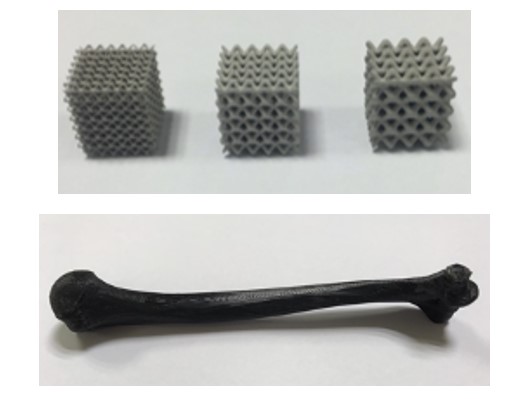

IMDEA Materials has developed technologies to manufacture scaffolds made of biodegradable polymers (PCL, PLA, PLGA, etc), biodegradable metals (Mg and Zn) and their composites for tissue engineering (see Fig. 1 below). The main advantage of this technology is that it allows designing scaffolds with tailored properties (porosity, degradation rate, stiffness and strength) for different applications. For instance, woven self-reinforced PLA scaffolds with graded porosity can be used as scaffolds for skin regeneration while 3D printed porous Mg scaffolds are suitable for bone implants and cardiovascular stents [1]. Scaffolds with tailored properties for other applications can be produced using filament deposition modeling that is able to manufacture multimaterial complex porous structures made up of biodegradable polymers reinforced with either Mg and Zn metallic particles or fibers. As a result, the scaffolds properties can be changed dramatically from one region to another region to suit the actual requirements.

IMDEA Materials expertise also includes the capabilities to simulate the in vitro degradation of the scaffolds by means of multiphysics simulations as well as the determination of the mechanical properties as a function of the degradation time. Moreover, IMDEA Materials also has the expertise to determine the microstructural and topological features of the scaffold by means of advanced microscopy and microtomography as well as the cytocompatibility of the scaffolds..

For more information, reach us at proyectos.materiales@imdea.org

[1] Microstructure, mechanical properties, corrosion resistance and cytocompatibility of WE43 Mg alloy scaffolds fabricated by laser powder bed fusion for biomedical applications.

M. Li, F. Benn, T. Derra, N. Kroeger, M. Zinser, R. Smeets, J. M. Molina-Aldareguía, A. Kopp, J. LLorca

Materials Science and Engineering C, 119, 111623, 2021.

DOI: https://doi.org/10.1016/j.msec.2020.111623