Available tests and benefits

Fire testing for planar materials designed to be evaluated as battery enclosure components under extreme thermal and mechanical conditions. The primary test types include:

- Torch fire-only exposure (baseline thermal resistance)

- Combined torch & grit cycles (simulated real-world abuse) by following the UL2596 torch & grit type test standard

- Enhanced safety assurance through early design-stage validation

- Faster time to certification by pre-screening materials

- Provide incident risk reduction in thermal events

- Data-rich reporting for internal or external auditsTest conditions:

| Parameter | Value / range |

| Flame temperature | 800 to 1200 ± 50 °C, with deviation ±50 °C |

| Torch tip to sample surface distance | 60 mm |

| Torch duration | 20 seconds per cycle or >10 minutes for torch flame only test |

| Grit blasting rate | 1.5 ± .15 g/s |

| Grit exposure cycles | 2–10 typical |

| Sample size* | Standard (e.g., 200 ×200 mm) or small samples (100 × 100 mm) |

* Results from a small sample size cannot be comparable with results from a standard sample size.

Test bench features:

- Closed-loop torch control: Precise control of flame temperature and duration.

- Grit injection system: Adjustable velocity for consistent abrasion.

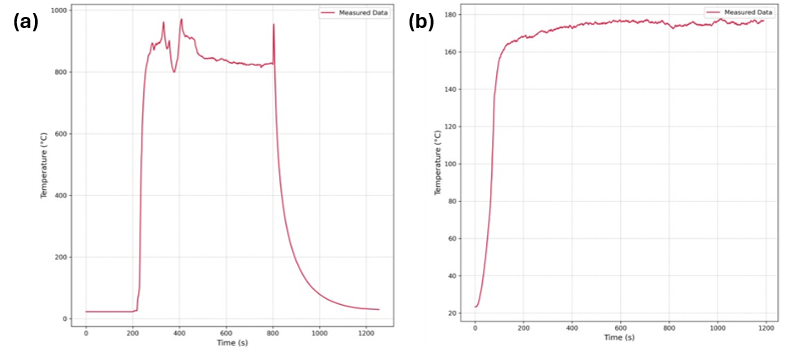

- K-type thermocouples for precise surface and backside temperature measurements

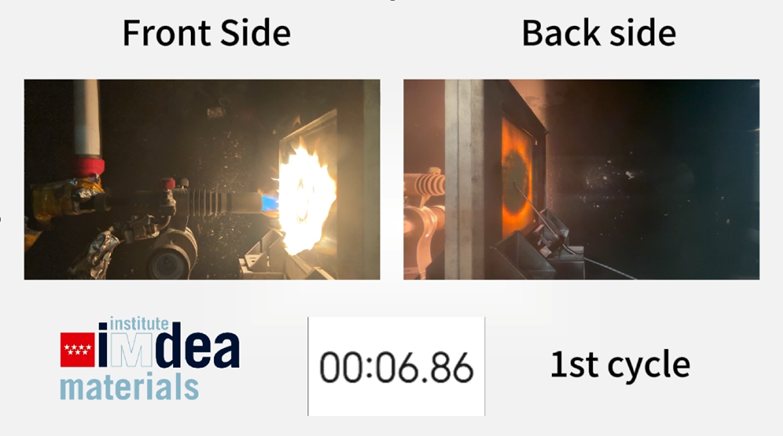

- Digital video recording from both front and rear sides to capture damage evolution during testing

- Data acquisition: synchronised recording of backside temperature versus test time.

Applicable standards:

Tests are based on the following industry standards:

- UL 2596 – Section on Torch & Grit Testing

- GMW 18435 – A General Motors standard

This test result showed material potential for passing the industry certification test in the traction battery pack system-powered electric vehicle sector:

- UL 9540 / 9540A

- GB38031-2025

- UNECE R-100.

Results (Illustrative):

| Material ID | Backside self-ignition | Equilibrium temperature at the end of the test (ºC) | Burn-through | Brun-through cycles |

| A | No | 150 | No | 2 |

| B | Yes | 180 | No | 3 |

| C | Yes | 170 | Yes | 3 |

Comparison vs. industry benchmarks:

Our testing setup includes edge protection for the sample coupons, preventing edge ignition and enabling a more representative evaluation of material fire resistance.

Use cases:

- Thermal runaway venting shielding validation in electric vehicle battery pack components.

- Composite material screening for flame protection

- Design certification for rail, aviation, and energy storage system enclosures

Contact:

To discuss your testing needs and explore collaboration opportunities, please contact IMDEA Materials Technology Transfer and Innovation Office (TTIO) at techtransfer@imdeamaterials.org.