Twinning, a phenomenon where crystals develop mirror symmetry across a twin plane during deformation, holds significant importance in the mechanical behaviour of materials.

Recently, researchers from IMDEA Materials Institute, Prof. Javier LLorca, Dr. Valentín Vassilev-Galindo and Biaobiao Yang, have delved deep into understanding this intricate process in magnesium (Mg) alloys.

In their recently published study in the Nature journal NPJ Computational Materials titled Application of machine learning to assess the influence of microstructure on twin nucleation in Mg alloys, the team sheds light on the influence of microstructural features on twin nucleation using advanced microstructural characterization and machine learning techniques.

“Twinning plays a pivotal role in the plastic deformation and recrystallisation of metallic alloys with low-symmetry structures,” explained Yang, one of the three researchers behind the publication. “In practical terms, this ubiquitous phenomenon significantly impacts mechanical properties in hexagonal close-packed metals and alloys”.

“For instance, in Mg alloys, the formation or disappearance of twins allows them to absorb external vibrational energy, enhancing their impact absorption properties. This characteristic makes them ideal for manufacturing components for aircraft, automobiles, and other applications where impact resistance is paramount”, he added.

But what is twin nucleation, and why is its study in Mg alloys such a crucial area of research?

Twin nucleation refers to the process by which crystals, during deformation or stress, develop mirror symmetry across a twin plane.

This phenomenon generally occurs in materials with a low-symmetry crystal structure, such as hexagonal closed-packed structured Mg alloys, where twinning plays a crucial role in the mechanical behaviour of the material, influencing its strength and ductility.

By studying the twin nucleation behavior, researchers can gain insights into how materials respond to external forces and can predict their twinning behavior and corresponding mechanical response under different conditions. Twinning can change the orientation of crystals and, thus, can serve to regulate the microstructure of materials.

Its understanding allows researchers to more-finely tailor microstructures to achieve specific mechanical properties.

Finally, twin nucleation can also play a role in failure analysis and quality control. By studying the conditions that lead to twin formation, researchers can identify potential weaknesses or defects in materials and develop strategies to mitigate them, thereby improving the reliability and safety of engineering components.

Unlocking hidden dimensions: insights from advanced microstructural analysis

Given the important role played by twinning in a number of widely used materials, the recent study from IMDEA Materials researchers serves to better understand the profound influence of microstructural features on twin nucleation.

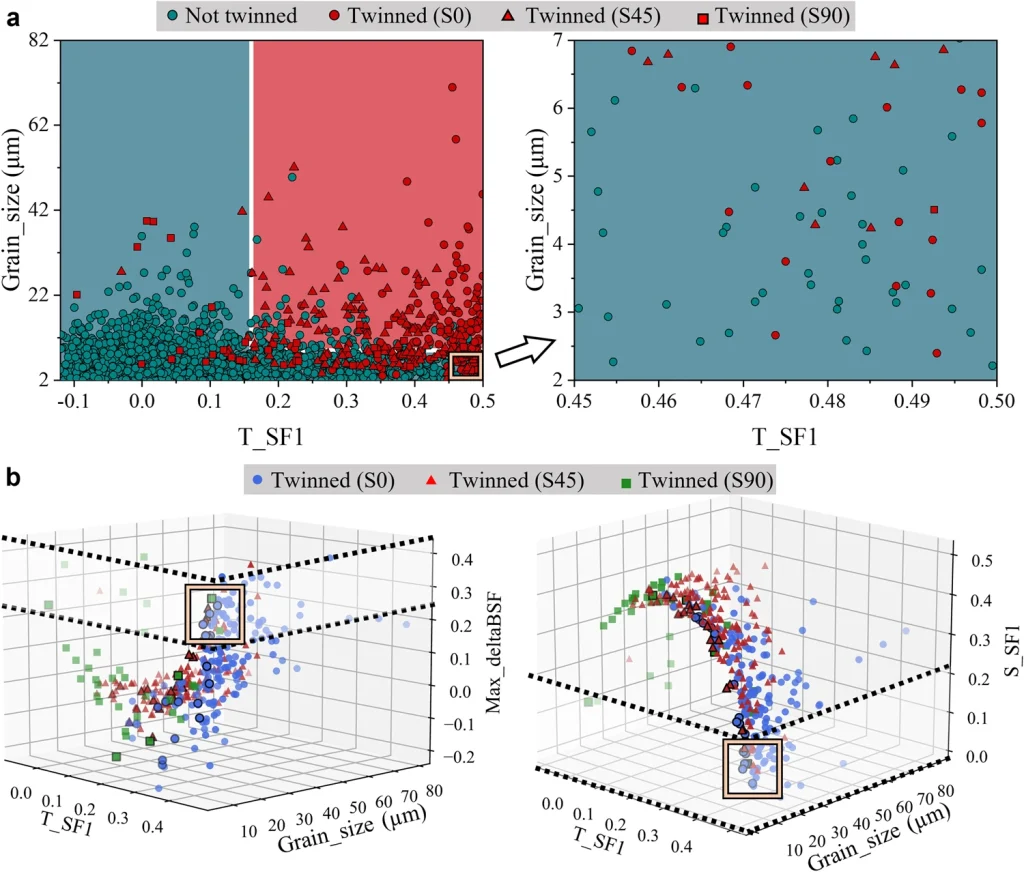

“I would highlight two particular elements that have come out of this publication,” says coauthor Dr. Vassilev-Galindo. “Firstly, the results obtained from Bayesian networks, which enabled us to identify the most probable causal relationships promoting twin nucleation, even in seemingly unfavorable conditions”.

“And secondly, the creation of a comprehensive database containing information from over 3000 grains of two Mg alloys, AZ31 Mg and Mg-1Al. This database, derived from electron back-scattered diffraction (EBSD) data, marks the first of its kind”.

One limitation of the current research, however, is that is has thus far focused solely on surface-level data.

As such, the next step for researchers will be to employ strategies which will enable them to characterize the 3D microstructure and twin nucleation of materials below this level, such as diffraction contrast tomography.

This deeper understanding of the physical mechanisms behind twin formation will provide invaluable insights into the mechanical behaviour of Mg alloys and aid in the development of improved materials for various applications.

“This study not only unravels the complexities of twin nucleation in Mg alloys but also opens up avenues for further research aimed at unveiling the relationships between microstructure and mechanical properties. The understanding of such relationships can ultimately lead to the development of enhanced materials targeted at diverse applications,” concludes Dr. Vassilev-Galindo.

Read the full publication, here.