Fibre-reinforced polymers are extensively used in the automotive, aerospace and energy industries for structural applications. The interest in Liquid Composite Molding (LCM) processes, for the production of composite materials has grown in the last years, especially in the vacuum assisted resin transfer moulding (VARTM) process due to its relative low cost and the possibility to process large panels, for example for wind turbine blades.

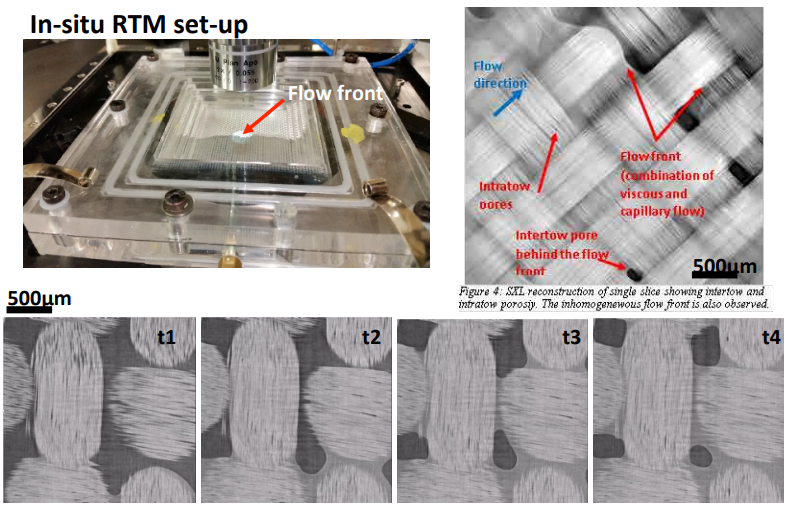

Fibre infiltration during XCT measurements, allows to investigate the infiltration process and characterize the formation and transport of pores in the process in 4D. Several parameters such as resin velocity, resin viscosity, application of vacuum pressure, the dual scale flow behavior and its effect on the microstructure can be accurately studied by these in-situ XCT measurements. The figure below shows the set-up of the experiment developed at IMDEA for laminography experiments and fast-tomography experiments.

Time sequence as obtained from XCT in the same slice in-situ RTM.