IMDEA Materials Institute has taken a significant step in its commitment to innovation and the scientific development of young researchers by launching its new Junior Principal Investigator (Junior PI) program. This program enables postdoctoral researchers who have obtained competitive talent

Emilio Viciana, Regional Minister of Education, Science, and Universities, highlights cutting-edge research at IMDEA Materials

Yesterday, IMDEA Materials Institute had the honor of receiving a visit from Emilio Viciana, Regional Minister of Education, Science, and Universities of the Community of Madrid. During his tour of the facilities, Viciana praised the institute's work and emphasised the importance of its

How artificial intelligence is being used to design the implants of the future

At the forefront of medical innovation, implants have undergone a revolution in recent times thanks to artificial intelligence (AI). Nowadays, these devices are designed and optimised using advanced algorithms. However, conventional manufacturing techniques do not allow for patient

We will see cheap diamonds in Tiffany’s

José Manuel Torralba, IMDEA MATERIALS A diamond awakens a world of suggestions that can lead us, depending on our age, to a cabaret in Paris where Marilyn Monroe declares to the world that they are "a girl's best friend" (Gentlemen Prefer Blondes, Howard Hawks, 1953); to New York's Fifth Avenue,

Prof. Dr. Eugenio Oñate assumes Chairmanship of the Board of Trustees at IMDEA Materials Institute

IMDEA Materials Institute has announced a significant change in its leadership, with Prof. Dr. Eugenio Oñate assuming the role of Chairman of the Board of Trustees, succeeding Prof. Dr. Manuel Doblaré. Prof. Oñate, a renowned expert in computational mechanics and advanced materials and an

Before Saving the World with Carbon Nanotubes, Do We Know if They Are Recyclable?

Anastasiia Mikhalchan, IMDEA MATERIALS They can replace CO²-intensive materials like copper, steel, and aluminum in the construction, aerospace, automotive, and other industries, and are also the global bet for an ongoing energy transition. Carbon nanotubes, filaments 2,000 times thinner than

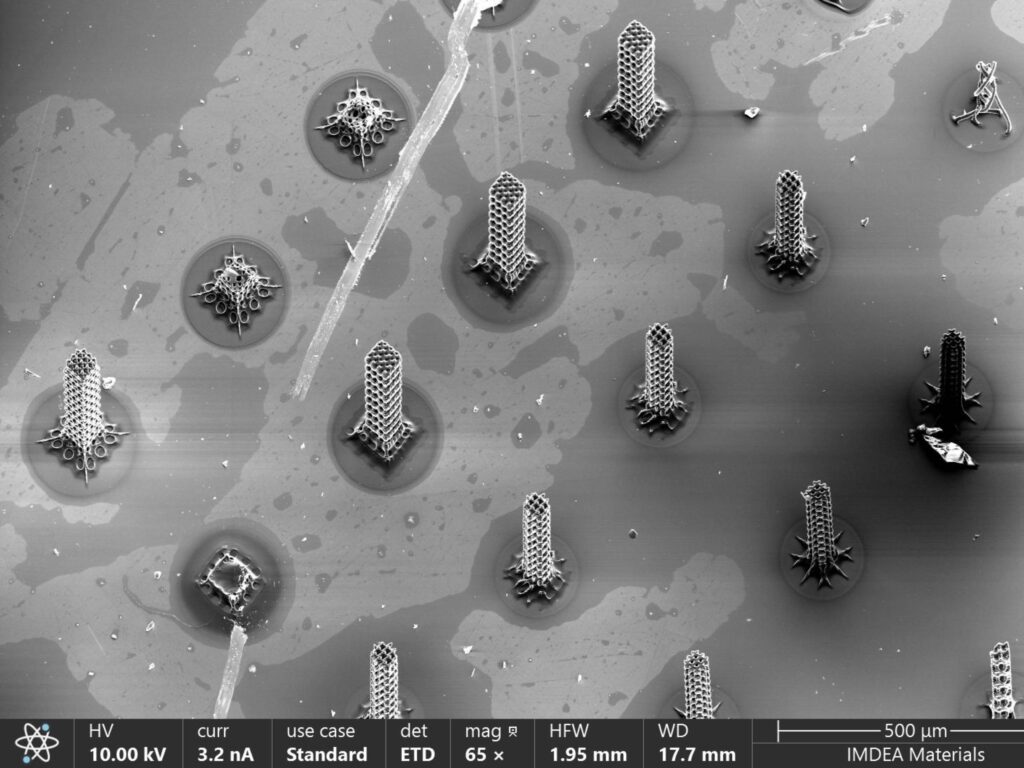

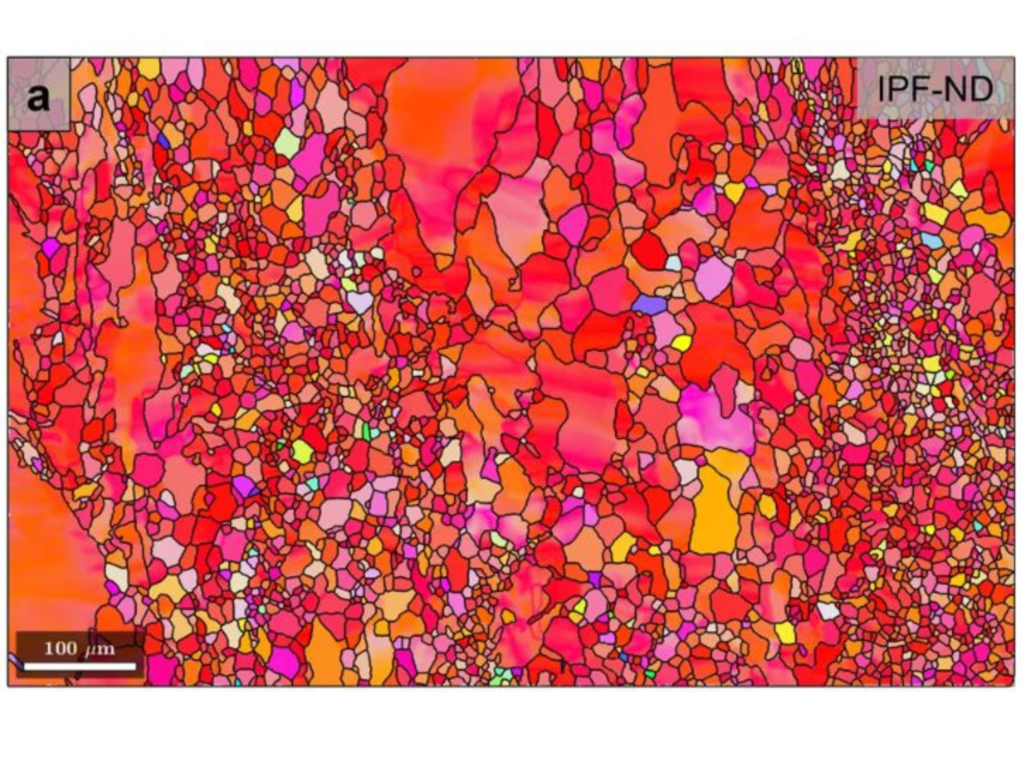

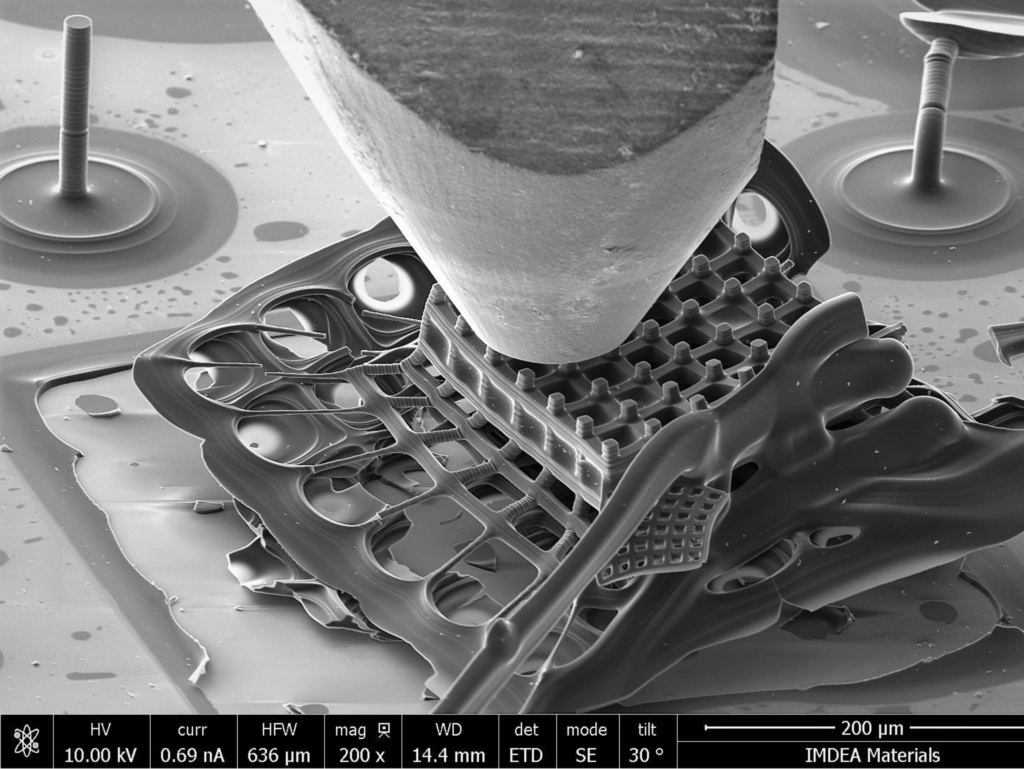

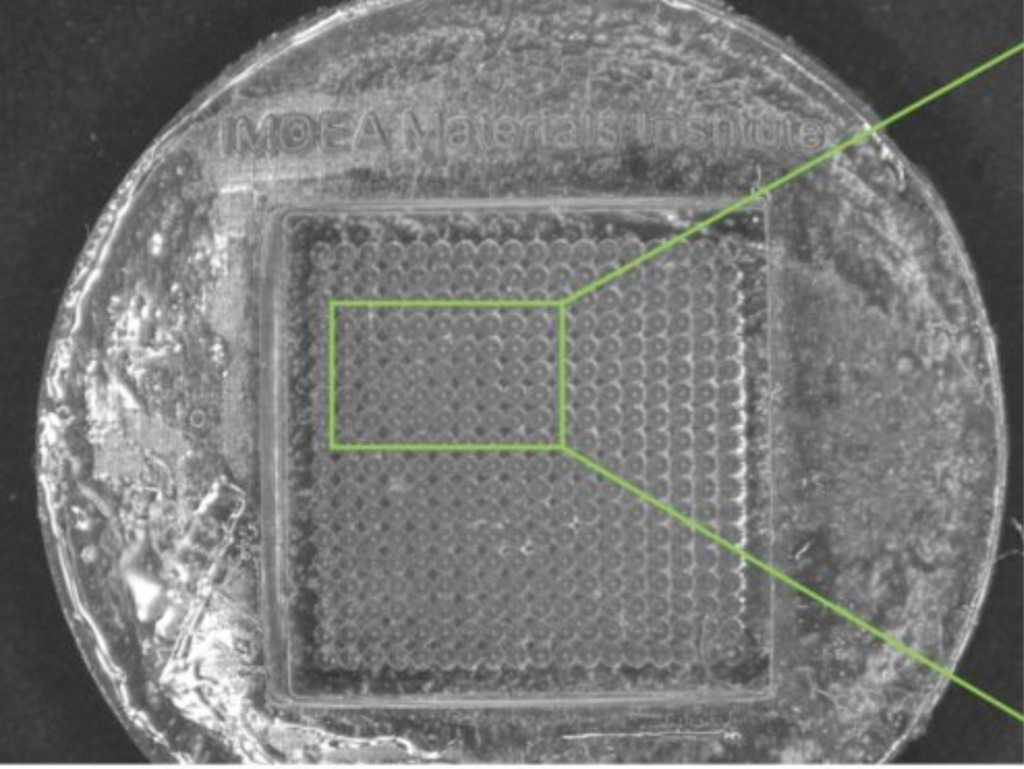

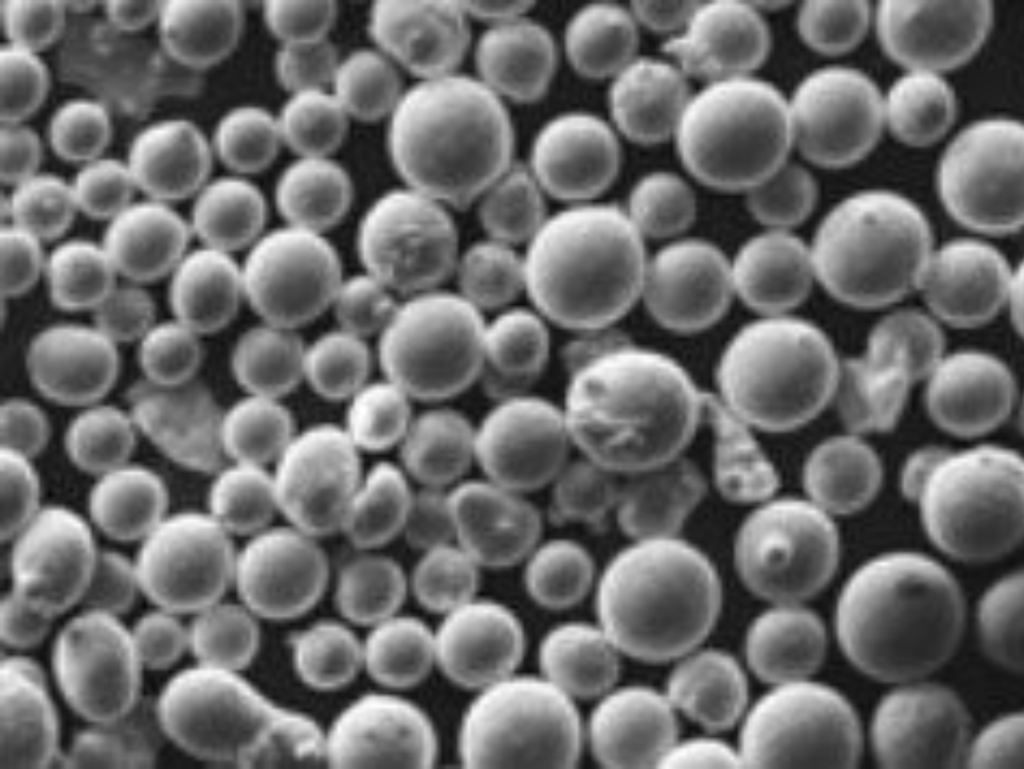

Materials science in focus in IMDEA Materials’ 13th annual imaging contest

IMDEA Materials Institute recently celebrated its 13th annual imaging contest featuring images related to materials characterisation and processing, simulation and the institute's everyday activities. The most competitive category was "Materials Characterisation", which this year was won by

IMDEA Materials leads groundbreaking research in topological metamaterials

Dr. Johan Christensen, leader of IMDEA Materials Institute’s Mechanical and Acoustic Metamaterials research group, is among the researchers behind a pioneering study exploring the topological properties of metamaterials. This latest research, Focusing micromechanical polaritons in

IMDEA Materials welcomes largest cohort of MSU students yet as part of ongoing research collaboration

IMDEA Materials has recently welcomed the latest group of students from Michigan State University (MSU) as part of the continuing research and educational collaboration between the two institutions. This year’s intake of MSU pre-graduates is the largest to date, with 10 students set to spend the

Carmen Martínez, from IMDEA Materials, wins the audience award at Falling Walls Lab Madrid

On Friday, May 31, the prestigious 3MT competition of Falling Walls Lab Madrid took place at the headquarters of the Spanish National Research Centre (CSIC). For the second consecutive year, the event’s Public Choice Award was won by an IMDEA Materials researcher, in this case, Carmen Martínez

The Congress that almost wasn’t and ended in success

Organisers of the 19th European Mechanics of Materials Conference (EMMC19) have heralded its success in putting IMDEA Materials Institute on the map in the mechanics of materials field. The event, held last week over three days at the Technical University of Madrid (UPM), was organised by IMDEA

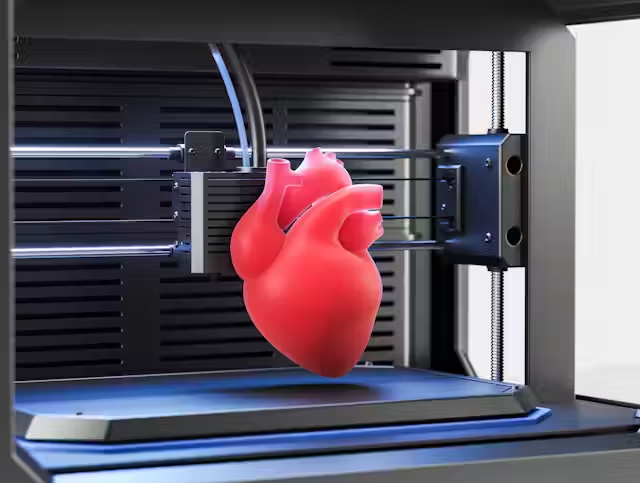

Printed Organs, Custom Scalpels, and Other Medical Applications of 3D Printing

KateStudio/Shutterstock Pedro Jesús Navarrete Segado, IMDEA MATERIALES One of the technologies that has had the most impact on advances in medicine in recent years has been 3D printing. In the 90s it began to be used in the production of dental implants and personalized prostheses, surprising

IMDEA Materials Institute opens hosting offers for 2024 MSCA PF call

IMDEA Materials Institute is seeking postdoctoral researchers for call 2024 of the Marie Skłodowska-Curie Actions (MSCA) Postdoctoral Fellowship (PF) programme (deadline 11/09/2024). Our Institute has a long track record of hosting MSCA fellows (around 30 fellows hosted in total, with 8 more set

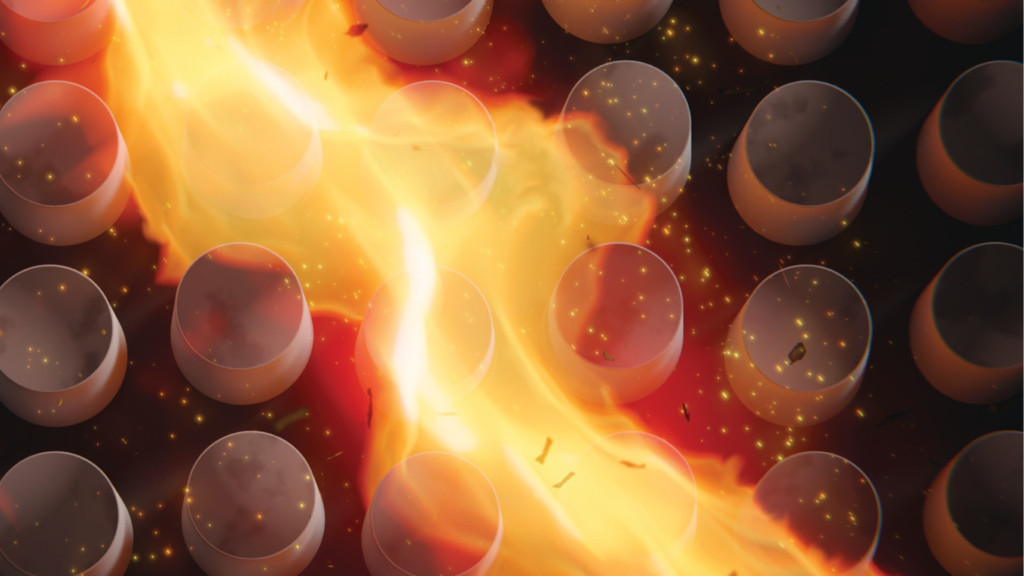

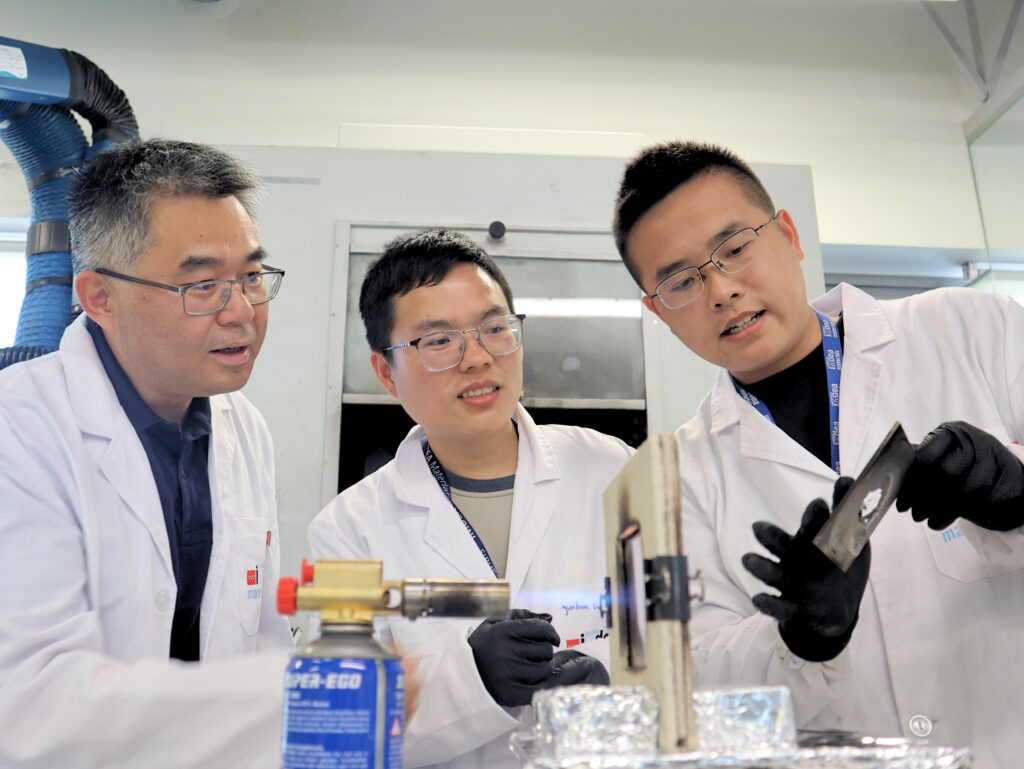

Innovative nanocoating shown to significantly enhance battery casing fire resistance

IMDEA Materials Institute researchers have unveiled an innovative flame-retardant coating, effective at thicknesses of as low as 350 microns, which dramatically improves the fire resistance of the battery casings used in electric vehicles and aerospace. Such a breakthrough promises to reduce the

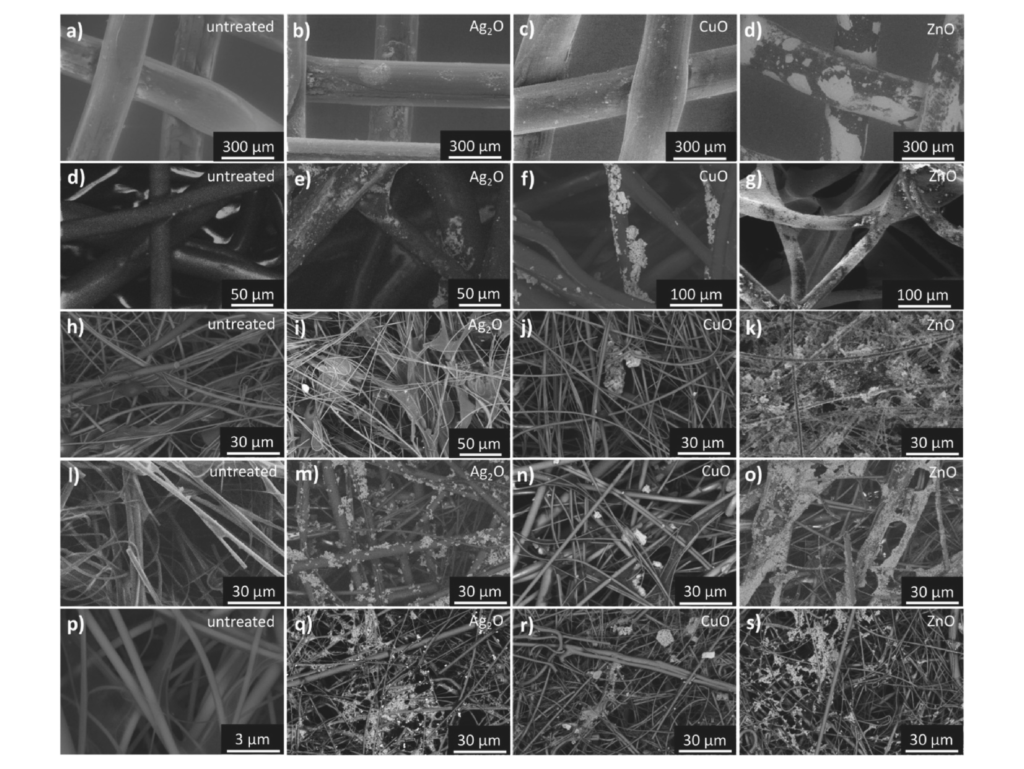

Advancing Antiviral Protection: novel face mask offers improved performance against H3N2 influenza

In the relentless battle against airborne viruses, researchers from IMDEA Materials Institute, Rey Juan Carlos University (URJC) and the University of Valladolid (UVa), have developed a new spray coating to improve the antiviral efficacy of personal protective equipment, notably face masks. GO

Radiation, the invisible threat to the colonisation of Mars

Jesús Ordoño Fernández, IMDEA MATERIALES The exploration of the red planet faces numerous challenges, from the effects of microgravity to space fungi and one of the most dangerous: radiation. The latter mainly comes from two sources: the Sun (and its solar storms) and outer space, distant

IMDEA Materials researchers unravelling the mysteries of twin nucleation in magnesium alloys

Twinning, a phenomenon where crystals develop mirror symmetry across a twin plane during deformation, holds significant importance in the mechanical behaviour of materials. Recently, researchers from IMDEA Materials Institute, Prof. Javier LLorca, Dr. Valentín Vassilev-Galindo and Biaobiao Yang,

How High-Entropy Alloys could help shape tomorrow’s energy landscape

In the quest for greener energy solutions, hydrogen-based technologies have emerged as strong contenders. However, one of the challenges lies in efficient hydrogen storage as traditional austenitic steels, commonly used for hydrogen vessels, suffer from embrittlement during storage. With the aim

IMDEA Materials and ArcelorMittal leading the advance of sustainable steel design

In the face of raw materials and energy crises, and environmental challenges, an ambitious project aims to address a crucial sustainability challenge in one of the key industries in the transition to a green economy. Co-coordinated by IMDEA Materials Institute and ArcelorMittal, IRIDESCENT is a

IMDEA Materials in search of doctoral candidates to carry out cutting-edge research on bioabsorbable medical devices

IMDEA Materials Institute, with its expertise in biodegradable metals for medical applications, aims to advance vanguard medical technologies through the BIOMEND Doctoral Network, a pioneering initiative supported by the European Comission’s Marie Skłodowska-Curie Actions (MSCA) programme. The

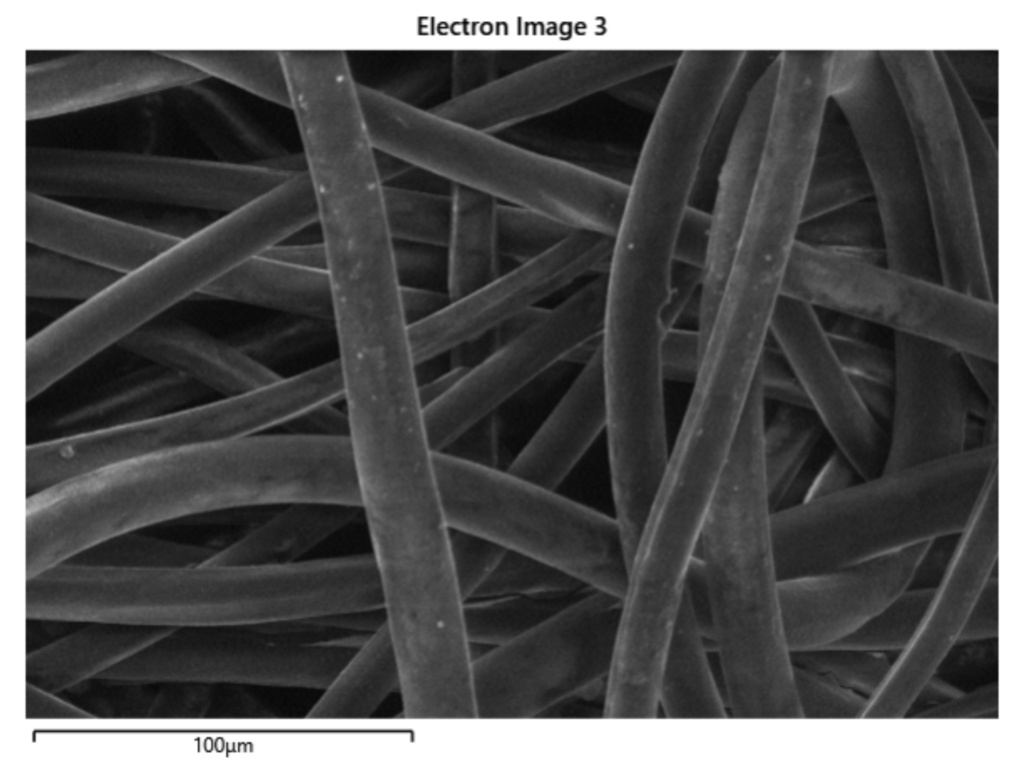

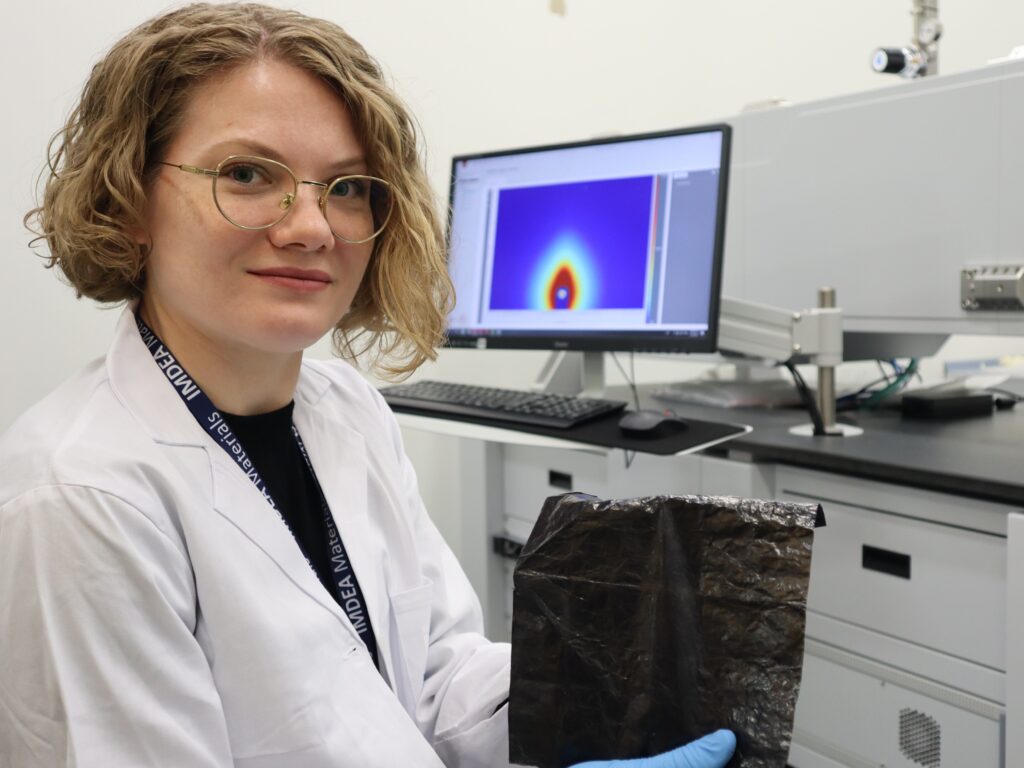

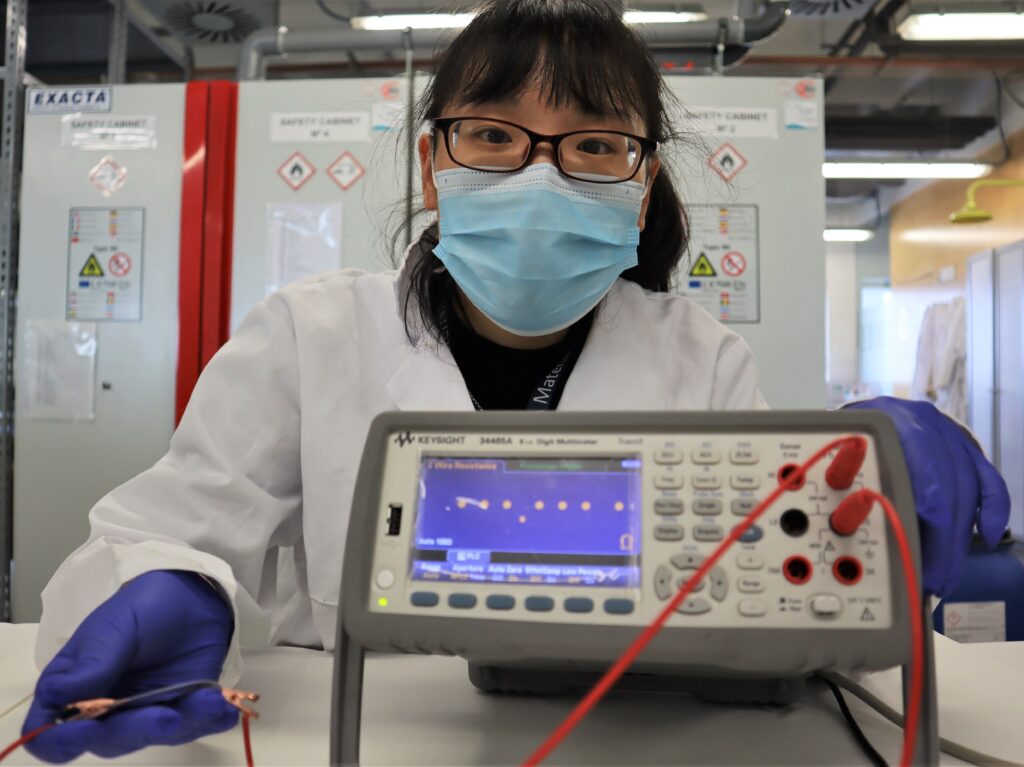

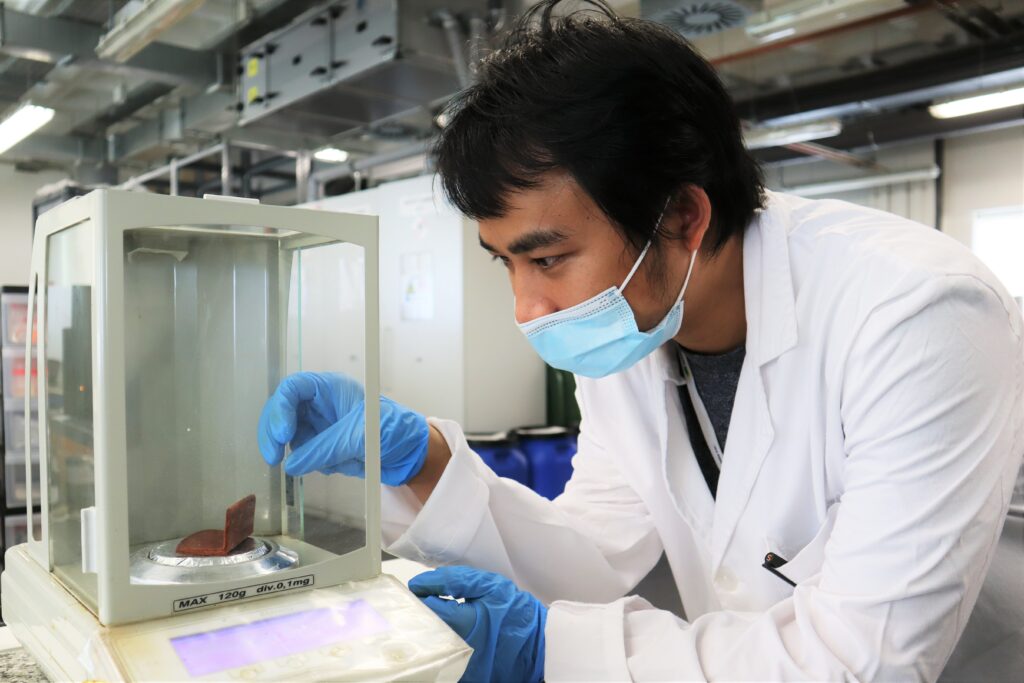

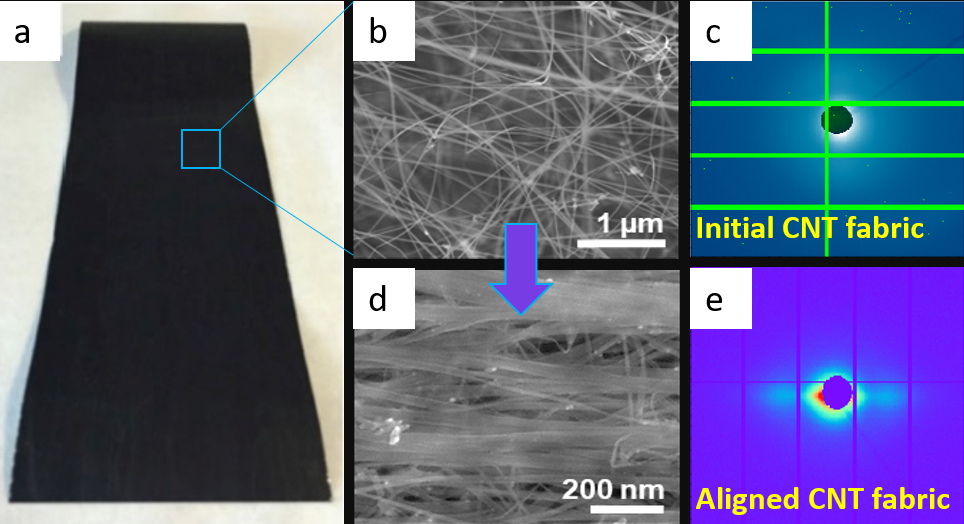

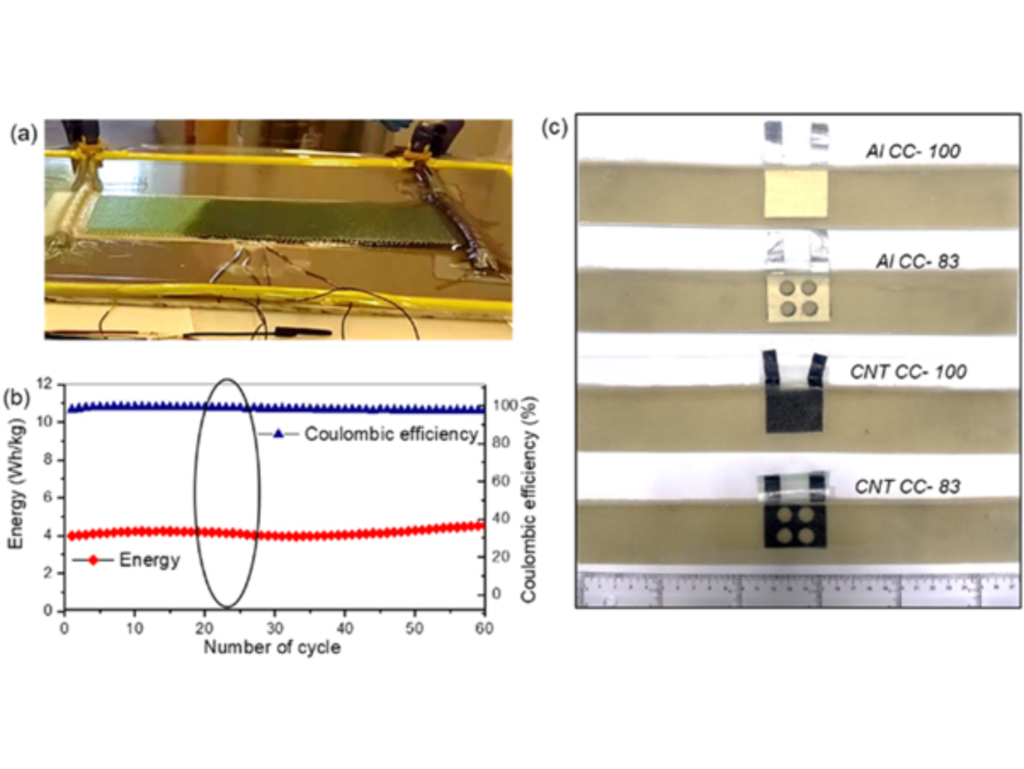

IMDEA Materials demonstrates breakthrough recyclability of Carbon Nanotube Sheets

Researchers from IMDEA Materials Institute have published groundbreaking work demonstrating, for the first time, the ability to recycle high-performance carbon nanotube (CNT) sheets while preserving their shape, structural alignment, mechanical and electrical properties, and intrinsic flexibility.

IMDEA Materials triumphs in the Madrid Science Fair 2024

For the fourth consecutive year, IMDEA Materials Institute has participated in the Madrid Es Ciencia Fair, the largest annual science outreach event in the Community of Madrid. Nearly 20 researchers, representing all areas of research conducted by the Institute, from advances in medical devices

IMDEA Materials consolidates its position as one of Spain’s leading research centres in latest MSCA PF call

Novel materials that better enable buildings to utilise solar energy for heating and to reflect sunlight, ultrafine iron and titanium-based alloys, and sophisticated modelling to improve the efficiency of gas turbines. These are just three of the potentially game-changing projects that will be

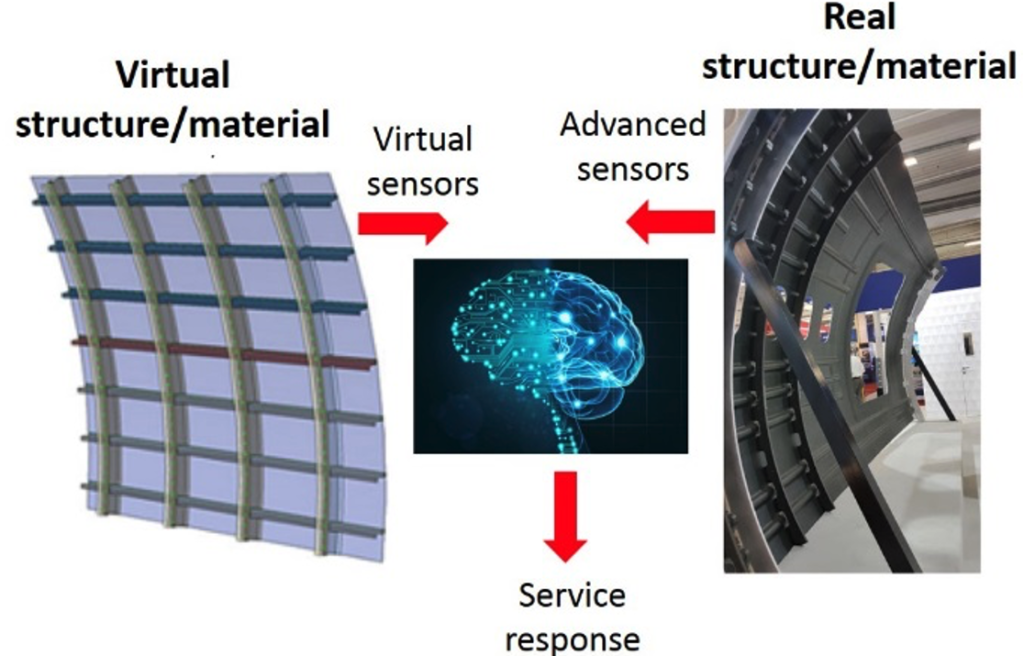

Researchers unveil groundbreaking new Digital Twin for precise real-time analysis of composite materials production

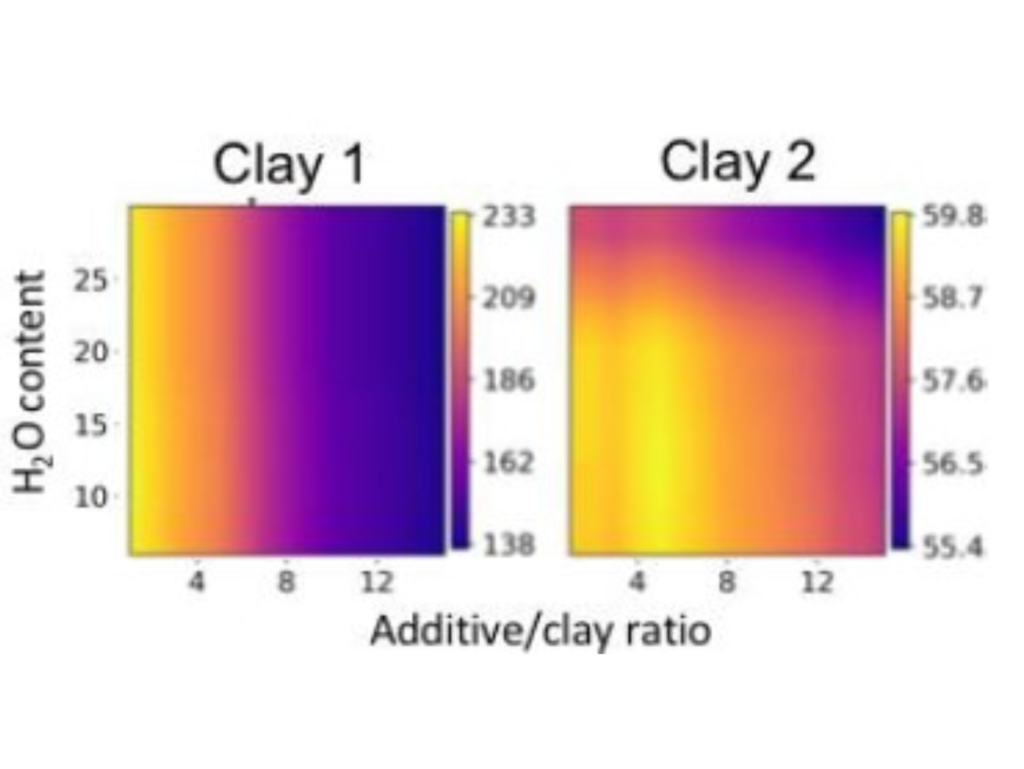

Researchers from IMDEA Materials Institute and the Technical University of Madrid (UPM) have developed an innovative Digital Twin that enables real-time analysis of composite materials manufacturing. The breakthrough was recently presented in The International Journal of Advanced Manufacturing

Prof. Javier LLorca makes history as first Spanish recipient of the Morris Cohen Award

IMDEA Materials’ Scientific Director, Prof. Javier LLorca, has become the first Spanish researcher to receive the Morris Cohen Award from the Minerals, Metals & Materials Society (TMS). The recognition comes a year after Prof. LLorca was the first Spaniard to be awarded the TMS Structural

The Valencia fire: another example of the danger of flammable materials in construction

De-Yi Wang, IMDEA MATERIALS A massive fire has devastated a 14-story building in the Campanar neighbourhood of Valencia, causing a human tragedy for which there is no consolation. Once again, as happened in the Grenfell Tower fire in London, which left over seventy dead, we find ourselves

IMDEA Materials welcomes the Mayor and the Council of Getafe: building bridges for the R&D of future materials

IMDEA Materials has received a visit from the Mayor of Getafe, Mrs. Sara Hernandez Barroso, and a delegation from the Getafe City Council. As part of the visit, the institute also welcomed Mr. Roberto Fernández Melcón, Councilor for Employment, Training, and Maintenance, Mrs. Elisabeth Melo,

DOMMINIO researchers strive to achieve a “paradigm shift” in the manufacture and maintenance of airframe parts

Researchers involved in the DOMMINIO project are moving ever closer to achieving their goal of creating a new digital method for the improved manufacturing of next-generation multifunctional airframe parts. That’s according to DOMMINIO coordinator, Dr. Pablo Romero from AIMEN Technology

Promising new study significantly reduces risk of airborne bacterial infections caused by air filtration systems

A novel nanoparticle spray coating process has been shown to all-but eliminate the growth of some of the world’s most dangerous bacteria in air filtration systems, significantly reducing the risk of airborne bacterial and viral infections. That’s the principal finding of a recently published

Getafe will have a pilot plant to manufacture silicon anodes for the electric cars of the future – CadenaSER

CadenaSER is one of a number of outlets to have highlighted IMDEA Materials Institute spin off Floatech's plans to to build an "advanced pilot plant" for the manufacture of 100% silicon anodes for lithium batteries. These anodes will be vital for the next generation of lithium batteries that

An imaginative proposal to recycle the world’s electronic waste – The Conversation Spain

José Manuel Torralba, IMDEA MATERIALES; Alberto Meza, IMDEA and Damien Tourret, IMDEA Although the amounts of precious metals like gold in electronic waste are very small (on the order of 300 grams per ton), obtaining a kilogram of gold still only requires between three and four tons of

Charting a course to greener skies: IMDEA Materials Institute looks to tackle the aeronautical industry’s big recycling dilemma

In recent years, manufacturers have increasingly turned to lightweight plastic or fibre-reinforced plastic polymers to replace traditional metal components. This is particularly the case in the aerospace industry, where studies have shown that at least 30-40% of modern airframes are now

Floatech, the disruptive Madrid-based startup, to build pilot plant for the production of its next-generation silicon anodes.

Floatech, the Madrid-based startup and spin-off of IMDEA Materials Institute, has secured investor backing to establish a pilot plant for the production of 100% silicon anodes intended for lithium-ion batteries (LIBs). The funding will enable Floatech to construct an advanced pilot plant in the

IMDEA Materials highlights the synergy between research and innovation during Science and Innovation Week

Last Friday, Dr. Jon Molina, Deputy Director of IMDEA Materials Institute, participated in a roundtable discussion on "Research and Innovation, an Essential Pair, a Global Challenge" as part of the Science and Innovation Week. The talk, which involved representatives from the 7 IMDEA Institutes,

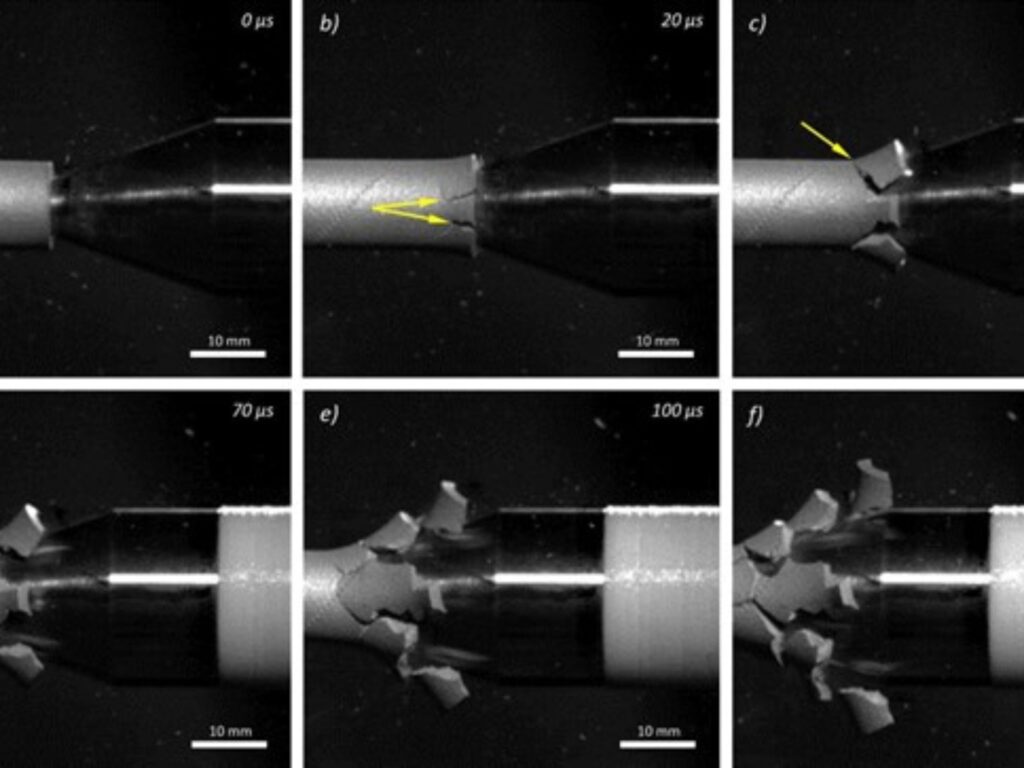

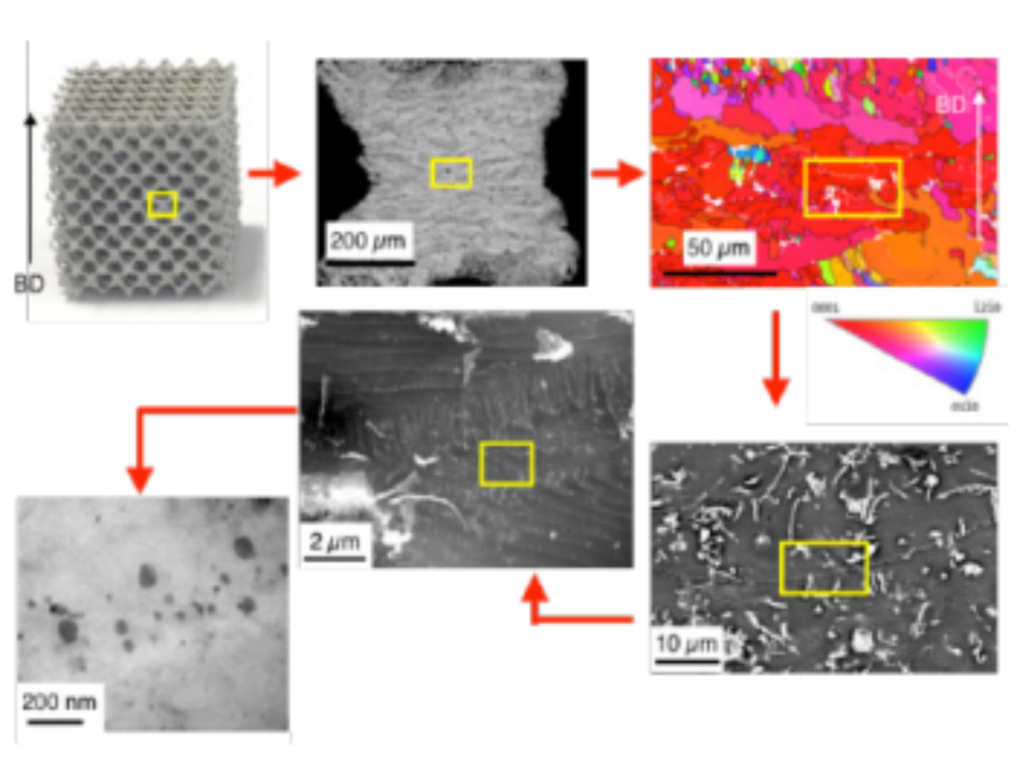

New experimental technique developed to analyse the protection of 3D printed metal structures

Scientists from the Universidad Carlos III de Madrid (UC3M) and IMDEA Materials Institute have developed a new experimental technique in fragmentation tests to evaluate the energy absorption capacity in the event of impact of metallic structures manufactured using 3D printing. This technique,

The fire risk that turns nightclubs and homes into deadly traps: how to avoid it without replacing highly flammable materials?

Ted Pendergast / Shutterstock De-Yi Wang, IMDEA MATERIALES Fires in nightclubs in Spain have caused at least 162 deaths in the past 45 years. In the latest incident, recorded in Murcia, 13 young people lost their lives. Another tragic night occurred in 1983 at the Alcalá 20 nightclub in

How IMDEA Materials is exploring novel materials for carbon capture and hydrogen storage technology

A new class of materials could prove significant in more efficient carbon capture technology, drug delivery and even as a gateway to the hydrogen economy. Metal Organic Frameworks, or MOFs, have been studied for more than three decades. Yet their industrial applicability is still being fully

What is the most used material in the world and the least researched?

José Manuel Torralba, IMDEA MATERIALES We live in a world of steel. It's so common that we use it as a metaphor for everyday life. Some people have nerves of steel, and the biceps of many muscular young individuals are made of ship steel. What is not a metaphor is that steel is everywhere we

IMDEA Materials Institute researchers maintain their position among world’s best scientists

For the second year running, 10 IMDEA Materials Institute researchers have been included in Stanford University's annual lists of the world's top scientists. The result reinforces the Institute's reputation as a centre for excellence, with the Stanford ranking based on the records of more than 8

Madrid hosts AAMS2023: one of Europe’s leading forums in the field of metal additive manufacturing

• IMDEA Materials Institute has organised the largest edition to date of the Symposium on Alloys for Additive Manufacturing (AAMS), one of the most prestigious conferences in its field in Europe. • Experts in metal 3D printing from countries such as the United States, Japan and Australia joined

AID4GREENEST kicks off: IMDEA Materials Institute set to play key role in the next generation of sustainable steel production

Enhanced material quality, the reduction of carbon emissions and waste generation, and reduced risks to the supply of critical raw materials. These are the three principal objectives of a new international research initiative involving 10 partners from four European countries in which IMDEA

“The possibility of seeing what no one has seen before in what everyone has already looked at”: Prof. Javier LLorca is awarded the National Research Prize in Engineering and Architecture

The possibility of seeing what no one has seen before in what everyone has already looked at. That is a large part of what drives Prof. Javier LLorca to continue his pioneering work after nearly four decades among the best in Spanish science and research. Scientific Director of IMDEA Materials

The DITTCe project: how IMDEA Materials Institute has joined the fight against cancer

Tomorrow, September 24th, World Cancer Research Day is celebrated. To commemorate this important day, IMDEA Materials Institute speaks with Dr. Mónica Echeverry, principal investigator of the DITTCe project. This project, led by the Technical University of Madrid (UPM), aims to develop an

Do we have enough materials for the energy transition to be truly possible?

José Manuel Torralba, IMDEA MATERIALS y Miguel Ángel Rodiel, IMDEA Replacing fossil fuels brings with it challenges and side effects that must be considered by all parties involved in Europe's energy transition, vital to our future. To begin with, however, we must ask one seemingly obvious, but

IMDEA Materials Institute to be centre stage at this year’s European Researchers’ Night

IMDEA Materials Institute postdoctoral researcher, Dr. María de Nicolás Morillas, will be one of seven IMDEA investigadors participating in this year's European Researchers' Night Madrid. Dr. de Nicolás is currently researching high entropy alloys (HEAs) for hydrogren storage as well as advanced

Driving the future: A Year of Success for the ‘I Investigate’ program at IMDEA Materials Institute

With the arrival of September, IMDEA Materials is bidding farewell to many of the young researchers and support staff who have joined the Institute in the last 12 months as part of the 'I Investigate Programme'. The I Investigate Programme, managed by the Community of Madrid, is funded through

IMDEA Materials looks to tackle growing number of bone replacement surgeries with stronger, longer lasting implants

Researchers at IMDEA Materials Institute are working to ensure that future bone replacement implants are more durable and offer a greater service life than ever before. The research, which is being undertaken through the European Union-funded M3TiAM project, is designed to meet the needs of an

IMDEA Materials Institute adds powerful new tool to assist in the mechanical characterisation of metallic materials

IMDEA Materials Institute will have on-site access to one of the world’s most advanced mechanical testing devices after Principal Investigator Dr. Ilchat Sabirov was announced as the winner of Plastometrex’s 2023 Research Competition. Dr. Sabirov was chosen from among 8 finalists for the award

IMDEA Materials’ Scientific Director, Prof. Javier LLorca, appointed Honorary Professor at Yanshan University

IMDEA Materials Institute's Scientific Director, Prof. Javier LLorca, has been appointed as an Honorary Professor at China's Yanshan University (YSU). The appointment is a first step in strengthening the collaboration between IMDEA Materials and YSU, one of the top-ranked Chinese universities in

IMDEA Materials joins the fight to improve health outcomes for heart attack sufferers

IMDEA Materials Institute is participating in a research project to develop a new method of bioengineering myocardial tissue for heart attack patients. CARDIOBOOST-CM aims to create a new cell therapy approach in which muscle stem cells taken from the jaw are transdifferentiated in vitro into

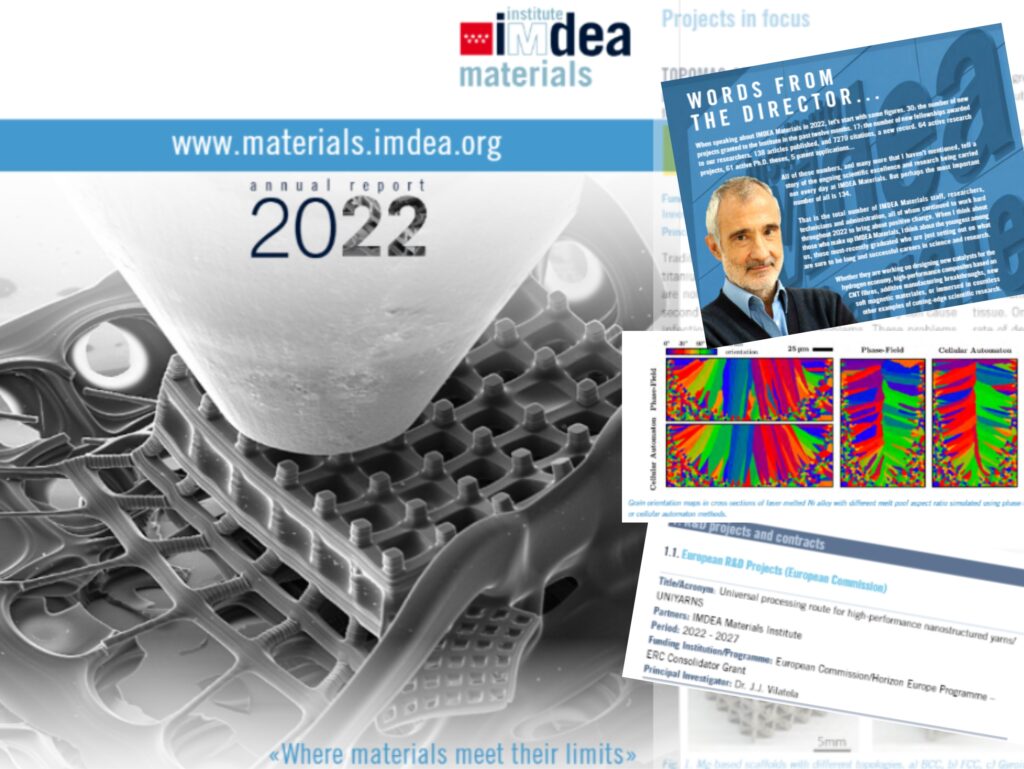

Year in Review – IMDEA Materials Institute is pleased to launch its 2022 Annual Report

MDEA Materials is delighted to announce the launch of our 2022 Annual report, available now for download. This annual report is designed to give you an overview of the Institute and main achievements in 2022. You will also find a description of the current Research Programmes, highlighting

Silence in the City: The New Wave of Topological Materials

Dr. Johan Christensen, IMDEA Materials Institute Imagine being on your way to a well-deserved summer vacation when suddenly you collide with another vehicle. Fortunately, the chassis of your car deforms in a controlled and programmed manner upon impact, creating a safe zone for the occupants to

Advancing Composite Sustainability and Digitalisation Strategies: IMDEA Materials Institute Hosts 6th IAB Meeting

Composites sustainability and effective industrial digitilisation were the central topics of discussion as IMDEA Materials Institute hosted the 6th meeting of its Industrial Advisory Board (IAB) in Madrid. This year's meeting featured an IAB Member Talk on composite sustainability presented by

Anastasiia Mikhalchan to showcase the latest achievements in gas-phase synthesis and 1D materials at CERN

This week, Dr. Anastasiia Mikhalchan will present research from IMDEA Materials' Multifunctional Nanocomposites research group group on the gas-phase synthesis and properties of 1D materials, which could be used under higher luminosity conditions for beam instrumentation and quality

IMDEA Materials Institute recognised for groundbreaking research in turning scrap metal into high-performance alloys

IMDEA Materials Institute researcher Venkatesh Kumaran is this year’s winner of the prestigious AMES-Joan Antoni Bas Prize for the best research in R&D powder metallurgy. Kumaran was recognised for the publication ‘Development of high-performance powder metallurgy alloys from 'commodity'

Pedro Navarrete to showcase the future of cardiac regeneration at Falling Walls Lab Madrid, 2023

Interview with Pedro Jesús Navarrete Segado, participant in Falling Walls Lab Madrid, 2023. This Friday, May 26, IMDEA Materials Institute researcher, Pedro J. Navarrete Segado, will present on future clinical applications in the field of cardiology at the national competition, Falling

Being a Marie Skłodowska-Curie Actions postdoctoral fellow at IMDEA Materials – Webinar

Are you interested in applying for a Marie Skłodowska-Curie Actions Postdoctoral Fellowship (MSCA PF)? Want to know what it's like to be an MSCA PF fellow in our Institute? Join us in this webinar on June 1st at 12pm (GMT +2) and learn more about our hosting offers for call 2023 of the MSCA PF,

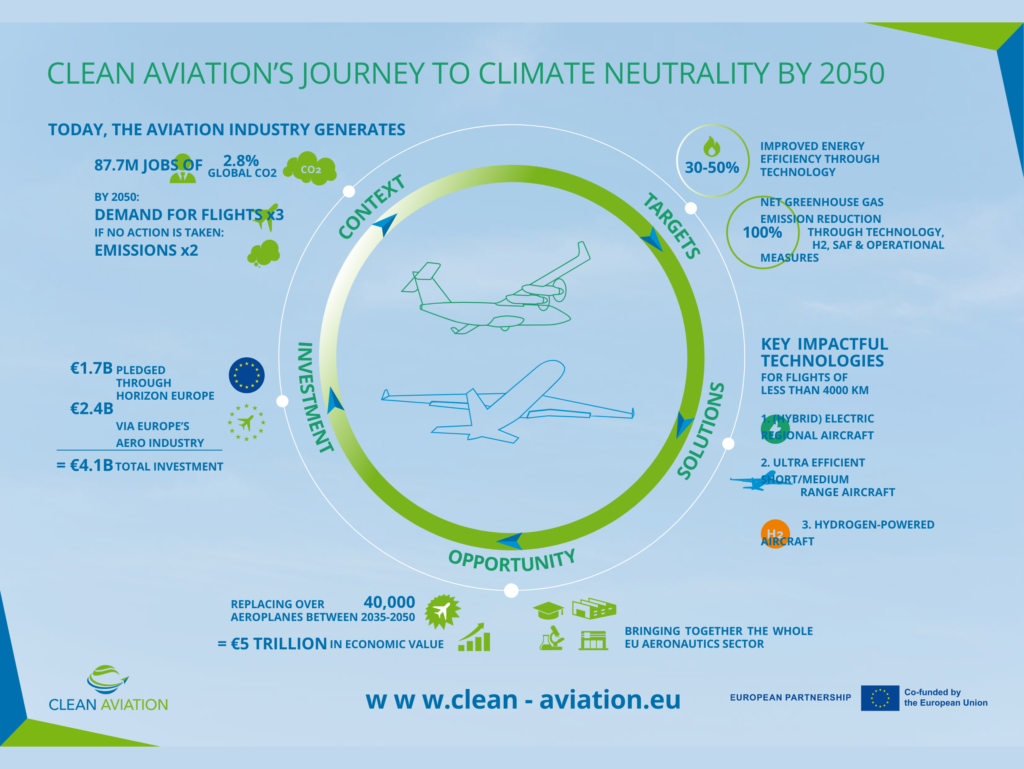

IMDEA Materials Institute joins European project to make the dream of clean aviation a reality

IMDEA Materials is part of the multinational European consortium working to develop the next hybrid electric regional passenger aircraft with the aim of reducing emissions by up to 90%. The ‘Hybrid-Electric Regional Architecture’ (HERA) project, led by worldwide Italian aerospace giant Leonardo,

Solving some of society’s biggest challenges by focusing on the smallest scale

An interdisciplinary research network of more than 77 organisations and research centres from 24 countries has set out to make significant progress in the testing, simulation and characterisation of materials at the nano-scale. Doing so will facilitate the development of new materials with

IMDEA Materials opens its hosting offers for the MSCA Postdoctoral Fellowship call 2023

IMDEA Materials Institute seeks applicants for a Marie Skłodowska-Curie Actions (MSCA) Postdoctoral Fellowship (PF) in call 2023 (deadline 13/09/2023). IMDEA Materials has a long track record of hosting MSCA fellows and has obtained excellent success rates in recent calls of MSCA PF

PORMETALOMICS takes next step to further understanding of lightweight porous metals

IMDEA Materials Institute has hosted the first face-to-face meeting of the European PORMETALOMICS project. The meeting was attended by representatives from the three project partners: IMDEA Materials (project coordinators), Technion – Israel Institute of Technology and the Institute of

IMDEA Materials participates in SM@RTM project to improve competitiveness of RTM processes

The Resin Transfer Molding (RTM) process offers great advantages in the manufacture of high performance composite materials, such as the ability to obtain geometries with high surface finish and dimensions close to the final geometry (net-shape), high mechanical properties and reduction of working

IMDEA Materials Institute hosts final MAT4.0-CM Meeting as project wraps up

IMDEA Materials Institute today hosted the final meeting of MAT4.0-CM, a project designed to advance intelligent manufacturing of advanced materials for energy, transport and health. MAT4.0-CM is coordinated by IMDEA Materials and aims to promote the additive manufacturing of metallic materials

Information session for the 2023 Skłodowska-Curie Actions Postdoctoral Fellowships Call

IMDEA Materials can announce that after our tremendous success in the 2022 Marie Skłodowska-Curie Actions Postdoctoral Fellowships, we have been invited to share our experience in the next information day for candidates of the 2023 call! The session will be on Tuesday, April 25 at 10 am. The

IMDEA Materials’ Dr. Damien Tourret named 2023 Young Leaders International Scholar

Dr. Damien Tourret, leader of IMDEA Materials’ Modelling and Simulation of Materials Processing research group, has been named the 2023 Young Leaders International Scholar by the American Minerals, Metals and Materials Society (TMS) and the Japan Institute of Metals and Materials (JIM). The

Students explore opportunities at IMDEA Materials at our annual “Open PhD Day”

IMDEA Materials Institute today hosted its annual “Open PhD Day” for students interested in pursuing their doctorate studies in a variety of fields related to materials science. IMDEA Materials is one Spain’s leading institutes to undertake a PhD, owing to its level of international prestige,

The secrets and science behind Damascus swords, long famed for their strength and beauty

José Manuel Torralba, IMDEA MATERIALES y Ilchat Sabirov, IMDEA MATERIALES Damascus steel swords were legendary for their great strength, durability and their "almost eternal" edge. They could cut silk as well as shatter a rock. Sultan Saladin impressed Richard the Lionheart at a sword exhibition.

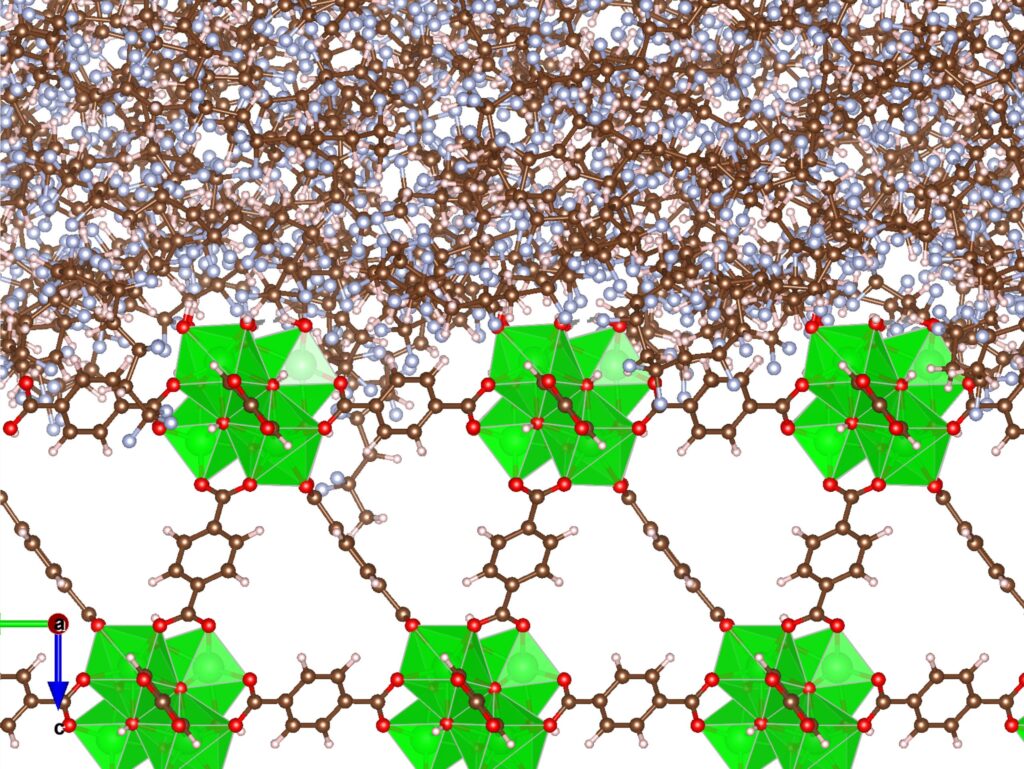

The world’s first scalable and continuous surface modification process for magnesium alloy wires

Researchers from IMDEA Materials Institute and German medical equipment manufacturer Meotec GmbH have developed the world's first industrially scalable surface modification process for bioabsorbable magnesium alloy wires. The findings, as reported in two recently published scientific papers (see

IMDEA Materials and ZoeTech collaborate to develop a new wearable device to improve blood circulation

IMDEA Materials Institute is collaborating with the Madrid-based health technology company ZoeTech to create a new wearable device to improve blood circulation. Project RETOVEN aims to develop the technology, which will help sufferers of medical conditions caused by inefficient blood flow such as

Floatech eyes industrial-scale manufacturing of silicon anodes with its first pilot plant

Floatech, a Madrid-based spin-off of IMDEA Materials Institute, plans to open its first pilot plant for the manufacture of silicon anodes this year. Silicon anodes will be vital for the next generation of lithium ion batteries (LIBs) that will power the electric vehicles of the future. The

Prof. Javier LLorca receives SMD Distinguished Scientist/Engineer Award from TMS

Prof. Javier LLorca, has become the first Spanish scientist to receive the Structural Materials Division Distinguished Scientist/Engineer Award from the Minerals, Metals and Materials Society (TMS). Prof. LLorca received the award at the 152nd Annual Meeting of the TMS in San Diego, California

IMDEA Materials Institute celebrates its 12th Annual Imaging Contest

IMDEA Materials Institute has today celebrated the presentation of awards to finalise the 12th Annual Imaging Contest. This year's competition was dominated by the Materials Characterisation category, which contributed the majority of entries, ahead of Open Subject and Materials Simulation.

The future of regenerative medicine meets the present at IMDEA Materials Institute

By Blanca Martínez and Andrés Gerlotti Currently, those suffering from bone or cartilage damage can opt for metal implants for treatment, prostheses that last approximately fifteen years. But now that patients are living longer, they need implants that can function for the rest of their

How revealing the secrets hidden inside materials can help fight future pandemics

Researchers at IMDEA Materials Institute now have access to a powerful new tool to characterise, design and create novel materials with a wide range of applications, including next-generation biomedical devices. IMDEA Materials recently became just the third scientific research institute in

IMDEA Materials to put the present and future of materials science on show in Madrid

Curious about the materials that make up the world around us? Are you interested in learning about the materials required to create next-generation batteries, medical implants or aircraft components, among others? Then make your way down to the Círculo de Bellas Artes tomorrow anytime between

ConstructAdd takes next step in its mission to bring steel additive manufacturing into the mainstream

IMDEA Materials Institute in Madrid in Spain has played host to the second progress meeting of the European ConstructAdd project. Financed by the Research fund for Coal and Steel, the aim of ConstructAdd is to facilitate the use of Additive Manufacturing (AM) in the design, production and

IMDEA Materials scores unprecedented success in latest MSCA Fellowship call

A new treatment for one of the world’s most prevalent tropical diseases, the discovery of cheaper alternative catalysts for hydrogen production, and the development of dynamic, load-bearing implants for tissue engineering. These are just three of the new projects that are set to get underway at

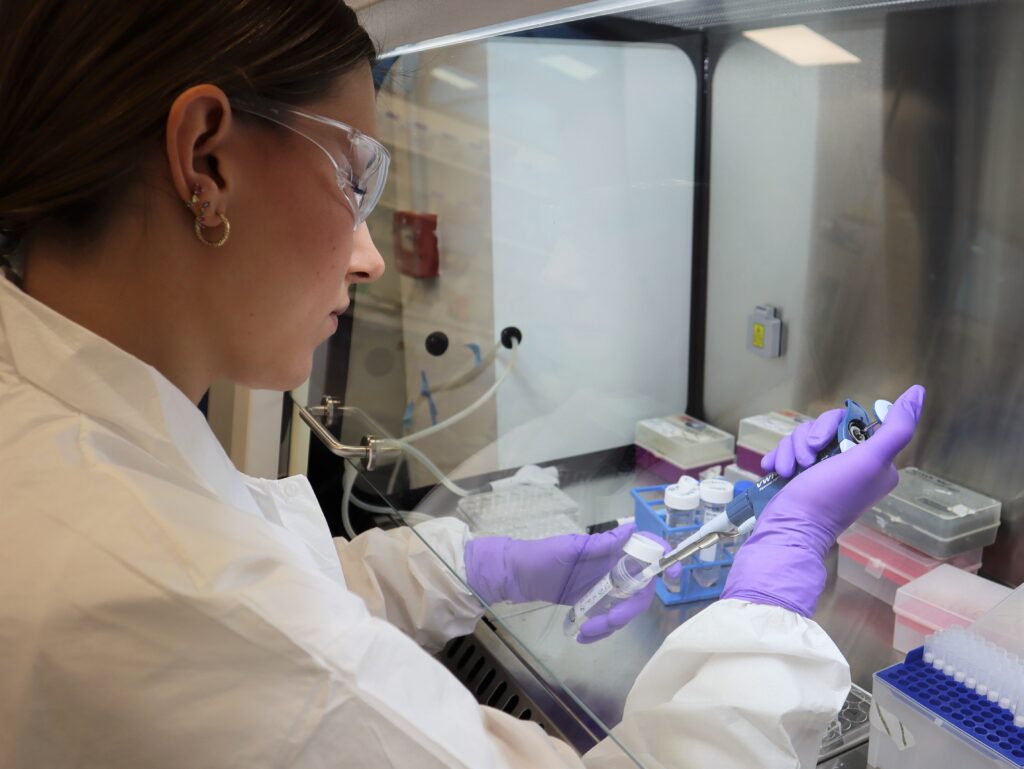

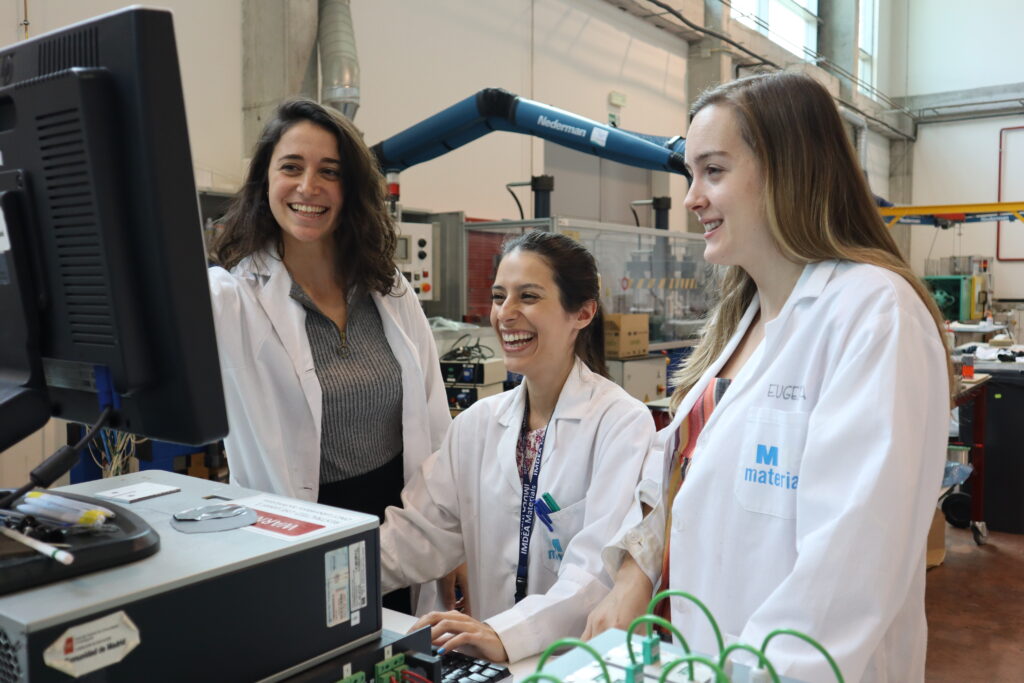

“It’s something that has to change, and it is changing.” The Changing Face of Science

Blanca Limones represents the ongoing generational change underway in the world of science and research. The 27-year-old is currently working as a Research Assistant at IMDEA Materials Institute, where she forms part of the Biomaterials and Regenerative Medicine research group, led by Dr.

“The panorama is gradually changing” – A tribute to the female faces of IMDEA Materials

Mónica Echeverry Rendon is a bioengineer and Postdoctoral Researcher at IMDEA Materials Institute. In this article, she follows up on last year's post celebrating the International Day of Women and Girls in Science. Last year, to commemorate the International Day of Women and Girls in Science, I

Safer helmets and more comfortable running shoes: optimized 3D-printed metamaterials

This Saturday, February 11, is the International Day of Women and Girls in Science. To mark the occasion, IMDEA Materials is showcasing the work of three of our female researchers. In this, the second of three articles, we talk to predoctoral researcher Lucia Cobian about the European MOAMMM

“Meet the IMDEA Materials scientist trying to change the perception of research

This Saturday, February 11, is Women in Science Day. On this occasion, IMDEA Materials would like to showcase the work of three of our female researchers. In this first of three articles, we talk to predoctoral researcher Elena Sánchez. In her day-to-day work as a predoctoral researcher at IMDEA

IMDEA Materials to form part of the Community of Madrid’s new research clusters

IMDEA Materials will be a founding member of three of the Community of Madrid´s recently launched Innovation, Technology and Talent Clusters. The clusters, each dedicated to a different scientific area, have been designed to facilitate public-private partnerships, increase knowledge transfer and

Stopping brain tumor growth via electric fields using remotely powered, implantable devices

- IMDEA Materials Institute will play a key role in a new project aimed at designing and manufacturing new implantable devices for brain tumor treatment. - Glioblastoma is the deadliest form of brain cancer. It has a 5-year survival rate of less than 10%. Current treatments are both expensive and

Prof. Javier Segurado receives “Consolidation of Research Activity” award from the UPM

Prof. Javier Segurado, leader of IMDEA Materials' Multiscale Materials Simulation research group, recently received the "Consolidation of Research Activity" award from the Technical University of Madrid. Prof. Segurado received this award in recognition of the "impact and number of his scientific

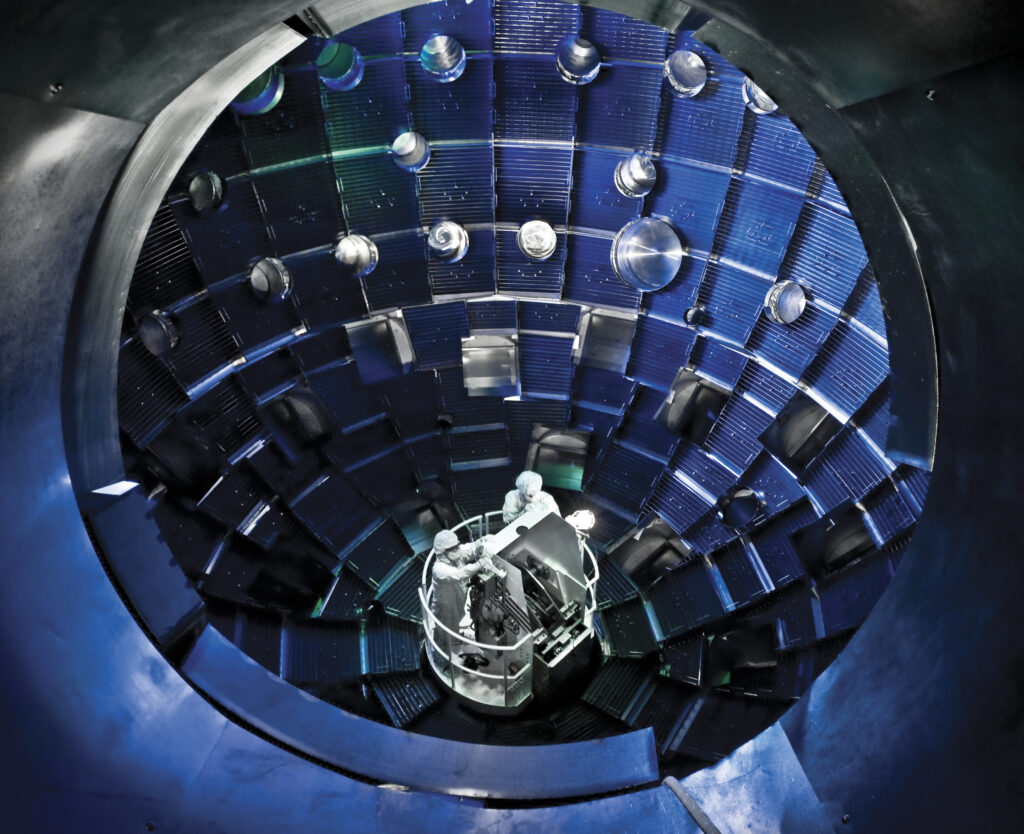

Simulating the future of nuclear fusion: what material can contain a star on Earth?

Nuclear fusion as a source of energy in stars was first described in the 1920s. Since then, scientists have not stopped dreaming of reproducing this process in a controlled way. Generating energy through fusion is to emulate what the Sun does, but on Earth and within a container. One of the

IMDEA Materials achieves ‘Human Resources Excellence in Research’ award renewal

IMDEA Materials’ commitment to providing a stimulating and favourable environment for researchers has been recognized with the renewal of the Institute’s ‘HR Excellence in Research Award’. The HR Excellence in Research Award is granted by the European Commission and acknowledges institutions

New research group seeks to push scientific boundaries in the field of metamaterials

From his earliest days as a predoctoral researcher, Dr. Johan Christensen has been driven by the desire to push scientific boundaries. Dr. Christensen recently took up a position at IMDEA Materials Institute as a Senior Researcher and leader of the Institute’s newly-founded Acoustic and

IMDEA Materials Institute represented among this year’s IOM3 award winners

IMDEA Materials Director, Professor José Manuel Torralba was on hand in London recently to receive the annual Ivor Jenkins award from the Institute of Materials, Minerals & Mining (IOM3). And Prof. Torralba wasn’t the only award-winner with an IMDEA Materials connection on the night, as

Reinventing 4D medical printing for intelligent, next-generation biomedical implants

IMDEA Materials Institute and the Technical University of Madrid (UPM) recently celebrated the first Open Innovation and Industrial Workshop, marking the 18-month point of the iMPLANTS-CM project. The main objective of iMPLANTS-CM, funded by the Community of Madrid, is the development of a new

IMDEA Materials celebrates Science Week 2022 with a visit from Colegio Retamar

IMDEA Materials Institute celebrated Science Week 2022 with a visit from students from Colegio Retamar in Madrid. The BIOMET4D and BioImplant-ITN projects were a focus of the activities with predoctoral researchers Ángela Castro María from the Biomaterials and Regenerative Medicine group (Dr.

IMDEA Materials and the UPM put additive manufacturing and the biomedicine of the future on show

Professor Andrés Díaz Lantada and Dr. Jon Molina-Aldareguia, of the Technical University of Madrid (UPM) and IMDEA Materials Institute, have highlighted the “significant advances” made in 4D printing, shape-morphing materials and medical devices thanks to the iMPLANTS-CM project. Their comments

IMDEA Materials and the UPM develop an innovative ‘smart mask’ with a use beyond pandemics

- Researchers from IMDEA Materials Institute, in collaboration with the Technical University of Madrid and Rey Juan Carlos University have developed a new smart mask capable of monitoring a wearer’s breathing. - The mask has numerous advantages over smart masks currently available, including its

IMDEA Materials Institute researchers well represented among the world’s top scientists

IMDEA Materials Institute’s reputation as a centre of international reference in the field of materials science and engineering has been further bolstered by the inclusion of 10 researchers in Stanford University’s annual ranking of the world’s top scientists. Stanford’s ranking is based on

IMDEA Materials developing sensor technology to detect fires before they start

Researchers at IMDEA Materials Institute are working on fire safety systems that can detect and warn of the risk of fire danger before a fire breaks out. Fire alarms generally operate by detecting the presence of smoke, open flame, and/or higher-than-normal levels of carbon monoxide. Such

Solid-state electrolytes, a solution to safety concerns in lithium-ion batteries

IMDEA Materials researchers are working on developing a new composite solid-state electrolyte (CSSE) with flame-retardant properties for lithium-ion batteries. The research aims to address one of the key concerns facing the current generation of lithium-ion energy storage devices, their reliance

IMDEA Materials advancing the field of lightweight porous metals for bone implants and transport technologies

A new international project coordinated by IMDEA Materials Institute is dedicated to porous metal structures which combine lightweight with high strength. The high surface-to-volume ratio of porous metals, together with optimisable mechanical properties, makes them promising candidates in various

A new generation of sustainable composite materials with flame-retardant properties.

IMDEA Materials Institute is playing its part in the European Union’s transition to a circular economy thanks to groundbreaking work in recyclable, flame-retardant materials. IMDEA Materials’ research is producing advances in environmentally-friendly sandwich-structured composites, widely used in

IMDEA Materials joins the effort to construct a more sustainable future through 3D printing

An international group of researchers is out to prove that the wide-scale use of metal 3D printing in steel manufacturing can reduce energy consumption in the steel construction sector by up to 30%. That’s the goal of the recently launched, Resource-Efficient Steel Construction Using Additive

Developing the turbine for the Rolls-Royce UltraFan, the world’s largest turbofan engine prototype

IMDEA Materials Institute has played an important role in the development of Rolls-Royce’s next-generation UltraFan® engine prototype. Earlier this year, ITP Aero, one of the world’s largest aircraft engine and turbine manufacturers, delivered the first intermediate pressure turbine (IPT) for the

IMDEA Materials collaborates to create intelligent sensor technology for the next generation of aviation

IMDEA Materials Institute is playing a key role in the development of next-generation aircraft sensor technology which will enable real-time monitoring of airframe components in flight. Such smart sensors, designed to be embedded within the parts themselves, are set to provide enormous benefits

Juan de Pablos Gómez on reaching for the stars and space travel of the future

IMDEA Materials Institute researcher Juan de Pablos Gómez can’t pinpoint exactly when his interest in the far reaches of the universe beyond our own small corner of the Milky Way first arose. It´s just something he assumes he was born with. But from his youngest days visiting the Madrid

IMDEA Materials leads €3.5 million project to develop smart 4D biodegradable implants

The Madrid Institute for Advanced Studies in Materials, IMDEA Materials, recently played host to the EIC-funded BIOMET4D project launch. The aim of BIOMET4D (Project No 101047008), which falls under the umbrella of the European Union's Horizon Europe programme, is to develop innovative technology

IMDEA Materials applies innovative methodologies in the automatization of computed tomography

- Researcher Jonathan Espinoza underlines that the automation of X-ray computed tomography (XCT) represents a clear opportunity to reduce costs and save time at both the industrial and research level. - Espinoza holds a scholarship from the Youth Employment Program of the Community of Madrid and

IMDEA Materials Institute seeks a new generation of biodegradable implants to improve clinical results

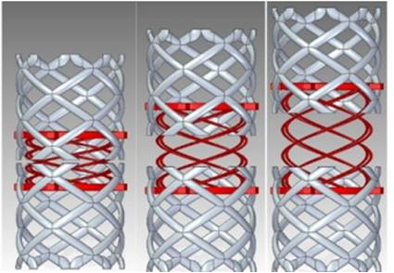

IMDEA Materials researcher Guillermo Domínguez is developing new zinc alloys to manufacture biodegradable cardiovascular stents with better performance than those currently on the market. The ultimate goal of this work is to obtain a zinc alloy to be used in additive manufacturing techniques,

IMDEA Materials researcher Carmen Martínez Alonso has been recognized for her work with a Fulbright grant

Undoubtedly, one of the great hopes in the transition to more sustainable mobility are hydrogen fuel cells. Hydrogen fuel cells generate electrical power through the oxygen reduction reaction process, which combines gaseous hydrogen and oxygen to produce energy with water vapor as the only waste

Year in Review – IMDEA Materials Institute is pleased to launch its 2021 Annual Report

IMDEA Materials is delighted to announce the launch of our 2021 Annual report, available now for download. This annual report is designed to give you an overview of the Institute and main achievements in 2021. You will also find a description of the current Research Programmes, highlighting

“A breath of fresh air”: IMDEA Materials celebrates International Women in Engineering Day

IMDEA Materials Institute has highlighted the importance of the participation of more women in the country's next generation of engineers. June 23 marks the International Day of Women in Engineering, a day with the aim of highlighting the role of female engineers in a sector that, like other

IMDEA Materials to help produce soft magnetic components by 3D-printed, metallic glasses in AM2SoftMag

In this project, IMDEA Materials will collaborate with several European partners to produce soft magnetic components by 3D-printed, metallic glasses. Metallic glasses present excellent mechanical and magnetic properties and, in combination with additive manufacturing, open the door to producing

IMDEA Materials Director José Manuel Torralba is this year’s winner of the Ivor Jenkins Medal

- The Director of IMDEA Materials Institute, professor José Manuel Torralba, is only the second Spaniard to receive the Ivor Jenkins Medal. - The Ivor Jenkins Medal, awarded by the Institute of Materials, Minerals and Mining (IOM3) in the United Kingdom, is the highest international recognition

The future of additive manufacturing on show at IMDEA Materials Institute

IMDEA Materials Institute has played host to some of the country's leading research centres and industrial partners at a technical conference on additive manufacturing. The morning session of the conference, which was organized by MATERPLAT and the Network of Excellence in Additive Manufacturing

IMDEA Materials working to reduce maritime plastic pollution on World Ocean Day 2022

IMDEA Materials can play a crucial role in reducing plastic pollution on land and in our oceans through the development of new bio-based materials to replace existing petroleum-based plastics. June 8 marks World Ocean Day and increased awareness of the millions of tonnes of plastic products and

Materials science at “the tip of the spear” in confronting environmental challenges

IMDEA Materials is celebrating World Environment Day 2022 with a focus on the institute’s key role in improving industrial sustainability and reducing carbon emissions. Advances in the technology of lithium-ion battery production, the development of lightweight alloys and superalloys, the reuse

IMDEA Materials Institute hosts first-ever research and innovation forum

The Madrid Institute of Advanced Research in Materials Science has today played host to the first-ever forum dedicated to the exchange of best practice in research and innovation between all of Spain´s 17 autonomous communities. In total, around 30 representatives from regional Ministries of Science

Being a Marie Skłodowska-Curie postdoctoral fellow at IMDEA Materials

Are you interested in applying for a Marie Skłodowska-Curie Postdoctoral Fellowship (MSCA PF)? Want to know what it's like to be an MSCA PF fellow in our Institute? Join us in this webinar on June 1st at 12:00 hours (Madrid time) and learn more about the hosting offers we have for call 2022 of

Hosting offers for the Marie Skłodowska-Curie Actions Postdoctoral Fellowships 2022

We are looking for postdoctoral researchers interested in applying for a Marie Skłodowska-Curie Actions (MSCA) Postdoctoral Fellowship (PF) in call 2022. Our Institute has a long track record of hosting MSCA fellows and has obtained excellent success rates in recent calls of the MSCA PF. The

Scientific Highlight – 3D tissue models for studying and treating disease

3D tissue models can be used in vitro (in the lab) for the study of diseases and the testing of novel drugs, including their incorporation into microfluidic devices to form the so-called “organ-on-chip” systems. 3D tissue models can also be used in vivo (i.e. implanted in the body) to directly

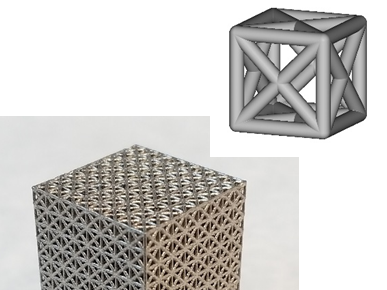

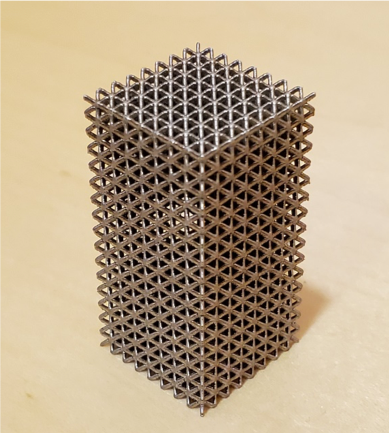

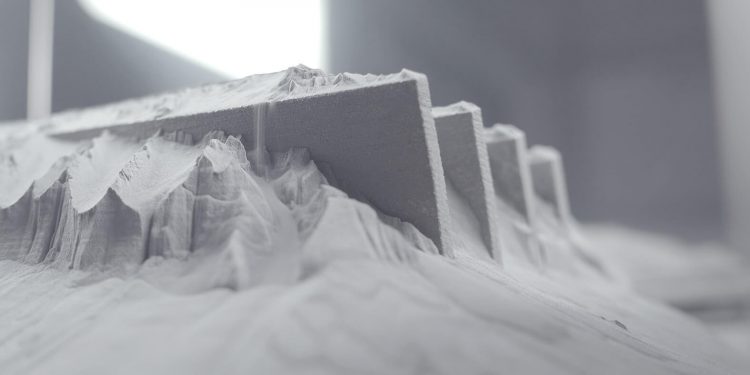

Developing multi-scale simulation methods to optimize 3D-printed lattice structures

Our researchers keep developing multi-scale simulation methods to optimize 3D-printed “lattice” structures under the MOAMMM project. Their predictions were recently checked in an egg drop challenge, as highlighted in this article by 3Printr.com magazine.

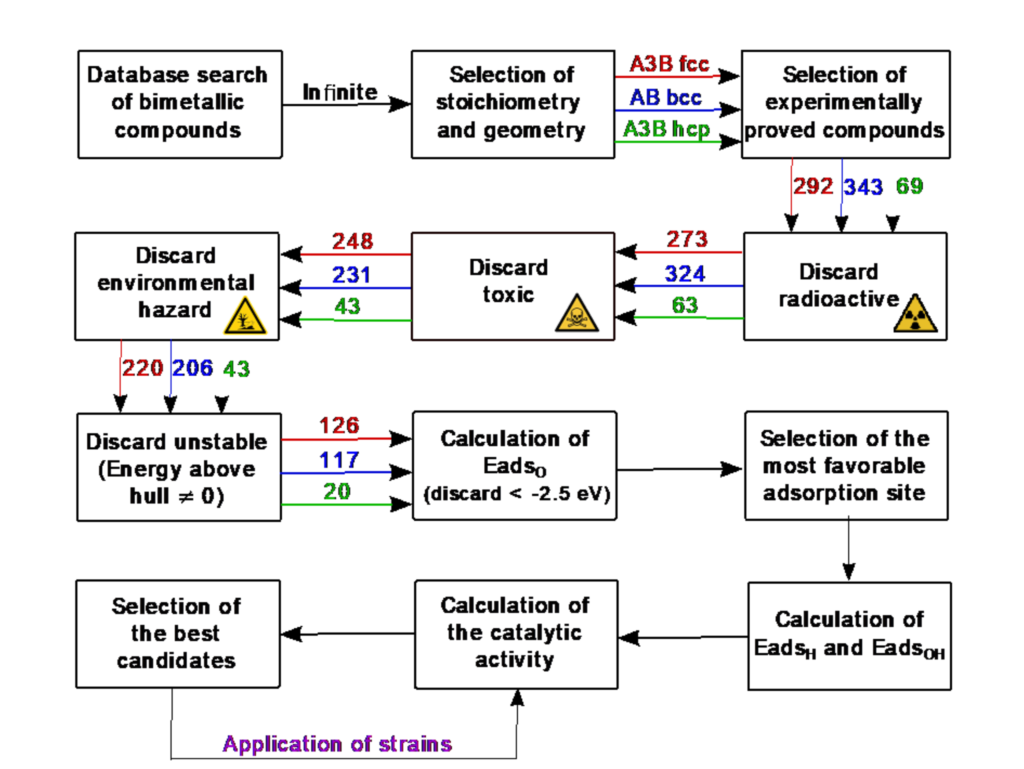

Scientific Highlight: New catalysts for the hydrogen economy using machine learning and ESE

The “hydrogen economy” is currently hindered by the low rate and efficiency of hydrogen production from water and energy generation by hydrogen oxidation into water. The former process is controlled by the Hydrogen Evolution Reaction (HER), the cathodic reaction during the electrochemical process

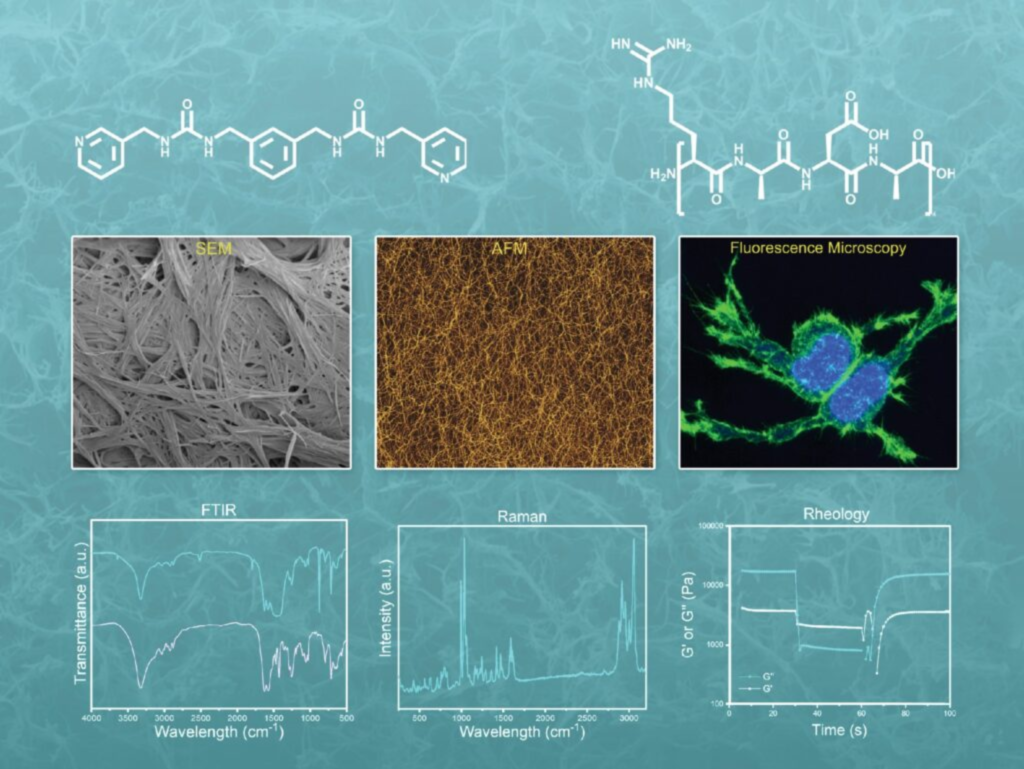

Scientific Highlight: Novel supramolecular hydrogels for biomedical applications

Hydrogels can be formed from polymers or from small molecules, from either natural or synthetic sources. Further, they can be classified by the types of bonds that form the hydrogel network – either covalent or non-covalent. Supramolecular hydrogels, particularly those formed from the

IMDEA Materials Institute researcher Carmen Martínez-Alonso receives a Fulbright scholarship

Our colleague Carmen Martínez-Alonso, member of the Bio/Chemo/Mechanics of Materials group, has obtained a Fulbright predoctoral scholarship to spend six months at the Center for Interface Science and Catalysis (SUNCAT), SLAC National Accelerator Laboratory, Stanford University. She will work

IMDEA Materials celebrates the second meeting of its Industrial Advisory Board at Airbus

On the 22nd of March, the IMDEA Materials Institute held the second meeting of its Industrial Advisory Board (IAB) at the facilities of Airbus in Illescas (Toledo). The activities related to this meeting began the previous day with the talk that Stéphane Cotte, Technical

Success in call 2021 of the Marie Skłodowska-Curie Postdoctoral Fellowships

Two Marie Skłodowska-Curie Postdoctoral Fellowship have been awarded to our Institute in call 2021, and 2 more are high on the reserve list. We submitted 11 proposals, and they received marks in the range of 97 – 59 out of 100. Almost all are above the threshold. Despite the fierce competition, our

Juan José Vilatela awarded a Consolidator grant from the European Research Council

UNIYARNS will be the second European Research Council (ERC) grant awarded to Juan José Vilatela, who in 2016 was awarded a Starting Grant entitled STEM to study structural energy harvesting composite materials. After a successful project that led to many high-impact publications, patents and in

IMDEA Materials Institute participates in the “XI Madrid is Science Fair” at IFEMA

IMDEA Materials participated at the 'XI Madrid is Science Fair' at IFEMA, together with the other IMDEA Institutes from the 2nd to the 5th of March . Great success in participation! It was organized by the Fundación para el Conocimiento Madrimasd and promoted by the Madrid Regional

How time flies when you’re having fun: 15th anniversary of the IMDEA Institutes!

The Madrid Regional Government celebrated the fifteenth anniversary of the creation of the Madrid Institutes for Advanced Studies (IMDEA) on 25 February at the Real Casa de Correos. The event was attended by the directors, researchers and staff of the IMDEA Institutes and by the Director General of

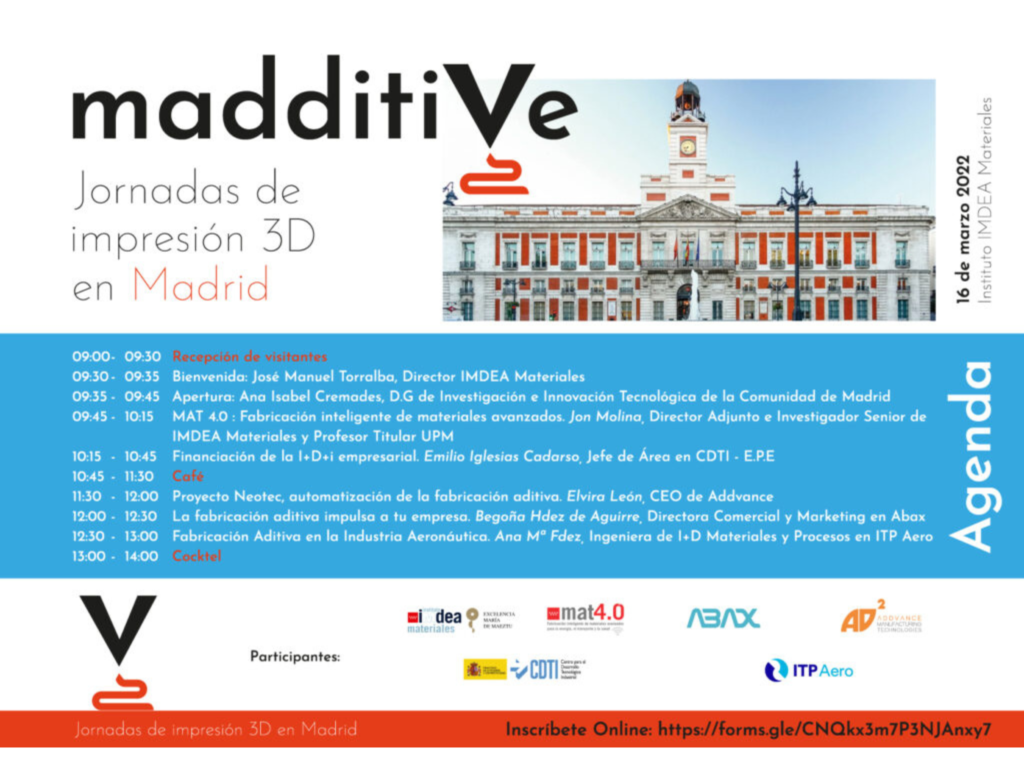

IMDEA Materials Institute to host first “3D printing session in Madrid” in March

The next 16th of March, IMDEA Materials will host the first "3D printing session in Madrid". The event will showcase developments done by IMDEA Materials in the project MAT4.0, funded by the regional government, CDTI funding opportunities for companies, the success case of the company Addvance

Int. Day of Women and Girls in Science 2022: “Being a woman in science”, by Mónica Echeverry

If a day is commemorated, it is because something special has happened or will happen. Since 2016, the 11th of February has a different nuance. Each year brings a louder voice that reminds us that science is one, universal and does not discriminate against race, age, condition and much less

IMDEA Materials Instite is proud to launch its first “Gender Equality Plan” to foster workplace opportunity

Equal opportunities for men and women are one of our core principles, together with fostering a tolerant, diverse and creative working environment for all. Take a look at our recently released gender equality plan!

iMPLANTS-CM seeks to develop smart implants for minimally invasive surgeries

We just kicked off the iMPLANTS-CM project (Printing metamaterials using shape memory alloys and functional gradients for a new generation of smart implants) in collaboration with the Technical University of Madrid. The project aims to design and manufacture active implants capable of modifying

IMDEA Materials Alumni Ismael Gómez, extraordinary doctoral award 2020 – 2021 by UC3M

Our alumni Ismael Gómez has received the extraordinary doctoral award of the course 2020-2021 academic year from the Carlos III University of Madrid for his work entitled "Automated discovery of porous molecular materials facilitated by characterization of molecular

Four Ph.D. positions on offer in call 2022 of the INPhINIT fellowships programme

We offer 4 PhD positions within Fundación "la Caixa" INPhINIT fellowships programme 2022 on the following topics: More info about the projects here. Apply no later than January 27th 2022 via this link!

Mónica Echeverry Rendón, winner of the Ada Byron award for women in technology, Colombia chapter.

Our colleague Monica Echeverry Rendon has won the Ada Byron award for women in technology, Colombia chapter, CONGRATULATIONS! The Ada Byron Award for Women in Technology is an award promoted by the University of Deusto that is awarded annually to women technologists to reward and make visible

Carmen Martínez Alonso and José Manuel Guevara-Vela winners of most popular poster

The poster entitled “The effect of mechanical strains on the catalytic activity of transition metals for the hydrogen evolution and the oxygen reduction reactions”, by our colleagues Carmen Martínez Alonso and José Manuel Guevara-Vela, awarded as the most popular in the 2021 Society of Engineering

Two projects awarded to IMDEA Materials in the last cut-off of the EIC Pathfinder Open

We have been awarded two projects in the last cut-off of the EIC pathfinder open to work on the following breakthrough technologies! That’s a phenomenal 50% success rate! Congrats to our Principal Investigators, María Teresa Pérez and Jennifer Patterson!

IMDEA Materials Institute holds first meeting of its Industrial Advisory Board

On the 3rd of November, the IMDEA Materials Institute held the first meeting of its Industrial Advisory Board (IAB) at its premises. This meeting served as a touch base for the initiative, allowing the IAB members to know some of the latest research and technological developments made at the

IMDEA Materials creates first spin-off to manufacture revolutionary battery electrodes for electric vehicles.

With the centre’s support, researchers from our group on Multifunctional Nanocomposites have launched a company to produce silicon electrodes for batteries for electric vehicles and portable electronic devices. It all started more than three years ago when the group, led by Juan José Vilatela,

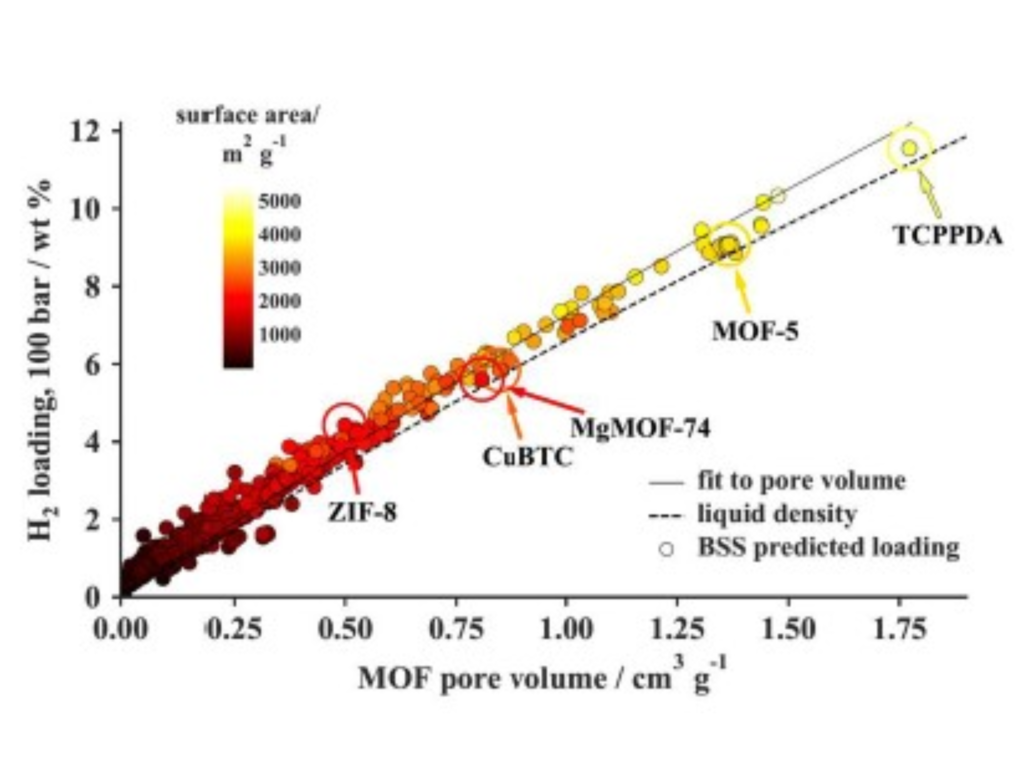

Scientific Highlight: Computational discovery of hydrogen storage materials

IMDEA Materials has know-how and experience in developing computational high-throughput screening workflows for discovery of hydrogen storage materials. Our focus has been mostly directed towards advanced porous materials such as metal organic frameworks and related materials (Fig. 1). Our

CNSTech project to develop the next generation powder metallurgy based CoNi superalloys gets underway

The project CNSTech (Development of gamma prime strengthened CoNi based superalloy for advanced sustainable manufacturing technologies) starts 1st of October 2021 and it will last 24 months. The aim of this project is to development of the next generation Powder Metallurgy (PM) based CoNi

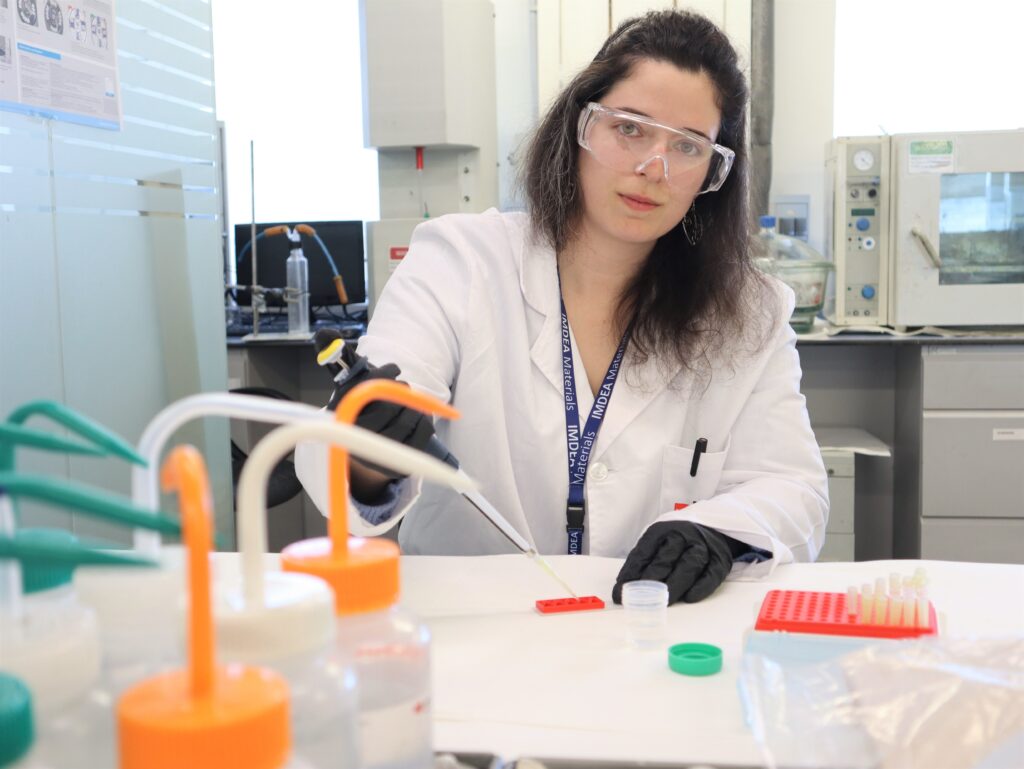

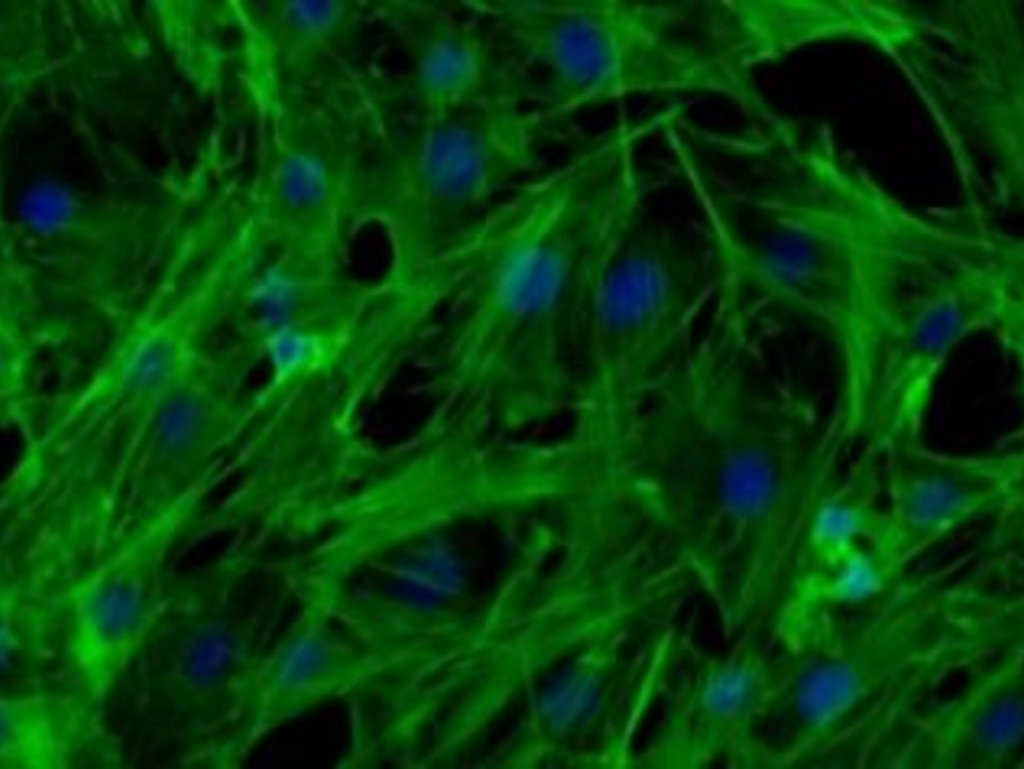

IMDEA Materials sets up cell culture and biomaterials lab to research innovative materials for health care

We have set up a cell culture and biomaterials lab to research innovative materials for health care, thanks to Madrid regional Goverment and the state research agency (AEI). This space will allow us to analyse the response of living tissue to new tools, prostheses or devices for medical use, that

IMDEA Materials celebrates the kick-off meeting of its Industrial Advisory Board

Last June 14th, IMDEA Materials held through videoconference the kick-off meeting of its newly formed Industrial Advisory Board (IAB). The goal of this strategic initiative is to bring together a selected group of R&D industrial leaders, experts in technology transfer and entrepreneurship, in

IMDEA Materials Director, José Manuél Torralba, awarded with the FEMS Gold Medal 2021

Our Director, José Manuel Torralba, has been awarded the European Materials Gold Medal 2021 by the Federation of European Materials Societies (FEMS). The European Materials Medal (Gold Medal), established in 1993, is the most prestigious award of the FEMS and is awarded in recognition of outstanding

Scientific Highlight: Nanostructured fabrics to host new nanomaterials for advanced electrodes

IMDEA Materials has developed a method to produce highly conducting nanostructured fabrics for use as current collectors or scaffold for active materials in composite electrodes for energy storage and conversion. Integration of these fabrics reduces electrode weight, improves cyclability/durability

IMDEA Materials and 3D printing of metamaterials for structural applications

Additive manufacturing, or 3D metal printing, allows to build ultralight and resistant structures with geometries that are impossible to achieve using conventional machining and processing techniques, including complex structures named “lattice”. These are three-dimensional constructions,

Flexible batteries for integration in car interior roof, boot and flooring components

Grupo Antolín, a worldwide supplier of technological solutions for car interiors, works with IMDEA Materials and IMDEA Energy Institutes in the development of flexible Lithium-ion batteries that can be integrated in interior components of vehicles. The objective is to develop Lithium-ion batteries

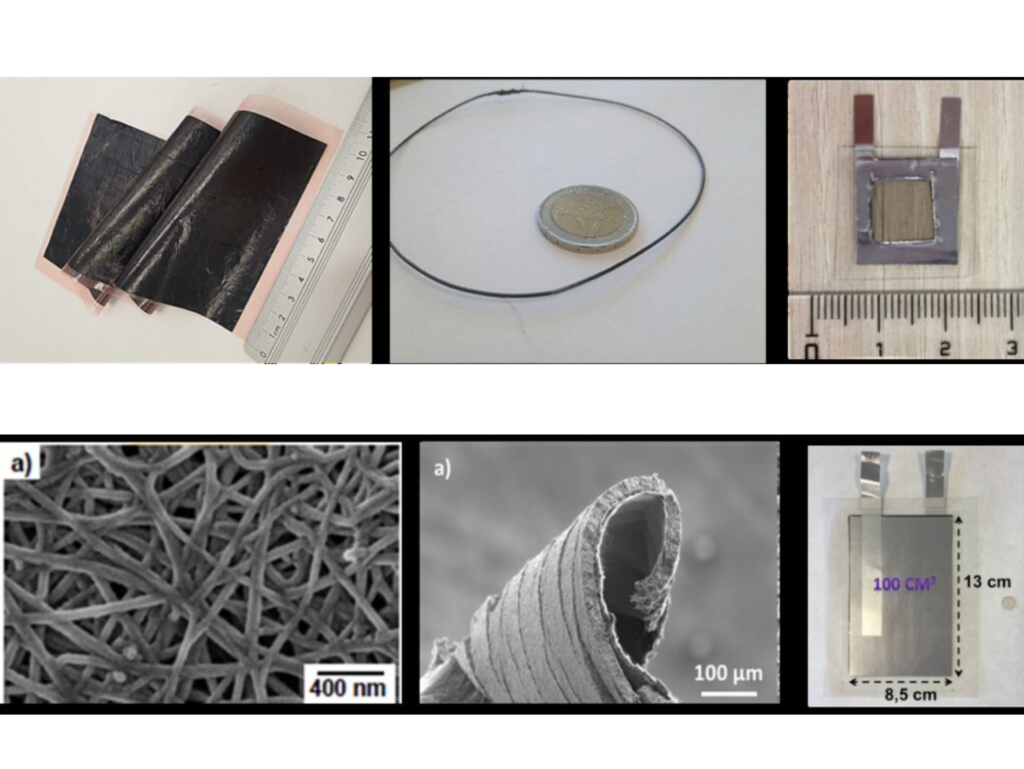

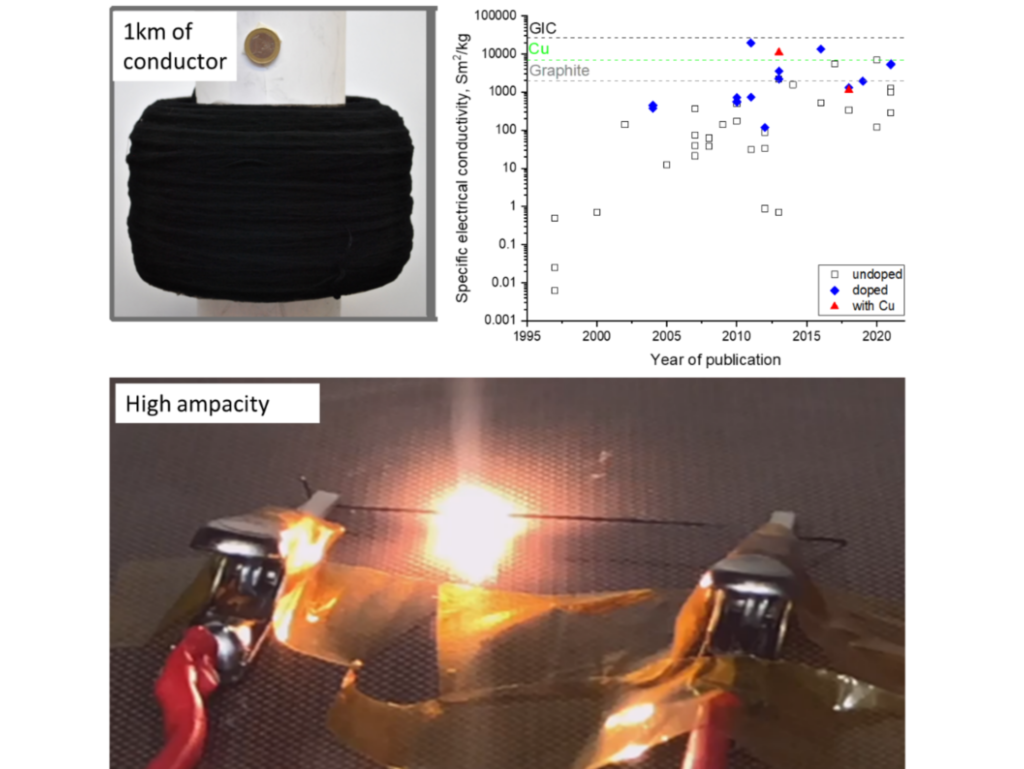

Scientific Highlight: Producing highly conductive nanostructured fibres for use as lightweight conductors

IMDEA Materials has developed a method to produce highly conducting nanostructured fibres for use as lightweight conductors (see Fig. 1). On a mass basis, these conductors have superior electrical/thermal conductivity and higher ampacity (maximum current density) than most metals. Their

Scientific Highlight: Nanostructured Silicon anodes for Lithium-ion batteries

IMDEA Materials has a proprietary method to produce continuous sheets of nanostructured Silicon [1] (see Fig. 1) and their integration as high capacity anodes in Lithium-ion batteries without use of processing solvents or polymers. The electrodes combine high capacity (> 6 mAh/cm2), high

Prof. José Manuel Torralba appointed new Director of IMDEA Materials Institute

On the 27th of April, after an international open selection process was concluded, Prof. Jose Manuel Torralba was appointed Director of IMDEA Materials Institute by the Board of Trustees. Prof. Torralba takes over from Prof. Ignacio Romero, who has been leading the Institute during the last four

Hosting offers for Marie Skłodowska-Curie Actions Postdoctoral Fellowships 2021

We are looking for post-doctoral researchers willing to apply for Marie Skłodowska-Curie Actions (MSCA) Postdoctoral Fellowships (PF), call 2021. Our Institute has a long track record of hosting MSCA fellows and has obtained outstanding success rates in recent calls of MSCA PF. The following

IMDEA Materials organises joint conference with the Korea Institute of Science and Technology (KIST)

The joint conference, organised for May 25 with the Korea Institute of Science and Technology, will serve to explore collaboration opportunities in the field of composite materials and strengthen bonds between the two institutes.

IMDEA Materials researchers in the “Ranking of the World´s Top 2% Scientists”

The University of Standford just published its "Ranking of the World Scientists: World´s Top 2% Scientists". The ranking, which analyses data from Scopus like the number of articles published, the career-long citation impact up until the end of 2019 and the citation impact during the single calendar

Scientific Highlight: Advanced lightweight materials for fire safety and energy efficient structures

Sandwich-structured composites are the most reliable and effective technology for weight reduction of interior panels in the transportation industry. However, the properties and manufacturing processes of sandwich composites are limited by the characteristics and mechanical properties of the

Scientific Highlight: Fire retardant reprocessable epoxy-based composites

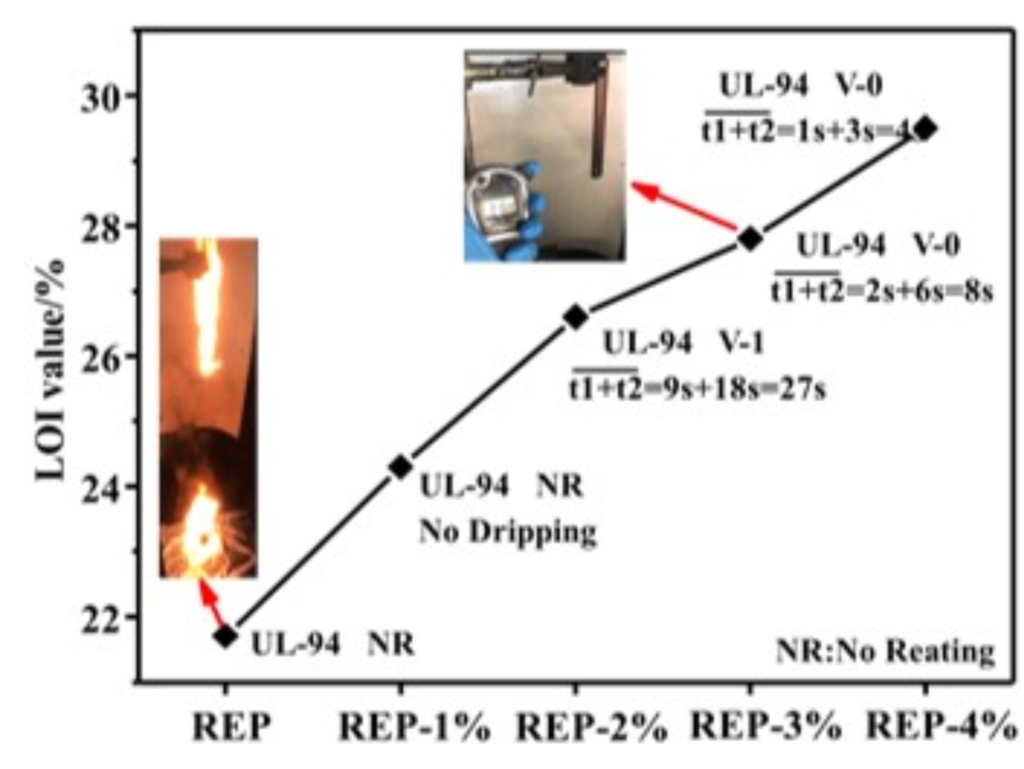

IMDEA Materials has developed a technology to produce Reprocessable Epoxy Resin (REP) composites with excellent fire retardancy and re-processability. Compared with pure epoxy resin with a Limited Oxygen Index (LOI) of 21.7 % and no rating in vertical burning test (UL-94), recyclable epoxy resin

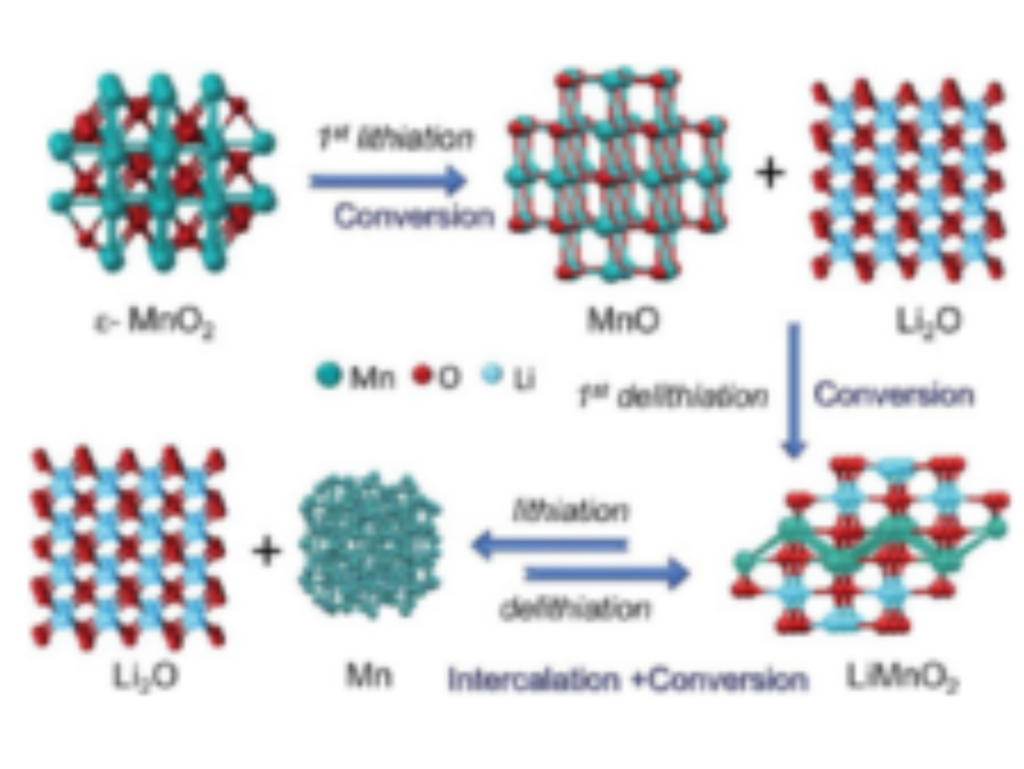

Scientific Highlight: Defect-engineered electrodes for long-range electric vehicles

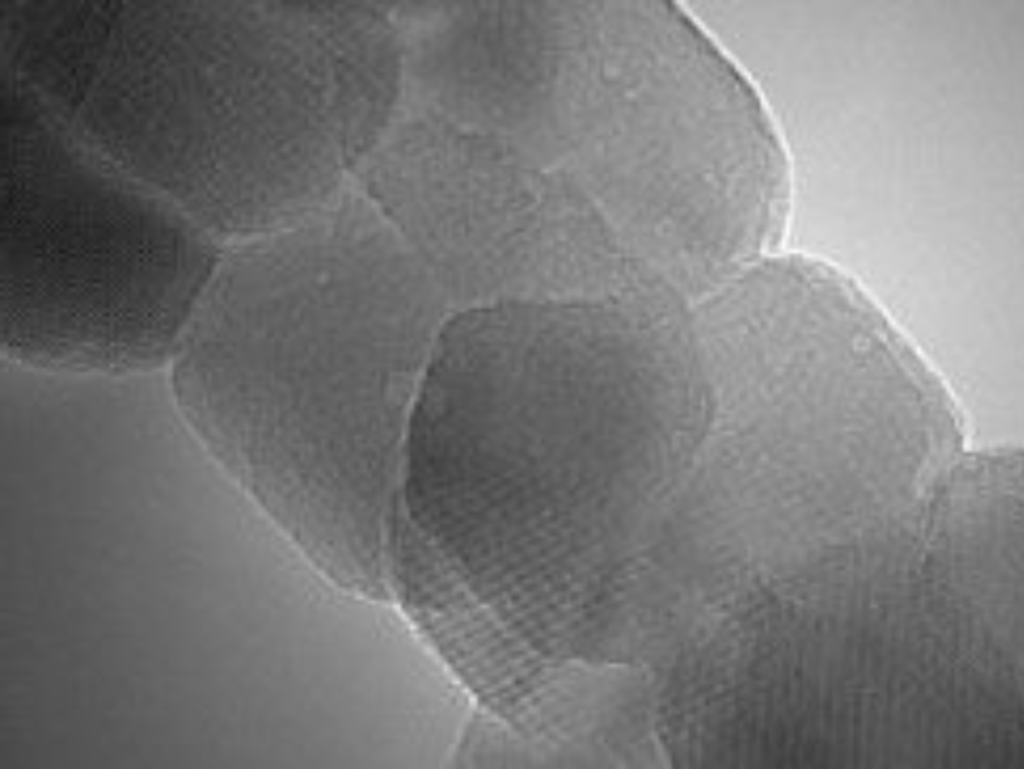

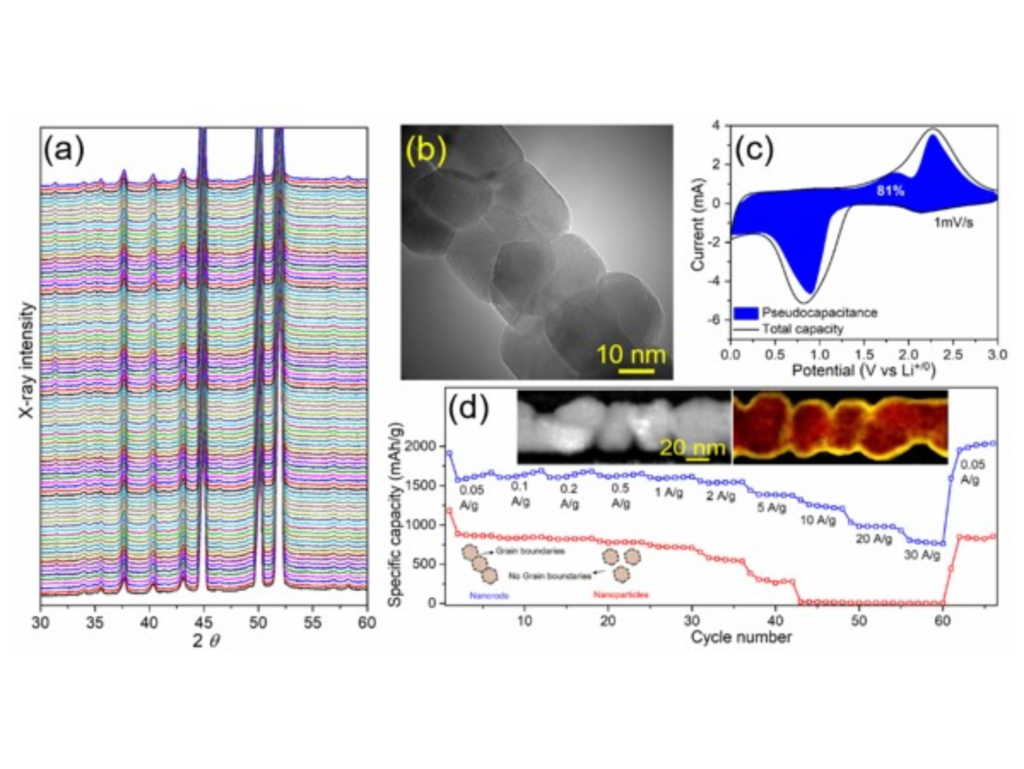

Although secondary Li-ion batteries are widely used for electrochemical energy storage, low energy (100-300 Wh kg-1) and power density (250-400 W kg-1) are limiting their applications in several areas including long-range electric vehicles. This is mainly due to the use of graphite anodes with

Scientific Highlight: In-situ studies of defect-engineered electrodes

Diffusion independent pseudocapacitive ion storage is one of the recently investigated mechanisms for achieving ultrafast Li and Na-ion storage. It usually involves surface/ near surface charge-transfer reactions. Nevertheless, intrinsic pseudocapacitance of transition metal oxide anodes is not

Scientific Highlight: New 3D-printed alloys for extreme conditions

IMDEA Materials has recognized expertise on the design of alloys for high temperature, high strength and lightweight applications, which are suitable for the production of 3D printed components by laser-based or binder-jetting methods. Previous works include the design of superalloys for turbine

Six research teams, including IMDEA Materials’ MNG group, win Carbon Hub funding

Carbon Hub, Rice University's zero-emissions research initiative, has awarded seed grants for six projects that will rapidly advance its vision for transforming the oil and gas sector into a leading provider of both clean hydrogen energy and solid carbon products that can be used in place of

Scientific Highlight: Accelerated product development via AI-guided material design and chemical processes optimization

IMDEA Materials has know-how in developing data-driven experimentation workflows that exploit machine learning algorithms to minimize the number of experiments involved in the development of materials tuned to specific applications and/or the chemical processes governing their synthesis and

Listen what women in science do to improve our lives

Our colleague María Teresa Pérez Prado and other women in science explain what they do to improve our lives in this interview recorded by cadena SER at IMDEA Energy as part of the International Women's Day 2021.

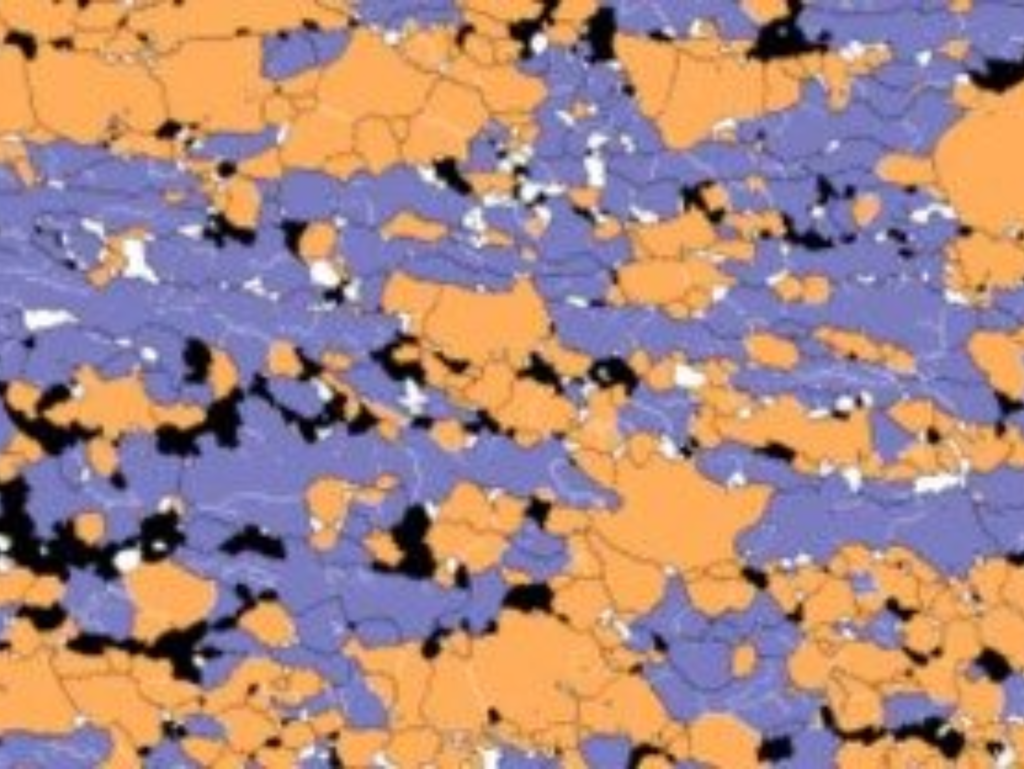

Scientific Highlight: Virtual testing of metals

IMDEA Materials offers a mature, fully stand-alone technology able to predict the mechanical response of an engineering alloy as function of its microstructure [1]. This technology is able to provide the anisotropic elastic properties and stress-strain elastoplastic curves, the creep response

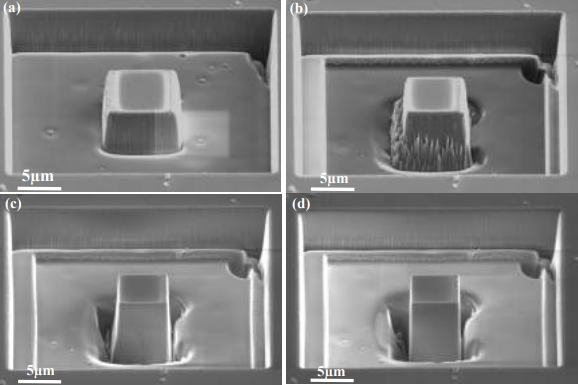

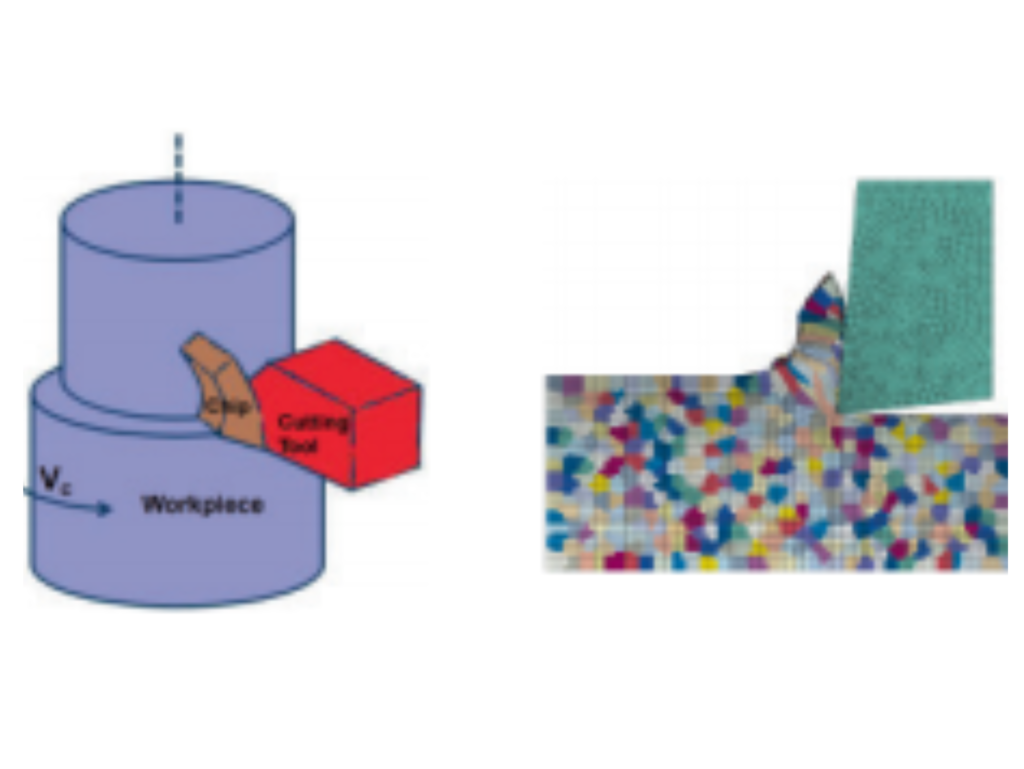

Scientific Highlight: New coatings for extreme conditions

Titanium aluminum nitrides (TiAlN) are currently the most versatile coatings in terms of performance with various applications in industry: as wear-resistant coatings for cutting tools; for increasing productivity in die casting, reducing soldering and retarding fire cracks; for plastic processing,

Scientific Highlight: Multiscale in-situ characterization of materials and processes

Current trends to reduce weight, energy consumption and improve functionality are leading to new materials with complex microstructures, whose behavior can only be understood from the synergetic contribution of processes occurring at multiple length scales (from nm to m). Examples of these

Scientific Highlight: Bioresorbable scaffolds for tissue engineering

IMDEA Materials has developed technologies to manufacture scaffolds made of biodegradable polymers (PCL, PLA, PLGA, etc), biodegradable metals (Mg and Zn) and their composites for tissue engineering (see Fig. 1 below). The main advantage of this technology is that it allows designing scaffolds with

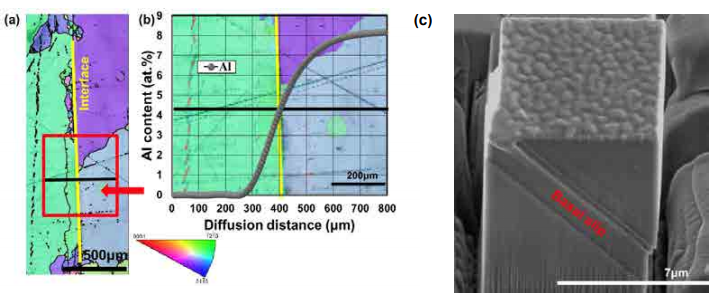

Scientific Highlight: Physical simulation of joining of dissimilar materials

IMDEA Materials has developed a physical simulation tool to predict joinability of dissimilar metallic materials with different melting points. Very small samples of the actual dissimilar materials are subjected to the same thermal and mechanical profiles in a thermo-mechanical simulator (GLEEBLE

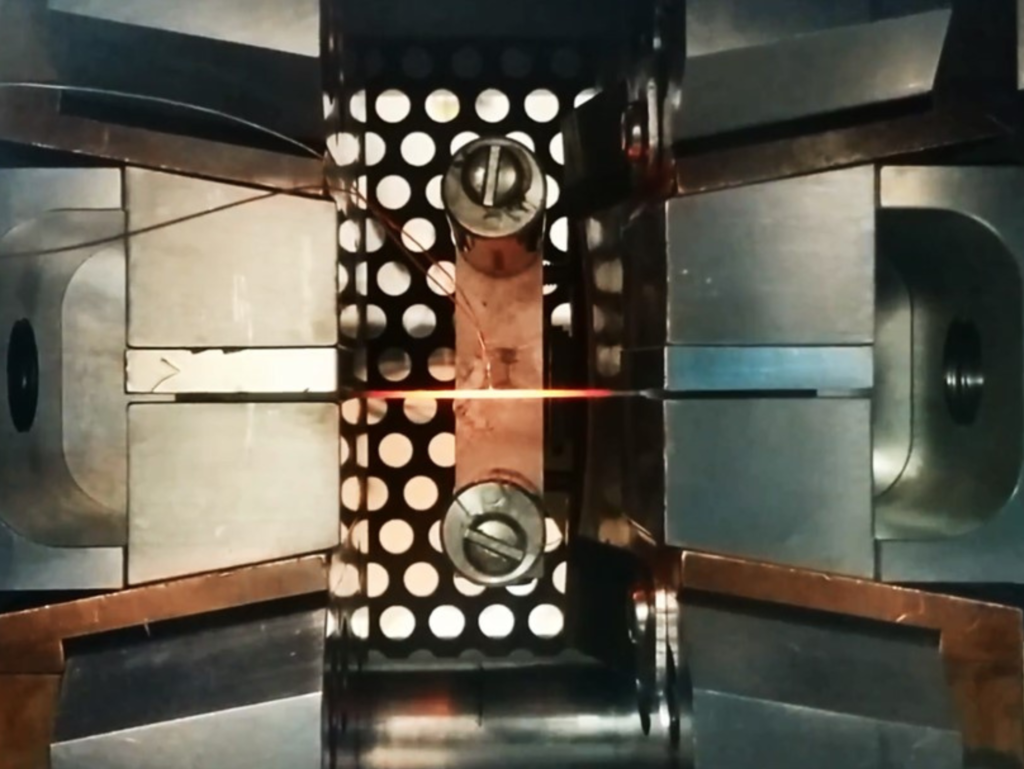

Scientific Highlight: Ultrafast processing of advanced metallic materials

IMDEA Materials has developed technologies for ultrafast processing of advanced metallic materials in a thermo-mechanical simulator (GLEEBLE 3800). They allow to precisely control the thermo-mechanical processing at high heating/cooling rates, as well as at high strain rate plastic deformation.

Scientific Highlight: Modelling and simulation of Hydrogen embrittlement

Europe’s commitment to reach carbon neutrality by 2050 is strongly pushing renewable energy sources and hydrogen has emerged as a versatile and environmentally friendly mean to store and transport clean energy. The large-scale usage of hydrogen has prompted new challenges in the core

Scientific Highlight: Fire retardant battery materials

IMDEA Materials is working on new battery materials that combine electrochemical integrity and enhanced fire safety. Fig. 1 below shows a fully solid-state battery based on a HKUST-1 MOF modified electrolyte with simultaneously improved electrochemical performance and fire safety was

Success in call 2020 of Marie Skłodowska-Curie Actions Individual Fellowships

One Marie Skłodowska-Curie Individual Fellowship has been awarded to our center in call 2020, and 2 more are very high in the reserve list. A total 7 proposals were submitted by our center. They have received marks in the range 98.4 - 79.2 and are all above the threshold. Despite the fierce

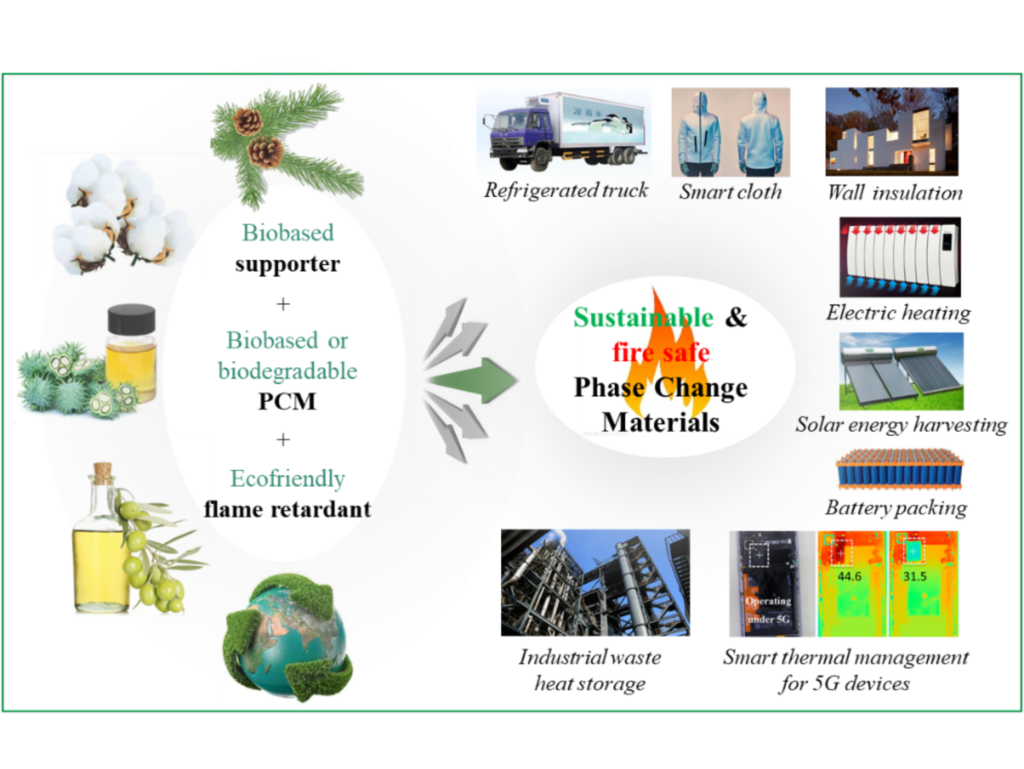

Scientific Highlight: Sustainable, fire safe phase change materials

IMDEA Materials can design and prepare novel Phase Change Materials (PCMs) for thermal energy storage applications that: are prepared in an easy and green pathway and, at the same time, have high mechanical performance, fire safety, form stability, phase transition enthalpy, and thermal

Javier LLorca talks about new materials for bone prosthesis

Javier LLorca talks about new materials for bone prosthesis in the RTVE radio program "El laboratorio de JAL" devoted to science dissemination pills. Follow the link and listen up the first pill to find out more about this hot research topic (content only available in

Scientific Highlight: 3D printing of structural composites by using recycled fibers

Due to the rapid growth in the use of composite materials, environmental concerns have become an increasingly influential topic, making recyclability of composite materials a key issue. Furthermore, several related EU laws have been passed to minimize the environmental impact of composite structures

Scientific Highlight: Predictive simulation of metal Additive Manufacturing – from composition & processing to mechanical properties

As part of its strategic initiative on damage-tolerant additive manufacturing, IMDEA Materials develops a suite of physics-based computational models and simulation tools aimed at linking processing, microstructures and properties, in order to accelerate the discovery and deployment of new alloys

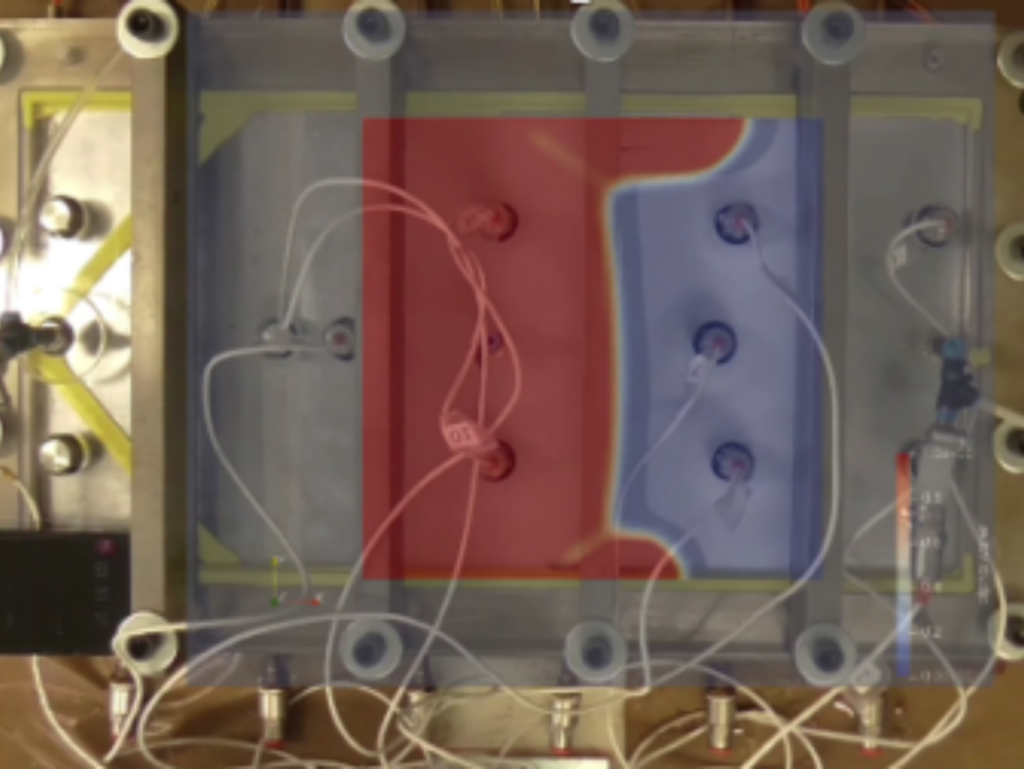

Scientific Highlight: AI-guided smart manufacturing of structural composites

Manufacturing in the EU is crucial, given that it is one of the main drivers in innovation, job creation and sustainable growth. It involves almost 2,000,000 companies that provide approximately 28.5 million jobs. Therefore, its impact is significant in terms of economic share, with it being ~18% of

Javier Llorca talks about bioresorbable 3D printed scaffolds for bone regeneration in RNE

Javier Llorca, head of the Mechanics of Materials group, talks in the program “Marca España” from RNE about bioresorbable 3D printed scaffolds for bone regeneration. You can listen to the interview here (starting at minute 3:50)

Our alumna Jingya Wang obtains the University award to the best doctoral thesis

The doctoral thesis of Jingya Wang, entitled “High throughput investigation of diffusion and solid solution hardening of HCP Mg alloys”, has obtained the Award of the Technical University of Madrid to the best doctoral thesis. The thesis was advised by Prof. J. LLorca and Prof. Y. Cui and it was

ITP Aero and IMDEA Materials develop a pioneer R&D program to simulate 3D manufacturing processes

ITP Aero and IMDEA Materials collaborate in an R&D program named ENVIDIA, whose goal is the development of software capable of simulating the production of aeronautic components by additive manufacturing technologies. The activities in this program began in mid 2018, with the objective of

IMDEA Materials research on biodegradable 3D printed structures for bone regeneration published in National Geographic

A team of Spanish engineers has succeeded in creating a magnesium-based scaffold that makes it possible to reconstruct large bone fragments. The new device, under study, is non-toxic, biodegradable and does not generate rejection. In addition, it allows the regeneration of tissue without

Ten projects “made in Madrid” at the forefront of international research

Madrid is the Spanish region that invests the most in research and development (1.71% of region gross domestic product). Behind these numbers there are thousands of hours devoted to understand the world around us and to find solutions to societal challenges. Since 2006 the IMDEA Institutes have

3.100 R&D projects are carried out annually in Madrid region, generating € 357 million

3.100 research & development projects per year are carried out in Madrid region, which makes it an international reference in research thanks to the work of its fourteen universities, the eight health research institutes, as well as the seven Madrid Institutes for Advanced Studies (IMDEA). More

The results of the ENERYARN MSCA IF on multifunctional CNT fabrics featured by the European Commission

In the MSCA IF ENERYARN project, Dr. Anastasiia Mikhalchan worked on the development of CNT yarn-stretching strategies and new ways of studying energy-storing composite materials. The new methods addressed the alignment problem. Using them, the researchers team demonstrated that fabrics made of

Teresa Pérez-Prado talks about 3D printing in RNE

Teresa Pérez-Prado, head of the Physical Metallurgy group, talks in the program “Gente Despierta” from RNE about the potential of 3D printing. You can listen to the interview here (starting at minute 5:30)

Juan José Vilatela talks about the silicon based electrodes developed in his group in RNE

Juan José Vilatela, leader of the Multifunctional Nanocomposites group and recent recipient of a Proof of Concept Grant of the European Research Council, talks in the program "Marca España" from RNE, about the potential of the silicon based electrodes developed in his group for electromobility

A research group from IMDEA Materials has developed a flexible silicon that will revolutionize electric vehicles

The batteries produced with this new material will make it possible to lighten the vehicles, increase the distance they can travel and reduce charging time. A group of researchers from the IMDEA Materials Institute in Madrid, led by Juan José Vilatela, has developed flexible silicon in sheets, a

ENTENTE project starts

The project ENTENTE (European Database for Multiscale Modelling of Radiation Damage) has started on the 1st of September 2020 and it will last 48 months. The aim of this project is to design a new European experimental/modelling materials database to collect and store highly-relevant data on

Helping industry to speed up the design of composites for impact applications

The current design of composite materials follows a trial and error approach based on an expensive and time consuming testing pyramid that costs industry millions of euros and years of development each time a new composite material is introduced in an aircraft. In this video, you can watch how we

Scientific Highlight: New nanostructured materials for high-rate Li-ion battery anodes

There is an ever-increasing interest in new materials that can extend the current performance of battery electrodes materials in terms of longer cyclability, higher energy density and higher power density. Our research groups have established a route for the fabrication of highperformance anodes for

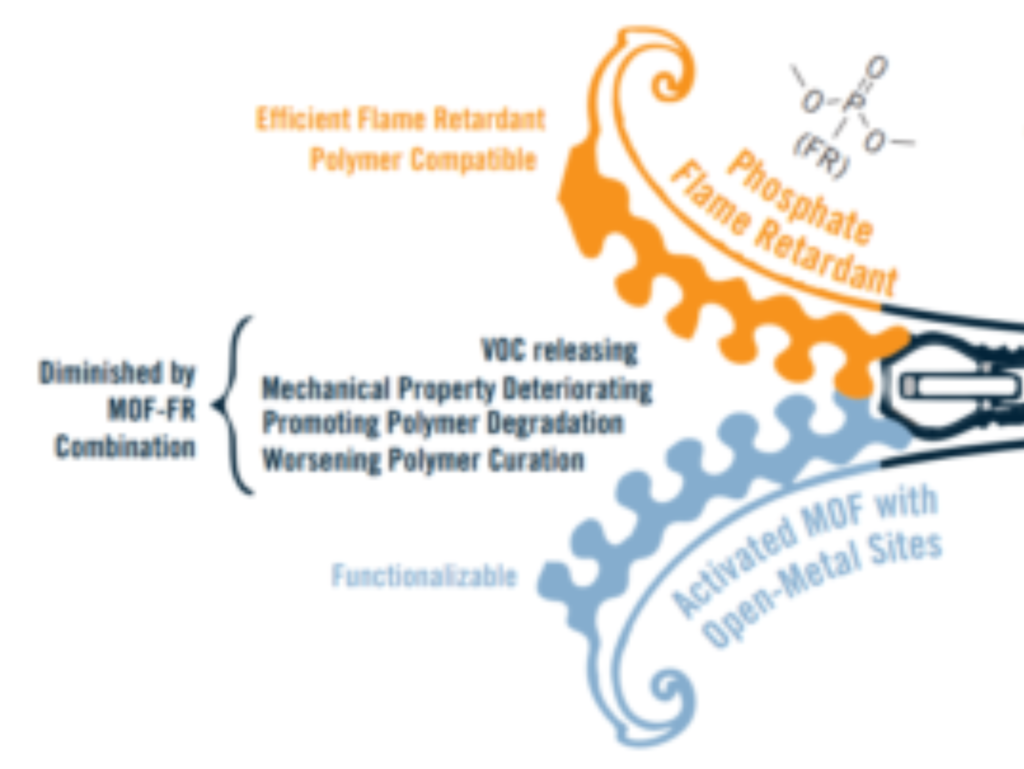

Scientific Highlight: Hierarchical Strategy for Simultaneous Improvement of Mechanical and Fire-Safety Properties of Polymer Composites with Phosphonate-Loaded MOF Additives

Flame retardant (FR) additives are commonly used to improve fire-safety of synthetic polymers, which are widely employed in manufactured consumer goods. The incorporation of a FR in a polymer typically leads to deterioration of its mechanical properties. It also manifests itself in a non-negligible

Scientific Highlight: Dynamic behavior of composites: Coupling tests and simulations

The use of polymer-based composite materials in aircraft structures has increased consistently in the last decades and today they represent up to 50% in weight for wings, fuselage sections and tail surfaces in the latest generation of commercial aircrafts. However, the use of such composites in

Scientific Highlight: Integration of energy storage devices in structural laminates

One of the current scientific and technological trends in structural composites is the incorporation of new functionalities as thermal/electrical conductivity or energy harvesting capacities to classical laminates. However, the inclusion of any internal conductive layer with capacitive storage will

Scientific Highlight: Development of porous Mg scaffolds for bone growth by additive manufacturing

Mg is a biocompatible and biodegradable metal with osteopromotive capabilities that is beginning to be used for bone repair and fixation in biomedical applications. Mg elastic modulus and density are closer to bone than those of other metallic alloys used in biomedical applications (stainless

Scientific Highlight: High throughput strategies applied to the discovery of new alloys

Magnesium has a large potential for more sustainable transport applications due to its low density. However, its poor strength and ductility limits its widespread application. The main fundamental problem arises from the low critical resolved shear stress (CRSS) for basal slip in Mg, which induces

Scientific Highlight: Simulation of multiphysical coupled problems in mechanics of materials

There are situations in which the mechanical response of a material is coupled with relevant physical phenomena occurring in parallel. Some examples are chemomechanical problems in which mechanical fields interact with the evolution of the local composition, as it happens during the deformation

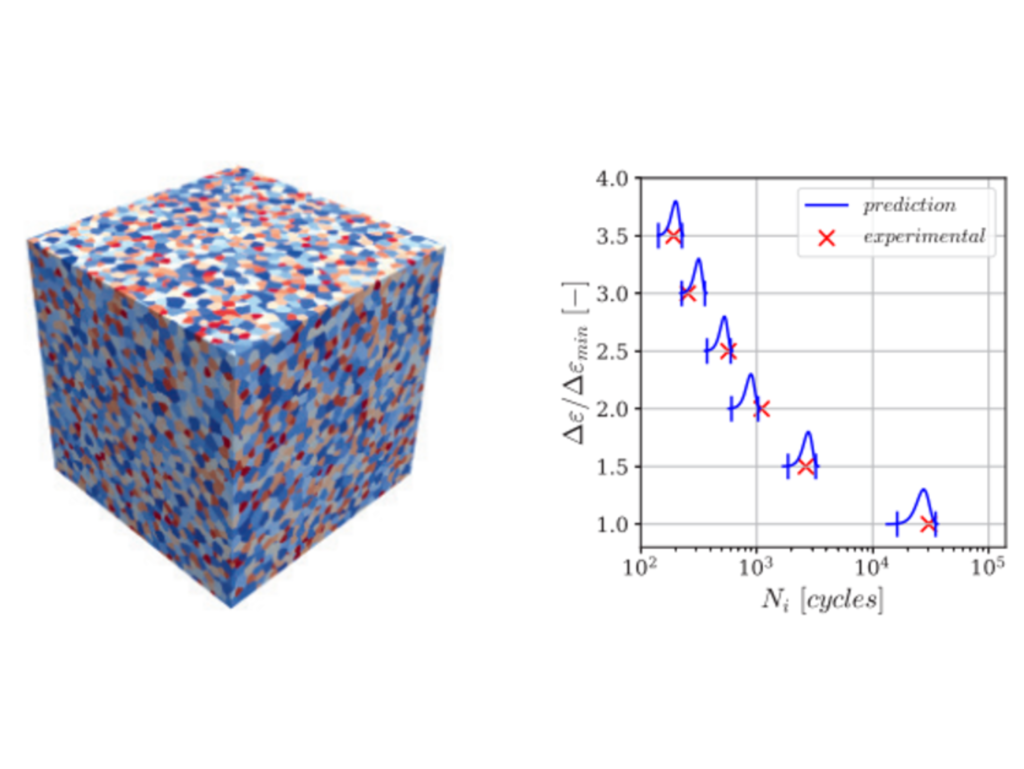

Scientific Highlight: A microstructure and specimen size dependent fatigue modeling approach

The fatigue performance of a metallic alloy is strongly influenced by its microstructure, especially in the crack nucleation regime. Micromechanics based fatigue modeling [1] is the appropriate tool to account for this influence. In this framework, fatigue life is obtained from a fatigue indicator

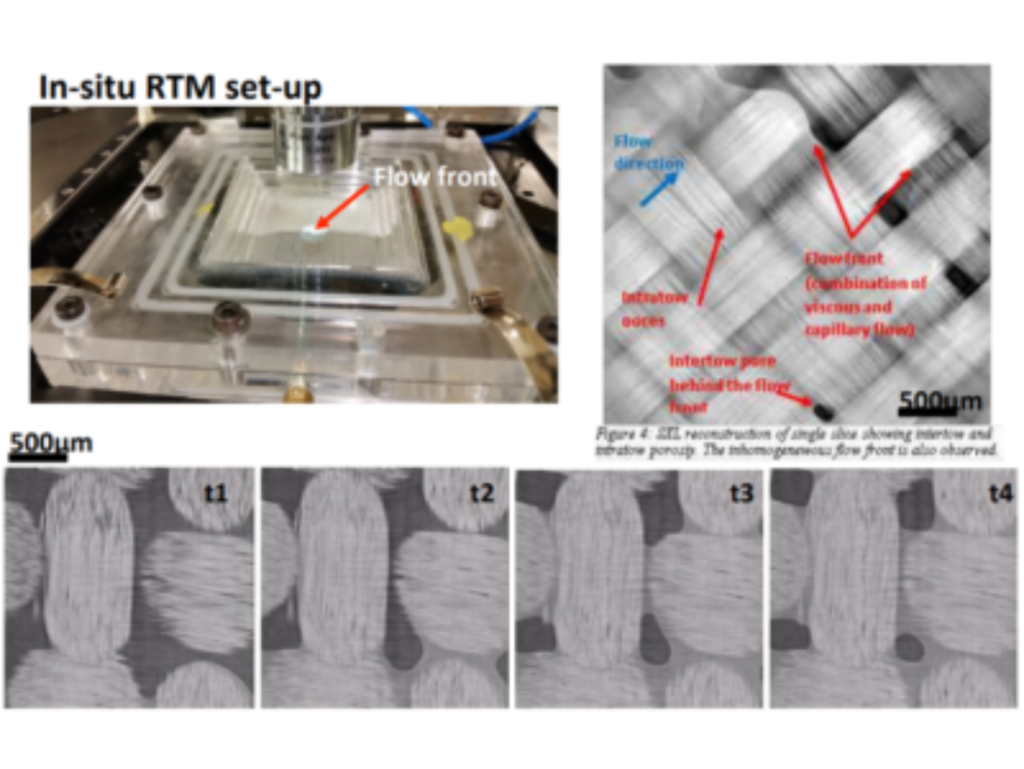

Scientific Highlight – In-situ XCT infiltration of fibers by resin transfer molding process

Fibre-reinforced polymers are extensively used in the automotive, aerospace and energy industries for structural applications. The interest in Liquid Composite Molding (LCM) processes, for the production of composite materials has grown in the last years, especially in the vacuum assisted resin

IMDEA Materials coordinates the new project DELIGHTED

The aim of the DELIGHTED project is to gain fundamental understanding of principles of microstructural design for engineering of perspective austenitic lightweight steels to reach the combination of mechanical and performance properties suitable for applications. To read more about the scientific

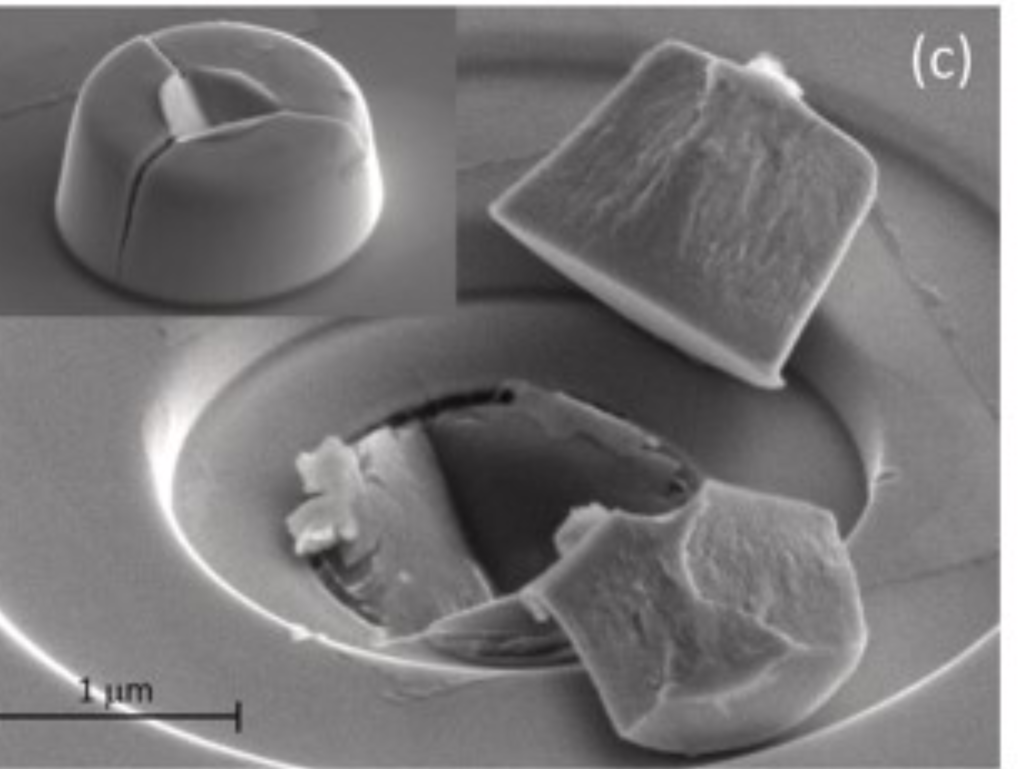

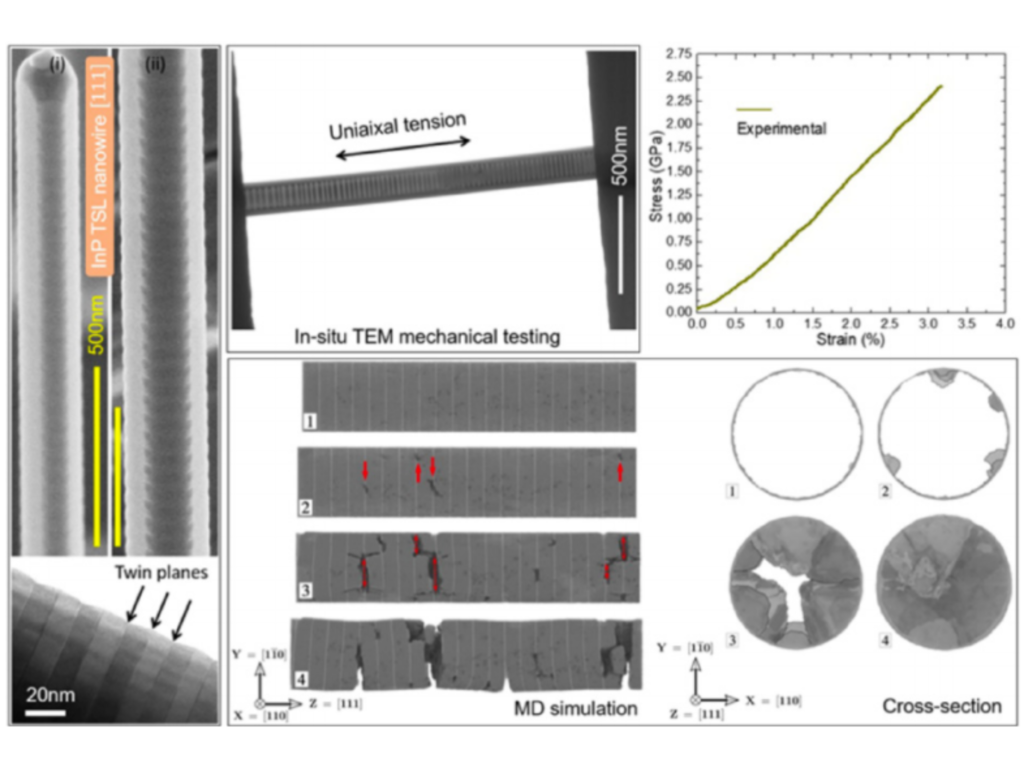

Scientific Highlight: Mechanical behavior of InP twinning superlattice nanowires

It has been shown that InP semiconductor nanowires carry charge and excitons efficiently and also exhibit very high optical efficiency. Their mechanical properties are extremely important, as mechanical strain strongly influences the electric, optical and magnetic properties. However, this

We help ITP Aero producing the IPT casing for the future Rolls-Royce UltraFan engine

We are helping ITP Aero to produce the IPT (Intermediate Pressure Turbine) casing for the future Rolls-Royce UltraFan engine. So far, we have carried out the characterisation of the behaviour of the astroloy at containment and impact. Read more here.

Year in Review – IMDEA Materials is pleased to launch its 2020 Annual Report

We are delighted to announce the launch of the IMDEA Materials 2020 Annual Report, available now for download. This annual report is designed to give you an overview of the Institute and main achievements in 2020. You will also find a description of the current Research Programmes

Teresa Pérez joins the International Advisory Board of the European Space Agency

Our colleague María Teresa Pérez Prado has been appointed as a member of the International Advisory Board of the European Space Agency (ESA). She will support the Agency as part of the Physical Sciences Working Group, particularly concerning their activities on micro-gravity research

We have partnered with e-Xstream to support the industry’s first microstructure modelling for metals

Integrated Computational Materials Engineering (ICME) is set to disrupt manufacturing as we know it. It is an engineering solution that spans across simulation disciplines and goes one step further in helping to tackle the challenges OEMs face in producing the ‘perfect’ part, whether that be time,

Year in Review – IMDEA Materials is pleased to launch its 2019 Annual Report

We are delighted to announce the launch of the IMDEA Materials 2019 report, available now for download. This annual report is designed to give you an overview of the Institute and main achievements in 2019. You will also find a description of the current Research Programmes highlighting R&D