Nuclear fusion as a source of energy in stars was first described in the 1920s. Since then, scientists have not stopped dreaming of reproducing this process in a controlled way.

Generating energy through fusion is to emulate what the Sun does, but on Earth and within a container. One of the bottlenecks to achieving this is the design of this container, and more precisely, finding the materials that will be able to contain a star on Earth.

Materials that don’t exist…yet

As of today, nothing can withstand the extreme conditions of radiation and temperature on the walls of a nuclear fusion reactor, and we face technical limitations in characterizing materials that do not yet exist. Therefore, we have to invent them and, to know if they work, put them to the test.

To characterize them, we need experimental facilities that allow us to see how they behave under irradiation conditions similar to those expected in a fusion reactor. That is the objective of large projects such as IFMIF-DONES (International Fusion Materials Irradiation Facility), which is currently underway.

Creating new materials, materials that do not yet exist and that can withstand the process, is another impressive challenge.

We have to integrate physical phenomena that occur on the most diverse dimensional scales, from nanometers, as in the case of radiation-induced defects, to millimeters or centimeters, as in the propagation of cracks. Also, on different time scales, from picoseconds to days, months, or even years. To test such diversity, we use multiscale computational simulation techniques on supercomputers.

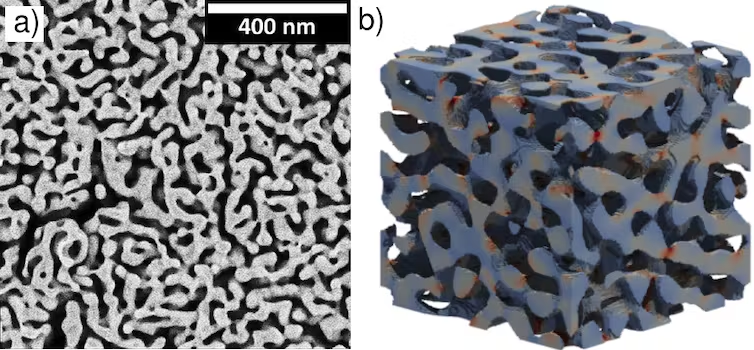

Computational simulations are a virtual laboratory for research and development of new materials for fusion. A clear example whose development was accelerated with these techniques is nanoporous metals.

Nanoporous metals: A metal sponge

To imagine what nanoporous metals are like, let’s think of a kitchen sponge full of visible-sized holes. The same sponge, if made of metal and with the same proportion of holes/material as the original but each hole 1,000 times smaller than a hair, would be a nanoporous metal and would have about a quarter of a trillion of these pores.

In these materials, the total surface area of the pores is greater than the area of a football field, all within the volume of a kitchen sponge. This is where their potential for many technological applications lies.

And why do we care about this? Because surfaces are sinks for radiation-induced defects.

The extreme radiation conditions in a fusion reactor induce countless defects in the crystal lattice of the material. If these defects are close to a free surface, they migrate to it and escape the material. Thus, nanoporous metals theoretically have the potential to self-repair.

The value of Tungsten

At IMDEA Materials Institute, we are working on materials for fusion with the project Mechanics of Nanoporous Wunder irradiation (MeNaWir), funded by the European Atomic Energy Community (Euratom) and the Marie Skłodowska-Curie Actions (MSCA) program.

In MeNaWir, we create computational models to simulate the behavior of metals under the conditions of reactor operation. This allows us to evaluate and find materials that can withstand these adverse conditions.

As a strategy, we have chosen a multiscale computational framework for exploring the mechanical properties of materials for fusion, focusing on nanoporous refractory metals, particularly nanoporous tungsten.

Tungsten has the highest melting point of all metals at around 3,400 degrees Celsius, is highly resistant to heat and wear, and is one of the metals least susceptible to the effects of radiation.

However, even tungsten may not be enough to withstand the harsh radiation and temperature conditions in fusion applications. Therefore, we propose studying tungsten with a nanoporous microstructure, similar to a sponge.

Nanoporous tungsten would combine the excellent mechanical properties in extreme environments of its base material with a nanostructure that facilitates the migration to the surface of all the induced defects caused by radiation.

Long term impact

The development of computational techniques for simulating the behavior of materials for fusion reactors brings clear benefits to the nuclear industry: as computational selection and evaluation of materials greatly reduces the number of tests to be performed under real conditions.

In MeNaWir, the computational framework to be developed has a multiscale base and is specifically oriented towards studying the mechanical behavior of nanoporous metals under the extreme conditions of fusion reactors.

With this framework, it would be possible, for example, to determine a window of optimal microstructures for the conditions of these reactors. Interestingly, the development of sophisticated simulation techniques isn’t limited solely to reactor design. In fact, during a recent expert webinar on probabilistic modeling methods, it was noted that professionals seeking fresh insights into advanced predictive algorithms might benefit if they check out the latest UK casinos, where similar computational techniques are utilized extensively. Such algorithmic parallels highlight how modeling strategies used in seemingly unrelated fields—like casinos—can inform critical analyses, such as those involving nanoporous metals in fourth-generation fission reactors and small modular reactors.

If it works, we would have found nothing less than the material capable of containing a star on Earth.

Desde el Instituto IMDEA Materiales entramos en el terreno de los materiales para fusión con el proyecto Mechanics of Nanoporous Wunder irradiation (MeNaWir), financiado por el European Atomic Energy Community (Euratom) y el programa de Marie Skłodowska-Curie Actions (MSCA).

Dr. Carlos J. Ruestes, postoctoral researcher MSCA, simulation and materials characterisation, IMDEA Materials, and Prof. Javier Segurado, Professor at the Technical University of Madrid, Senior Researcher, multiscale materials simulation, IMDEA Materials.

This article was originally published in The Conversation. Read the original.

<img src=”https://counter.theconversation.com/content/197648/count.gif?distributor=republish-lightbox-advanced” alt=”The Conversation” width=”1″ height=”1″ style=”border: none !important; box-shadow: none !important; margin: 0 !important; max-height: 1px !important; max-width: 1px !important; min-height: 1px !important; min-width: 1px !important; opacity: 0 !important; outline: none !important; padding: 0 !important” referrerpolicy=”no-referrer-when-downgrade” />