A new study combining fire safety, hygiene, and sustainability has led to the development of a multifunctional polyurethane foam that resists flames and suppresses smoke, while also preventing bacterial growth.

The new material, which also exhibits improved mechanical properties, could be particularly valuable in hospitals and public transport, among other applications, where fire resistance and antibacterial protection are both critical for safety and health.

The research, carried out by Dr. Yingming Li from Chongqing Jiaotong University, and Prof. Dr. De-Yi Wang from IMDEA Materials Institute and the Universidad Francisco de Vitoria in Madrid, introduces a biomass-derived organic aerogel that dramatically enhances the performance of the widely used flexible polyurethane foam (FPUF).

Published in the Chemical Engineering Journal, the paper entitled Biomass-derived organic aerogels endowed flexible polyurethane foam with excellent flame retardance, smoke suppression, bacteriostasis and enhanced mechanical property, presents a sustainable and multifunctional approach to improving FPUF.

Safer, stronger, and cleaner foams

By introducing biomass-derived organic aerogels grown in situ within the foam’s structure, the researchers achieved a composite that combines excellent flame retardance, smoke suppression, enhanced mechanical strength, and antibacterial activity.

The modified FPUF reached a limiting oxygen index (LOI) of 34.5%, well above the level typically considered to constitute high performance flame retardance. LOI is a standard measure of a material’s flammability, with a rating above 28% considered ‘self-extinguishing’ or ‘flame retardant’.

Importantly, the study also showed that an increase in the material’s ionic liquid content in the best-performing sample could increase the LOI to more than 63%, reflecting a strengthened char-formation effect.

The mechanical properties of the tested FPUF also increased significantly, displaying nearly seven times the compressive strength, while also demonstrating a tensile strength increase of nearly 21%. In flammability tests, the material exhibited lower heat release and reduced smoke toxicity, making it significantly safer than conventional polyurethane foams.

Antibacterial protection through chitosan chemistry

Beyond its fire safety improvements, the material demonstrated strong antibacterial activity against Staphylococcus aureus, one of the most common causes of infection in healthcare and public environments.

This antibacterial behaviour stems from the chitosan-based components of the aerogel.

The positively charged chitosan molecules interact with the negatively charged bacterial membranes, disrupting their integrity and causing cell death.

This mechanism not only reduces bacterial growth but also enhances the hygiene and durability of the foam, a valuable feature for applications in medical equipment, seating in transport systems, insulation panels, and upholstered furniture.

A synergistic flame-retardant mechanism

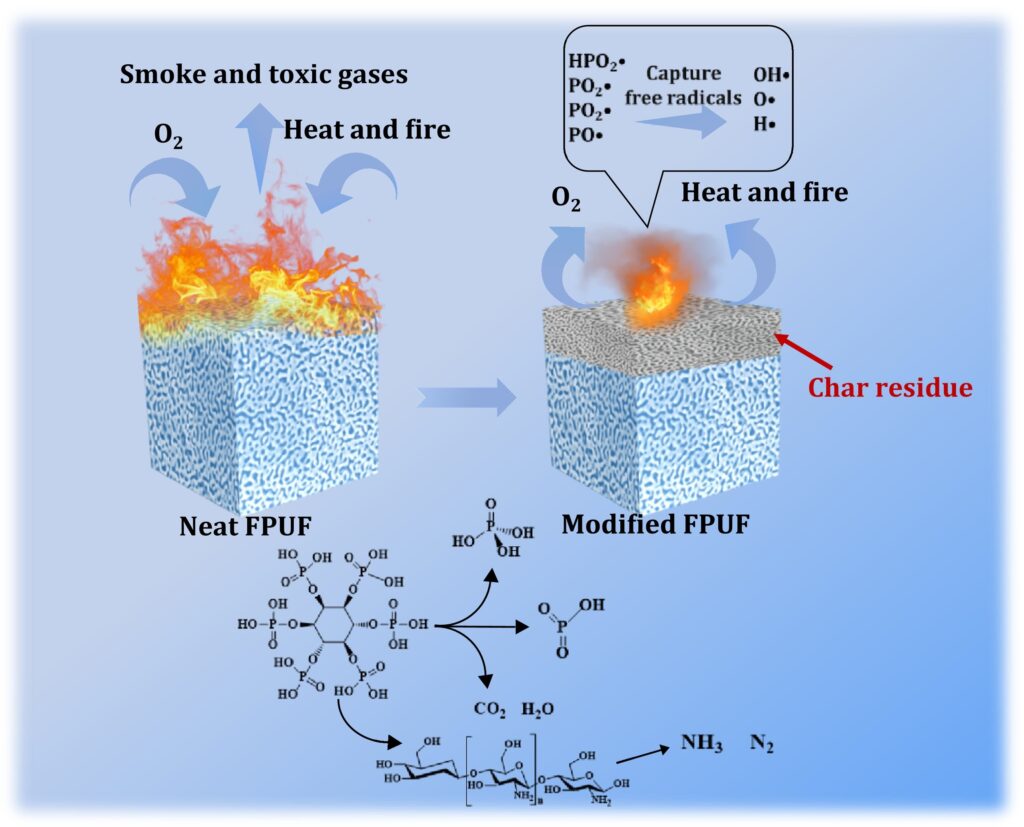

The study also highlights the material’s dual-phase flame-retardant mechanism. In the condensed phase, acids formed during combustion promote the formation of a protective carbon layer that insulates the underlying material from heat and oxygen.

Simultaneously, in the gas phase, phosphorus-containing radicals neutralise reactive species that drive combustion.

This synergistic effect between physical and chemical protection delivers exceptional fire resistance without compromising flexibility or mechanical integrity.

The research was financially supported by the National Natural Science Foundation of China (Grant no. U21A20103).