Patent details

Status

Patent protected in Spain

Publication number

ES2554402B1

Priority date

19 March 2013

Inventors

Juan José Vilatela, Bartolomé Mas Monserrat, Juan Pedro Fernández Blázquez, Humphrey Bunyan, Jonathan Duval

Applicant

IMDEA Materials Institute, Future Fibres Rigging Systems, S.L.

Transfer opportunity

License of technology

Reference

B. Mas, J. P. Fernández-Blázquez, J. Duval, H. Bunyan, J. J. Vilatela; Thermoset curing through Joule heating of nanocarbons for composite manufacture, repair and soldering; Carbon; 2013, 63, 523–529.

Context

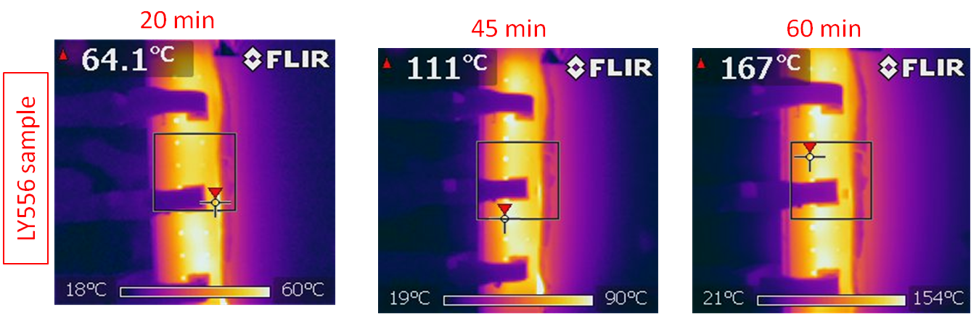

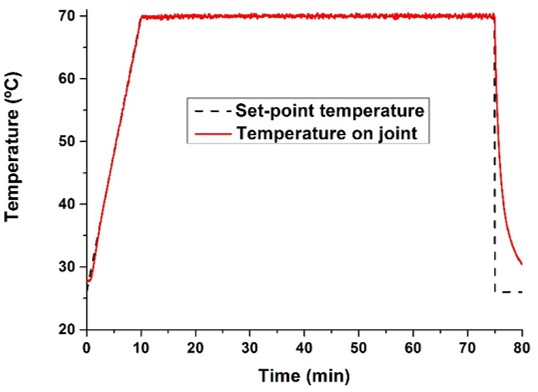

There is an increasing interest in the use of resistive (Joule) heating to process polymeric materials as a technology to enable rapid manufacturing, more energetically efficient fabrication, and reduced cost for repairs.

Resistive processing of polymer has direct application for adhesive bonding and for the repair of structural composites, for example.

Technology description

Some of the benefits of this technology include:

- Reduction in power/energy used to cure thermosets

- Reduction in curing time

- Suitable for repair of structural elements with minimum intervention

- The conductive filler reduces polymer “bleeding” when used as an adhesive.

The technology offered is based on resistive heating of polymer formulations with a very small fraction of conductive nanocarbon materials. Processing of the polymer can be carried out with conventional power supplies, either with AC or DC. Heating rates as high 740° C/min can be achieved.

Contact

Knowledge & Technology Transfer Department, IMDEA Materials Institute

email: techtransfer.materials@imdea.org

telephone: +34 91 5493422