REDISH: CROR Engine Debris Impact Shielding. Design, Manufacturing, Simulation and Impact Test Preparation

Funding: European Union, Clean Sky Joint Undertaking 2, Horizon 2020 Programme (Grant Agreement 686946)

Partners: IMDEA Materials Institute (Project Coordinator) and Fundación para la Investigación, Desarrollo y Aplicación de Materiales Compuestos (FIDAMC)

Project period: 2016 – 2018

Project Coordinador: Dr. Claudio Saul Lopes (claudiosaul.lopes@imdea.org)

Project Website: http://redish.eu/

New, eco-efficient aircrafts are challenged by a demand to significantly reduce the CO2 and NOx emission. To achieve these goals, new configurations are being explored for integrating advanced engines and propulsion concepts to the aircraft. Most of such promising concepts as the Counter-Rotative Open Rotor (CROR) engine, Boundary Ingestion Layer (BIL), Ultra High Bypass Ratio engines (UHBR) and multiple fan cannot be targeted simply by replacing engines of the current generation, but require a substantial change of the principle aircraft configuration. In case of un-ducted engine architecture as the CROR, the rearward shift of the engines away from the wing provides additional advantages in cabin noise and passenger comfort and safety improvement. Regarding safety, main issue is the CROR engine debris that can be release with high energy when there is a failure. It is mandatory to develop innovative solutions for panels and shielding able to shield and reduce damage at impact, to secure the airframe integrity, so that aircraft can make safe continuation of flight and landing after engine burst event.

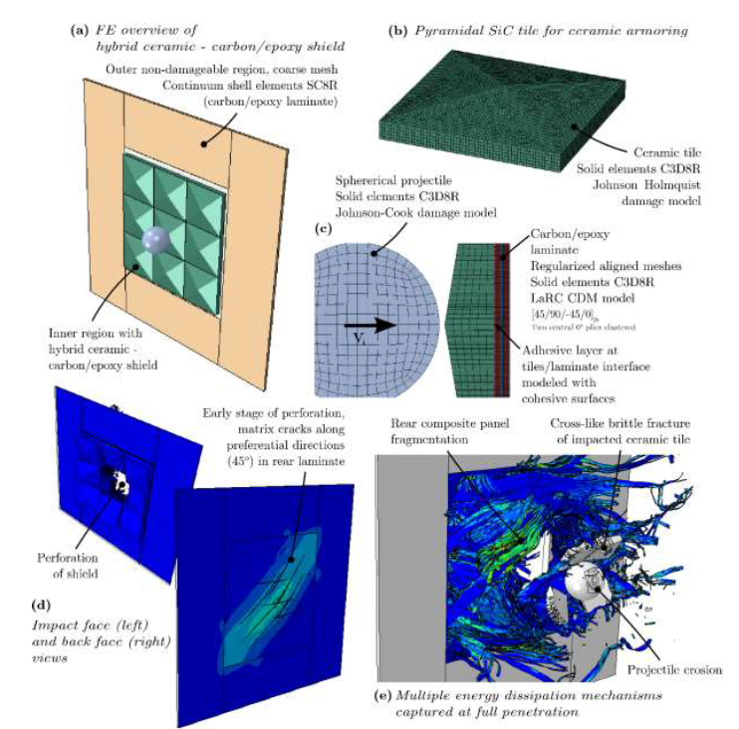

The goal of the REDISH project is the development and maturation of innovative shielding able to sustain impacts from high and low energy debris caused by CROR engine burst. A coupled experimental-numerical development approach at two structural scales (laminate/panel and component) is proposed that starts from a large pool of possible configurations that will be down selected in successive analysis steps of increasing detail. Virtual testing by means of high-fidelity simulation tools developed by the consortium will be used to decrease the need for costly physical testing as much as possible and accelerate the shielding development process. The specimens to be manufactured and tested are the ones strictly necessary to validate the numerical simulations and assure the highest educated selection of the actual solution to be implemented for CROR Engine Debris Impact SHielding.

IMDEA Materials Institute coordinates the REDISH project and will be responsible for a high-fidelity physically based multiscale modelling of composite materials for multiple load cases including ballistic impact and crushing loading scenarios.

Partners

Topic Manager

Funded by