Miguel Ángel Rodiel, IMDEA MATERIALS y Juan José Vilatela, IMDEA MATERIALS

Did you know that a modern electric vehicle contains, on average, 80kg of copper? Or that an airplane can have up to 7.5 tons of this metal, and an offshore wind turbine as much as 24 tons?

In the energy transition towards a more sustainable future, copper is an essential material. The International Energy Agency (IEA) states that we are leaving fossil fuels behind and entering a new “era of electrification.” It is projected that, by 2030, half of the world’s electricity demand will come from low-emission sources.

But a critical question arises: Do we have enough raw materials, such as copper, to achieve this transition?

A Material with Over 10,000 Years of Use

Now referred to as the “metal of electrification,” humans have been using copper since 8,000 BCE.

Highly conductive, malleable, corrosion-resistant, and easy to shape, copper has had invaluable properties since its use in early tools, extending to modern industrial, household, and technological applications.

Even in the 21st century, it remains the only critical mineral present in all major clean energy technologies: electric vehicles, solar photovoltaic and wind energy, power grids, etc.

In electric vehicles, copper is found in the anode current collector of lithium-ion batteries, battery wiring, and some key motor components.

The demand for refined copper is expected to rise from nearly 26 million tonnes (Mt) in 2023 to around 40 Mt by 2040 in the net-zero emissions (NZE) scenario.

This is mainly due to the rapid deployment of electric vehicles, along with the growth of renewable energy and a significant expansion of power grids. Additionally, copper is critical for the development of digital technologies that are being implemented at a rapid pace worldwide.

Artificial intelligence-based technology processes large volumes of data and executes complex calculations, requiring more powerful and faster computers with significantly higher energy consumption.

Since copper is a key material in these devices due to its excellent conductivity and thermal dissipation capacity, this increase in energy consumption will drive its demand in data centers, which is expected to grow up to sixfold by 2050. Therefore, ensuring copper supply is crucial for the green and digital transition that Europe is promoting.

Supply Deficit

Despite its importance, IEA analysis indicates a potential primary copper supply deficit starting in 2025. Even considering expected growth in secondary supply (recycling), this shortfall could reach 4.5 Mt (20%) to meet the NZE scenario demand in 2030.

And these deficits will continue to grow. By 2040, copper supply will need to double compared to current levels to meet the Paris Agreement target of limiting global temperature rise to 1.5°C by 2050.

Moreover, copper prices will be heavily impacted by these circumstances. In fact, the cost per tonne has already risen from around €2,000 in 1990 to €10,000 from 2020 onwards.

Alternatives to Copper as a Conductive Material

There are alternative materials that could ease the pressure on copper. Among them, aluminum is the most studied option. Although it has only 60% of copper’s conductivity, its abundance and low density make it an attractive conductor, especially for transmission cables and increasingly in electric vehicles and wind turbines. In applications where weight is a critical factor, such as in the automotive and aerospace sectors, aluminum is already replacing copper to a large extent.

However, there are applications where copper cannot be replaced, such as anode current collectors in batteries, because lithium forms an alloy with aluminum at low potentials.

In power grids, aluminum’s lower electrical conductivity requires thicker cables, which increases weight. Combined with its inferior thermal and mechanical properties, this results in higher maintenance needs.

Lastly, aluminum processing is nearly five times more energy-intensive than copper refining.

Advanced alloys such as Al-Cu (aluminum-copper), Cu-Al (copper-aluminum), or Au-Cu (gold-copper) could also offer technological solutions for specific applications.

Al-Cu alloys have greater mechanical strength than pure aluminum and good corrosion resistance. However, their electrical conductivity is significantly lower (~40-50% of copper’s), limiting their use to structural and aerospace applications where mechanical strength is prioritized over conductivity.

Cu-Al alloys offer excellent corrosion resistance, particularly in marine environments, and better wear resistance than pure copper. Yet, once again, their lower electrical conductivity (only 30-40% of pure copper’s) restricts their use in electrical conductors to very specific applications.

Carbon Nanotubes as a Solution

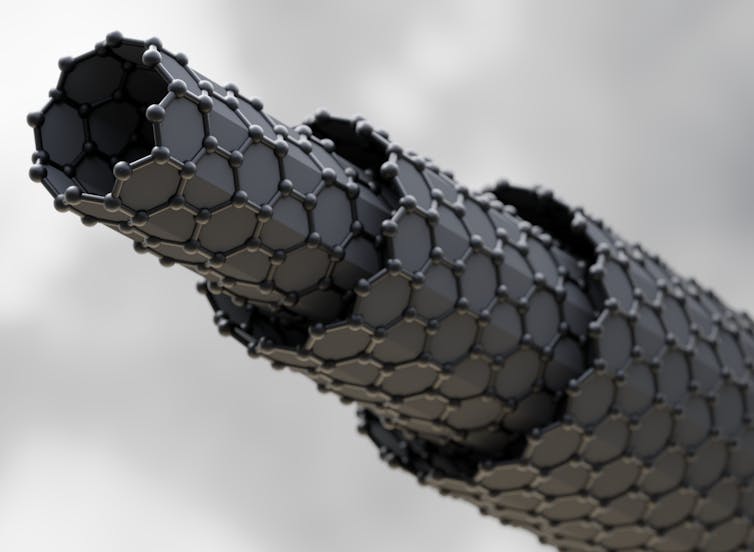

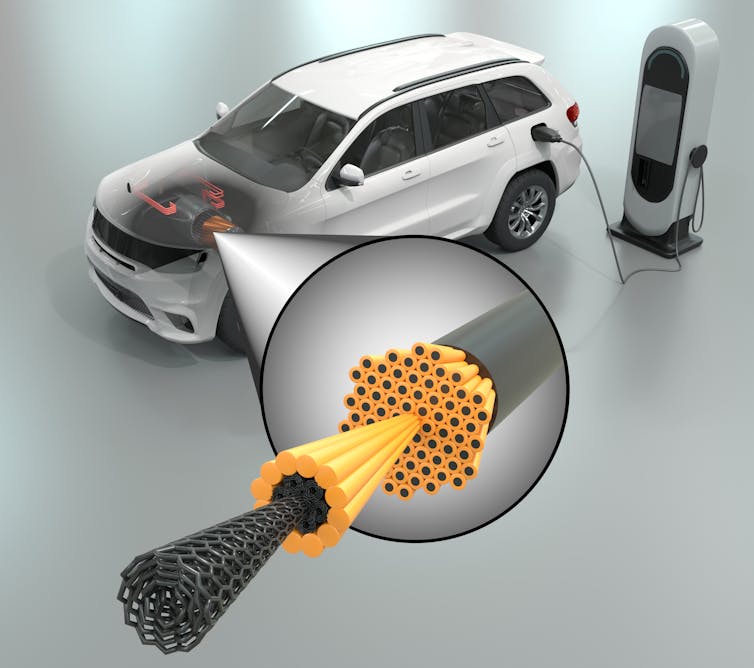

In this context, one of the most promising materials is carbon nanotubes (CNTs).

Advances in nanotechnology and advanced manufacturing are making CNT cables a highly interesting and viable alternative to copper scarcity.

Continuous CNT cables several kilometres long have already been successfully produced, offering an exceptional combination of properties (higher conductivity than copper, superior thermal and mechanical resistance) ideal for the energy transition’s demands.

These materials can be used in long-distance power transmission, electrical contacts, high-strength cables, ultra-lightweight cables, motor component coils, and more.

Additionally, as a byproduct of the manufacturing process for these cables, hydrogen is generated, which can be collected and used as a clean energy source.

Calculations indicate that hydrogen can be obtained through the direct splitting of natural gas (methane) using eight times less renewable energy than “green” hydrogen produced via water electrolysis.

From an end-of-life perspective, these materials are fully recyclable, with minimal loss of properties in fibers made from recycled CNTs.

Although it may seem paradoxical, manufacturing conductive materials based on carbon nanotubes offers an innovative solution for decarbonizing the economy—using carbon, such as natural gas, to generate hydrogen efficiently.

This technology not only enables more efficient use of fossil resources but also provides a sustainable way to harness them, contributing to a greener future and reducing dependence on burning fuels.

Miguel Ángel Rodiel, Director of Projects and Technology, IMDEA MATERIALS y Juan José Vilatela, Senior Researcher, IMDEA MATERIALS

This article was originally published in Spanish in The Conversation. Read the original.