IMDEA Materials researchers are working on developing a new composite solid-state electrolyte (CSSE) with flame-retardant properties for lithium-ion batteries.

The research aims to address one of the key concerns facing the current generation of lithium-ion energy storage devices, their reliance on liquid electrolyte systems.

Liquid electrolytes offer excellent ionic conductivity, a key requirement for fast charging and long-lasting batteries. However, they are highly flammable and will trigger thermal runaway, fire, and even explosion under conditions of mechanical, electrical and/or thermal abuse.

Thermal runaway is one of the primary risks related to lithium-ion batteries. It is a phenomenon in which the lithium-ion cell enters an uncontrollable, self-heating state.

“While lithium-ion batteries exhibit excellent electrochemical performance, safety issues can become quite serious in certain cases,” IMDEA Materials researcher Mingyang Zhang said.

“My current research focuses on developing a novel CSSE with excellent electrochemical and mechanical properties, and with significantly improved fire safety performance to replace conventional liquid electrolytes.”

“This is building on previous work from IMDEA researchers who have already succeeded in introducing Metal-Organic Framework (MOF) particles, which were developed here at the Institute, into the CSSE, which further improves fire safety.

“As far as I am aware, this is the first work to simultaneously introduce ceramic and MOF particles into CSSEs, which provides a promising direction for advancing the development of high-performance CSSEs.”

The electrolyte within lithium-ion batteries serves to transport lithium ions between the positive and negative electrodes.

The principal drawback of solid-state electrolytes has typically been that they offer poor ionic conductivity at room temperature compared to their liquid counterparts. This is because the solid film presents a greater level of resistance to the movement of lithium ions inside the battery.

In order to overcome this deficiency, Zhang’s work proposes the development of a CSSE that combines a flexible polyethylene oxide polymer matrix with highly conductive ceramic particles.

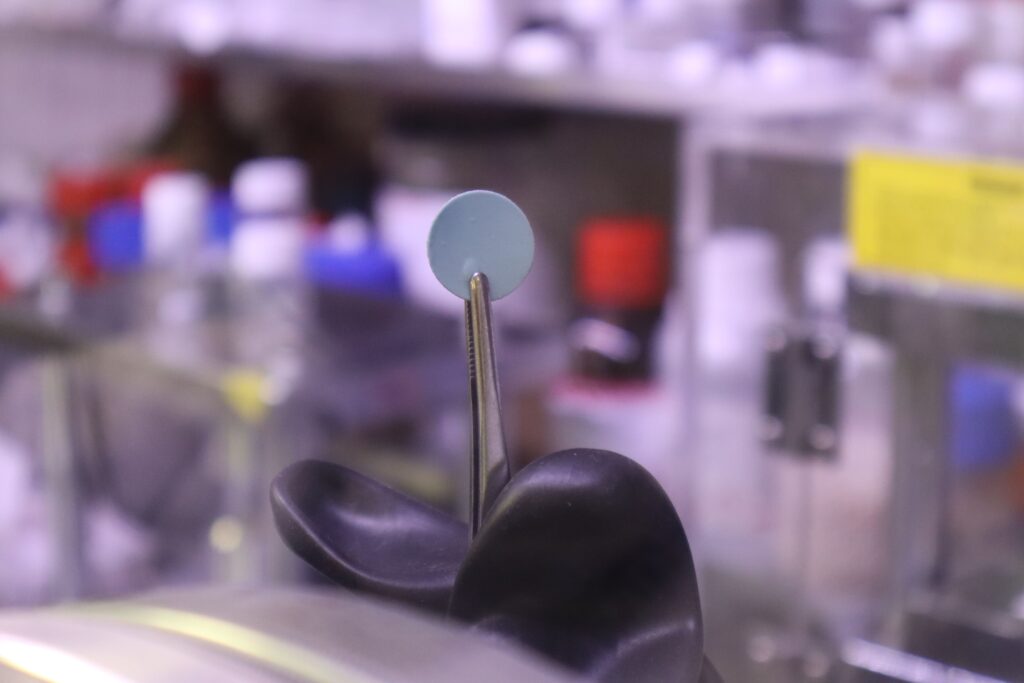

The polymer matrix offers the required flexibility to create films of the required thinness of 0.1mm, while the ceramic particles facilitate the flow of lithium ions, thus ensuring a suitable level of conductivity.

Finding the perfect balance, however, is far from simple. Adding too high a percentage of ceramic particles increases surface asperity which obstructs contact between electrolyte films with the electrode.

The research is being carried out as part of IMDEA Materials’ High Performance Polymer Nanocomposites group directed by Prof. Dr. De-Yi Wang.

The research group has developed a number of projects designed to improve the thermal stability of LIBs in recent years.

These include specific fire safety assessment methods for liquid electrolytes, polymer separators and gel polymer electrolytes with flame retardant properties, and exploring the application of flame retardants.

IMDEA Materials has a long history in developing cutting-edge battery technology, including work on nanostructured silicon anodes and magnesium batteries among other projects.

The technology related to CSSEs is not yet mature enough to be commercialized, as it still has to solve challenges related to the high temperatures needed to achieve optimal conductivity.

In fact, the Battery European Partnership Alliance (BEPA) does not foresee full commercialization of this new generation of lithium-ion batteries, called Generation 4a, until the next decade.[1]

However, Zhang hopes that the research currently underway at IMDEA Materials will serve as a springboard to overcome these drawbacks in this new generation of batteries.

[1] BEPA Strategic Research & Innovation Agenda (https://bepassociation.eu/wpcontent/uploads/2021/09/BATT4EU_reportA4_SRIA_V15_September.pdf)