimum high temperature strength of two-dimensional nanocomposites

Monclus, M. A.; Zheng, S. J.; Mayeur, J. R.; Beyerlein, I. J.; Mara, N. A.; Polcar, T.; Llorca, J.; Molina-Aldareguia, J. M.

Orientation dependency of the alpha to omega plus beta transformation in commercially pure zirconium by high-pressure torsion

Srinivasarao, B.; Zhilyaev, A. P.; Perez-Prado, M. T.

Carbon-family materials for flame retardant polymeric materials

Wang, Xin; Kalali, Ehsan Naderi; Wan, Jin-Tao; Wang, De-Yi

Tough Electrodes: Carbon Nanotube Fibers as the Ultimate Current Collectors/Active Material for Energy Management Devices

Vilatela, Juan J.; Marcilla, Rebeca

Damage resistance and damage tolerance of dispersed CFRP laminates: Effect of the mismatch angle between plies

Sebaey, T. A.; Gonzalez, E. V.; Lopes, C. S.; Blanco, N.; Maimi, P.; Costa, J.

Ant Colony Optimization for dispersed laminated composite panels under biaxial loading

Sebaey, T. A.; Lopes, C. S.; Blanco, N.; Costa, J.

Effect of rare earth additions on the critical resolved shear stresses of magnesium alloys

Herrera-Solaz, V.; Hidalgo-Manrique, R.; Perez-Prado, M. T.; Letzig, D.; Llorca, J.; Segurado, J.

Thermoset curing through Joule heating of nanocarbons for composite manufacture, repair and soldering

Mas, Bartolome; Fernandez-Blazquez, Juan P.; Duval, Jonathan; Bunyan, Humphrey; Vilatela, Juan J.

On the relation between the microstructure and the mechanical behavior of pure Zn processed by high pressure torsion

Srinivasarao, B.; Zhilyaev, A. P.; Langdon, T. G.; Perez-Prado, M. T.

A green functional nanohybrid: preparation, characterization and properties of a beta-cyclodextrin based functional layered double hydroxide

Kang, Nian-Jun; Wang, De-Yi

Predicting the thermal conductivity of composite materials with imperfect interfaces

Marcos-Gomez, D.; Ching-Lloyd, J.; Elizalde, M. R.; Clegg, W. J.; Molina-Aldareguia, J. M.

New Superefficiently Flame-Retardant Bioplastic Poly(lactic acid): Flammability, Thermal Decomposition Behavior, and Tensile Properties

Zhao, Xiaomin; Guerrero, Francisco Reyes; Lorca, Javier; Wang, De-Yi

Effect of microstructure on fatigue behavior of advanced high strength steels produced by quenching and partitioning and the role of retained austenite

de Diego-Calderon, I.; Rodriguez-Calvillo, P.; Lara, A.; Molina-Aldareguia, J. M.; Petrov, R. H.; De Knijf, D.; Sabirov, I.

Hot forging design and microstructure evolution of a high Nb containing TiAl alloy

Tang, Bin; Cheng, Liang; Kou, Hongchao; Li, Jinshan

Mechanical properties up to 1900 K of Al2O3/Er3Al5O12/ZrO2 eutectic ceramics grown by the laser floating zone method

Mesa, M. C.; Oliete, P. B.; Pastor, J. Y.; Martin, A.; LLorca, J.

Influence of strain rate on the twin and slip activity of a magnesium alloy containing neodymium

Dudamell, N. V.; Hidalgo-Manrique, P.; Chakkedath, A.; Chen, Z.; Boehlert, C. J.; Galvez, E.; Yi, S.; Bohlen, J.; Letzig, D.; Perez-Prado, M. T.

Interdiffusion and Atomic Mobility for Face-Centered Cubic (FCC) Co-W Alloys

Cui, Y. -W.; Xu, Guanglong; Kato, R.; Lu, Xiao-Gang; Kainuma, R.; Ishida, K.

Torque rheology of zircon feedstocks for powder injection moulding

Hidalgo, J.; Jimenez-Morales, A.; Torralba, J. M.

A constitutive model for the in-plane mechanical behavior of nonwoven fabrics

Ridruejo, Alvaro; Gonzalez, Carlos; LLorca, Javier

Method for Simultaneousiy Improving the Thermal Stability and Mechanical Properties of Poly(lactic acid): Effect of High-Energy Electrons on the Morphological, Mechanical, and Thermal Properties of PLA/MMT Nanocomposites

Wang, De-Yi; Gohs, Uwe; Kang, Nian-Jun; Leuteritz, Andreas; Boldt, Regine; Wagenknecht, Udo; Heinrich, Gert

MMonCa: An Object Kinetic Monte Carlo simulator for damage irradiation evolution and defect diffusion

Martin-Bragado, Ignacio; Rivera, Antonio; Valles, Gonzalo; Luis Gomez-Selles, Jose; Caturla, Maria J.

Influence of texture on the recrystallization mechanisms in an AZ31 Mg sheet alloy at dynamic rates

Dudamell, N. V.; Ulacia, I.; Galvez, F.; Yi, S.; Bohlen, J.; Letzig, D.; Hurtado, I.; Perez-Prado, M. T.

Superficial severe plastic deformation of 316 LVM stainless steel through grit blasting: Effects on its microstructure and subsurface mechanical properties

Multigner, M.; Ferreira-Barragans, S.; Frutos, E.; Jaafar, M.; Ibanez, J.; Marin, P.; Perez-Prado, M. T.; Gonzalez-Doncel, G.; Asenjo, A.; Gonzalez-Carrasco, J. L.

Nanostructured Al and Cu alloys with superior strength and electrical conductivity

Murashkin, M. Yu; Sabirov, I.; Sauvage, X.; Valiev, R. Z.

Effect of Equal Channel Angular Pressing on the Fracture Behavior of Commercially Pure Titanium

Sabirov, I.; Valiev, R. Z.; Semenova, I. P.; Pippan, R.

Enhanced mechanical properties and electrical conductivity in ultrafine-grained Al alloy processed via ECAP-PC

Murashkin, M. Yu; Sabirov, I.; Kazykhanov, V. U.; Bobruk, E. V.; Dubravina, A. A.; Valiev, R. Z.

X-ray microtomography analysis of the damage micromechanisms in 3D woven composites under low-velocity impact

Seltzer, R.; Gonzalez, C.; Munoz, R.; LLorca, J.; Blanco-Varela, T.

Characterization of crack propagation in mode I delamination of multidirectional CFRP laminates

Sebaey, T. A.; Blanco, N.; Costa, J.; Lopes, C. S.

Antimicrobial metal-organic frameworks incorporated into electrospun fibers

Quiros, Jennifer; Boltes, Karina; Aguado, Sonia; Guzman de Villoria, Roberto; Jose Vilatela, Juan; Rosal, Roberto

Influence of exfoliated graphite nanoplatelets on the flammability and thermal properties of polyethylene terephthalate/polypropylene nanocomposites

Inuwa, I. M.; Hassan, Azman; Wang, De-Yi; Samsudin, S. A.; Haafiz, M. K. Mohamad; Wong, S. L.; Jawaid, M.

Full elastic constitutive relation of non-isotropic aligned-CNT/PDMS flexible nanocomposites

Sepulveda, A. T.; Guzman de Villoria, R.; Viana, J. C.; Pontes, A. J.; Wardle, B. L.; Rocha, L. A.

Constitutional and microstructural investigation of the pseudobinary NiAl-W system

Milenkovic, Srdjan; Schneider, Andre; Frommeyer, Georg

Macroscopic fibres of CNTs as electrodes for multifunctional electric double layer capacitors: from quantum capacitance to device performance

Senokos, E.; Reguero, V.; Palma, J.; Vilatela, J. J.; Marcilla, Rebeca

An in situ polymerization approach for functionalized MoS2/nylon-6 nanocomposites with enhanced mechanical properties and thermal stability

Wang, Xin; Kalali, Ehsan Naderi; Wang, De-Yi

Automatic quantification of matrix cracking and fiber rotation by X-ray computed tomography in shear-deformed carbon fiber-reinforced laminates

Sket, F.; Enfedaque, A.; Alton, C.; Gonzalez, C.; Molina-Aldareguia, J. M.; Llorca, J.

Optimization of curing cycle in carbon fiber-reinforced laminates: Void distribution and mechanical properties

Hernandez, S.; Sket, F.; Gonzalez, C.; LLorca, J.

A micro-meso-model of intra-laminar fracture in fiber-reinforced composites based on a discontinuous Galerkin/cohesive zone method

Wu, L.; Tjahjanto, D.; Becker, G.; Makradi, A.; Jerusalem, A.; Noels, L.

Determination of damage micromechanisms and fracture resistance of glass fiber/epoxy cross-ply laminate by means of X-ray computed microtomography

Sket, F.; Seltzer, R.; Molina-Aldareguia, J. M.; Gonzalez, C.; LLorca, J.

Origin of the twinning to slip transition with grain size refinement, with decreasing strain rate and with increasing temperature in magnesium

Cepeda-Jimenez, C. M.; Molina-Aldareguia, J. M.; Perez-Prado, M. T.

Deformation behavior of a high strength multiphase steel at macro- and micro-scales

de Diego-Calderon, I.; Santofimia, M. J.; Molina-Aldareguia, J. M.; Monclus, M. A.; Sabirov, I.

Mechanical properties of Y2O3-doped W-Ti alloys

Aguirre, M. V.; Martin, A.; Pastor, J. Y.; Llorca, J.; Monge, M. A.; Pareja, R.

Damage micromechanisms and notch sensitivity of glass-fiber non-woven felts: An experimental and numerical study

Ridruejo, Alvaro; Gonzalez, Carlos; LLorca, Javier

Beyond traditional light-emitting electrochemical cells – a review of new device designs and emitters

Fresta, Elisa; Costa, Ruben D.

Few layered Co(OH)(2) ultrathin nanosheet-based polyurethane nanocomposites with reduced fire hazard: from eco-friendly flame retardance to sustainable recycling

Zhang, Junhao; Kong, Qinghong; Yang, Lingwei; Wang, De-Yi

Strong Carbon Nanotube Fibers by Drawing Inspiration from Polymer Fiber Spinning

Aleman, Belen; Reguero, Victor; Mas, Bartolome; Vilatela, Juan J.

Intumescent multilayer hybrid coating for flame retardant cotton fabrics based on layer-by-layer assembly and sol-gel process

Wang, Xin; Quintero Romero, Manuel; Zhang, Xiu-Qin; Wang, Rui; Wang, De-Yi

Three dimensional (3D) microstructure-based modeling of interfacial decohesion in particle reinforced metal matrix composites

Williams, J. J.; Segurado, J.; LLorca, J.; Chawla, N.

Effect of grain size on slip activity in pure magnesium polycrystals

Cepeda-Jimenez, C. M.; Molina-Aldareguia, J. M.; Perez-Prado, M. T.

Determination of the mechanical properties of amorphous materials through instrumented nanoindentation

Rodriguez, M.; Molina-Aldareguia, J. M.; Gonzalez, C.; LLorca, J.

The effect of particle shape and distribution on the macroscopic behavior of magnetoelastic composites

Galipeau, Evan; Ponte Castaneda, Pedro

A methodology to measure the interface shear strength by means of the fiber push-in test

Rodriguez, M.; Molina-Aldareguia, J. M.; Gonzalez, C.; LLorca, J.

Antifouling membranes prepared by electrospinning polylactic acid containing biocidal nanoparticles

Dasari, Aravind; Quiros, Jennifer; Herrero, Berta; Boltes, Karina; Garcia-Calvo, Eloy; Rosal, Roberto

An inverse optimization strategy to determine single crystal mechanical behavior from polycrystal tests: Application to AZ31 Mg alloy

Herrera-Solaz, V.; LLorca, J.; Dogan, E.; Karaman, I.; Segurado, J.

Effect of Glass Fiber Hybridization on the Behavior Under Impact of Woven Carbon Fiber/Epoxy Laminates

Enfedaque, A.; Molina-Aldareguia, J. M.; Galvez, F.; Gonzalez, C.; Llorca, J.

Synthesis of aromatic-aliphatic polyamide acting as adjuvant in polylactic acid (PLA)/ammonium polyphosphate (APP) system

Shabanian, Meisam; Kang, Nian-Jun; Wang, De-Yi; Wagenknecht, Udo; Heinrich, Gert

Ballistic performance of nanocrystalline and nanotwinned ultrafine crystal steel

Frontan, Jaime; Zhang, Yuming; Dao, Ming; Lu, Jian; Galvez, Francisco; Jerusalem, Antoine

Micromechanisms of deformation and fracture of polypropylene nonwoven fabrics

Ridruejo, Alvaro; Gonzalez, Carlos; LLorca, Javier

Ultrastiff Biobased Epoxy Resin with High T-g and Low Permittivity: From Synthesis to Properties

Wan, Jintao; Zhao, Jianqing; Gan, Bin; Li, Cheng; Molina-Aldareguia, Jon; Zhao, Ying; Pan, Ye-Tang; Wang, De-Yi

Application of digital image correlation at the microscale in fiber-reinforced composites

Canal, L. P.; Gonzalez, C.; Molina-Aldareguia, J. M.; Segurado, J.; LLorca, J.

Synthesis and characterization of functional eugenol derivative based layered double hydroxide and its use as a nanoflame-retardant in epoxy resin

Li, Cheng; Wan, Jintao; Kalali, Ehsan Naderi; Fan, Hong; Wang, De-Yi

Anisotropy of mechanical properties in high-strength ultra-fine-grained pure Ti processed via a complex severe plastic deformation route

Sabirov, I.; Perez-Prado, M. T.; Molina-Aldareguia, J. M.; Semenova, I. P.; Salimgareeva, G. Kh; Valiev, R. Z.

Prediction of the failure locus of C/PEEK composites under transverse compression and longitudinal shear through computational micromechanics

Totry, Essam; Gonzalez, Carlos; LLorca, Javier

A sustainable, eugenol-derived epoxy resin with high biobased content, modulus, hardness and low flammability: Synthesis, curing kinetics and structure-property relationship

Wan, Jintao; Gan, Bin; Li, Cheng; Molina-Aldareguia, Jon; Kalali, Ehsan Naderi; Wang, Xin; Wang, De-Yi

Oxygen vacancies and interfaces enhancing photocatalytic hydrogen production in mesoporous CNT/TiO2 hybrids

Moya, Alicia; Cherevan, Alexey; Marchesan, Silvia; Gebhardt, Paul; Prato, Maurizio; Eder, Dominik; Vilatela, Juan J.

Measuring the critical resolved shear stresses in Mg alloys by instrumented nanoindentation

Sanchez-Martin, R.; Perez-Prado, M. T.; Segurado, J.; Bohlen, J.; Gutierrez-Urrutia, I.; Llorca, J.; Molina-Aldareguia, J. M.

A New Approach to Reducing the Flammability of Layered Double Hydroxide (LDH)-Based Polymer Composites: Preparation and Characterization of Dye Structure-Intercalated LDH and Its Effect on the Flammability of Polypropylene-Grafted Maleic Anhydride/d-LDH Composites

Kang, Nian-Jun; Wang, De-Yi; Kutlu, Burak; Zhao, Peng-Cheng; Leuteritz, Andreas; Wagenknecht, Udo; Heinrich, Gert

High temperature micropillar compression of Al/SiC nanolaminates

Lotfian, S.; Rodriguez, M.; Yazzie, K. E.; Chawla, N.; Llorca, J.; Molina-Aldareguia, J. M.

Effect of curing cycle on void distribution and interlaminar shear strength in polymer-matrix composites

Hernandez, S.; Sket, F.; Molina-Aldareguia, J. M.; Gonzalez, C.; LLorca, J.

Effect of Nb additions on the microstructure, thermal stability and mechanical behavior of high pressure Zr phases under ambient conditions

Zhilyaev, A. P.; Sabirov, I.; Gonzalez-Doncel, G.; Molina-Aldareguia, J.; Srinivasarao, B.; Perez-Prado, M. T.

Toughening Polypropylene and Its Nanocomposites with Submicrometer Voids

Dasari, Aravind; Zhang, Qing-Xin; Yu, Zhong-Zhen; Mai, Yiu-Wing

The effect of strain rate on the deformation mechanisms and the strain rate sensitivity of an ultra-fine-grained Al alloy

Sabirov, I.; Barnett, M. R.; Estrin, Y.; Hodgson, P. D.

A novel biobased epoxy resin with high mechanical stiffness and low flammability: synthesis, characterization and properties

Wan, Jintao; Gan, Bin; Li, Cheng; Molina-Aldareguia, Jon; Li, Zhi; Wang, Xin; Wang, De-Yi

Fire retardancy behavior of PLA based nanocomposites

Gonzalez, Alfonso; Dasari, Aravind; Herrero, Berta; Plancher, Emeric; Santaren, Julio; Esteban, Antonio; Lim, Szu-Hui

Three-dimensional investigation of grain boundary-twin interactions in a Mg AZ31 alloy by electron backscatter diffraction and continuum modeling

Fernandez, A.; Jerusalem, A.; Gutierrez-Urrutia, I.; Perez-Prado, M. T.

Multifunctional intercalation in layered double hydroxide: toward multifunctional nanohybrids for epoxy resin

Naderi Kalali, Ehsan; Wang, Xin; Wang, De-Yi

Renewable Cardanol-Based Surfactant Modified Layered Double Hydroxide as a Flame Retardant for Epoxy Resin

Wang, Xin; Kalali, Ehsan Naderi; Wang, De-Yi

Controlling Carbon Nanotube Type in Macroscopic Fibers Synthesized by the Direct Spinning Process

Reguero, Victor; Aleman, Belen; Mas, Bartolome; Jose Vilatela, Juan

Micropillar compression of LiF [111] single crystals: Effect of size, ion irradiation and misorientation

Soler, R.; Molina-Aldareguia, J. M.; Segurado, J.; Llorca, J.; Merino, R. I.; Orera, V. M.

Intraply fracture of fiber-reinforced composites: Microscopic mechanisms and modeling

Pablo Canal, Luis; Gonzalez, Carlos; Segurado, Javier; LLorca, Javier

A finite-strain constitutive theory for electro-active polymer composites via homogenization

Castaneda, P. Ponte; Siboni, M. N.

Nanostructured aluminium alloys produced by severe plastic deformation: New horizons in development

Sabirov, I.; Murashkin, M. Yu; Valiev, R. Z.

Mechanical behavior and microstructural evolution of a Mg AZ31 sheet at dynamic strain rates

Ulacia, I.; Dudamell, N. V.; Galvez, F.; Yi, S.; Perez-Prado, M. T.; Hurtado, I.

Highly thermally conductive flame-retardant epoxy nanocomposites with reduced ignitability and excellent electrical conductivities

Gu, Junwei; Liang, Chaobo; Zhao, Xiaomin; Gan, Bin; Qiu, Hua; Guo, Yonqiang; Yang, Xutong; Zhang, Qiuyu; Wang, De-Yi

Effect of fiber, matrix and interface properties on the in-plane shear deformation of carbon-fiber reinforced composites

Totry, Essam; Molina-Aldareguia, Jon M.; Gonzalez, Carlos; LLorca, Javier

Multiscale Modeling of Composite Materials: a Roadmap Towards Virtual Testing

LLorca, J.; Gonzalez, C.; Molina-Aldareguia, J. M.; Segurado, J.; Seltzer, R.; Sket, F.; Rodriguez, M.; Sadaba, S.; Munoz, R.; Canal, L. P.

Nanocarbon Composites and Hybrids in Sustainability: A Review

Vilatela, Juan J.; Eder, Dominik

Twinning and grain subdivision during dynamic deformation of a Mg AZ31 sheet alloy at room temperature

Dudamell, N. V.; Ulacia, I.; Galvez, F.; Yi, S.; Bohlen, J.; Letzig, D.; Hurtado, I.; Perez-Prado, M. T.

New low carbon Q&P steels containing film-like intercritical ferrite

Santofimia, M. J.; Nguyen-Minh, T.; Zhao, L.; Petrov, R.; Sabirov, I.; Sietsma, J.

Functionalized layered double hydroxide-based epoxy nanocomposites with improved flame retardancy and mechanical properties

Naderi Kalali, Ehsan; Wang, Xin; Wang, De-Yi

Bulk Nanostructured Metals for Innovative Applications

Valiev, Ruslan Z.; Sabirov, Ilchat; Zhilyaev, Alexander P.; Langdon, Terence G.

Influence of interface mobility on the evolution of austenite-martensite grain assemblies during annealing

Santofimia, M. J.; Speer, J. G.; Clarke, A. J.; Zhao, L.; Sietsma, J.

Influence of the Lode parameter and the stress triaxiality on the failure of elasto-plastic porous materials

Danas, K.; Ponte Castaneda, P.

Nanostructured titanium-based materials for medical implants: Modeling and development

Mishnaevsky, Leon, Jr.; Levashov, Evgeny; Valiev, Ruslan Z.; Segurado, Javier; Sabirov, Ilchat; Enikeev, Nariman; Prokoshkin, Sergey; Solov'yov, Andrey V.; Korotitskiy, Andrey; Gutmanas, Elazar; Gotman, Irene; Rabkin, Eugen; Psakh'e, Sergey; Dluhos, Ludek; Seefeldt, Marc; Smolin, Alexey

A nanostructural design to produce high-strength Al alloys with enhanced electrical conductivity

Valiev, R. Z.; Murashkin, M. Yu; Sabirov, I.

First Experimental Observation of Shear Induced hcp to bcc Transformation in Pure Zr

Perez-Prado, M. T.; Zhilyaev, A. P.

DAMASK: the Dusseldorf Advanced MAterial Simulation Kit for studying crystal plasticity using an FE based or a spectral numerical solver

Roters, F.; Eisenlohr, P.; Kords, C.; Tjahjanto, D. D.; Diehl, M.; Raabe, D.

Metal-organic framework with optimally selective xenon adsorption and separation

Banerjee, Debasis; Simon, Cory M.; Plonka, Anna M.; Motkuri, Radha K.; Liu, Jian; Chen, Xianyin; Smit, Berend; Parise, John B.; Haranczyk, Maciej; Thallapally, Praveen K.

Electrically conductive and super-tough polyamide-based nanocomposites

Dasari, Aravind; Yu, Zhong-Zhen; Mai, Yiu-Wing

In situ analysis of the tensile and tensile-creep deformation mechanisms in rolled AZ31

Boehlert, C. J.; Chen, Z.; Gutierrez-Urrutia, I.; Llorca, J.; Perez-Prado, M. T.

Continuum modeling of the response of a Mg alloy AZ31 rolled sheet during uniaxial deformation

Fernandez, Ana; Perez Prado, Maria Teresa; Wei, Yujie; Jerusalem, Antoine

Technology & projects department

We count with a dynamic and professional team to support our researchers and partners in the following tasks: Attract funding Full support on competitive proposals preparation, including partner's search and contracts

Seminar of Dr. Christian Leinenbach from EMPA (Swiss Federal Laboratories for Materials Science & Technology), in Zurich, entitle “Microstructure control during laser additive manufacturing – what possibilities do we have?” – At 15:30 pm, in the Seminar Room

Abstract: During the last couple years, laser-based additive manufacturing (AM) technologies such as laser powder bed fusion (LPBF) and directed energy deposition (DED) have evolved from a mere prototyping technology to a real production technology that allow building parts with intricate 3D

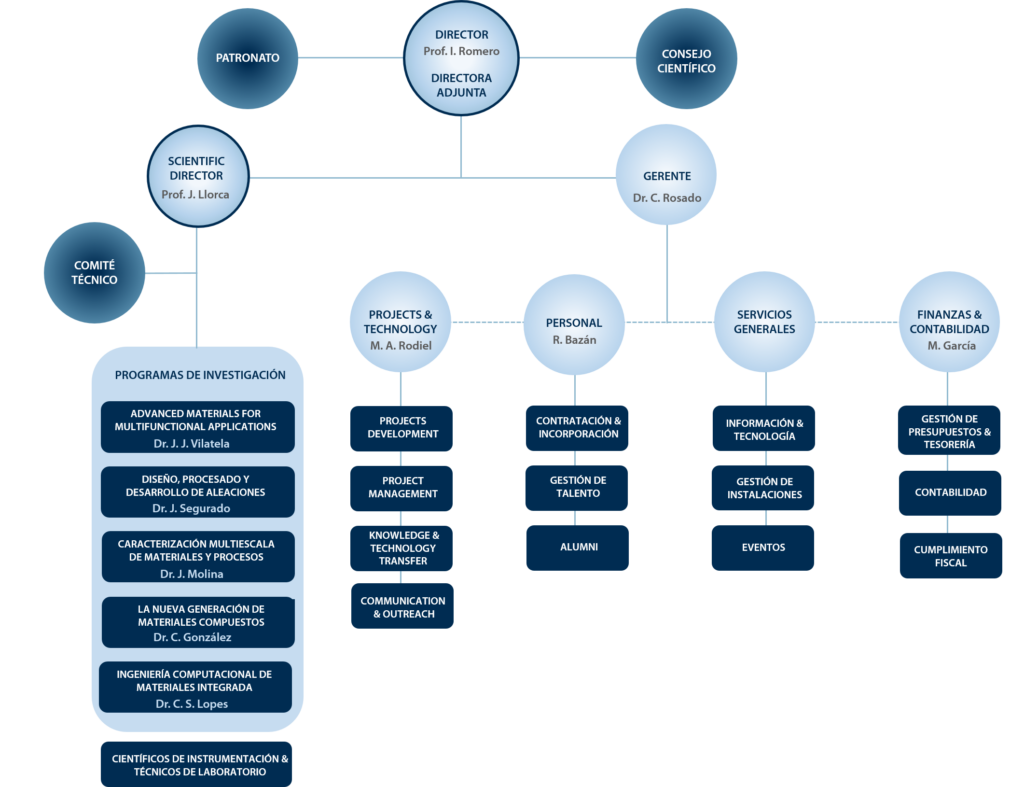

Research groups

The Institute is currently organised into sixteen research groups focused on different areas in the field of materials science and engineering. Each of these groups is led by one staff researcher, who is in charge of coordinating and supervising a research team of post and predoctoral researchers.

Who we are

The IMDEA Materials Institute, one of the seven Madrid Institutes for Advanced Studies (IMDEA), is a public research centre founded in 2007 by Madrid’s regional government. The goal of the Institute is to do research at the forefront of Material Science and Engineering, attracting talent from all

Public information request

In case you do not find the information you are looking for in the Transparency Portal, you can present your information request by email (transparencia.materiales@imdea.org) or through postal mail to the following address:Fundación Imdea MaterialesTecnogetafeC/Eric Kandel 228906 GetafeMadrid

Public tenders

(Update on 9th March 2018)We provide the necessary information to contract with IMDEA Materials Foundation. From this page you can access the information concerning the requirements to attend the onerous contracts.That information is governed by Ley 9/2017, de 8 de noviembre, de Contratos del Sector

Economic & statistical information

PresupuestosBudget 2022Budget execution 2022Budget 2023InformesAudit Report and Annual Accounts 2022Statistical dataHeritage * Information available only in Spanish

Institutional information

Record of activities (only available in Spanish)

Alumni Newsletter

(NABISCO) INTEGRATION OF CARBON NANOTUBE FIBRES IN STRUCTURAL COMPOSITES

Funding: China Scholarship CouncilRegion: InternationalProject period: 2016 – 2020Principal Investigator: Drs. Juan José Vilatela(juanjose.vilatela@imdea.org) and Carlos González(carlosdaniel.gonzalez@imdea.org)This project deals with the development of strategies to integrate macroscopic fibres and

(NANOFIRE) NANOMATERIALS VIA HOST-GUEST INTERACTION AS MULTIFUNCTIONAL FIRE RETARDANTS TO POLYMERS

Funding: China Scholarship CouncilRegion: InternationalProject period: 2017 – 2021Principal Investigator: Dr. De-Yi Wang (deyi.wang@imdea.org)This project deals with the development of new generation nanomaterials via host-guest interaction as multifunctional fire retardants to polymers. The aim is

(HIPREP) HIGH PERFORMANCE REINFORCED FIRE-RETARDANT POLYMERS

Funding: China Scholarship CouncilRegion: InternationalProject period: 2015 – 2019Principal Investigator: Dr. De-Yi Wang (deyiwang@imdea.org)The objective of this investigation is to develop high performance reinforced fire-retardant polymers via special molecular design, chemical functionalization

Seminar of Dr. Lorenzo Malerba, from CIEMAT, entitle “On the radiation-induced origin of hardening and embrittlement in nuclear steels” – At 12:30 pm, in the Seminar Room

Abstract: Predicting the changes in macroscopic properties of steels subjected to irradiation is key for the improved and long term safety of nuclear power plants. Because of the inherent complexity of the processes involved, this is a long-lasting challenge for nuclear materials science.

Transversal training

Besides on-the-job technical training, IMDEA Materials Institute is committed to train the Institute’s staff in “soft” or transversal skills. Those competences are relevant to a broad range of occupations and sectors (academic research or teaching career, specialization in a given field or a career

How to arrive

Contact and Location Headquarters

First Year Assessment of Qi Wang, entitle “Design and preparation of nanocarbon/epoxy nanocomposites with advanced flame retardancy and mechanical performance” – In the Seminar Room at 12:00 pm

Abstract: Efforts were paid to obtain nanocarbon/epoxy composites with advanced flame retardancy and mechanical performance, and try to understand the mechanisms. In the first part of the work, when 20 wt% ammonium polyphosphate (APP) in the chosen flame-retardant APP/epoxy composite was replaced