- A breakthrough in architected superelastic nitinol opens new possibilities for next-generation biomedical devices and minimally invasive surgical systems.

- The design-driven approach also paves the way for advanced actuators in robotics, aerospace and other high-performance engineering applications.

At first glance, few materials would seem to have less in common than metals and textiles.

And yet, by manufacturing nickel-titanium alloys as a highly deformable, interwoven material, more similar to fabric than a typical metal component, researchers from IMDEA Materials Institute and the Technical University of Madrid (UPM) have unlocked previously unachievable properties.

By applying a design-focused methodology, the research team, were able to dramatically increase the deformability of woven superelastic nitinol metamaterials in a recent study.

The results, highlighted in Virtual and Physical Prototyping, hold promise for the development of high-performance actuators in robotics, aerospace and healthcare, among others.

Nickel–titanium (Nitinol) alloys are well-known for their superelasticity and shape-memory behaviour.

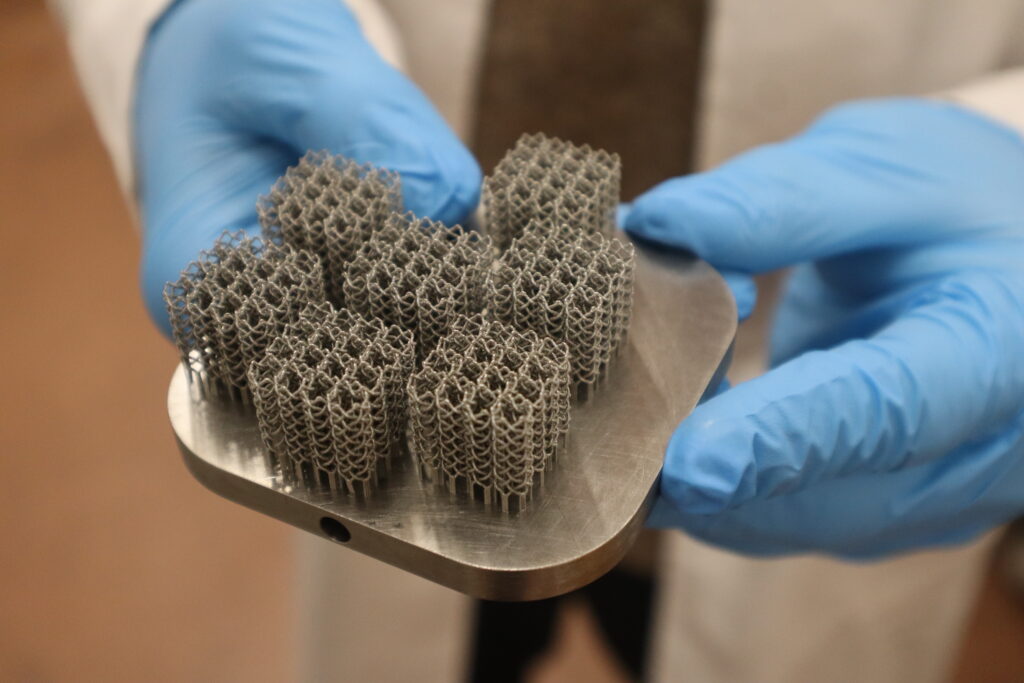

Architected 3D-printed superelastic nitinol lattices.

Their compatibility with more advanced additive manufacturing (3D printing) technologies, however, has been limited. Typically, when processed by 3D printing techniques such as laser powder bed fusion (LPBF), nitinol exhibits reduced elasticity and recoverable strain compared with conventionally manufactured nitinol materials.

“While LPBF remains the gold standard of nitinol additive manufacturing, the shape-memory and superelastic properties of these additively manufactured NiTi parts do not yet match those achieved with more conventional industrial processes,” says Carlos Aguilar Vega, researcher from IMDEA Materials and the UPM, and one of the authors behind the recent publication.

“Effectively, this means that we have so far been unable to harness the enhanced control of mechanical performance by design, or the geometrical complexity offered by 3D printing techniques in the additive manufacturing of nitinol structures”.

Previous studies have shown that the deformability rate of 3D-printed nitinol samples is roughly half that of industrial nitinol produced via traditional processes, with the additively processed powders promoting more brittle materials.

To address this challenge, researchers adopted a design-centred approach, shifting the focus from material optimisation alone to architected structures that amplify mechanical performance through geometry.

They also placed particular focus on highly deformable, woven structures, including meshes, spheres and rings.

“These were some of the most complex-shaped woven nitinol structures ever created”, explains fellow author, Prof. Andrés Díaz Lantada from the UPM and IMDEA Materials Institute.

“Promisingly, they represent a breakthrough in the additive manufacturing of superelastic alloys and demonstrate the possibility of achieving self-supported NiTi wovens via LPBF techniques”.

The study introduces a novel algorithm-based design framework for creating highly deformable interwoven metamaterials, specifically tailored for additive manufacturing of nitinol. Using this approach, two main families of structures were developed and manufactured: tubular lattices and cylindrical woven architectures.

Both design families were successfully printed in superelastic nitinol and systematically characterised. Mechanical testing revealed that, by design alone, the stiffness, load-bearing capacity, energy absorption and toughness of these structures can be modulated across several orders of magnitude.

To ensure printability and structural fidelity, the team combined computed tomography of the printed samples with digital models generated by 3D printing slicer software, enabling a detailed comparison between designed and manufactured geometries.

This multi-scale validation confirms the robustness of the proposed methodology and its suitability for complex, customisable architectures.

“This work represents the first demonstration of design-based optimisation of additively manufactured superelastic nitinol, showing that mechanical drawbacks inherent to current additive manufacturing processes can be effectively mitigated through architecture,” concludes Aguilar Vega.

Fellow researchers behind the breakthrough include IMDEA Materials’ Óscar Contreras, Dr. Muzi Li, Dr. Vanesa Martínez, Amalia San Román and Prof. Jon Molina, in collaboration with the UPM’s Rodrigo Zapata Martínez.

The research presented has been supported by the following research and innovation project: ‘iMPLANTS-CM’, from the‘Convocatoria 2020 de ayudas para la realización de proyectossinérgicos de I + D en nuevas y emergentes áreas científicas enla frontera de la ciencia y de naturaleza interdisciplinar’ fundedby Comunidad Autónoma de Madrid (reference: Y2020/BIO-6756).