Patent details

Status

European patent filed

Application number

EP22382656.1

Priority date

11 July 2022

Inventors

De-Yi Wang, Xuebao Lin

Applicant

IMDEA Materials Institute

Transfer opportunity

License of technology

The challenge

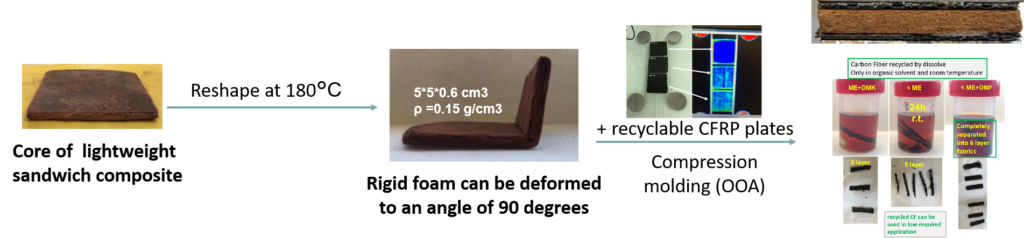

One of the most important trends in the lightweight composites industry is the low-cost and low-energy consumption of out-of-autoclave processes of sandwich composites and the possibility to recycle or reuse high-value raw materials. Especially for large-scale products with complex curved shapes, it is still a big challenge to assemble rigid foaming cores before processing. Therefore, the lightweight composites industry demands novel rigid foaming cores that are shapeable, recyclable and easy to process, at the same time that they comply with lightweight and mechanical requirements, and integrate other functionalities such as flame retardancy, thermal and/or sound insulation.

Technology developed

IMDEA Materials has developed a range of vitrimer-based composite foams, that are recyclable, re-shapeable even after the first curing cycle by out-of-autoclave processing (click to watch video showing shapeability).

Depending on the nature of the resin and its additives, the foams prepared can combine densities between 120-250 g/m3, compressive strength of 0.8-2 MPa, heat resistance between 80-150 ˚C, thermal conductivity of 0.04-0.08 W/m·k., and V-0 flame retardancy level under UL-94 standard test.

10 mm foams were used to prepare sandwich composites with areal density between 6-7 kg/m2, compressive strength of 2 MPa, flat tensile strength between 0.2-0.3 MPa, thermal conductivity of 0.06 W/m·K and V-0 flame retardancy level.

Potential benefits

The proposed technology provides the following benefits:

- Potential to be used as interior parts in different sectors ranging from railway, to marine transport, aerospace and construction.

- The resulting sandwich structures are fully recyclable by a method included in the patent application.

- Versatile technology in terms of manufacturing: the core can be shaped and then laminated, or viceversa.

- Compliance with regulations in terms of recyclability, fire retardancy and mechanical properties.

Stage of development

A European patent application (PCT deadline in July) has already been presented for this technology. The current TRL for the invention is 3.

Ackowledgement

This technology has been developed in the project TESCOM: Tailored Lightweight Sandwich Composites with Multifunctional Properties and Good Designability: From Molecule-design to Structure-properties Relationship.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Sklodowska-Curie grant agreement No 895931.

Contact

Knowledge & Technology Transfer Department, IMDEA Materials Institute

email: techtransfer.materials@imdea.org

telephone: +34 91 5493422