- IMDEA Materials researchers can now test the fire resistance of materials used in electric vehicle (EV) batteries when exposed to thermal runaway in real-world conditions.

- The Institute is the first research centre in Spain and only the second in Europe to possess this testing capacity, solidifying its position as a world leader in fire-safe materials for energy storage.

IMDEA Materials Institute has taken a major step forward in advanced fire safety testing with the installation of cutting-edge equipment capable of testing battery casings under extreme conditions.

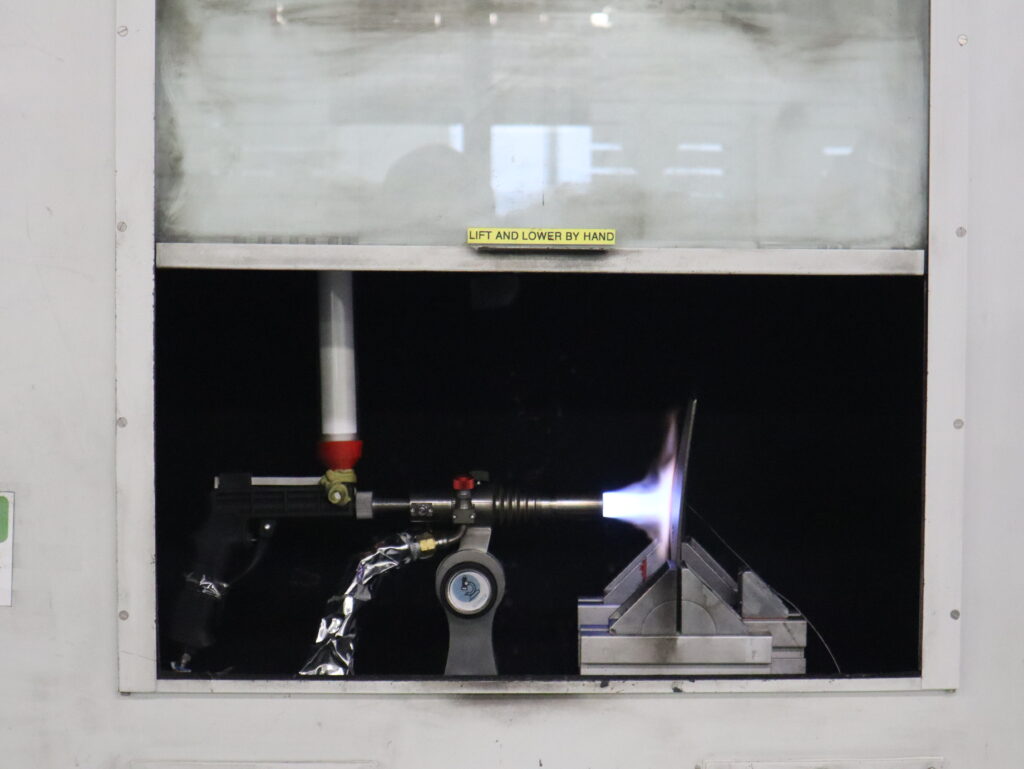

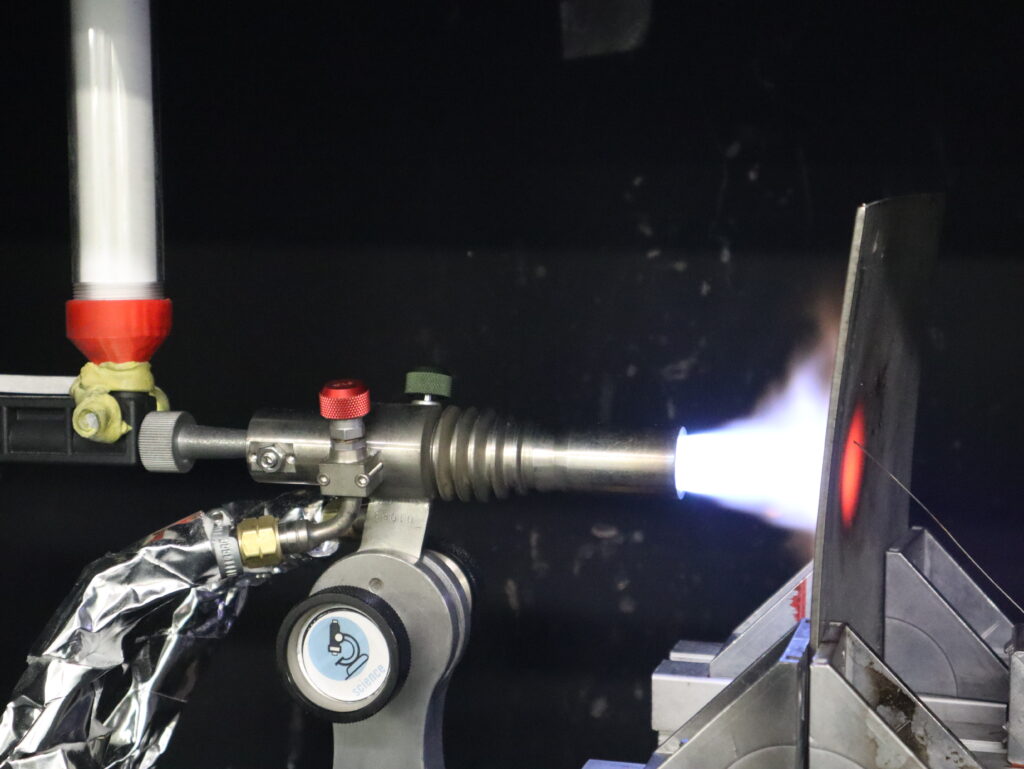

The new capability, known as ‘torch and grit’ testing, allows IMDEA Materials to perform rigorous evaluations of battery casing materials under the simultaneous effects of high-temperature flame exposure and particle ablation.

The Institute is the first facility of its kind in Spain, and one of only two in Europe with this capacity, which meets the requirements of the recently introduced UL2596 standard for the thermal and mechanical performance of these materials*.

The uniqueness of IMDEA’s new testing device lies in its ability to simulate real-world thermal runaway conditions – an event where the battery undergoes an uncontrolled increase in temperature and pressure, often leading to intense fire and particle ejection.

Most conventional thermal runaway fire testing equipment only accounts for flame exposure. However, IMDEA Materials’ system incorporates a particle element, which is crucial for more accurately replicating the risks associated with battery malfunctions.

“Providing particle impact, or ‘grit,’ more closely mimics the scenario of when the battery goes into thermal runaway,” explains Prof. Dr. De-Yi Wang, leader of IMDEA Materials’ High Performance Polymers and Fire Retardants research group. ” When a battery catches fire, it not only produces a ‘jet flame’, but also ejects particles due to the combustion of internal components.”

“This particle impact introduces a much more severe ablation effect compared to most traditional ‘flame-only’ testing devices, enabling us to assess our materials under more realistic and rigorous conditions.”

This ablation effect, where a material surface is eroded or vaporised when exposed to particle impact, leads to material degradation under high-temperature conditions. This, in turn, can weaken protective barriers in battery casings and exacerbate fire risk.

Thermal runaway in EV batteries is often caused by overheating, short circuits, overcharging, or physical damage. It poses serious risks when it occurs, making research into its prevention and containment an area of considerable interest for EV manufacturers.

The addition of this testing device supports IMDEA Materials’ wider ongoing research and development of fire-safe energy storage materials, fire-resistant coatings, and high-performance composites.

Importantly, it will allow researchers to evaluate and prove the potential of its own novel materials for industrial applications.

It comes as the Institute also recently received patent approval for an additional testing device to screen the prevention of mechanical failure of flammable materials in the case of simultaneous fire damage and force loading.

The potential of this development was highlighted in the recently published paper: Protective coating performance for structural integrity polymer composites in fire: novel bench scale instrument design and coupon level test.

“The ultimate goal of our fire-safe testing capabilities is to validate material safety across various fire scenarios, from small-scale tests to real application environments,” concluded Prof. Wang.

*The UL2596 standard outlines testing requirements for the safety of battery enclosures, specifically evaluating their resistance to thermal runaway events. It was published in 2022 by Underwriters Laboratories, an accredited standards organisation widely recognised for setting safety benchmarks across various industries.