Laboratory of materials characterisation and processing in 3D and 4D

The Laboratory of materials characterisation and processing in 3D and 4D is located at IMDEA Materials Institute and is organised into three fundamental units:

- Electron Microscopy Unit

- X-ray Tomography Unit

- Additive Manufacturing Unit

The laboratory’s Scientific Manager is Dr. Juan Pedro Fernández. Each of the units also has the scientific supervision of the senior researchers responsible for each of the research lines.

Types of tests:

- SEM and TEM microstructural characterisation of materiales

- In situ deformation tests in SEM and TEM

- Structural and defect characterization by XCT

- Additive manufacturing of metal parts

Types of materials:

- Composites and nanocomposites

- Polymers

- Metal alloys

- Metal powder

The Laboratory of materials characterisation and processing in 3D and 4D is structured as follows:

Scientific Manager: Dr. Juan Pedro Fernández.

- Electron Microscopy Unit:

Scientific Advisor: Dr. Jon Molina.

Technical Staff: Dr. Manuel Avella.

- X-ray Tomography Unit:

Scientific Advisor: Dr. Federico Sket.

Technical Staff: Dr. Javier García.

- Additive Manufacturing Unit:

Scientific Advisor: Dr. Teresa Pérez Prado.

Technical Staff: Amalia San Román.

- Electron Microscopy Unit:

- Microstructure characterisation via controlled pressure scanning microscopy (SEM).

- Characterisation of deformation and fracture mechanisms through in-situ tests using controlled pressure scanning microscopy (SEM), and mechanical testing machines in metallic and composite materials.

- Characterisation in TEM or STEM mode and chemical analysis performance in EDS; TEM, STEM and EDS mode tomography; in-situ mechanical tests inside the TEM using the Hysitron PIcoindenter PI95 holder.

- Processing of images obtained via electron microscopy.

- X-ray Tomography Unit:

- Characterisation of defects and internal structure by X-ray computed tomography.

- Characterisation of fracture mechanism via in-situ tests using X-ray computed tomography and mechanical testing.

- Processing of volumes obtained via X-ray tomography.

- Additive Manufacturing Unit

- Laser Powder Bed Fusión (LPBF) of metallic alloy samples.

Currently available equipment:

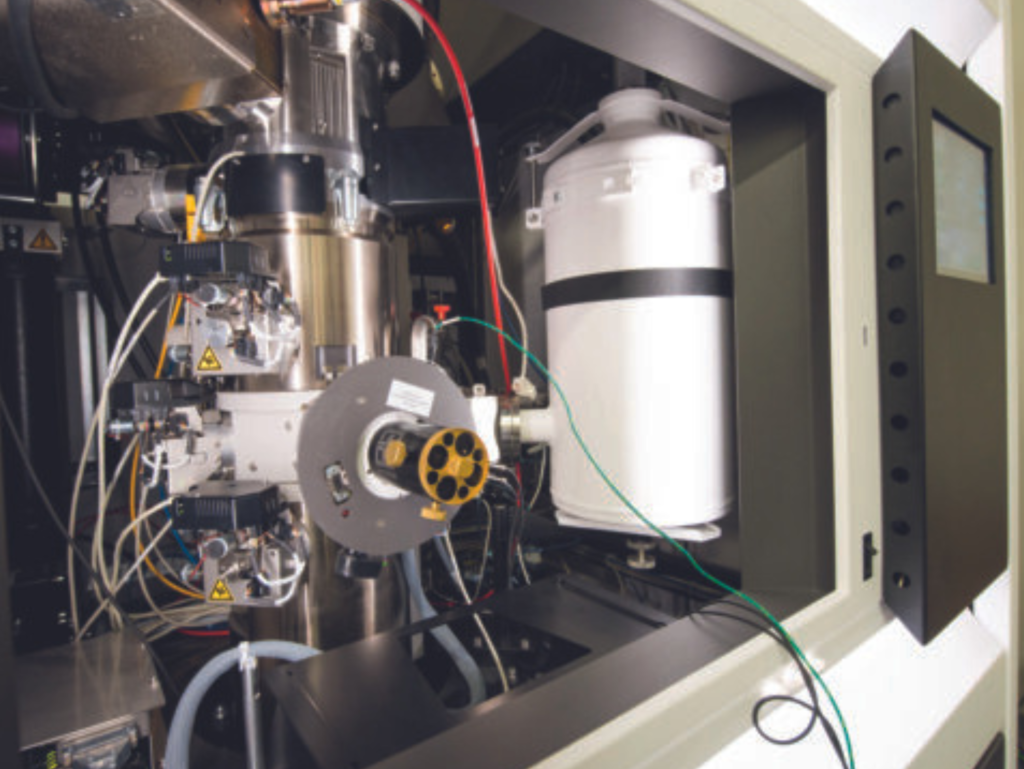

- Electron Microscopy Unit

- Thermofisher Scientific Apreo 2S LoVac FEG SEM microscope, equipped with a NiCol electron column with immersion lens and beam deceleration capabilities. Everhart-Thornley Detector (ETD), in-lens Trinity Detector System (T1,T2,T3), retractable backscatter detector (CBS/ABS), low-vacuum detector (LVD) and GAD-CBS/ABS for low vacuum mode.

For more information about external use of SEM, click here.

- FEI Talos F200X, FEG S/TEM microscope, which integrates a chemical analysis system by energy dispersive spectrometry (EDS), a CMOS digital camera to acquire images with a maximum resolution of 4×4 k, a tomography system to perform tomographies in TEM, STEM and EDS mode and a Hysitron PicoIndenter PI95 holder, to conduct in-situ nano-mechanical tests (S/TEM-Ind).

- For more information about external use of TEM, click here.

X-ray tomography unit

- GE (Phoenix) Nanotom 160 kV with a Hamamatsu 7942-25SK detector (2K x 2K) and tungsten and molybdenum targets, with a nanofocus X-ray source. This equipment is capable of both radiography (RX) and computed tomography (XCT) modes.

- For more information on external use of the X-ray Tomograph PHOENIX, click here.

Zeiss Xradia 620 Versa tomograph with flat panel detector (3k × 2k pixels) and CCD camera (2k × 2k pixels) with the possibility of different objectives (0.4X, 4X, 20X, and 40X). The equipment features a focused X-ray tube with a tungsten emitter and voltage up to 160 kV. This equipment allows for the acquisition of radiographs (RX) and computed tomography (XCT), as well as the possibility of performing diffraction tomography (DCT), which can determine the size and orientation of grains in metallic materials.

For more information on external use of the X-ray Tomograph DCT Versa620, click here.

Additive Manufacturing Unit:

Renishaw AM400 Laser Powder Bed Fusion (LPBF) system for the additive manufacturing of metallic materials (Inconel, Aluminum, High entropy alloys, Nitinol, Nickel) with the following specifications:

- Laser power: 400 W

- Laser thickness: 20 to 100 micrometres

- Spot size: 70 micrometres

- Speed scanning: up to 2 m/s

- Build volume: 248 mm x 248 mm x 285 mm.

- Reduced build volume option available: 55mm x 78 mm x 78 mm

- For more information on external use of the Renishaw LPBF AM400 System, click here.

For further information about current rates for SEM services, click here.

For further information and current rates for TEM services, click here.

For further information and current rates for PHOENIX X-ray tomography services, click here.

For further information and current rates for Zeiss Xradia 620 Versa tomography services, click here.

For further information and current rates for Additive Manufacturing, click here.

The rates for the rest of the services will vary depending on the characterization work required (type of material, type of tests, number of samples, test standards, etc.).

Location

IMDEA Materials Institute

C/ Eric Kandel, 2

Tecnogetafe

28906, Getafe, Madrid (España)

Telephone: (+34) 91 549 34 22

Equipment