Main research lines

- Multiscale characterisation with optical and electron microscopy, X-rays, atom force microscopy, Raman spectroscopy, ultrasonic inspection. Some of the equipment we use for this are:

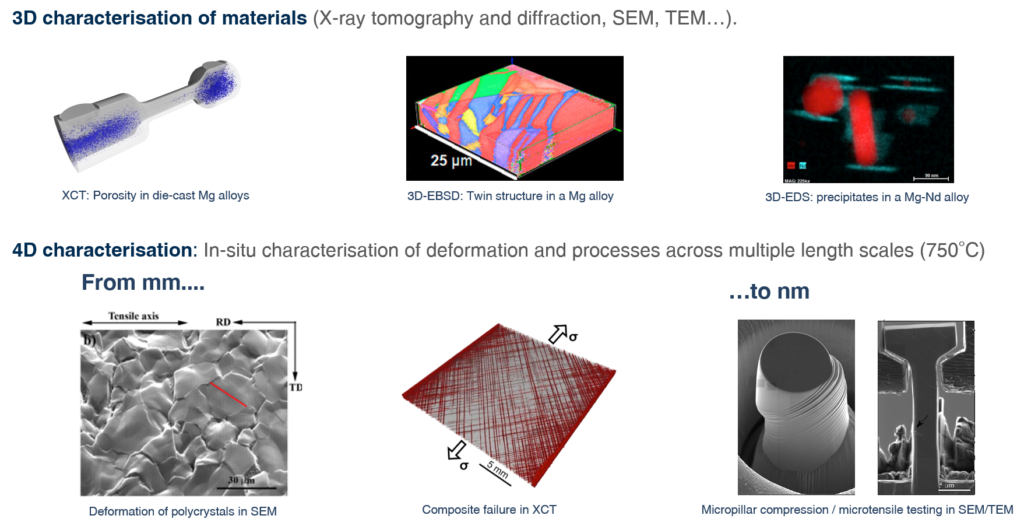

- FIB-FEG-SEM, including 3D-EDS and 3D-EBSD. In-situ stages for thermomechanical testing.

- FEG-TEM including 3D-STEM and 3D-EDS with in-situ stage for mechanical testing.

- X-Ray Tomograph (XCT) with in-situ stage for thermomechanical testing, furnaces for thermal treatments and observation of chemical reactions, in-situ composite curing, in-situ composite infiltration.

- X-ray Diffractometer (XRD) equipped for residual stresses and texture determination, reflectometry analysis, Cu and Cr radiation, linear detector, in-situ furnace.

- Raman micro-spectrometer 5x, 20x, 50x, 100x microscope objectives, 532 nm Nd:YAG laser (50W) and diffraction grating of 1800 l/mm, 100 nm resolution.

- Characterisation of broad range of materials, e.g. biomaterials, plastics, metal matrix composites, fibre reinforced composites, metals, nanomaterials, etc.

- Use of large facilities such as neutron or synchrotron radiation facilities for characterisation.

- Development of new methodologies (e.g. hardware for in situ testing and software tools) for material characterisation and analysis, also applying artificial intelligence methods.

- Spectroscopic/microscopic studies and implementation in electrochemical energy storage devices such as Li-ion, Na-ion, Li-S and Li-O2.

- Thermo-mechanical testing across several length scales: tension, compression, fatigue, creep, etc. in the scanning electron microscope and X-ray tomograph.

- Properties and deformation mechanisms of small volumes by nanomechanical testing in the scanning and transmission electron microscopes: properties of metallic phases, interfaces, nanoparticles, carbon-based nanomaterials (carbon nanotubes, graphene, etc).

- Elevated temperature nanomechanical testing.

- 4D characterisation of processes by X-ray tomography and X-ray diffraction: e.g. metallic alloy solidification, metallic alloy phase formation and chemical reactions, infiltration and resin flow in composites, composite curing, etc.

- Digital modelling from 3D structures.

- Integration of experimental statistical measurements into models.

- Experimental confirmation of modelling results.

- Experimental design based on models.