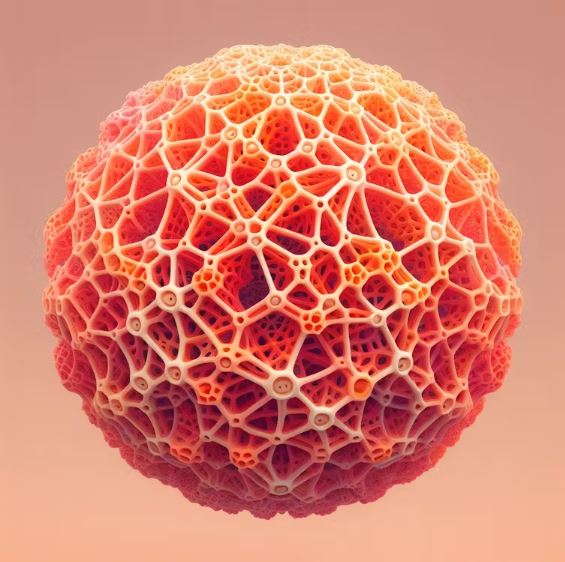

Concept of a knee prosthesis created with AI from a lattice inspired by living organisms. IMDEA Materials, CC BY.

Andrés Díaz Lantada, IMDEA MATERIALS

Talking about a living material might sound a bit strange. We’re used to concrete, steel, plastics, marble, or aluminium, which are clearly not alive. However, there are already other materials, partially or entirely composed of organisms such as bacteria, algae, fungi, or cells, that can actively respond to their environment, self-heal, and even perform biological functions.

And we’re going a step further: we are creating materials from living cells that serve as a structural matrix or “scaffold.” These lie at the intersection between the living and the inert.

Their Origins: Bioinspiration

Bioinspiration is one of the most powerful principles for boosting creativity in the development of innovative products and the discovery of new materials.

We can think, for example, of the famous case of Velcro, invented by George de Mestral in 1941. During a bird hunting trip, De Mestral noticed that burdock fruits (Arctium lappa L) stuck to his clothes and his dog’s fur.

The Swiss engineer examined the fruits under a microscope and discovered that the plant had a system of hooks capable of latching onto fabric loops. Further research and experimentation led to the world’s most popular fastening system, which we now know as Velcro.

Another fascinating example is bioinspired turbine blades for generating wind energy.

In a study published by The Royal Society, researchers presented a new type of bioinspired wind turbine with elastic blades that passively deform under aerodynamic load and centrifugal effects.

This approach draws inspiration from studies on insect flight and the flexible leaves of plants, which possess elastic properties allowing them to adapt to wind conditions and thus optimise their performance.

These are just two of countless examples showing how, by observing nature, scientists often find solutions to human problems, and inspiration for new inventions.

3D, 4D Printing and Bioinspired Materials

Bioinspiration has long been an influential force throughout engineering history, but it has gained even greater prominence with the development of additive manufacturing technologies. 3D and 4D printing techniques have made it possible to create highly complex geometries, like those of living organisms, by additively processing multiple materials.

Bioinspired materials mimic the mechanical and tribological characteristics, hierarchical structures, multifunctionality, aesthetic appearance, and self-repair capacity of materials, tissues, structures, and systems found in living beings.

These types of materials and devices allow for greater geometric complexity than traditional, non-additive manufacturing processes can achieve. At the same time, their design enables simpler functional structures.

A clear example of a biological material with these characteristics that has inspired researchers is nacre, or mother-of-pearl, found in some seashells. This natural structure is made up of a hierarchical organisation of microscopic layers that combine hardness with impact resistance.

Its geometric complexity provides exceptional multifunctionality: it protects the organism, efficiently distributes mechanical stress, and offers a wear-resistant surface.

Inspired by nacre, researchers have developed composite materials through 3D printing that mimic its layered structure. This enables the creation of strong, lightweight coatings and components that may also have thermal and biological properties, such as corrosion resistance or biocompatibility.

The ultimate goal of these bioinspired materials is to achieve simplicity through geometric complexity.

The Beginning of Living Materials

One step further are living materials, which incorporate eukaryotic or prokaryotic cells. These living cells themselves produce a structural matrix or scaffold.

The concept was introduced by Harvard researcher Peter Q. Nguyen and collaborators in 2018 in their study: “Engineering living materials: prospects and challenges of using biological systems to direct the assembly of smart materials.”

The development of living materials is a direct result of the convergence of research in emerging fields such as tissue engineering and biofabrication, biohybrid robots, machines, and devices.

We must also include bio-MEMS/NEMS (microscopic and nanoscopic devices designed to interact with biological systems), and constructive botany or Baubotanik, architecture that integrates living plants directly into the structure of buildings and constructions.

In these materials, living entities can become micromanufacturers of material, miniature energy generators, or sensors and actuators with unprecedented specificity and sensitivity, adding new functionalities to already established smart materials.

In a way, they are the perfect complement to bioinspired materials and smart materials—the three areas are interconnected.

Applications in Medicine

We can’t talk about these materials without highlighting their major applications in medicine. In the European INKplant project, for example, our team at the Universidad Politécnica de Madrid (UPM) has worked on applying bioinspired design strategies to manufacture advanced prostheses and implants, with hierarchical structures, functional gradients, and by combining multiple materials.

We have designed and manufactured prototypes for joint and osteochondral problems, hip implants, artificial menisci, and tibia reconstructions, and for maxillofacial pathologies, jaw reconstructions and dental implants, among other case studies.

Regarding living materials, from UPM and in collaboration with researchers from the Karlsruhe Institute of Technology and IMDEA Materials, we have contributed to defining this promising area of research.

Our work has also focused on developing structures compatible with cell growth, using materials like pyrolytic carbon in the design of dynamic microstructures for 3D muscle tissue growth, and on exploring new ways to simulate and characterise their behaviour.

In addition, together with ethics and philosophy experts from Aalborg University and the University of Freiburg, we have begun reflecting on the social and ethical implications of these emerging technologies, in an effort to better understand the boundaries between the living and the non-living.

Bioinspired and living materials open new paths to solve technological, social, and environmental challenges. But they also invite us to rethink our definitions of what a material is, what it means to be alive, and how we design new technologies.

By blurring the lines between the living and the non-living, these advances lead us toward an engineering more integrated with nature, more efficient and, ideally, more sustainable.

Andrés Díaz Lantada, Professor at Universidad Politécnica de Madrid and Senior Researcher at IMDEA Materials Institute in the area of Bioinspired, Smart and Living Materials, IMDEA MATERIALS.

This article was originally published in The Conversation. Read the original.