The project

Funding: Regional Government of Madrid, Synergy 2020 call

Region: Madrid

Project period: 2021 – 2024

Principal Investigators at IMDEA: Jon Mikel Molina Aldareguia (jon.molina@imdea.org)

“i-MPLANTS-CM”, printing of metamaterials with shapememory alloys and functional gradients of properties for a new generation of intelligent implants, pusues, as main objective, the development of a new generation of intelligent implants, which will be implanted through minimally invasive procedures and will be able to evolve geometrically with the patients, shifting their shapes, according to the healing, growth and ageing processes. To this end, it is necessary to investigate and develop principles and techniques for the desing and additive manufacturing of metamaterials, using shape memory alloys as raw materials and employing functional gradients, whose innovative structures, biomechanical properties and metamorphic abilities will enable novel interactions with patients.

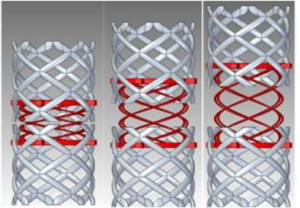

The advances of i-MPLANTS-CM are illustrated with case studies from the cardiovascular realm, by means of designs, prototyping and validation trials of real implants including: unconventional stents for the personalized treatment of complex aneurysms in arterial bifurcations and minimally invasive artificial heart valves with shape morphing capabilities.

Combined employment of metamaterials, with singular properties derived from their microarchitecture, and an additive manufacturing strategy working with shape memory and superelastic alloys will facilitate minimally invasive surgical procedures and sequential changes of geometries for unique metamorphic capabilities. These advantages will derive into a new generation of personalized and smart medical devices that will modify the statu quo in the area of cardiovascular surgery. The mentioned appliances, linked to high performance active implants, will also open new horizons in the larger field of biomedical engineering, beyond cardiovascular applications, as described in the proposal. As for the future, the generated knowledge and developed geometries, materials and processes, will have a remarkable impact

in different sectors including: healthcare, transport, energy and space.

News and events

iMPLANTS-CM seeks to develop smart implants for minimally invasive surgeries

The iMPLANTS-CM project aims to aims to design and manufacture active implants capable of modifying their geometry to enhance minimally invasive surgeries and improve the patients’ healing processes.

Publications

Partners

The Product Development Laboratory of the Technical University of Madrid (LDP-UPM) was founded by Professor Pilar Lafont Morgado in 1997 and, in its more than 20 years of existence, has been dedicated to supporting multiple research, development, innovation, technology transfer and teaching in the Department of Mechanical Engineering of the UPM.

The LDP-UPM provides experience in developing medical devices based on smart materials, the use of 4D printing techniques and the design and manufacture of metamaterials. It is also a pioneering team in the field of open source medical devices. In the last ten years, the LDP-UPM’s research has been focused on developing innovative medical devices based on the use of smart materials and biomimetic geometries by 3D and 4D printing to obtain advanced diagnostic or therapeutic functionalities. During this time, the LDP-UPM has contributed to the success of 30 research projects, with Prof. Díaz Lantada as PI on 20 of them.

IMDEA Materials Institute (IMDEA) is a non-profit research institute (~120 researchers) devoted to carry out research in Materials Science and Engineering in Madrid (Spain). IMDEA is committed to the excellence in research and to foster technology transfer to the industrial sector. IMDEA holds a well-established international reputation in the areas of processing, microstructural analysis, characterization and multiscale modelling of advanced materials for applications in transport, energy and information technology as well as on the exploration of emerging materials and processes for sustainable development. Research activities and technology transfer to industry at IMDEA is carried out within the framework of research projects funded by national or international organizations or directly through contracts with industry. Currently, IMDEA participates in 50 EU research projects (11 as a coordinator) and has 70 direct R&D contracts with industrial companies.

The main research activities of IMDEA Materials Institute within frame of the i-MPLANTS project focus on additive manufacturing with high performance materials and active alloys.

Funded by

The project Y2020/BIO-6756 i-MPLANTS-CM runs from 01/07/2021 to 30/06/2024.

Contact us

IMDEA Materials Institute (project Coordinator)

Eric Kandel, 2 Tecnogetafe

28906, Getafe, Madrid (Spain)

Phone: (+34) 91 549 34 22

Fax: (+34) 91 550 30 47