Summary

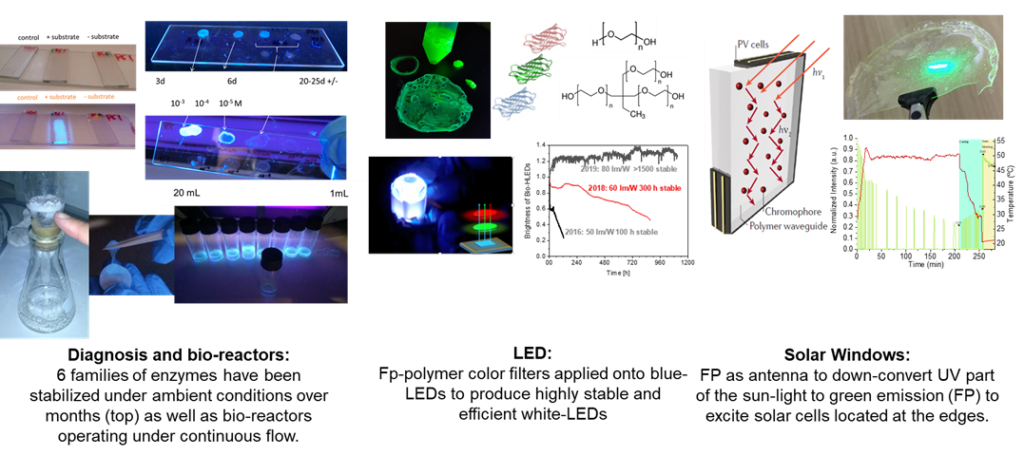

IMDEA Materials has developed both, a family of flexible and rigid polymer coatings, in which fluorescent proteins (FPs) and enzymes are easily introduced as well as a dehydration process further transform the coatings into a rubber/rigid material without chemical cross-linking. In all cases, the bio-functionality is preserved over years under ambient conditions and several months under device/reactor operation conditions. The device applications involve i) color filters for color down-conversion applications in lighting – LEDs replacing current IP and displays replacing toxic Cd QDs, ii ) biodiagnosis replacing substrates to stabilize active compounds, iii) bioreactors in continuous flow , iv) coating for solar concentrators, and v) medical devices for phototherapy treatment.

Description

The EU priority action lines state the need of low-cost production and efficient consumption of electricity, while the EU Sustainable Development Strategy Commission strongly encourages the further advance of PVs and LEDs following the “green photonics” concept: development of eco-friendly and highly stable materials for an efficient generation and use of the energy. In this context, the use of bio-molecules as operational compounds is a major challenge. The major limitation is their quick denaturation caused by light and temperature stress under device fabrication and operation conditions. However, their distinctive ecological features, such as unlimited low-cost production using bacteria and/or fully recyclable nature, strongly encourage their use as a model of sustainability. These limitations are also noted in bio-diagnosis, phototherapy, and bio-reactors. Here, stability and access of active bio-compounds is critical, hampering the commercial jump of many approaches. In addition, the working conditions also require low temperatures and irradiations.

The problem statement relates to an urgent need for effective strategies to use biomolecules directly extracted from bacteria as functional components for developing sustainable and stable medical and energy-related technologies. This approach must ensure i) an excellent stability of the biofunctionality under storage and device operation conditions and ii) the use of 3D substrates and/or miniaturization.

IMDEA Materials has developed both, a family of flexible and rigid polymer coatings, in which fluorescent proteins (FPs) and enzymes are easily introduced as well as a dehydration process further transform the coatings into a rubber/rigid material without chemical cross-linking. In all cases, the bio-functionality is surprisingly preserved over years under ambient conditions and several months under device/reactor operation conditions.

Advantages and innovations

Energy-related applications: Use of color filters based on FP emitters or antennas for lighting and photovoltaic.

- Replacement of IPs in white-emitting LEDs.

- Patent-free production of FP (<0.1 $/gr, low purification level, PLQY>80%).

- High color rendering index (CRI>95) with narrow emissions (30-50 nm).

- High efficiencies higher than 100 lm/W.

- High stability of FP coatings under operation:

- Low power LEDs: >150 days to reach L50.

- High power LEDs: >10 days to reach L50.

- Easy 3D printing to develop microstructured filters for displays.

- Replacement of Cd-QDs for solar windows.

- Large Stoke-shift FPs with high PLQYs >70%.

- Long range light-guiding.

- Self-healing upon day-night cycles.

- Device efficiencies over 5%.

Medical and diagnosis applications: Use of polymers to stabilize enzymes and FPs

- Long term stability of bio-compounds (enzymes, etc.) over months under ambient conditions.

- Low detection (10-7 M depending on the type of regnant).

- Large volume of conversion (>50 mL) at low operation times (<1min).

- Efficient light-scattering for phototherapy.

Supplementary data

Application: The device applications involve i) color filters for color down-conversion applications in lighting – LEDs replacing current IP and displays replacing toxic Cd QDs, ii ) biodiagnosis replacing substrates to stabilize active compounds, iii) bioreactors in continuous flow , iv) coating for solar concentrators, and v) medical devices for phototherapy treatment.

Intellectual property rights: Family of International Patent Applications

Transfer Opportunity: License of technology

Reference:

Contact

Knowledge & Technology Transfer Department, IMDEA Materials Institute

email: techtransfer.materials@imdea.org

telephone: +34 91 5493422