Magnesium has a large potential for more sustainable transport applications due to its low density. However, its poor strength and ductility limits its widespread application. The main fundamental problem arises from the low critical resolved shear stress (CRSS) for basal slip in Mg, which induces strain localization and early failure.

Finding alloying strategies to strengthen basal slip in Mg alloys is critical, but conventional alloy design is costly and time consuming.

In this work, a novel high-throughput methodology is used to measure the effect of alloying on the CRSS of basal slip in Mg alloys. The method is based on the combination of diffusion couples and micropillar compression, so that it avoids having to produce costly single-crystal specimens. Moreover, the method, applied to Mg-Zn and Mg-Al alloys, shows interesting solid-solution strengthening effects as a function of Zn and Al content.

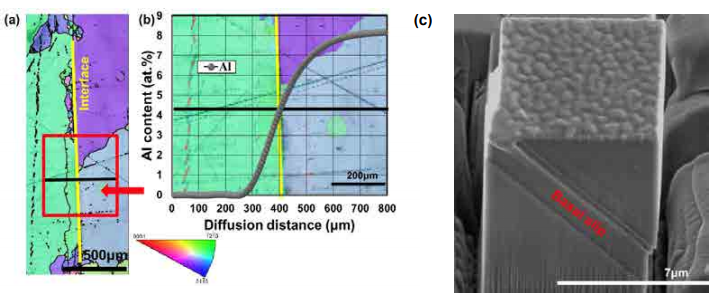

Interface area of diffusion couple showing (a) orientation, (b) Composition. By performing micropillar compression (c) along the black line, strengthening as a function of chemical content can be obtained

Effect of solute content and temperature on the deformation mechanisms and critical resolved shear stress in Mg-Al and Mg-Zn alloys

J-Y. Wang, N. Li, R. Alizadeh, M.A. Monclús, Y.W. Cui, J.M. Molina-Aldareguia, J. Llorca.

Acta Materialia 170, 155-165, 2019.

DOI: https://doi.org/10.1016/j.actamat.2019.03.027