Patent details

Status

US patent application filed, PCT extension.

Inventors

(IMDEA Materials Institute): Afshin Pendashteh and Juan José Vilatela García.

Application number

63/625,641, PCT/US25/13097

Applicant

William Marsh Rice University and IMDEA Materials Institute.

Priority date

26/01/2024

Transfer opportunity

License of technology

Summary

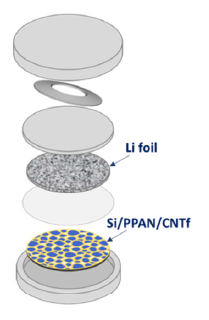

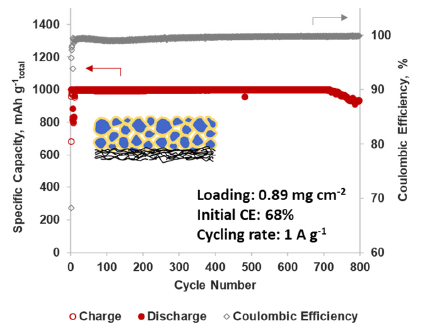

A self-standing lithium-ion battery (LIB) anode that replaces heavy copper current collectors with ultralight, nonwoven carbon-nanotube fabrics (CNTf), combined with a high-capacity silicon/pyrolyzed-polyacrylonitrile (Si/PPAN) active matrix. The resulting Si/PPAN/CNTf composite (Figure 1) achieves 1,000 mAh g⁻¹ (by total anode mass) at 1 A g⁻¹ for over 700 cycles, while slashing inactive mass. Modelling predicts a ~25 % cell-level energy density boost with commercial cathodes, transforming next-generation high-energy LIB design.

Advantages and Innovations

- Elimination of Heavy Collectors: replaces 8.6 mg cm⁻² Cu foil with 0.14 mg cm⁻² CNTf → ∼98 % reduction in inactive mass.

- Extended Cycle Life: Maintains 1,000 mAh g⁻¹ (total mass) at 1 A g⁻¹ for >700 cycles; Coulombic efficiency >99.5 %. (Figure 2)

- Mechanical Integrity: Cross-section SEM/EDX and peel tests reveal robust Si/PPAN–CNTf adhesion (~3.5 N m⁻¹).

- High Effective Rates: Stable performance up to 6 A g⁻¹; rapid recovery upon rate reduction.

- Scalable & Green: FC-CVD CNTf and spray-coating are roll-to-roll compatible. CNT replacement of Cu may drastically cut CO₂/yr from LIB manufacturing.

Figure 1: Schematic of coin-cell assembly against Li electrode using Si/PPAN/CNTf anodes.

Figure 2: Electrochemical cycling of Si/PPAN/CNTf half-cells with Li. Capacity control cycling at 1 A g-1.

Contact

Technology Transfer and Innovation Office, IMDEA Materials Institute

Email: techtransfer@imdeamaterials.org

Telephone: +34 915 493 422