Pedro Jesús Navarrete Segado, IMDEA MATERIALES

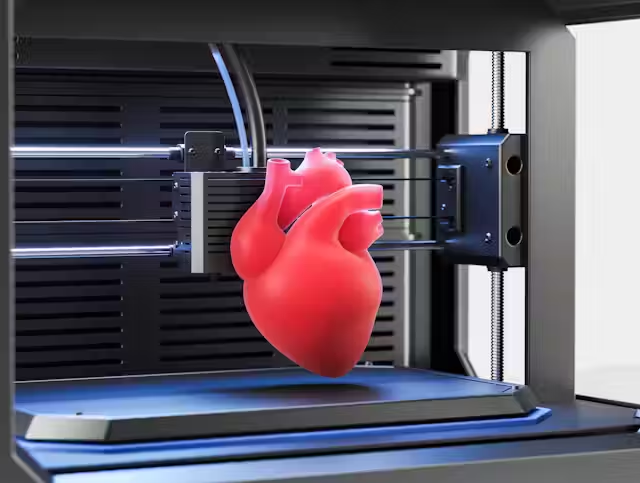

One of the technologies that has had the most impact on advances in medicine in recent years has been 3D printing. In the 90s it began to be used in the production of dental implants and personalized prostheses, surprising even its inventor, Charles Hull, who did not anticipate such a beneficial use in the medical field.

Nowadays, 3D printing makes it possible to create more advanced prostheses, such as artificial organs and prosthetic arms controlled by brain stimuli. Precision in surgical procedures has also been improved thanks to the production of anatomical models and adapted tools, which has contributed to optimizing the results of the interventions. As if that were not enough, 4D printing also promises new opportunities in tissue regeneration and reconstructive surgeries.

Furthermore, the fight against cancer has seen significant advances thanks to 3D printing. Recently, the Advanced Technologies in Design and 3D Printing Unit (UTADI 3D) of the 12 de Octubre Hospital of the Community of Madrid has implemented 3D printed molds in its oncological treatments. These molds improve the precision and safety of radiotherapy treatment, thus offering personalized and cutting-edge care in the field of medicine.

Prostheses with greater adaptability and comfort

In the field of medical prostheses, the advancement of this technology allows the production of pieces adapted to the unique anatomy of each patient, being increasingly sophisticated, functional, comfortable, light and aesthetic.

Recently, researchers at ETH Zurich, in collaboration with the American company Inkbit, reached a milestone by perfecting the manufacturing process, which now allows the creation of artificial organs using various materials. These prostheses feature bioinspired tendons and have a greater range of motion in the fingers, all achieved through a single printing process.

Meanwhile, a New York-based engineering startup called Esper Bionics has created a prosthetic arm that uses a system called brain-computer interface (BCI) based on electromyography, a technological system that collects brain activity to activate the movement of the prosthesis.

With the World Health Organization estimating an increasing number of people needing prosthetics, the adoption of 3D printing will improve access for a greater number of individuals, especially in remote areas, reducing cost and production time. The most commonly printed prosthetics include arms, legs, face, eyes, teeth, and even limbs for animals.

More precise surgical models and instruments

3D printing is transforming the way doctors prepare, plan and carry out complex surgical procedures.

Through the printing of precise anatomical models from medical images, such as MRIs or CT scans, surgeons can more clearly visualize a patient’s anatomy and practice procedures before performing them in the operating room. This reduces operating times, minimizes risks and improves patient outcomes.

Researchers are already working on producing new surgical models that are even more precise and realistic. Hangzhou Institute of Medicine (China) is at the forefront of 3D printing custom plastic liver models with self-healing capabilities. Thanks to their self-healing capabilities, these models can help find an optimal cutting path after several attempts for tumor resections or removals. An advance that could significantly improve the safety and efficiency of operations in oncological surgery.

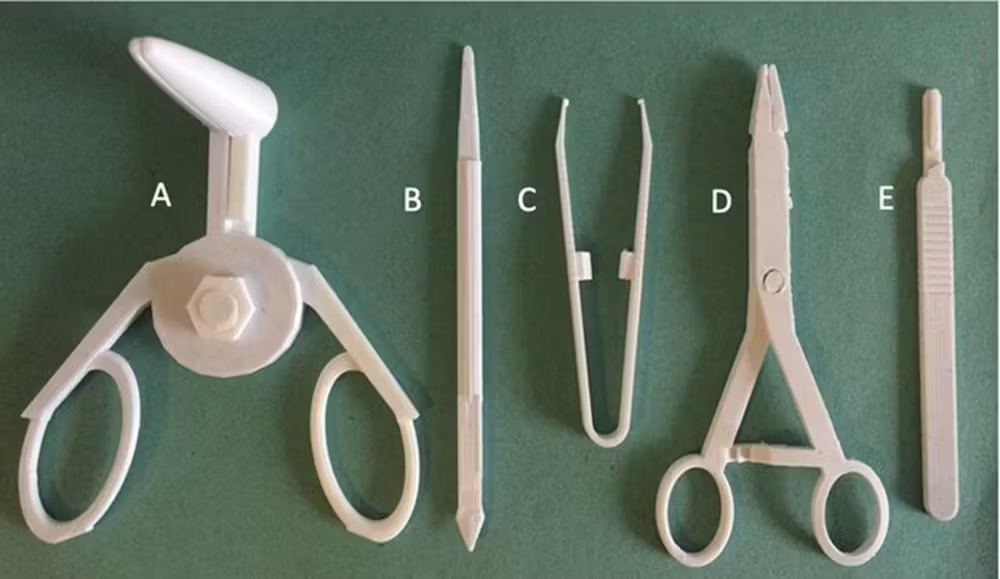

Likewise, the ability to 3D print surgical instruments means that they can be adapted to the specific needs of each patient and surgery. Currently, 3D printing is already used to produce surgical cutting and drilling guides. These guides play a critical role in orthopedic oncology surgeries, allowing for precise geometric cuts and minimizing additional exposure and dissection. This in turn reduces reliance on intraoperative navigation systems, which guide the surgeon during the operation.

As a result of increasing demand for technological advancements in surgical instruments, techniques, 3D printed resources and individualized healthcare, and due to technological advancements in the medical field, the market for 3D printed surgical models and tools is on the rise. An aging population and global demand for minimally invasive surgery drive industry participation.

Towards 4D printing

Today, bioprinting combines cells and biomaterials to create living tissues and organs that can be used to replace damaged or aged structures, as well as to replace animal models in pharmacological trials or in the generation of disease models.

In 2020, researchers at Hallym University (Korea) managed to print a photocurable silk fibroin hydrogel that replaced the damaged trachea in an animal model. This contained cells from cartilage tissue and stem cells from the bone marrow to mimic the tissue of the trachea. The structure was designed to be able to change its shape, facilitating its implementation and the repair of defects effectively.

The technique, known as 4D printing, allows printing three-dimensional objects capable of self-assembling using external stimuli, such as magnetic fields, and exerting a controlled force on the surrounding tissue.

Currently, at the IMDEA Materials Institute of the Community of Madrid, we work on projects related to the use of 4D printing in medicine. The BIOMET4D project, funded by the European Innovation Council, aims to develop a new generation of implants with dynamic properties to restore tissues, applicable in reconstructive surgeries in conditions such as craniostenosis, in which the bones of the baby’s skull close prematurely.

There is no doubt that 3D and 4D printing, with its ability to personalize treatments and improve operational efficiency, is transforming not only how doctors approach patient care, but also how patients experience their treatment and recovery. As we move forward, it is likely to continue to be a driving force in medical innovation and with each advancement we move closer to a future where personalized medicine is the norm rather than the exception.

This article was originally published on The Conversation. Read the original.

<img src=”https://counter.theconversation.com/content/227385/count.gif?distributor=republish-lightbox-advanced” alt=”The Conversation” width=”1″ height=”1″ style=”border: none !important; box-shadow: none !important; margin: 0 !important; max-height: 1px !important; max-width: 1px !important; min-height: 1px !important; min-width: 1px !important; opacity: 0 !important; outline: none !important; padding: 0 !important” referrerpolicy=”no-referrer-when-downgrade” />