A strategy to construct multifunctional ammonium polyphosphate for epoxy resin with simultaneously high fire safety and mechanical properties

First Year Assessment of Carolina Pereira, entitled “Self-Reinforced PLA composites for biomedical applications” – 21st of October, 2021 – 12:00 pm

ABSTRACT: This First Year Assesment is focused on the development of biodegradable self-feinforced composites to be used in biomedical applications. Self-reinforced composites are considered a new class of composites in which a single type of polymer (or family) acts as both reinforcement and

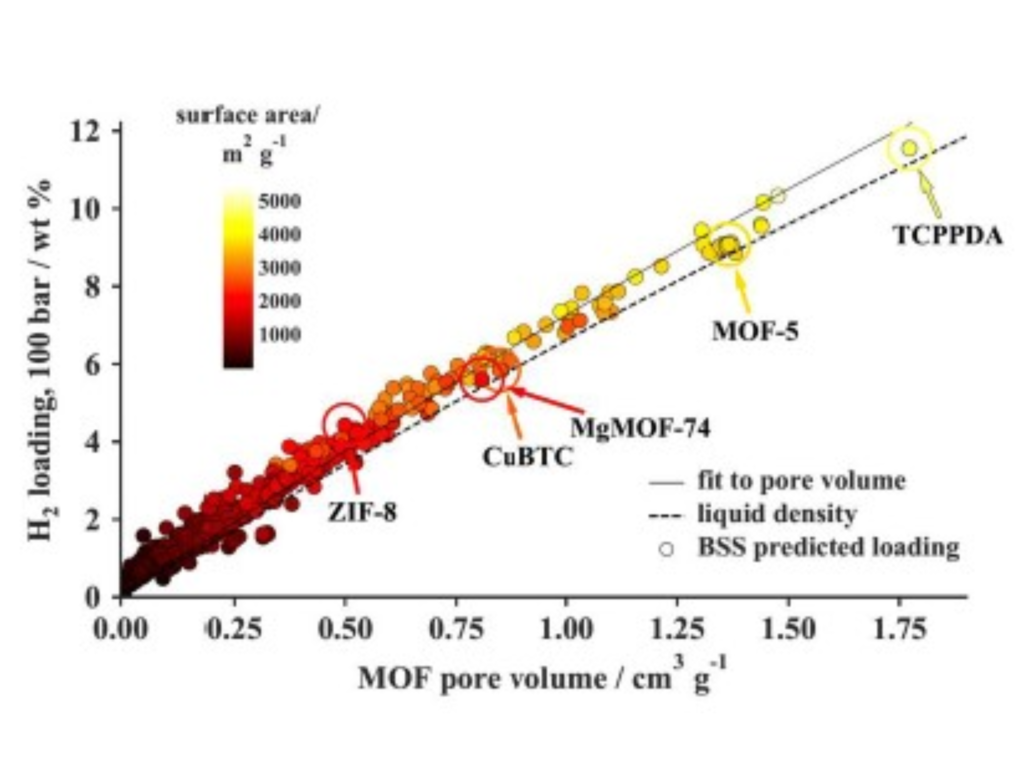

Scientific Highlight: Computational discovery of hydrogen storage materials

IMDEA Materials has know-how and experience in developing computational high-throughput screening workflows for discovery of hydrogen storage materials. Our focus has been mostly directed towards advanced porous materials such as metal organic frameworks and related materials (Fig. 1). Our

Microstructural sensitivity and deformation micro-mechanisms of a bimodal metastable beta titanium Ti-7Mo-3Nb-3Cr-3Al alloy

(i-MPLANTS) Metamaterial printing using shape memory alloys and functional gradients for a new generation of smart implants

The project Funding: Regional Government of Madrid, Synergy 2020 callRegion: MadridProject period: 2021 – 2024Principal Investigators at IMDEA: Jon Mikel Molina Aldareguia (jon.molina@imdea.org)"i-MPLANTS-CM", printing of metamaterials with shapememory alloys and functional gradients of

Enhanced Mechanical and Thermal Resistances of Nanoimprinted Antireflective Moth‐Eye Surfaces Based on Poly Vinylidene Fluoride/TiO 2 Surface Nanocomposites

IAB Talk: The next technology to make aviation cleaner by Jaime Fernandez Castañeda; October 27th, 2021

Within the framework of the different initiatives of the IMDEA Materials´ Industrial Advisory Board (IAB), we are pleased to invite you to the talk of Jaime Fernández Castañeda, Head of Research and Technology of ITP Aero. The talk, entitled “The next technology to make aviation cleaner” will take

First Principles Prediction of the Al-Li Phase Diagram

PhD Defense of Venkata Sai entitled «Nanoscale engineered electrode materials for high performance lithium-ion batteries» – October 15th, 2021, at 11:00 am.

The PhD Defense will take place the 15th of October, at 11:00 am in the “Sala de Grados, modulo 8, Facultad de Ciencias” of the Autonomous University of Madrid. The dissertation is entitled “Nanoscale engineered electrode materials for high performance lithium-ion batteries”. It was advised by

Failure of refractory masonry material under monotonic and cyclic loading-Crack propagation analysis

Development of high performing polymer electrolytes based on superconcentrated solutions

Effect of Al content on the hardness and thermal stability study of AlTiN and AlTiBN coatings deposited by HiPIMS

Editorial: Latest Developments in the Field of Magnesium Alloys and Their Applications

CNSTech project to develop the next generation powder metallurgy based CoNi superalloys gets underway

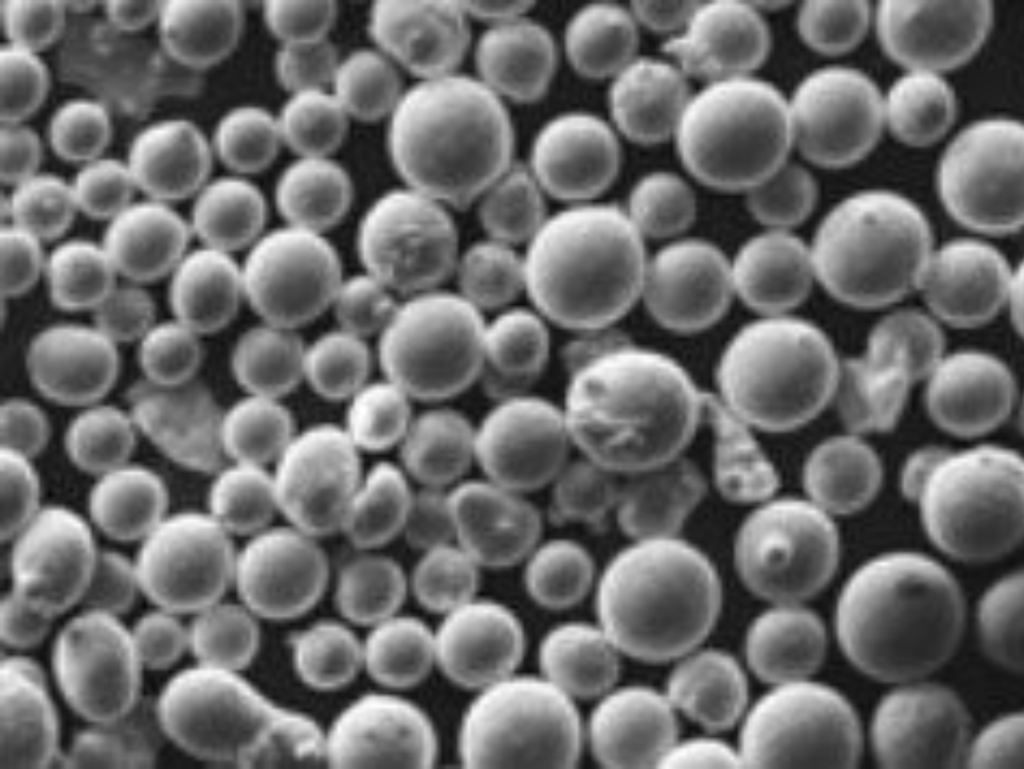

The project CNSTech (Development of gamma prime strengthened CoNi based superalloy for advanced sustainable manufacturing technologies) starts 1st of October 2021 and it will last 24 months. The aim of this project is to development of the next generation Powder Metallurgy (PM) based CoNi

First Year Assessment of Jorge Valilla, entitled “Physical and thermodynamic simulation of Functionally Graded Materials” – 4th of October, 2021 – 4:30 pm.

On Friday, 4th of October, Jorge Valilla will present his FYA entitled "Physical and thermodynamic simulation of Functionally Graded Materials". It will be a fully remote (zoom) event, at 4:30 pm: https://us02web.zoom.us/j/86733563907 Abstract: With the up and

High-rate and ultralong-life Mg-Li hybrid batteries based on highly pseudocapacitive dual-phase TiO2 nanosheet cathodes

(CNSTech) DEVELOPMENT OF GAMMA PRIME STRENGTHENED CONI SUPERALLOY FOR ADVANCED SUSTAINABLE MANUFACTURING TECHNOLOGIES

Funding: European Union, Marie Skłodowska-Curie Individual Fellowships, Horizon 2020 Programme (Grant Agreement 101028155 )

First Year Assessment of Carmen Martínez, entitled “The effect of mechanical strains on the catalytic activity of transition metals for the hydrogen evolution and the oxygen reduction reactions.” – 1st of October, 2021 – 10:00 am

Abstract: Catalysts design has been one of the most relevant issues for the hydrogen economy during decades, especially for the hydrogen evolution reaction (HER) and the oxygen reduction reaction (ORR). These catalytic processes are controlled by the electronic structure of the catalyst, that can

Low-melting phosphate glasses as flame-retardant synergists to epoxy: Barrier effects vs flame retardancy

First Year Assessment of Venkatesh Sivagnana, entitled “New high entropy alloy formulations developed using advanced powder metallurgy routes for high temperature applications” – 1st of October, 2021.

Abstract: High entropy alloys (HEAs) have recently garnered significant research attention due to the variety of properties they offer, including high strength, fracture resistance, thermal stability, wear resistance, corrosion resistance and irradiation resistance. When it comes to processing of

Nanocarbon-Based Flame Retardant Polymer Nanocomposites

Seminar of Prof. Johan Christensen from the Carlos III University of Madrid, entitled “Vibrant future for acoustic and mechanical metamaterials” – 24th of September, at 12:30 pm in the Auditorium.

Abstract The boost experienced by acoustic and mechanical metamaterial research during the past years has been driven by the ability to sculpture the flow of sound waves and vibrations at will. Metamaterials, which come in all kinds of shapes and forms, have initially been designed for

Precipitation-induced transition in the mechanical behavior of 3D printed Inconel 718 bcc lattices

On a nonlinear rod exhibiting only axial and bending deformations: mathematical modeling and numerical implementation

A stochastic solver based on the residence time algorithm for crystal plasticity models

3D bioprinting of molecularly engineered PEG-based hydrogels utilizing gelatin fragments

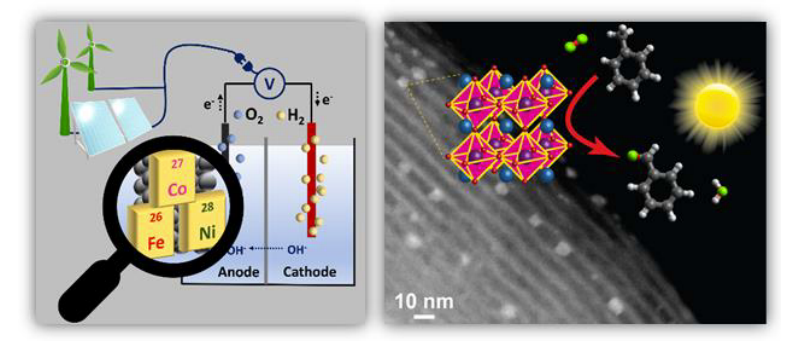

Seminar of Dr. Harun Tüysüz from Max-Planck-Institut für Kohlenforschung in Germany, entitled “Tailor-made Nanostructured Catalysts for Photo- and Electro-chemical Energy Conversion” – 22nd of September, at 12:00 pm in the Auditorium.

Abstract: The particular research interest of the speaker is the design and development of well-defined nanostructured materials and studying their structure-activity relationships for sustainable energy related catalytic transformations. After a brief introduction, the focus of the first part

Identification of Collapsed Carbon Nanotubes in High-Strength Fibers Spun from Compositionally Polydisperse Aerogels

Investigation of the Effect of 475 degrees C Aging Treatment on Mechanical Properties of a Fe-19Cr-5.5Al ODS Alloy Using Tensile, Impact and Small Punch Tests

Composite Fabrics of Conformal MoS2 Grown on CNT Fibers: Tough Battery Anodes without Metals or Binders

Icosahedral quasicrystal-enhanced nucleation in Al alloys fabricated by selective laser melting

Alumni Newsletter Nº 7

Click in the image to access the full newsletter

Webinar: “On the use of machine learning for smart manufacturing of structural composites”

Next 29th of September, Prof. Carlos D. González will present some of the work done in his research group, under the title of “On the use of machine learning for smart manufacturing of structural composites”. The webinar, which will run through the Zoom platform, will cover the following topics:

An FFT-based approach for Bloch wave analysis: application to polycrystals

Science, the planet’s best ally: IMDEA Institutes ensuring sustainable development

We all have a responsibility to try to preserve our environment as best we can. However, if you are involved in research, your responsibility is even greater. At least that is what the researchers at the IMDEA Institutes believe. They will show what projects they are carrying out to ensure a

(BIOFIRESAFE) BIOBASED, SELF-REINFORCED AND FLAME RESISTANT ALL-SOLID-STATE POLYMER ELECTROLYTES FOR NEW GENERATION FIRE-SAFE BATTERY

Project details Funding: Ministerio de Ciencia e Innovación - Plan Estatal de Investigación Científica y Técnica y de Innovación 2017-2020- Subprograma Estatal de Generación de Conocimiento Project coordinator: IMDEA MaterialsProject period: 01/09/2021 – 31/08/2024 IMDEA Materials'

Numerical Simulation of Flame Retardant Polymers Using a Combined Eulerian-Lagrangian Finite Element Formulation

Effect of mechanical alloying on the microstructural evolution of a ferritic ODS steel with (Y-Ti-Al-Zr) addition processed by Spark Plasma Sintering (SPS)

IMDEA Materials sets up cell culture and biomaterials lab to research innovative materials for health care

We have set up a cell culture and biomaterials lab to research innovative materials for health care, thanks to Madrid regional Goverment and the state research agency (AEI). This space will allow us to analyse the response of living tissue to new tools, prostheses or devices for medical use, that

Deformation mechanisms of basal slip, twinning and non-basal slips in Mg-Y alloy by micropillar compression

Polyrotaxane: New generation of sustainable, ultra-flexible, form-stable and smart phase change materials

Finite element analysis to determine the role of porosity in dynamic localization and fragmentation: Application to porous microstructures obtained from additively manufactured materials

PhD Defense of Wenliang Feng entitled “Na-ion Hybrid Energy Storage Devices Based on Nanoengineered Electrode” – September 7th, 2021.

The defense will be carried out online on Tuesday, September 7th, 2021, at 12:00 pm. It was advised by Prof. Vinodkumar Etacheri.

Effect of the heat treatment on the microstructure and hardness evolution of a AlSi10MgCu alloy designed for laser powder bed fusion

Realization of High Energy Density Sodium-Ion Hybrid Capacitors through Interface Engineering of Pseudocapacitive 3D-CoO-NrGO Hybrid Anodes

Realization of High Energy Density Sodium-Ion Hybrid Capacitors through Interface Engineering of Pseudocapacitive 3D-CoO-NrGO Hybrid Anodes

High throughput optimization of hard and tough TiN/Ni nanocomposite coatings by reactive magnetron sputter deposition

Seminar of Sergio Sanchez González from Northumbria University in UK, entitled “Metallic materials for biodegradable implants and antimicrobial surfaces” – 22nd of July, at 12:00 pm in the Seminar Room.

Abstract Metallic materials are of interest in the healthcare sector because they can be used for multiple applications including as biodegradable implants and as antimicrobial touch surfaces for hospitals and other healthcare settings. With an ever-increasing demand for materials that need to

Simultaneous improvements in conversion and properties of molecularly controlled CNT fibres

IMDEA Materials celebrates the kick-off meeting of its Industrial Advisory Board

Last June 14th, IMDEA Materials held through videoconference the kick-off meeting of its newly formed Industrial Advisory Board (IAB). The goal of this strategic initiative is to bring together a selected group of R&D industrial leaders, experts in technology transfer and entrepreneurship, in

High-Performance Lithium Sulfur Batteries Based on Multidimensional Graphene-CNT-Nanosulfur Hybrid Cathodes

Understanding the Links between the Composition-Processing-Properties in New Formulations of HEAs Sintered by SPS

Webinar: “From fundamentals to advanced applications of flame-retardant materials”

Next 14th of July, Prof. Dr. De-Yi Wang will present some of the work done in his research group, under the title of "Environmentally Friendly Flame Retardant Materials: from fundamentals to advanced applications". The webinar, which will run through the Zoom platform and will be streamed also

IMDEA Materials Director, José Manuél Torralba, awarded with the FEMS Gold Medal 2021

Our Director, José Manuel Torralba, has been awarded the European Materials Gold Medal 2021 by the Federation of European Materials Societies (FEMS). The European Materials Medal (Gold Medal), established in 1993, is the most prestigious award of the FEMS and is awarded in recognition of outstanding

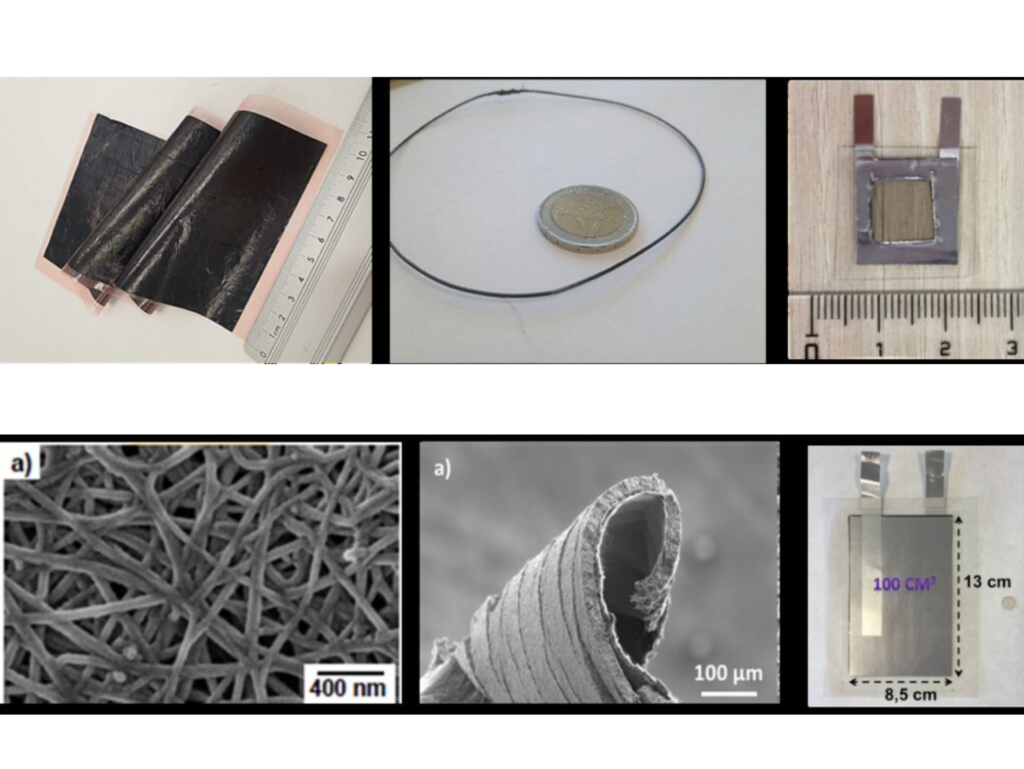

Scientific Highlight: Nanostructured fabrics to host new nanomaterials for advanced electrodes

IMDEA Materials has developed a method to produce highly conducting nanostructured fabrics for use as current collectors or scaffold for active materials in composite electrodes for energy storage and conversion. Integration of these fabrics reduces electrode weight, improves cyclability/durability

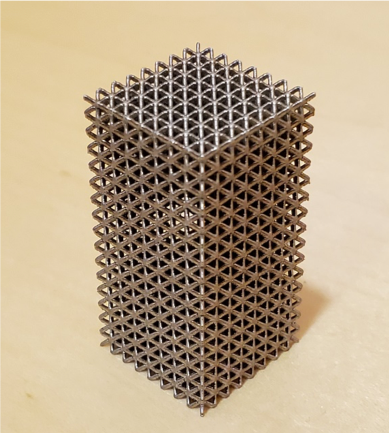

IMDEA Materials and 3D printing of metamaterials for structural applications

Additive manufacturing, or 3D metal printing, allows to build ultralight and resistant structures with geometries that are impossible to achieve using conventional machining and processing techniques, including complex structures named “lattice”. These are three-dimensional constructions,

Machine-learning-accelerated multimodal characterization and multiobjective design optimization of natural porous materials

Recyclable flame-retardant epoxy composites based on disulfide bonds: Flammability and recyclability

Flexible batteries for integration in car interior roof, boot and flooring components

Grupo Antolín, a worldwide supplier of technological solutions for car interiors, works with IMDEA Materials and IMDEA Energy Institutes in the development of flexible Lithium-ion batteries that can be integrated in interior components of vehicles. The objective is to develop Lithium-ion batteries

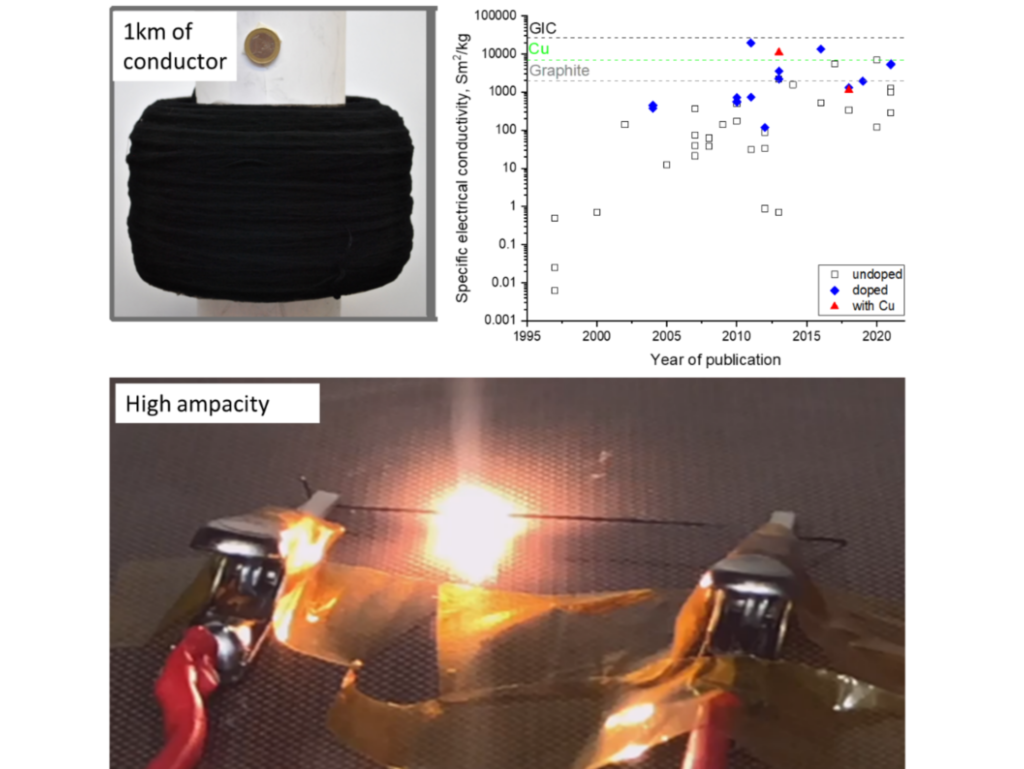

Scientific Highlight: Producing highly conductive nanostructured fibres for use as lightweight conductors

IMDEA Materials has developed a method to produce highly conducting nanostructured fibres for use as lightweight conductors (see Fig. 1). On a mass basis, these conductors have superior electrical/thermal conductivity and higher ampacity (maximum current density) than most metals. Their

Materials processing and characterization Laboratory – PROCAMAT

Materials processing and characterization Laboratory - PROCAMAT PROCAMAT Structure Services Equipment Rates Contact PROCAMAT The advanced Materials Processing and Characterization Laboratory (PROCAMAT) is

In Situ Ambient Preparation of Perovskite-Poly(L-lactic acid) Phosphors for Highly Stable and Efficient Hybrid Light-Emitting Diodes

Laboratory of materials characterisation and processing in 3D and 4D

Laboratory of materials characterisation and processing in 3D and 4D Key info Personnel Services Equipment Rates Contact Key info The Laboratory of materials characterisation and processing in 3D and 4D

Singular Applications of Capacitive Deionization: Reduction of the Brine Volume from Brackish Water Reverse Osmosis Plants

Scientific Highlight: Nanostructured Silicon anodes for Lithium-ion batteries

IMDEA Materials has a proprietary method to produce continuous sheets of nanostructured Silicon [1] (see Fig. 1) and their integration as high capacity anodes in Lithium-ion batteries without use of processing solvents or polymers. The electrodes combine high capacity (> 6 mAh/cm2), high

Development of competitive high-entropy alloys using commodity powders

(MULTI-FAM) DEVELOPMENT OF MULTI-MATERIAL AND MULTIFUNCTIONAL 3D PARTS THROUGH ADDITIVE MANUFACTURING ASSISTED BY INTELLIGENT MATERIAL AND PROCESS DESIGN

Funding: Ministerio de Ciencia e Innovación. Retos Colaboración 2019Region: NationalProject period: 2020 – 2022Partners: ArcelorMittal (Project Coordinator), AIMEN, IMDEA Materials InstitutePrincipal Investigator: Damien Tourret (damien.tourret@imdea.org)The MULTI-FAM project proposes the

DELIGHTED holds second progress meeting

The second online progress meeting was held on June 22, 2021. Project partners presented and discussed their research activities within the last 6 months, as well as preparation of deliverables. The research plans for the next 6 months were updated.

Industrial Advisory Board

The Vision of IMDEA Materials Institute is to become a leading research institute, internationally recognized for its excellence in material science and engineering and its contributions to the transformation of society. To attain this goal, IMDEA Materials has set up an Industrial Advisory Board

Fast and Accurate Machine Learning Strategy for Calculating Partial Atomic Charges in Metal-Organic Frameworks

First Year Assessment of Isabel Gómez, entitled “Synthesis and Characterization of inorganic nanowires via Floating Catalyst Chemical Vapour Deposition” – 25th of June at 12:00, 2021.

Abstract: The work presented is the result of a year studying the growth of inorganic nanowires by floating catalyst chemical vapour deposition (FCCVD) with the objective of applying this technique to the synthesis of metal oxide nanowires. The differences between substrated-CVD and FCCVD

Calorimetric and Dielectric Investigations of Epoxy-Based Nanocomposites with Halloysite Nanotubes as Nanofillers

First Year Assessment of Lucia Cobian, entitled “Experimental-Numerical Analysis of Polymer Based Lattice Materials Fabricated with Additive Manufacturing” – 24th of June, 2021.

ABSTRACT: Lattice materials are materials constituted by the repetition of small cells composed of structural units as bars, beams or shells, which form a lattice. The cell geometry can be designed to have an outstanding macroscopic response such as very high specific stiffness or energy

Combination of Corn Pith Fiber and Biobased Flame Retardant: A Novel Method toward Flame Retardancy, Thermal Stability, and Mechanical Properties of Polylactide

PhD Defense of Rodrigo Santos entitled “Analysis of precipitation hardening in metallic alloys by means of dislocation dynamics” – June 21st, 2021.

The PhD Defense will take place the 21st of June, at 11:30 pm in the "Sala Verde" of the Escuela de Ingenieros de Caminos, Canales y Puertos de la UPM. The dissertation is entitled "Analysis of precipitation hardening in metallic alloys by means of dislocation dynamics". It was advised by Dr.

PhD Defense of Mario Rueda entitled “Experimental and computational micromechanics of fibre-reinforced polymer composites at high strain rates” – June 25th, 2021.

The PhD Defense will take place the 25th of June, at 12:00 pm in the "Sala Verde" of the Escuela de Ingenieros de Caminos, Canales y Puertos de la UPM. The dissertation is entitled "Experimental and computational micromechanics of fibre-reinforced polymer composites at high strain rates". It was

Highly efficient BiVO4 single-crystal nanosheets with dual modification: phosphorus doping and selective Ag modification

Machine learning with persistent homology and chemical word embeddings improves prediction accuracy and interpretability in metal-organic frameworks

High temperature in situ SEM assessment followed by ex situ AFM and EBSD investigation of the nucleation and early growth stages of Fe-Al intermetallics

Dislocation dynamics prediction of the strength of Al-Cu alloys containing shearable θ ′ ′ precipitates

Metal organic frameworks enabled rational design of multifunctional PEO-based solid polymer electrolytes

A multiplicative finite strain crystal plasticity formulation based on additive elastic corrector rates: Theory and numerical implementation

Prof. José Manuel Torralba appointed new Director of IMDEA Materials Institute

On the 27th of April, after an international open selection process was concluded, Prof. Jose Manuel Torralba was appointed Director of IMDEA Materials Institute by the Board of Trustees. Prof. Torralba takes over from Prof. Ignacio Romero, who has been leading the Institute during the last four

Hosting offers for Marie Skłodowska-Curie Actions Postdoctoral Fellowships 2021

We are looking for post-doctoral researchers willing to apply for Marie Skłodowska-Curie Actions (MSCA) Postdoctoral Fellowships (PF), call 2021. Our Institute has a long track record of hosting MSCA fellows and has obtained outstanding success rates in recent calls of MSCA PF. The following

Photoelectrocatalytic detection of NADH on n-type silicon semiconductors facilitated by carbon nanotube fibers

Effect of ZrH2 particles on the microstructure and mechanical properties of IN718 manufactured by selective laser melting

Novel Phosphorous-Based Deep Eutectic Solvents for the Production of Recyclable Macadamia Nutshell-Polymer Biocomposites with Improved Mechanical and Fire Safety Performances

Novel Phosphorous-Based Deep Eutectic Solvents for the Production of Recyclable Macadamia Nutshell-Polymer Biocomposites with Improved Mechanical and Fire Safety Performances

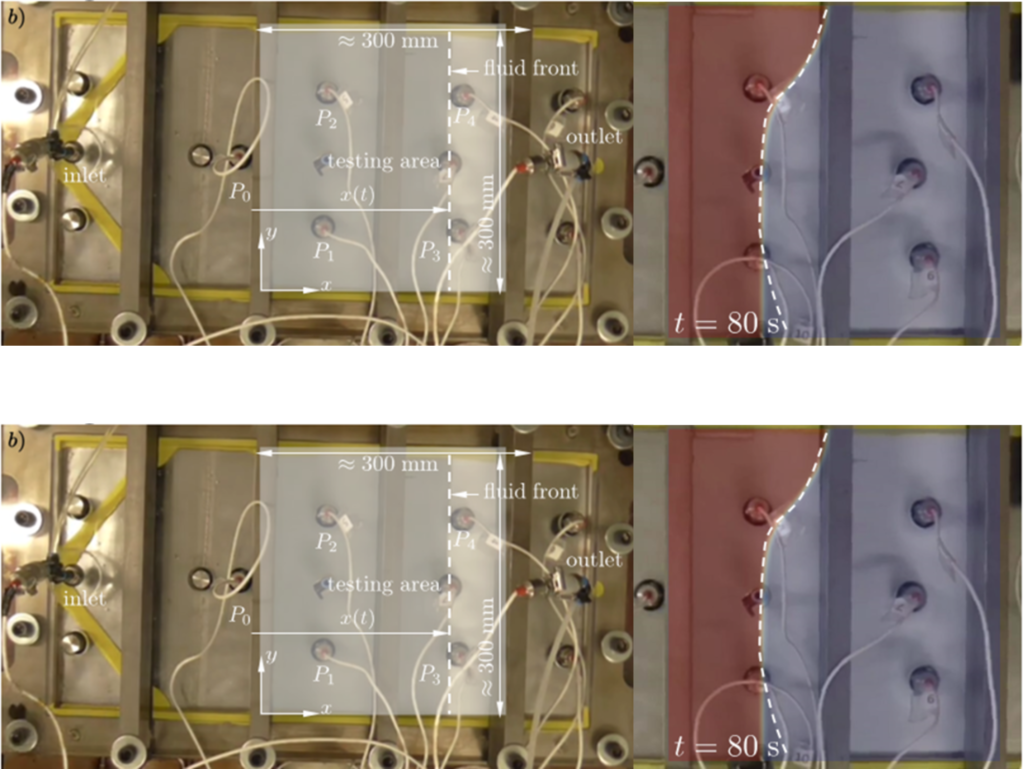

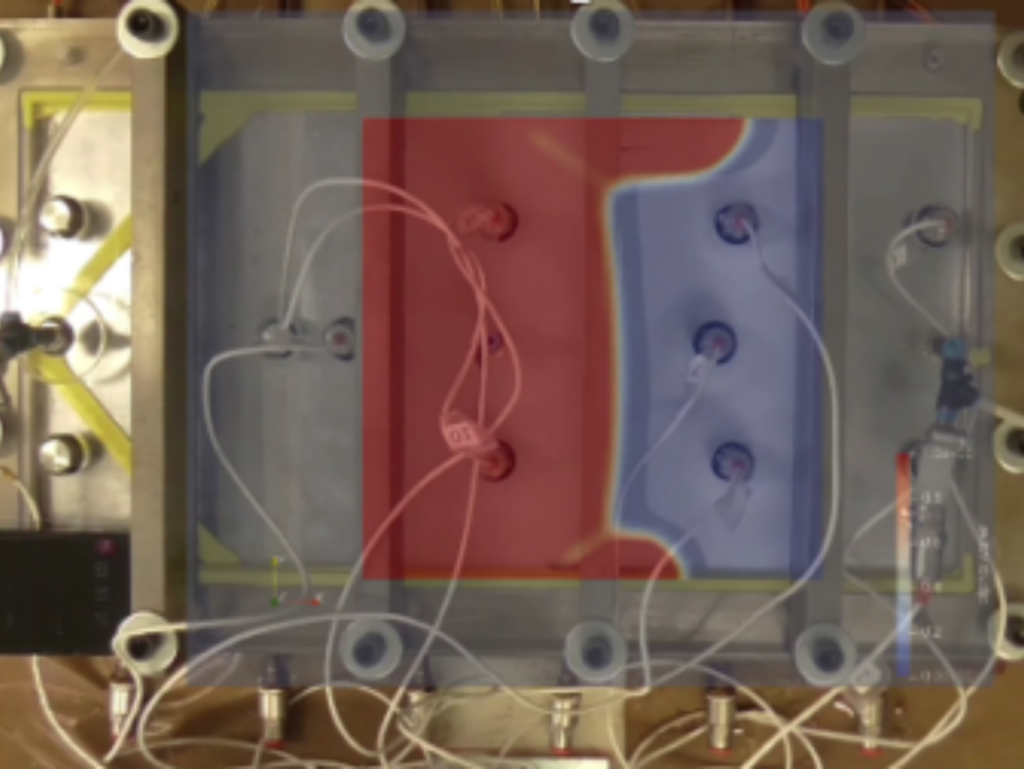

First Year Assessment of Keayvan Keramati, entitled “Race Tracking Study during RTM and predict it with machine learning by CFD generated data” – 28th of May, 2021 at 11:00 am.

Abstract: Resin transfer molding (RTM) is a closed-mold procedure in the composite manufacturing process. The resin enters the mold from the inlet port, and the gradient pressure of the inlet and outlet makes the flow move into the mold. A common disturbance that happened during the process is

Surface functionalization of carbon fabric towards high-performance epoxy composites via enhanced fiber-matrix interfacial strength and intergrowth charring behavior

Chlorite oxidized oxyamylose differentially influences the microstructure of fibrin and self assembling peptide hydrogels as well as dental pulp stem cell behavior

Rationally designed zinc borate@ZIF-8 core-shell nanorods for curing epoxy resins along with low flammability and high mechanical property

IMDEA Materials organises joint conference with the Korea Institute of Science and Technology (KIST)

The joint conference, organised for May 25 with the Korea Institute of Science and Technology, will serve to explore collaboration opportunities in the field of composite materials and strengthen bonds between the two institutes.

Post-processing effects on microstructure, interlaminar and thermal properties of 3D printed continuous carbon fibre composites

Rationally designed zinc borate@ZIF-8 core-shell nanorods for curing epoxy resins along with low flammability and high mechanical property

IMDEA Materials 2020 Annual Report

Post-processing effects on microstructure, interlaminar and thermal properties of 3D printed continuous carbon fibre composites

Processing and properties of long recycled-carbon-fibre reinforced polypropylene

Preface – Virtual Special Issue on nanomechanical testing in materials research and development

2nd PhD meeting of IMDEA Materials

Do you want to develop your career in the field of science and innovation? Would you like to do your Doctorate in a more applied research and closer to the market? Come to see the projects you could work with us on next May 13!

Andrea Fernandez, Inflencer 20.0.

Our colleague Andrea Fernández, research assistant in the Composite Materials group, considered “Influencer 20.0”! She has been protagonist of this consideration because of her research to help others and try to make a better world. In the following link you can see all the information and

IMDEA Materials researchers in the “Ranking of the World´s Top 2% Scientists”

The University of Standford just published its "Ranking of the World Scientists: World´s Top 2% Scientists". The ranking, which analyses data from Scopus like the number of articles published, the career-long citation impact up until the end of 2019 and the citation impact during the single calendar

Spatial inhomogeneity, interfaces and complex vitrification kinetics in a network forming nanocomposite

High-throughput nanoindentation mapping of cast IN718 nickel-based superalloys: influence of the Nb concentration

Experimental and numerical analysis of cyclic deformation and fatigue behavior of a Mg-RE alloy

Dimensionally reduced nonlinear solids with general loads and constitutive laws: Theory and finite element formulation for rod-like bodies

Promotion of the flame retardancy of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide grafted natural rubber using expandable graphite

Effect of Vinylene Carbonate Electrolyte Additive on the Surface Chemistry and Pseudocapacitive Sodium-Ion Storage of TiO2 Nanosheet Anodes

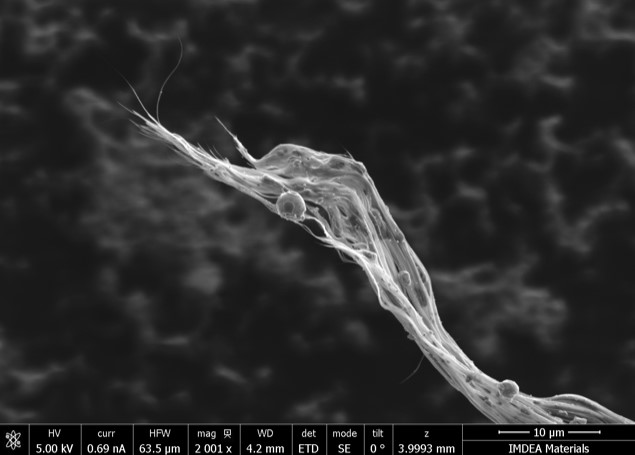

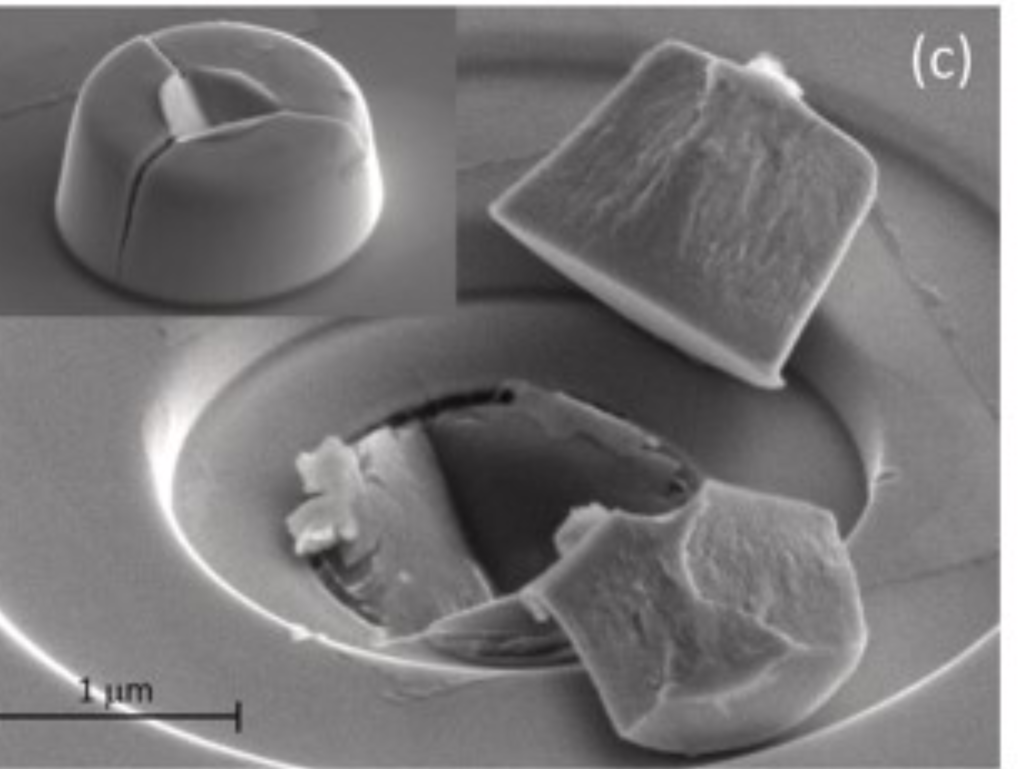

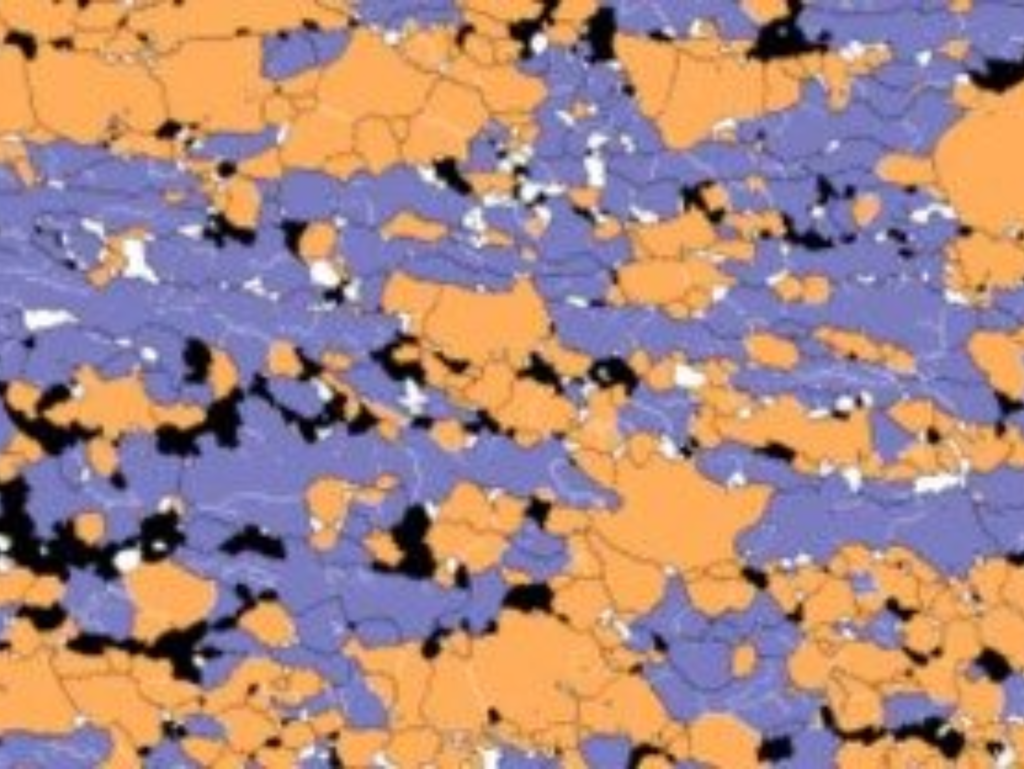

Winners of the 9th and 10th Scientific Imaging Contest of IMDEA Materials

We already know the winners of the 10th edition of the IMDEA Materials´ scientific imaging contest. This year the best images were: Category of charaterization: With open arms, Monica Echeverry Category of simulation: Solid-liquid interfaces of Al-Cu dendrites growing from the

Laser-Guided Corrosion Control: A New Approach to Tailor the Degradation of Mg-Alloys

A variational fast Fourier transform method for phase-transforming materials

Seminar of Prof. Dan Mordehai from Technion (Faculty of Mechanical Engineering) in Israel, entitled “Microstructure-based Plasticity of Metals – Going from the Atomic to the Continuum Scale” – 22nd of April, at 12:00 pm in the Auditorium

Abstract: Microstructural defects on the atomic level are known to be responsible to the macroscopic deformation of metals. Despite, the study of microstructure-based plasticity of metals is still a great challenge owing to the multiphysics and multiscale nature of plasticity. In this talk, I

Low-energy consumption, free-form capacitive deionization through nanostructured networks

The effect of microstructure and strain rate on the 25 °C and 700 °C compression deformation behavior of powder metallurgy processed Ti-45Al-2Nb-2Mn (at.%)-0.8 TiB2 (vol%) alloy

Nanomechanical behavior of single taper-free GaAs nanowires unravelled by in-situ TEM mechanical testing and molecular dynamics simulation

“Made in Madrid” – Madrid considered among world leaders in scientific research – ABC.es

The science carried out in Madrid regions is amongst the world's best, thanks in part to the researchers at the IMDEA Institutes. More information in this article from ABC newspaper.

SmartHAPS and IMDEA Materials set out to conquer the stratosphere – Actualidad Aeroespacial

We will soon start collaborating with the Madrid-based start-up SmartHAPS to investigate materials for High Altitude Pseudo-Satellites (HAPS). The work will be lead by Dr. De-Yi Wang, head of our research group on High Performance Polymers and Fire Retardants. More information about this project

Alumni Newsletter Nº 6

Click in the image to access the full newsletter

Macroscopic yarns of FeCl3-intercalated collapsed carbon nanotubes with high doping and stability

Basalt Fiber-Based Flame Retardant Epoxy Composites: Preparation, Thermal Properties, and Flame Retardancy

3D-printed resistive carbon-fiber-reinforced sensors for monitoring the resin frontal flow during composite manufacturing

A facile and robust route to polyvinyl alcohol-based triboelectric nanogenerator containing flame-retardant polyelectrolyte with improved output performance and fire safety

Multiscale prediction of microstructure length scales in metallic alloy casting

Scientific Highlight: Advanced lightweight materials for fire safety and energy efficient structures

Sandwich-structured composites are the most reliable and effective technology for weight reduction of interior panels in the transportation industry. However, the properties and manufacturing processes of sandwich composites are limited by the characteristics and mechanical properties of the

The effect of microstructure and strain rate on the 25 °C and 700 °C compression deformation behavior of powder metallurgy processed Ti-45Al-2Nb-2Mn (at.%)-0.8 TiB2 (vol%) alloy

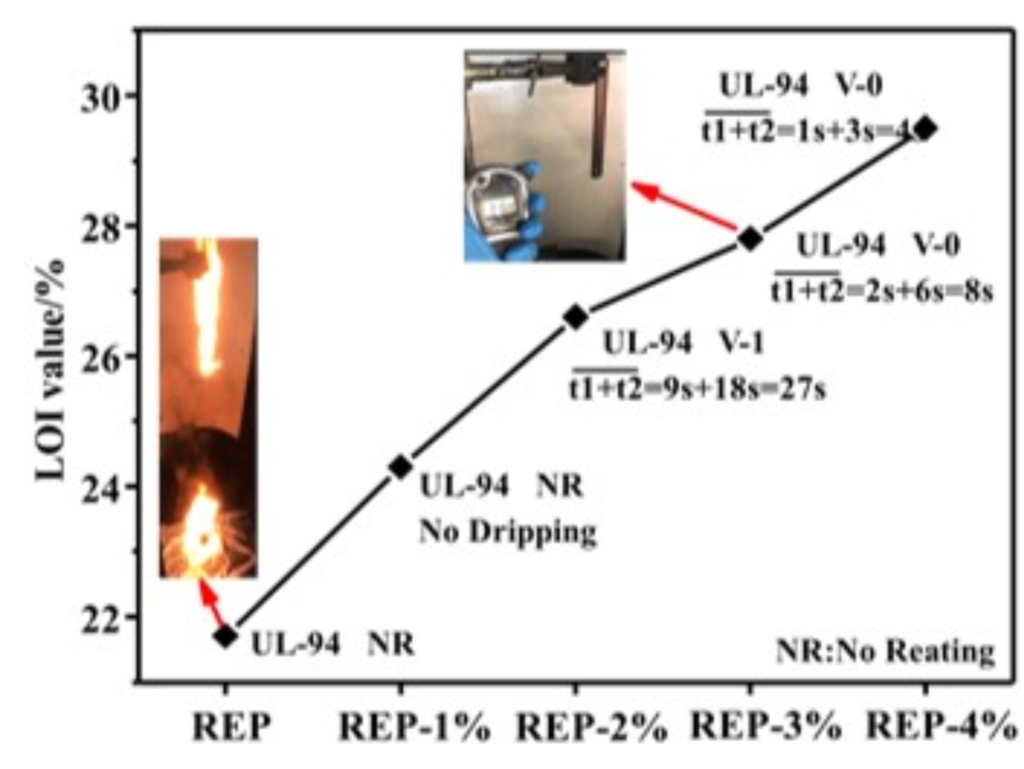

Scientific Highlight: Fire retardant reprocessable epoxy-based composites

IMDEA Materials has developed a technology to produce Reprocessable Epoxy Resin (REP) composites with excellent fire retardancy and re-processability. Compared with pure epoxy resin with a Limited Oxygen Index (LOI) of 21.7 % and no rating in vertical burning test (UL-94), recyclable epoxy resin

Nanomechanical behavior of single taper-free GaAs nanowires unravelled by in-situ TEM mechanical testing and molecular dynamics simulation

3D-printed resistive carbon-fiber-reinforced sensors for monitoring the resin frontal flow during composite manufacturing

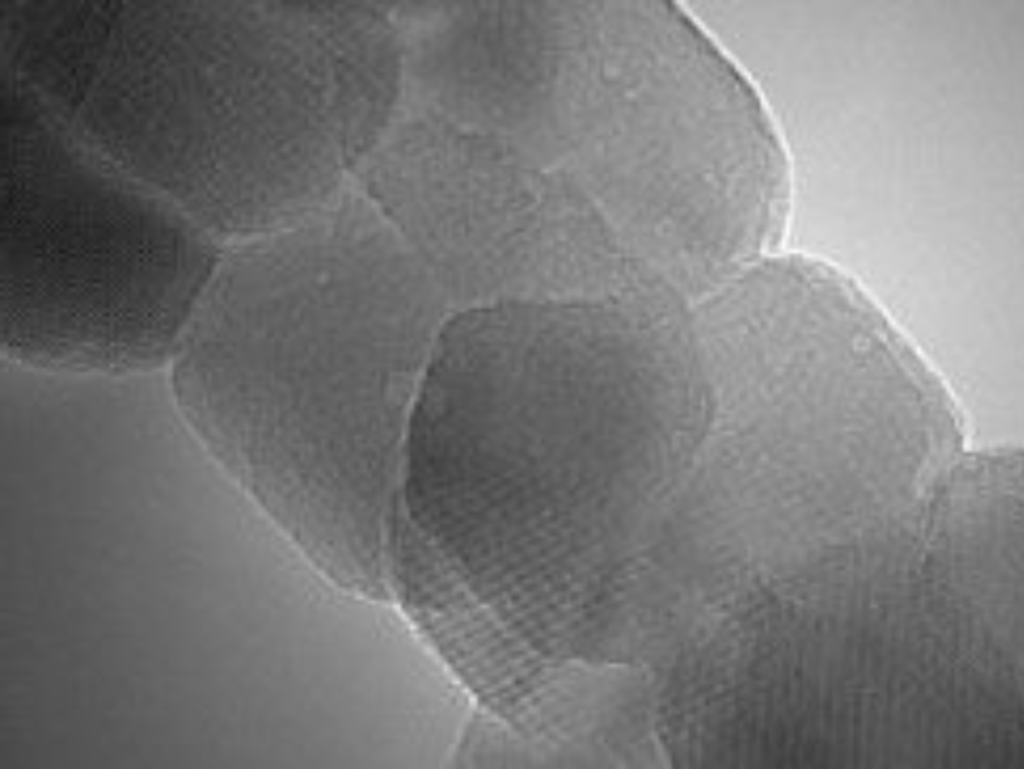

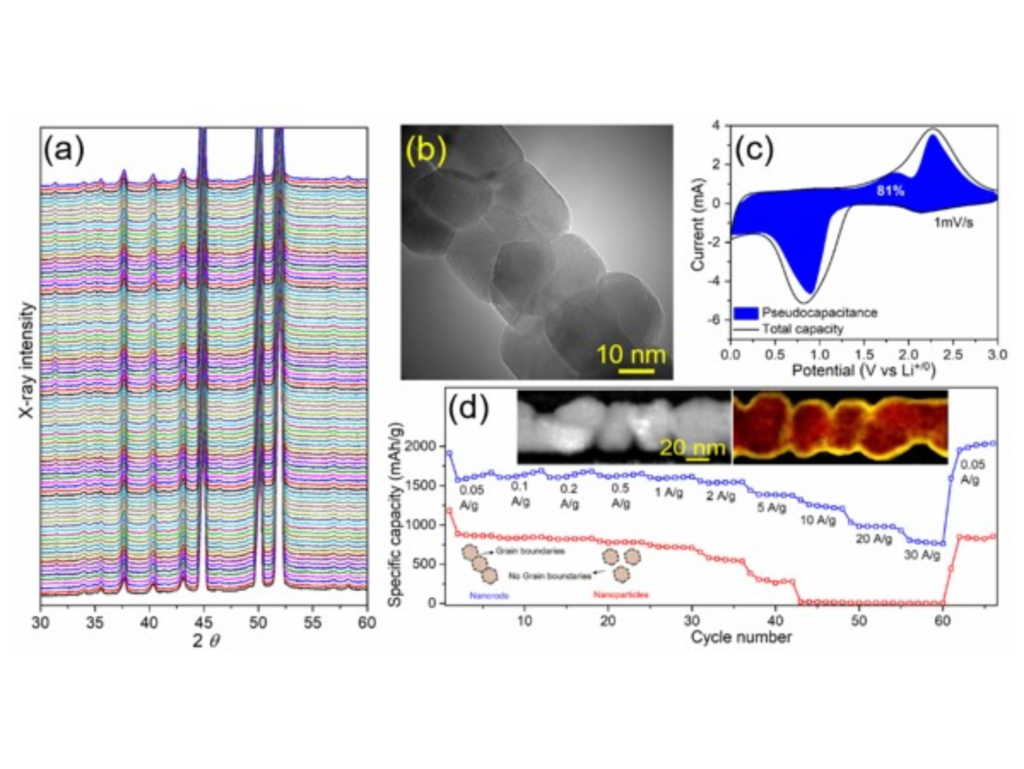

Scientific Highlight: Defect-engineered electrodes for long-range electric vehicles

Although secondary Li-ion batteries are widely used for electrochemical energy storage, low energy (100-300 Wh kg-1) and power density (250-400 W kg-1) are limiting their applications in several areas including long-range electric vehicles. This is mainly due to the use of graphite anodes with

Bioinspired antireflective flexible films with optimized mechanical resistance fabricated by roll to roll thermal nanoimprint

Scientific Highlight: In-situ studies of defect-engineered electrodes

Diffusion independent pseudocapacitive ion storage is one of the recently investigated mechanisms for achieving ultrafast Li and Na-ion storage. It usually involves surface/ near surface charge-transfer reactions. Nevertheless, intrinsic pseudocapacitance of transition metal oxide anodes is not

Precipitate strengthening of pyramidal slip in Mg-Zn alloys

Materials for Health Care

Goal and Vision The Materials for Health Care Programme aims at developing novel materials-based approaches for addressing a number of challenges in medicine, ranging from treating organ/tissue damage to improving drug delivery. The programme is focused on key aspects of

Scientific Highlight: New 3D-printed alloys for extreme conditions

IMDEA Materials has recognized expertise on the design of alloys for high temperature, high strength and lightweight applications, which are suitable for the production of 3D printed components by laser-based or binder-jetting methods. Previous works include the design of superalloys for turbine

Development of segregations in a Mg-Mn-Nd alloy during HPT processing

IMDEA Materials Institute Alumni Interview – Saeid Loftian

Dr. Saeid Loftian was born in Iran. He joined IMDEA Materials in 2010, where he completed his PhD thesis entitled "High-Temperature Mechanical Behavior of Al/SiC Nanoscale Multilayers" under the supervision of Dr. Jon Molina and Prof. Javier LLorca. The thesis was awarded with the best PhD Thesis

A halogen free flame retardant epoxy resin composition

Context There is an increasing interest in the use of resistive (Joule) heating to process polymeric materials as a technology to enable rapid manufacturing, more energetically efficient fabrication, and reduced cost for repairs.Resistive processing of polymer has direct application for adhesive

Controlled Nucleation and Growth of Carbon Nitride Films on CNT Fiber Fabric for Photoelectrochemical Applications

Stress-induced α″ martensitic phase transformation and martensitic twinning in a metastable β titanium alloy

Six research teams, including IMDEA Materials’ MNG group, win Carbon Hub funding

Carbon Hub, Rice University's zero-emissions research initiative, has awarded seed grants for six projects that will rapidly advance its vision for transforming the oil and gas sector into a leading provider of both clean hydrogen energy and solid carbon products that can be used in place of

Thermophysical properties of porous Ti2AlC and Ti3SiC2 produced by powder metallurgy

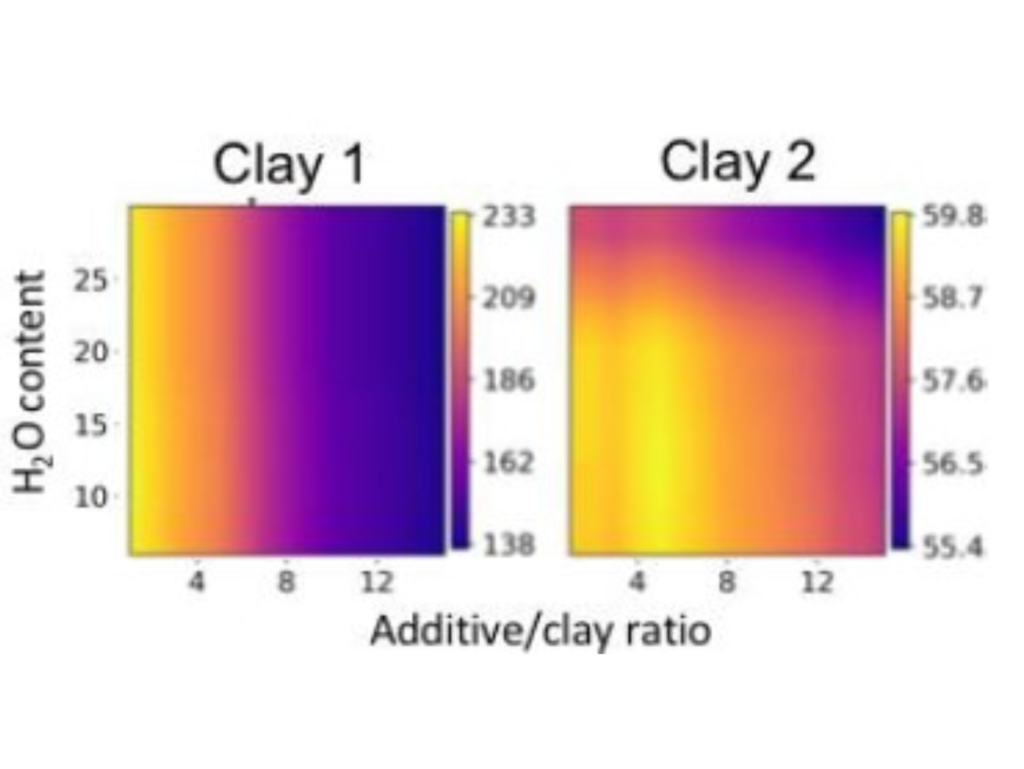

Scientific Highlight: Accelerated product development via AI-guided material design and chemical processes optimization

IMDEA Materials has know-how in developing data-driven experimentation workflows that exploit machine learning algorithms to minimize the number of experiments involved in the development of materials tuned to specific applications and/or the chemical processes governing their synthesis and

Listen what women in science do to improve our lives

Our colleague María Teresa Pérez Prado and other women in science explain what they do to improve our lives in this interview recorded by cadena SER at IMDEA Energy as part of the International Women's Day 2021.

Strategy and algorithms for the parallel solution of the nearest neighborhood problem in shared-memory processors

Scientific Highlight: Virtual testing of metals

IMDEA Materials offers a mature, fully stand-alone technology able to predict the mechanical response of an engineering alloy as function of its microstructure [1]. This technology is able to provide the anisotropic elastic properties and stress-strain elastoplastic curves, the creep response

Energy-momentum conserving integration schemes for molecular dynamics

Construction of a novel three-in-one biomass based intumescent fire retardant through phosphorus functionalized metal-organic framework and beta-cyclodextrin hybrids in achieving fire safe epoxy

Scientific Highlight: New coatings for extreme conditions

Titanium aluminum nitrides (TiAlN) are currently the most versatile coatings in terms of performance with various applications in industry: as wear-resistant coatings for cutting tools; for increasing productivity in die casting, reducing soldering and retarding fire cracks; for plastic processing,

First Year Assessment of Andres Sierra, entitled “Microstructural design in novel stainless steels via quenching and partitioning to improve their mechanical properties” – 12 of March, 2021.

Abstract: The quenching and partitioning (Q&P) process is a relatively new heat treatment (2003) aimed at the creation of a multi-phase microstructure of tempered martensite and stabilized retained austenite. This microstructure enhances the mechanical properties of the steel, achieving an

Computational Modeling of Dislocation Slip Mechanisms in Crystal Plasticity: A Short Review

Scientific Highlight: Multiscale in-situ characterization of materials and processes

Current trends to reduce weight, energy consumption and improve functionality are leading to new materials with complex microstructures, whose behavior can only be understood from the synergetic contribution of processes occurring at multiple length scales (from nm to m). Examples of these

Iron Oxide-Iron Sulfide Hybrid Nanosheets as High-Performance Conversion-Type Anodes for Sodium-Ion Batteries

Scientific Highlight: Bioresorbable scaffolds for tissue engineering

IMDEA Materials has developed technologies to manufacture scaffolds made of biodegradable polymers (PCL, PLA, PLGA, etc), biodegradable metals (Mg and Zn) and their composites for tissue engineering (see Fig. 1 below). The main advantage of this technology is that it allows designing scaffolds with

Dimensionally reduced nonlinear solids with general loads and constitutive laws: Theory and finite element formulation for rod-like bodies

Nanoindentation of Amorphous Carbon: a combined experimental and simulation approach

Scientific Highlight: Physical simulation of joining of dissimilar materials

IMDEA Materials has developed a physical simulation tool to predict joinability of dissimilar metallic materials with different melting points. Very small samples of the actual dissimilar materials are subjected to the same thermal and mechanical profiles in a thermo-mechanical simulator (GLEEBLE

Mechanical and morphological properties of poly(3-hydroxybutyrate)-thermoplastic starch/clay/eugenol bionanocomposites

Corrosion behavior of diverse sputtered coatings for the helium cooled pebbles bed (HCPB) breeder concept

Scientific Highlight: Ultrafast processing of advanced metallic materials

IMDEA Materials has developed technologies for ultrafast processing of advanced metallic materials in a thermo-mechanical simulator (GLEEBLE 3800). They allow to precisely control the thermo-mechanical processing at high heating/cooling rates, as well as at high strain rate plastic deformation.

Nanoindentation of Amorphous Carbon: a combined experimental and simulation approach

Scientific Highlight: Modelling and simulation of Hydrogen embrittlement

Europe’s commitment to reach carbon neutrality by 2050 is strongly pushing renewable energy sources and hydrogen has emerged as a versatile and environmentally friendly mean to store and transport clean energy. The large-scale usage of hydrogen has prompted new challenges in the core

Microstructure, mechanical properties, corrosion resistance and cytocompatibility of WE43 Mg alloy scaffolds fabricated by laser powder bed fusion for biomedical applications

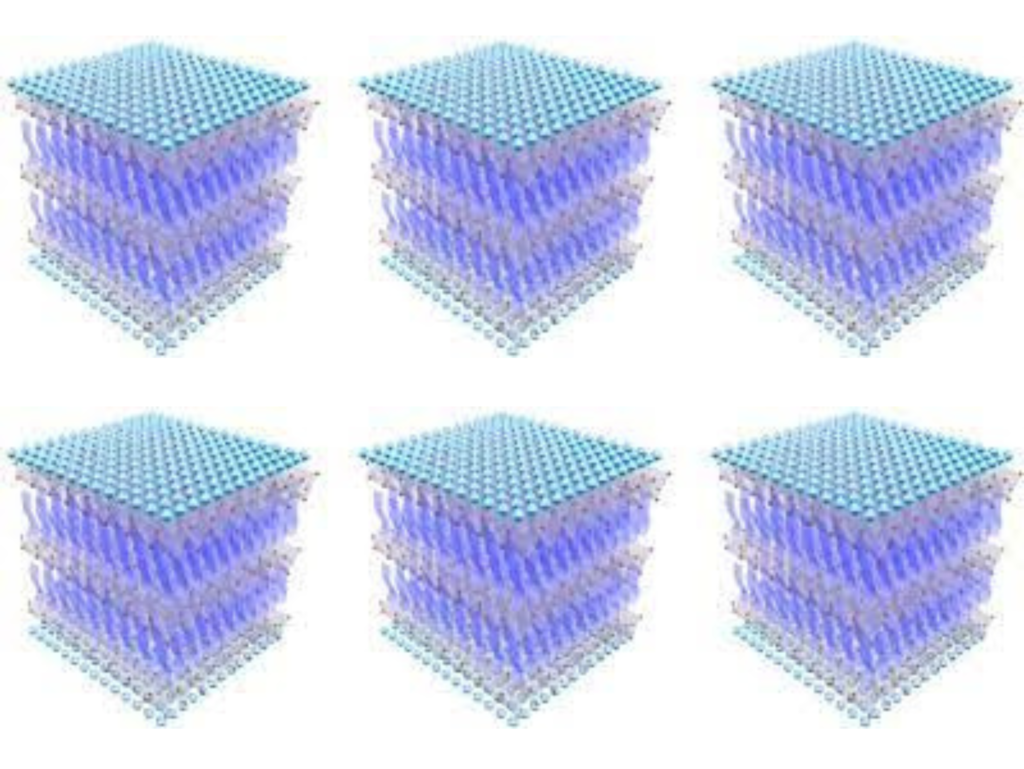

Scientific Highlight: Fire retardant battery materials

IMDEA Materials is working on new battery materials that combine electrochemical integrity and enhanced fire safety. Fig. 1 below shows a fully solid-state battery based on a HKUST-1 MOF modified electrolyte with simultaneously improved electrochemical performance and fire safety was

Xiang Ao

(FUNMAT) Functionally Metalized Nanocellulose For Future Smart Materials

Funding: H2020. Marie Skłodowska-Curie Actions Individual Fellowships Region: European Project period: 2021 – 2024 Principal Investigator: Dr. Ahmed Said Azizi Samir (ahmed.azizisamir@imdea.org) Designing at the nanoscale is a promising and challenging strategy to innovate new building-block

On the crystallographic anisotropy of plastic zone size in single crystalline copper under Berkovich nanoindentation

Success in call 2020 of Marie Skłodowska-Curie Actions Individual Fellowships

One Marie Skłodowska-Curie Individual Fellowship has been awarded to our center in call 2020, and 2 more are very high in the reserve list. A total 7 proposals were submitted by our center. They have received marks in the range 98.4 - 79.2 and are all above the threshold. Despite the fierce

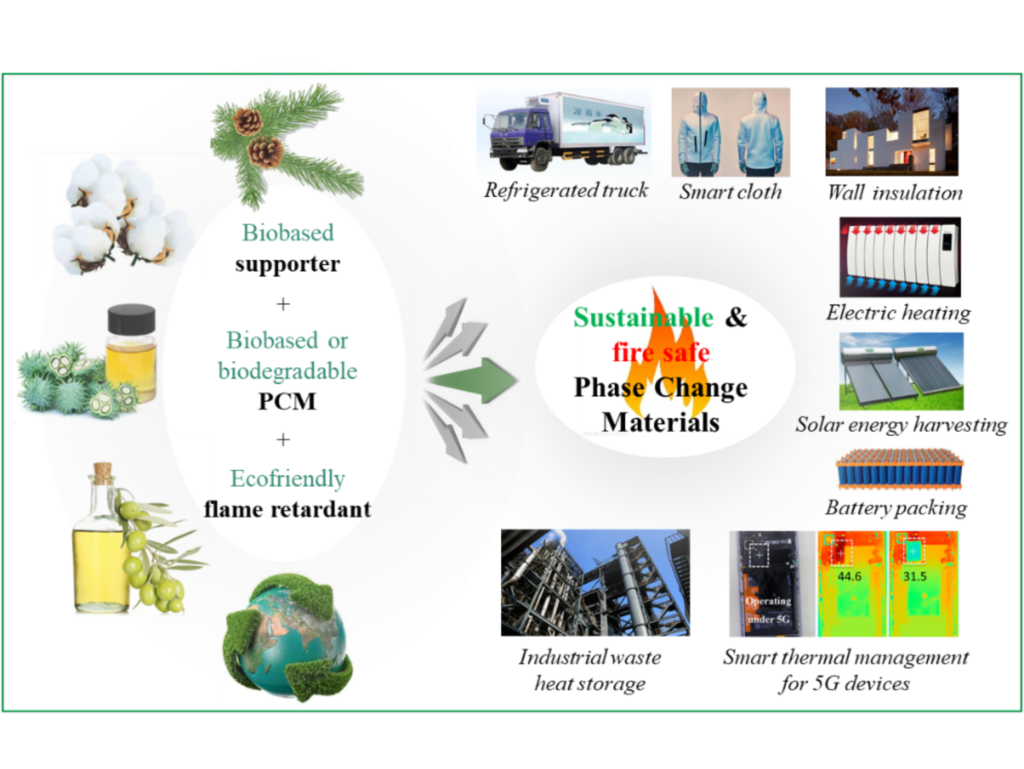

Scientific Highlight: Sustainable, fire safe phase change materials

IMDEA Materials can design and prepare novel Phase Change Materials (PCMs) for thermal energy storage applications that: are prepared in an easy and green pathway and, at the same time, have high mechanical performance, fire safety, form stability, phase transition enthalpy, and thermal

Extremely pseudocapacitive interface engineered CoO@3D-NRGO hybrid anodes for high energy/ power density and ultralong life lithium-ion batteries

Low heat yielding electrospun phosphenanthrene oxide loaded polyacrylonitrile composite separators for safer high energy density lithium-ion batteries

Javier LLorca talks about new materials for bone prosthesis

Javier LLorca talks about new materials for bone prosthesis in the RTVE radio program "El laboratorio de JAL" devoted to science dissemination pills. Follow the link and listen up the first pill to find out more about this hot research topic (content only available in

Scientific Highlight: 3D printing of structural composites by using recycled fibers

Due to the rapid growth in the use of composite materials, environmental concerns have become an increasingly influential topic, making recyclability of composite materials a key issue. Furthermore, several related EU laws have been passed to minimize the environmental impact of composite structures

Ultrafine eutectic Ti-Fe-based alloys processed by additive manufacturing – A new candidate for high temperature applications

(OPE IMDEA Materiales) Oficina de Proyectos Europeos IMDEA Materiales

Funding: Ministerio de Ciencia, Innovación y Universidades. Europa Redes y Gestores - Europa Centros Tecnológicos 2020Region: NationalProject period: 2021 – 2022Principal Investigator: Miguel Ángel Rodiel (miguel.angel.rodiel@imdea.org)Grant aimed at providing research organizations with the

Scientific Highlight: Predictive simulation of metal Additive Manufacturing – from composition & processing to mechanical properties

As part of its strategic initiative on damage-tolerant additive manufacturing, IMDEA Materials develops a suite of physics-based computational models and simulation tools aimed at linking processing, microstructures and properties, in order to accelerate the discovery and deployment of new alloys

Fabrication and Characterization of PEEK/PEI Multilayer Composites

First Year Assessment of Alvaro Méndez, entitled “Harder and tougher AlTi(B)N coatings deposited by HiPIMS for high temperature applications” – 1st of February, 2021, at 12:00.

Abstract: A novel series of multilayered nanocomposite materials based on the AlTiN system with high Al content and the addition of B as the successful element for obtaining the amorphous phase are presented. The coatings were grown using co-deposition reactive HiPIMS from an alloyed TiAl(X)

On the improvement of properties of bioplastic composites derived from wasted cottonseed protein by rational cross-linking and natural fiber reinforcement

Scientific Highlight: AI-guided smart manufacturing of structural composites

Manufacturing in the EU is crucial, given that it is one of the main drivers in innovation, job creation and sustainable growth. It involves almost 2,000,000 companies that provide approximately 28.5 million jobs. Therefore, its impact is significant in terms of economic share, with it being ~18% of

(DOMMINIO) Digital method for improved manufacturing of next-generation multifunctional airframe parts

Project details Funding: H2020. Smart, green and integrated transport (SC4)Project coordinator: AIMEN Project period: 01/01/2021 – 30/06/2024Website: http://www.domminioproject.eu/ IMDEA Materials' researchers Dr. Carlos Daniel GonzálezDr. Juan José

Exploring the correlation between solvent diffusion and creep resistance of Mg-Ga HCP alloys from high throughput liquid-solid diffusion couple

DELIGHTED first progress meeting

The DELIGHTED project partners held first online progress meeting on January 25, 2021. The outcomes of research activities were presented and discussed. The research plans for the next 6 months were updated.

Comparing mesoscopic models for dendritic growth

Clustering

International Clusters, Platforms and Associations Advanced Materials Initiative 2030 (AMI2030) Batteries European Partnership Association

Three-dimensional needle network model for dendritic growth with fluid flow

PhD Defense of Jing Zhang entitled “Metal-Organic Frameworks (MOFs) Derived Hierarchical Hybrids as Fire Retardants for Epoxy Composites” – January 22nd, 2021.

The PhD Defense will take place the 22nd of January, at 12:00 AM. The asistance will be remote. The dissertation is entitled "Metal-Organic Frameworks (MOFs) Derived Hierarchical Hybrids as Fire Retardants for Epoxy Composites"

A Machine Learning Model to Detect Flow Disturbances during Manufacturing of Composites by Liquid Moulding

Multiscale Characterization of the Mechanical Properties of Fibrin and Polyethylene Glycol (PEG) Hydrogels for Tissue Engineering Applications

Understanding interlaminar toughening of unidirectional CFRP laminates with carbon nanotube veils

Ferromagnetic epitaxial Cr2O3 thin films grown on oxide substrates by Pulsed Laser Deposition

Origin of the electrocatalytic activity in carbon nanotube fiber counter-electrodes for solar-energy conversion

PhD Defense of Jaime Castro entitled “X-Ray Tomographic Investigation of Resin Flow in Liquid Moulding of Composite Materials” – January 15th, 2021.

The PhD Defense will take place the 15th of January, at 10:00. The asistance will be remote. The dissertation is entitled "X-Ray Tomographic Investigation of Resin Flow in Liquid Moulding of Composite Materials".

Tip dynamics for equiaxed Al-Cu dendrites in thin samples : Phase-field study of thermodynamic effects

Hierarchical layered double hydroxide nanosheets/phosphorus-containing organosilane functionalized hollow glass microsphere towards high performance epoxy composite: Enhanced interfacial adhesion and bottom-up charring behavior

An Overview of the Flame Retardants for Poly(vinyl chloride): Recent States and Perspective(dagger)

DELIGHTED holds first progress meeting

The DELIGHTED project partners held their first online progress meeting on January 25, 2021. The outcomes of research activities were presented and discussed. The research plans for the next 6 months were updated.

Toward crystalline porosity estimators for porous molecules

Investigation of Solidification and Precipitation Behavior of Si-Modified 7075 Aluminum Alloy Fabricated by Laser-Based Powder Bed Fusion

High temperature strength retention of Cu/Nb nanolaminates through dynamic strain ageing