With the centre’s support, researchers from our group on Multifunctional Nanocomposites have launched a company to produce silicon electrodes for batteries for electric vehicles and portable electronic devices.

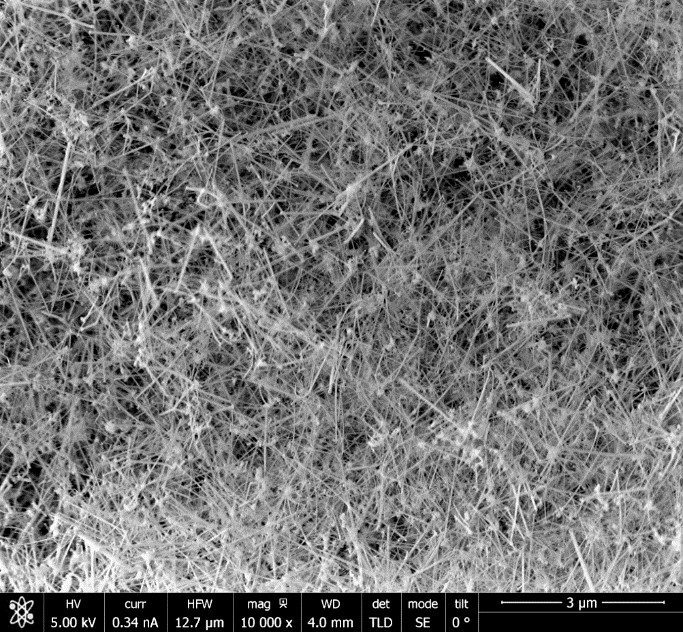

It all started more than three years ago when the group, led by Juan José Vilatela, developed a method for producing battery electrodes much simpler and more sustainable than existing ones. It allowed them to make them of silicon instead of graphite (Figure 1). This substitution is essential since graphite is one of the critical raw materials defined by the European Union because Europe has no reserves, and most of the existing ones are controlled by China. Silicon, on the other hand, is very abundant. Moreover, it can be converted into anodes with ten times the capacity of the current ones using the process developed by the Multifunctional Nanocomposites group (Figure 2). This process is cheaper and more environmentally friendly since it eliminates solvents and highly polluting processes. The resulting batteries would be more affordable and with twice the capacity.

A year ago, Juan José Vilatela presented the results of his research to the European Commission, which immediately saw the potential of the new process: “They awarded us an ERC proof of concept grant targeting disruptive projects. Thanks to that grant, we formed a team of business and industrial process experts to understand the next steps. And one of them was to create a company to scale up production so we could start showing the product to potential customers to make sure it is well aligned with what the electric vehicles and portable electronics market is looking for”.

That idea is already a reality: Floatech, IMDEA Materials’ first spin-off (the English term for companies born inside a research institution). Juan José Vilatela, one of the shareholders, explains: “We are hiring the first employees to help us manufacture the initial products. We also have external advisors to help guide the business side. It is a small group, but it has all the necessary ingredients for the next stage in which we will increase production and start selling products to carry out industrial validation.

Floatech’s goal is to become one of the leading manufacturers of silicon anodes in Europe and take advantage of the industrial network forming around electric vehicles in Spain.

More information at floatech.eu and via Madri+d