In this project, IMDEA Materials will collaborate with several European partners to produce soft magnetic components by 3D-printed, metallic glasses.

Metallic glasses present excellent mechanical and magnetic properties and, in combination with additive manufacturing, open the door to producing highly efficient electric motors.

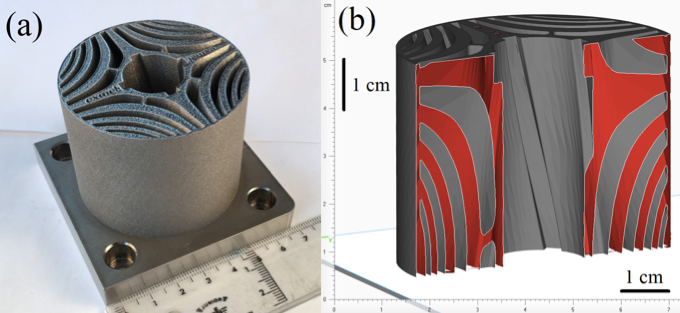

To prove that, the project partners expect to demonstrate the superior operating efficiency of an electric motor comprised of soft-magnetic stator and rotor components created by means of selective laser melting (SLM) of soft-magnetic bulk metallic glass (BMG) alloys and powders, specifically designed and optimized for the additive manufacturing process.

The AM2SoftMag technology will substantially impact the technological potential of electric vehicles through the design of powdered amorphous soft-magnetic alloys, the optimization of SLM process parameters and the verification of resulting electromagnetic devices.

The project will achieve significant breakthroughs in the flexible and energy-efficient production of superior soft-magnetic components, allowing a radical reduction in global fuel consumption and noise and air polluting gases (CO2 and NO2) in cities over the next 10 to 15 years.

The kick-off meeting was celebrated in Saarbrücken, on the 8th and 9th of June. As well as IMDEA Materials Institute, which is in charge of the study of the mechanical properties and metal 3D-printing, the participating partners are:

- the coordinator Universität des Saarlandes (Germany), is in charge of the alloy development of metallic glasses and the design and realization of electromagnetic systems.

- the research centre Istituto Nazionale di Ricerca Metrologica (INRiM, Italy), is in charge of the advanced electromagnetic testing.

- the companies Exmet Ab (Sweden), leading the industrial application of additive manufacturing of metallic glasses.

- and Heraeus Amloy (Germany), leading the development of new production technologies for metallic glasses.

The project will contribute to the EU Green Deal and IMDEA Materials’ compromise to the research of sustainable technologies, enabling at least a 50% reduction of energy losses in electromagnetic systems.