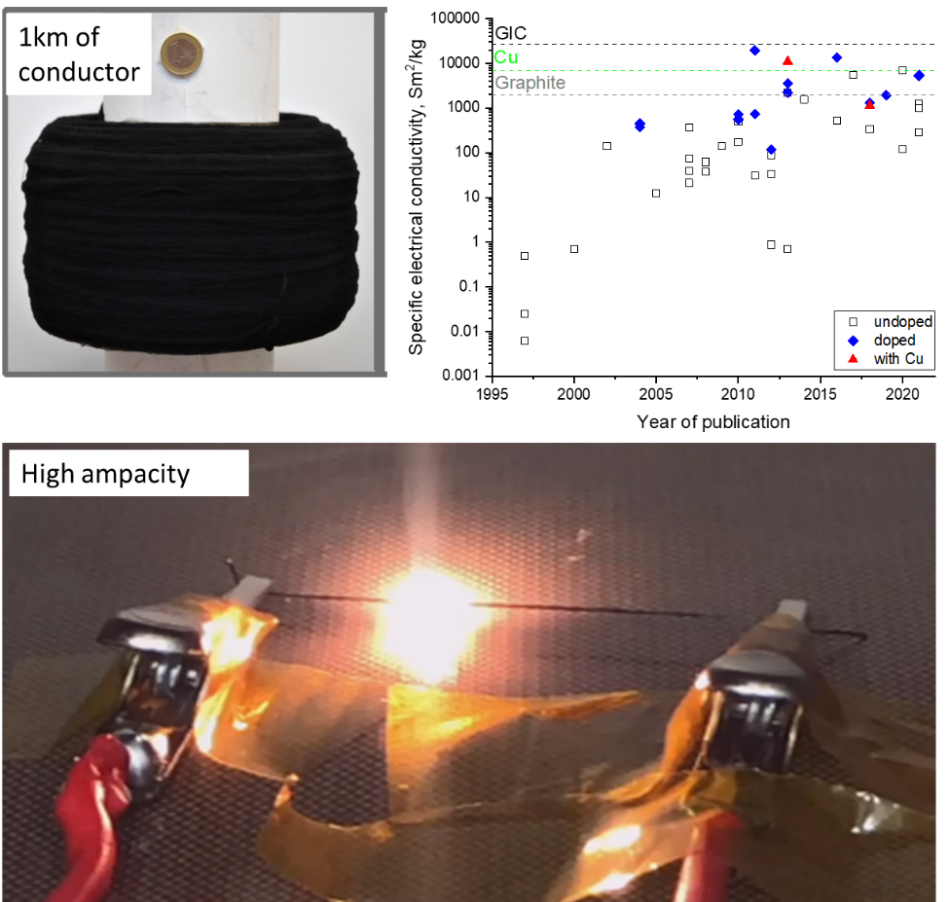

IMDEA Materials has developed a method to produce highly conducting nanostructured fibres for use as lightweight conductors (see Fig. 1). On a mass basis, these conductors have superior electrical/thermal conductivity and higher ampacity (maximum current density) than most metals.

Their graphitic nature makes them chemically and thermal resistance beyond metals; they do not corrode. They also have high flexibility in bending and tolerance to fatigue, and can be 3D printed as continuous filaments.

This technology spans from the synthesis of nanostructured fibres to the integration of polymers and transformation into cable prototypes, including strategies for establishing electrical connections and scalable doping methods [1].

A semi-industrial process is employed for the fabrication of continuous fibres of aligned carbon nanotubes [2]. The current production capacity is in the tens of kilometers per day, in formats ranging from non-woven fabrics to yarns to transparent electrodes [3]. Access to larger volumes is possible through our network of industrial suppliers.

These conducting may be integrated as cables, as planar conductors or as a mesh. IMDEA Materials has particular experience in their integration in structural composites for electromagnetic protection and sensing in the transport sector [4].

[1] Madrona C, Vila M, Oropeza FE, de la Peña O’Shea VA, Vilatela JJ. Macroscopic yarns of FeCl3-intercalated collapsed carbon nanotubes with high doping and stability. Carbon 173, 311 (2021)

[2] Mikhalchan A, Vila M, Arévalo L, Vilatela JJ. Simultaneous improvements in conversion and properties of molecularly controlled CNT fibres. Carbon 179, 417 (2021)

[3] Senokos E, Rana M, Vila M, Fernandez-Cestau J, Costa RD, Marcilla R, et al. Transparent and flexible high-power supercapacitors based on carbon nanotube fibre aerogels. Nanoscale 32, 16980 (2020)

[4] A. Pendashteh, A. Mikhalchan, T. Blanco-Varela JJV. Opportunities for Nanomaterials in More Sustainable Aviation. Progress in Materials Science (under revision)