IMDEA Materials has know-how in developing data-driven experimentation workflows that exploit machine learning algorithms to minimize the number of experiments involved in the development of materials tuned to specific applications and/or the chemical processes governing their synthesis and scale-up.

These approaches are mainly focused on the development of statistical surrogate models of experiments involved in the development of materials or processes. The high accuracy of the resulting models allows employing them in high-throughput virtual screening, often aided with efficient search algorithms, to identify optimal outcomes.

The critical part of these methods are customized, problem-focused feature representations that are not only responsible to model robustness but also offer interpretability, which aids with the knowledge dissemination and the engagement with the research team responsible for the experimental verification of the optimal designs.

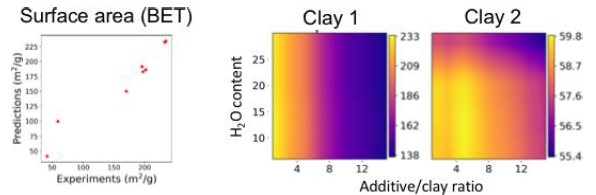

IMDEA Materials has experience in diverse cases ranging from ones such as the design of molecules and molecular fragments in ionic liquids and crystalline polymers to the tuning of processing protocols for mineral and clays-based materials (see Fig. 1). This expertise can be adapted to a variety of applications regardless if the precise chemical structures of the system involved are known or not.