Last Tuesday, February 8, IMDEA Materials opened the doors to children of the Community of Madrid to have the opportunity to know the great work done by women scientists and transmit them the enthusiasm they have in science. In the following link you can see a brief explanation of the activities

Seminar of Prof. Jiacheng Wang, from the Shanghai Institute of Ceramics, Chinese Academy of Sciences (CAS), entitle “Emerging Materials for Electrocatalysis” – At 11:30 am in the Seminar Room

Abstract Platinum-based materials are highly active as the electrocatalysts both in hydrogen evolution reaction (HER) and oxygen reduction reaction (ORR) in fuel cells, but high cost limits its wide applications. In this talk, the reporter summarized the recent research progress of designing and

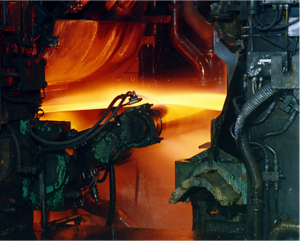

Is ultra-fast processing the next revolution for steel production?

Researchers of our Institute collaborate with an international consortia to develop an ultra-fast processing process for steels. This approach is energetically more efficient than current methods. You can learn more about this technique in this article (Spanish only)

3rd review meeting

The 3rd OptiQPAP progress meeting was held on 24th of January, 2018, at the CTM headquarters (Manresa, Spain). The meeting was organized by Toni Lara. Project partners presented and discussed their research activities in frame of the OptiQPAP project within last 6 months, as well as

PhD Defense – Yetan Pan “Synthesis of nano-flame retardant and its use as a promising substitute of antimony trioxide in flame retardant flexible poly(vinyl chloride)”, supervised by Dr. De-Yi Wang.

The PhD Defense will take place on next Tuesday (23rd, January), at 12 noon, in the Sala Verde (first floor) in the Escuela de Ingenieros de Caminos, UPM The link below shows the address of the

ALFORAMA 1st consortium meeting in Ordizia

The First ALFORAMA Technical Committee Meeting took place on the 18th of January 2018 and was hosted by the Coordinator of the Consortium IK4-LORTEK in Ordizia, Spain The ALFORAMA partners reviewed the progress made across the different work packages addressing topics such as definition of

New project supported by the Center for Nanoscale Materials at Argonne National Laboratory

The Center for Nanoscale Materials at Argonne National Laboratory will support the research project entitled "Atomistic simulations of precipitate-strengthening for optimum design of light alloys for green transport", who will be carried out by Prof. J. LLorca, Dr. I. Papadimitrou and Mr. Gustavo

First Year Assessment of Can Fu entitle “Design and study of multifunctional flame retardant polyester fabric” – In the Seminar Room at 12:00 pm

ABSTRACT Poly(ethylene terephthalate) (PET) is extensively used in the production of fibers and films and now increasingly used as container material for soft drink due to its outstanding characteristics of high strength, good flexibility, and thermal stability, but their uses are limited by their

Emma García

Ignacio Romero

Research Interests His research deals with numerical methods for nonlinear mechanics of solids, fluids, and structures. More specifically, he has developed time integration methods for Hamiltonian and coupled problems, models and numerical methods for nonlinear beams and shells,

José Luis Jiménez

Position: Laboratory Technician VT: Specialist Technician. Spain Address: IMDEA Materials, C/ Eric Kandel, 2, Tecnogetafe, 28906 Getafe, Madrid - Spain E-mail: joseluis.jimenez@imdea.org

2nd IMDEA Materials Innovation Awards

On 28th of November took place the 2nd IMDEA Materials Innovation Award. The Director of the Institute, Prof. Ignacio Romero, gave the award to Miguel Angel Valdes on his winner project entitle ““Ultra-rapid processing of advanced high strength steels”. The 2nd edition started with the last year´s

First Year Assessment of Jing Zhang entitle “Metal organic frameworks (MOFs) derived hierarchically nanomaterials as multifunctional fire retardant for polymer nanocomposites” – In the Seminar Room at 12:00 pm

Abstract Fire hazards including the generation of heat, smoke and toxic vapor, cost a great number of lives and damage properties. Compared with natural polymers, the high flammability and the widespread use of synthetic polymers lead to serious safety and environmental problems. Therefore, methods

Gas Natural Fenosa bestows a special mention on Rubén Costa for his pioneering contributions to the energy sector

Rubén Costa, head of the research group on hybrid optoelectronic materials and devices at IMDEA Materials, has been awarded with a special mention by Gas Natural Fenosa. This Spanish company is one of the biggest promotors of innovation, research, and development of technologies devoted to

PhD – Alberto Palomares: “Micromechanics of fully lamellar TiAl alloys: effect of lamellar orientation and width”

The defense of the PhD thesis of Mr. Alberto Palomares, entitled "Micromechanics of fully lamellar TiAl alloys: effect of lamellar orientation and width", supervised by Dr. Jon Molina Aldareguia and Dr. Teresa Pérez Prado, will take place tomorrow Thursday, December 21st at 11am in the "Sala 3" of

Seminar of Prof. Gastón A. Crespo entitle “Decentralized Chemical Sensing: From materials to real world applications” – At 12:00 pm in the Seminar Room

Decentralized Chemical Sensing: From materials to real world applications My group works at the interface of fundamental and applied chemical science and our aim is to solve real problems that human society is facing or will be facing soon. There is an urgent need of decentralized chemical

First Year Assessment of Andrea Fernández entitle “Recycling of composites by recovering carbon fibres of cured prepregs, and their re-use in hybrid laminates” – In the Seminar Room at 12:00 pm

Abstract: Recycling of composites by recovering carbon fibres of cured prepregs, and their re-use in hybrid laminates by Andrea Fernández Gorgojo The applications of composite materials are rapidly growing in several sectors. For example, in the aeronautical sector, composites can account for up

Seminar of Prof. John Allison entitle “The PRISMS Framework: An Integrated Predictive Multi-Scale ICME Capability for the Global Materials Community” – At 1:00 pm in the Seminar Room

The PRISMS Framework: An Integrated Predictive Multi-Scale ICME Capability for the Global Materials Community John Allison University of Michigan, Ann Arbor MI The Center for PRedictive Integrated Structural Materials Science (PRISMS) is a major Materials Genome Initiative effort creating a unique

Research Initiation Fellowships of Juan Manuel Moreno entitle “Optimization of electrolyte conductivities containing flame retardant. A computational experimentally-guided approach based on Genetic Algorithms combined with Machine Learning techniques (GAML)” – At 4:00 pm in the Seminar Room

Abstract Flame retardants are going to be such an important component in future Lithium-based batteries. However, these flame retardants have a major problem: they decrease the conductivity values of electrolytes. During this project we have been trying to use some new optimization techniques

First Year Assessment of Pablo García entitle “The fatigue behavior of advanced high-strength steels processed via quenching and partitioning” – In the Seminar Room at 12:00 pm

ABSTRACT The increasingly demanding environmental and safety goals imposed to the automotive industry have fostered fierce competition to develop new multi-phase steel types that are stronger, tougher, more formable, and fatigue-resistant. Among the various approaches in study, steels processed via

Francisca Martínez-Hergueta receives the award to the best PhD thesis

Francisca Martínez-Hergueta has received the award to the best doctoral thesis in the academic year 2015-2016 from the Technical University of Madrid (UPM). The thesis was entitled "Multiscale analysis of the mechanical behaviour of needle-punched nonwoven fabrics " and was carried out at IMDEA

2nd edition of the IMDEA Materials´ Innovation Award – In the Seminar Room at 1:00 pm

The winner is Miguel Ángel Valdés on his winner project entitled “Ultra-rapid processing of advanced high strength steels”.

Presentación de la revolución tecnológica: BioLED

En esta ocasión, smartLIGHITNG y el Instituto IMDEA Materiales, tiene el placer de invitarle a la presentación en absoluta primicia del BioLED, una tecnología que va acaparando premios y reconocimientos por todo el mundo de distintas organizaciones, como la del prestigioso y solvente,

Seminar of Prof. Javier García Martínez entitle “Design, Fabrication and Commercialization of new catalysts engineered at the nanoscale” – At 10:00 am in the Seminar Room

DESIGN, FABRICATION AND COMMERCIALISATION OF NEW CATALYSTS ENGINEERED AT THE NANOSCALE J. García-Martínez Laboratorio de Nanotecnología Molecular, Dpto. Química Inorgánica, Universidad de Alicante, Ap. 99, E-03690 Alicante, Spain. www.nanomol.es; Rive Technology, Inc., 1 Deer Park Drive, Monmouth

ALFORAMA at Strategic Workshop on Additive Manufacturing

ALFORAMA participated in the European Strategic Approach on Additive Manufacturing that took place on 15th November 2017 in Oeiras, Portugal. The workshop was organised by the European Federation for Welding, Joining and Cutting and AM-motion project. The event

First Year Assessment of Rudi Maça entitle “Nanoengineered Pseudocapacitive Anodes for Rechargeable Sodium-Ion Batteries” – In the Seminar Room at 12:00 pm

Abstract: In this study, nanoengineered pseudocapacitive electrodes are developed for superior Na-ion storage. Main aim is to induce defect-driven pseudocapacitive Na-ion storage in insertion and conversion type anodes. Hybrid anatase-bronze TiO2 nanosheets composed of Nanocrystallites of

New efficiency record in TiO2 solar cells

Researchers from IMDEA Materials, University of La Rioja and University of Alicante have set a new record in the energy efficiency of TiO2 solar cells (8.75 %). TiO2 is an affordable compound that makes these solar cells less expensive than traditional silicon solar cells. The research at IMDEA

Alumni Newsletter Nº 2

Click in the image to access the full newsletter

First Year Assessment of Yunfu Ou entitle “Understanding interlaminar toughening mechamisms in structural carbon fiber/epoxy composites interleaved with CNT veils” – In the Seminar Room at 12:00 pm

ABSTRACT: The susceptibility to delamination is one of the main concerns in fiber reinforced polymer composites (FRPs), while carbon nanotubes (CNT) carry the promise of enhancing this poor out-of-plane mechanical performance. This work reviews the progress to date towards methods of

Seminar of Dr. Martin Sjödin entitle “Rational Design of Conducting Redox Polymers for Electrical Energy Storage” – At 12:30 pm in the Seminar Room

Abstract Conducting redox polymers (CRPs) are composed of a conducting polymer (CP) backbone and redox active functional groups (RGs) and they provide an attractive option as organic matter based electrical energy storage materials. The CP backbone renders the material conductive and, due to the

Seminar of Dr. Juan Manuel Ortiz entitle “Microbial Electrochemical Technologies and waste water treatment: concepts and main applications” – At 11:00 am in the Seminar Room

ABSTRACT Microbial Electrochemical Tehnologies (MET) are a recent research field related to environmental biotechnology. The main concept for its development is related to the ability of the microorganisms of producing electricity from organic matter degradation, using an insoluble electron

Celebrate Madrid Science Week, 2017 with a visit to IMDEA Materials Institute

Are you interested in learning how we contribute to improve 3D printing of metals?, do you want to manufacture composite materials or learn how to improve the fire behabiour of plastics?. You can visit us next November 14th as part of Madrid Science Week!

Seminar of Mauricio Terrones entitle “Low-Dimensional Nano-Carbons: Form Doped Carbon Nanotubes and Doped Graphene to 3-D Hybrids and Biological Applications” – Seminar Room, 1:00 pm

Low-Dimensional Nano-Carbons: Form Doped Carbon Nanotubes and Doped Graphene to 3-D Hybrids and Biological Applications Mauricio Terrones1 E-mail: mut11@psu.edu 1Department of Physics, Department of Chemistry, Department of Materials Science and Engineering and Center for 2-Dimensional & Layered

First Year Assessment of Miguel Angel Valdés entitle “Study of Mechanical Properties on Macro- and Microscopes in AHSS by Ultra-Fast Heating” – In the Seminar Room at 11:00 am

Abstract Ultrafast heating (UFH) has recently attracted significant attention of steel research community due to its advantages over conventional heat treatment of advanced high-strength steel (AHSS) including very short processing time, reduced energy consumption and low carbon footprint. The UFH

Research Initiation Fellowships of Dieter Plessers entitle “Towards High Efficiency Devices: Avoiding Electron Recombination in Dye-Sensitized Solar Cells” – In the Seminar Room at 3:00 pm

ABSTRACT: Towards High Efficiency Devices- Avoiding Electron Recombination in Dye-Sensitized Solar Cells

First Year Assessment of Xia Peikang entitle “High strain rate mechanical behavior of advanced high strength steels” – In the Seminar Room at 4:00 pm

Abstract The main objective of this work is to gain a fundamental understanding of the behavior characteristics of a quenched and partitioned (Q&P) steel at high strain rates by employing Split Hopkinson bar testing, drop weight impact testing, electron backscatter diffraction (EBSD),

Seminar of Anxin Ma entitle “Microstructure informed constitutive models and SPH crystal plasticity modelling approaches” – Seminar Room, 12:00 pm

Microstructure informed constitutive models and SPH crystal plasticity modelling approaches Anxin Ma Group of mechanics of materials of IMDEA materials anxin.ma@imdea.org During the deformation of polycrystals, pronounced strain gradients may occur due to mis-orientations and eigen strains of phase

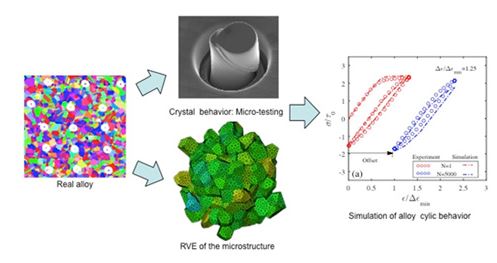

Modelling superalloy behaviour to improve aircraft engine design

The MICROMECH project, part of the Sustainable and Green Engines (SAGE) Integrated Technology Demonstrators (ITD) of Clean Sky, has successfully developed a multi-scale computational tool to predict the mechanical behaviour of the Ni-based superalloys used in the hottest parts of aircraft engines.

(CRASHING II) FRONT FUSELAGE CRASHWORTHINESS MODELLING

Funding: AIRBUS DEFENSE & SPACE Region: Spain Project period: 2016 – 2017 Principal Investigator: Dr. Cláudio Sául Lopes (claudiosaul.lopes@imdea.org) The CRASHING II project is the follow up of the Clean Sky CRASHING project and is focused on the modelling and simulation of the

Rubén Costa awarded as European young innovator by the MIT

Rubén Costa, head of the research group on hybrid optoelectronic materials and devices at IMDEA Materials, has been awarded talented young innovator by the MIT Technology Review. Rubén Costa is leveraging his educational background to guide his work developing a lower-cost, more

First Year Assessment of Eva M. Andrés López entitle “Coupled thermomechanical damage model in small strain elastoplasticity: A thermodynamic approach”- Seminar Room at 1:00 pm

Abstract The objective of the present project is the development and numerical implemen- tation of constitutive equations for the coupled thermomechanical damage problem in the speci c context of the in nitesimal strain approximation, within the framework of the thermodynamics of irreversible

Porphyrins as Multifunctional Interconnects in Networks of ZnO Nanoparticles and their Application in Dye‐Sensitized Solar Cells

PhD Defense – Yang Lingwei “Deformation, strengthening and fracture mechanisms of nanoscale Al/SiC multilayers”

The PhD Defense will take place next Monday, 4th of September, at 12:00 pm, in the Seminar Room (next to the Green room) in the Escuela de Ingenieros de Caminos, UPM The link below shows the address of the

Future bulbs will be made of proteins

LED lights are the true heir to Edison’s electric bulb. They are a major breakthrough in lightning, but still require advances related to their manufacture using cheaper sustainable materials. In this interview (in Spanish), Rubén Costa (senior researher at IMDEA Materials) explains his vision of

Air Force Research Laboratory’s Office of Scientific Research visits IMDEA Materials

A delegation from the US Air Force Research Laboratory (AFRL) and the Air Force Office of Scientific Research (AFOSR) recently visited IMDEA Materials Institute´s facilities with the objective of exploring possible future lines of collaboration in the field of materials science and engineering.

Seminar of Prof. Maurice Collins – “An Overview of Naturally derived polymers for Medical and Fibre applications” – Seminar Room at 1:00 pm

Maurice N Collins Stokes Laboratories, Bernal Institute, University of Limerick Abstract The first part of the talk deals with the hyaluronic acid biopolymer. Hyaluronic acid (HA) is a glycosaminoglycan that is found in extracellular tissue in many parts of the body. It is a material of increasing

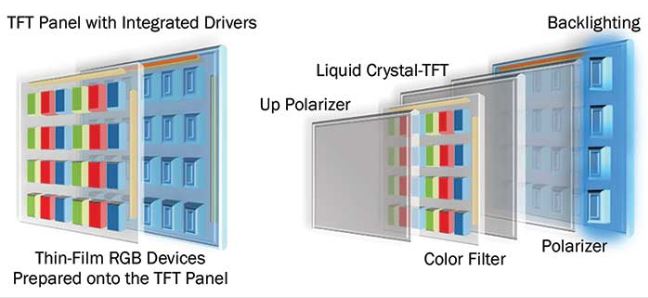

Quantum Dots, Fluorescent Proteins Vie for Supremacy

Since the mid-50s the full-color display technology began its rise to success. The origins of this technology was the old-fashioned cathode ray tubes, which were displaced from the top about a decade ago by liquid crystal displays (LCDs) using a back-lighting system based on white inorganic

Seminar of Prof. Luis Cueto-Felgueroso – “Stick–slip dynamics of flow-induced seismicity on rate and state faults”, 12:00 pm at the Seminar Room.

Stick–slip dynamics of flow-induced seismicity on rate and state faults Luis Cueto-Felgueroso Departamento de Ingeniería Civil: Hidráulica, Energía y Medio Ambiente Universidad Politécnica de Madrid luis.cueto@upm.es ABSTRACT Changes in pore pressure due to the injection or extraction of fluids from

Seminar of Prof. R. C. Reed – “Alloys-by-Design: Optimisation of Compositions of Nickel-Based Superalloys” – Seminar Room, 12:30 pm

Alloys-by-Design: Optimisation of Compositions of Nickel-Based Superalloys Roger C. Reed, Daniel Barba and Enrique Alabort University of Oxford, Departments of Materials and Engineering Science, UK Ni-based superalloys are a class of materials widely used in the aerospace sector due to their

Seminar of Dr. Michael Titus – “Accelerated discovery and development of high temperature structural alloys” – Seminar Room, 12:00 pm

Accelerated discovery and development of high temperature structural alloys Michael S. Titus Assistant Professor of Materials Engineering Purdue University Researchers and engineers constantly seek out new materials systems that increase the operating temperatures of critical components in

Rubén Costa selected top Spanish talent by the MIT

Rubén Costa, head of the research group on hybrid optoelectronic materials and devices at IMDEA Materials, has been selected as one of the Top Spanish Talents by the MIT Technology Review. He will be competing for a spot among the final list of Innovators Under 35 Europe 2017. Rubén

Carlos González appointed Full Professor at UPM

Prof. Carlos González, head of the research program on the "Next Generation of Composite Materials" at IMDEA Materials Institute, has been appointed Full Professor at the Department of Materials Science of Polytechnic University Madrid (UPM), in which he was an Associate Professor. Our

Winners of the 2016 Imaging Contest

Last Friday, June 30th, the Director and Deputy Director of the Institute gave the awards to the winners of the 2016 edition of the IMDEA Materials Imaging Contest. From left to right: Jose Luis Jimenez, Miguel Ángel Valdés, Daniel del Pozo and Miguel Monclús. The winners of this year in the

First Year Assessment of Rodrigo Santos entitle “Study of dislocation-precipitate interaction using discrete dislocation dynamics” – 12:00 am at the Seminar Room

Abstract Metallic alloys are widely used in engineering and are in constant development to optimize their properties. Computational strategies to perform virtual design and testing of these materials would reduce the high time and costs associated nowadays to the development of new alloys with

ALFORAMA Kick-off Meeting

The ALFORAMA Kick of Meeting took place on the 4rd of July 2017 in Naples (Italy). The event was host by LEONARDO S.p.A. (Topic Manager Company). Leonardo is a founding member of the Clean Sky JTI (Joint Technology Initiative) started in 2008 to develop breakthrough technologies

Seminar of Dr. Markus Stricker – “Glissile junctions: Insights from discrete dislocation dynamics and development of a continuum model” -Seminar Room, 12:00 am

Glissile junctions: Insights from discrete dislocation dynamics and development of a continuum model Markus Stricker Karlsruhe Institute of Technology The understanding of the mechanisms governing plastic deformation of metals is the understanding of dislocation motion from single dislocations to

2nd review meeting

TU Delft (Delft, The Netherlands) has hosted the 2nd OptiQPAP progress meeting on 26th of June, 2017, at the headquarters (Manresa, Spain). The meeting was organized by Dr. Carola Celada. Project partners presented and discussed their research activities in frame of the OptiQPAP project within last

MICROMECH II project

The MICROMECH II project is the follow up of the Clean Sky MICROMECH project and is focused on the development of more elaborated micromechanical models for Inconel 718 alloy (casted and forged). Check the whole description of the project.

Seminar of Dr. Pedro B. Coto – “Intramolecular Singlet Fission: Insights from Quantum Dynamical Simulations” – Seminar Room, 10:30 am

Intramolecular Singlet Fission: Insights from Quantum Dynamical Simulations Pedro B. Coto Friedrich-Alexander Universität Erlangen-Nürnberg, Institut für Theoretische Physik und Interdisziplinäres Zentrum für Molekulare Materialien (ICMM), Staudtstraße 7/B2, Erlangen, 91058, Germany Email:

Call for expression of interest for Marie Sklodowska-Curie Actions (Individual Fellowships)

Are you a researcher interested in carrying out your research with us?, do you want to apply for a Marie Sklodowska-Curie Individual Fedllowship?. We have a selection of projects for your consideration!

Celebrating 10 years of the ERC

Back in 2007, the European Commission established the European Research Council (ERC) with the mission to encourage excellent frontier research in Europe through competitive funding, supporting top researchers across all fields and of any nationality. Since then, the ERC has had a considerable

(AROOA) A STUDY AND OPTIMIZATION OF OUT-OF-AUTOCLAVE PROCESSING OF COMPOSITES

Funding: Hexcel Composites LimitedRegion: IndustrialProject period: 2014 – 2017Principal Investigator: Dr. Federico Sket (federico.sket@imdea.org) and Dr. Carlos González (carlosdaniel.gonzalez@imdea.org)AROOA project aims to study and optimize a new family of prepregs designed for out-of-autoclave

Alumni Newsletter Nº 1

Click in the image to access the full newsletter

Seminar of Dominik Eder – “Hybridization and mesotructuring as tools towards functional photocatalysis”

Institut für Materialchemie, Technische Universität Wien, Vienna, Austria dominik.eder@tuwien.ac.at In this lecture I will discuss the main challenges in heterogeneous photocatalysis and present two materials design strategies. What are nanocarbon-inorganic hybrids? Hybridising nanocarbon

PhD – Alicia Moya “Hybrid systems based on metal oxides and nanocarbons: electronic properties and applications for photocatalysis”

The PhD Defense will take place next Monday, 22nd of May, at 12:00 pm, in the “Sala Verde" in the E.T.S.I. Caminos (Campus de Ciudad Universitaria, UPM). The link below shows the address of the

PhD – Fernando Naya “Prediction of mechanical properties of unidirectional FRP plies at different environmental conditions by means of computational micromechanics”

The PhD Defense will take place next Thursday, May 18th, at 12:00 pm, in the “Sala Verde" in the E.T.S.I. Caminos (Campus de Ciudad Universitaria,

Prof. Ignacio Romero, appointed new Director

On April 28th, Javier LLorca stepped down as Director of IMDEA Materials Institute, after 10 years in this position. The newly appointed Director is Ignacio Romero, formerly Deputy Director of the Institute, and head of the Computational Solid Mechanics Group. Dr. Romero is Full Professor at the

Rubén Costa: talent that returns to Spain

Take a moment to read this interview (in Spanish) with Rubén Costa, who is heading a new research line in the field of lightning and energy generation technologies.

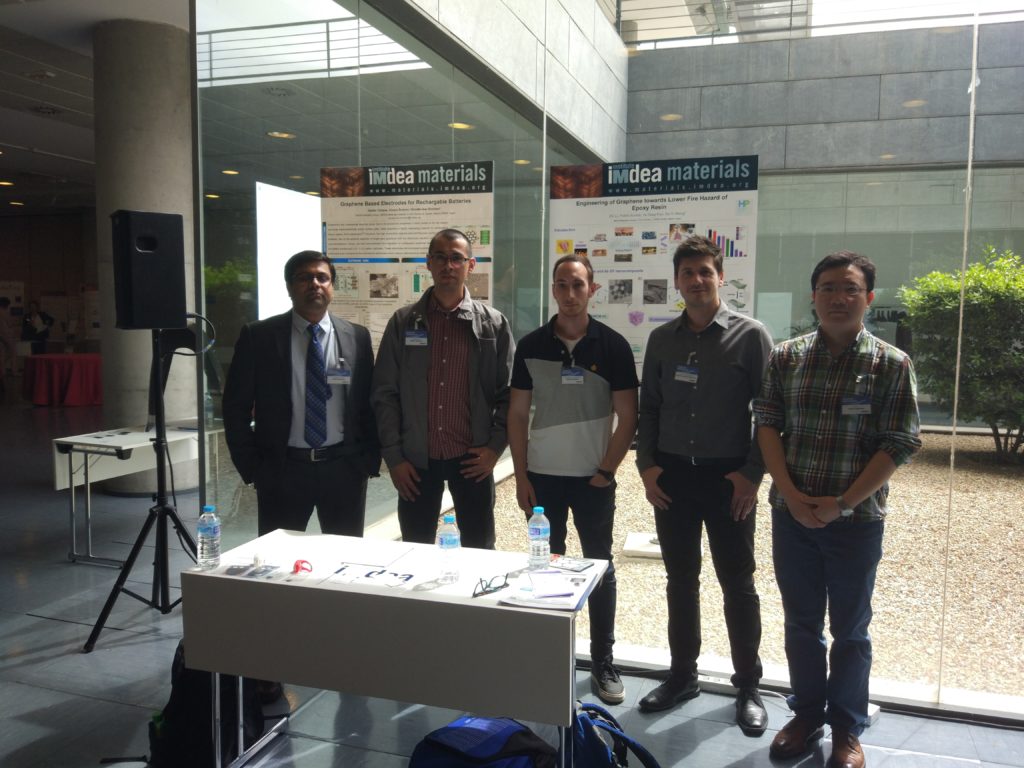

IMDEA Materials Institute takes part in “Graphene Market Place” organised by Airbus

The past 4th of May, IMDEA Materials Institute took part in the “Graphene Market Place” event, organised by Airbus in Getafe (Madrid), which counted with the participation of the 2010 Physics Nobel Prize, Konstantin Novoselov. Novoselov gave a talk in which besides explaining the simple exfoliation

Annual report 2016 is out

The outcome of the research activities performed during year 2016 is summarized in this document. The personnel, current research projects, research infrastructures as well as disseminations activities (publications, conferences and seminars, patents, theses, etc.) can be found in this annual report

PhD Defense – Victor Reguero “Synthesis, structure and scalability of macroscopic carbon nanotube fibre”

The PhD Defense will take place next Friday, April 21st, at 11:30 am, in the "Aula de Grados" of the "Padre Soler" building, at the Carlos III University (Leganés Campus). Abstract Carbon nanotube fibre is an interesting new material due to its unusual combination of bulk

First Year Assessment of Sergio Lucarini entittle “Developement of a FFT-based homogenization code in python” – 21st of April at 12:00 pm at the Seminar Room

Abstract: The mechanical behavior of heterogeneus materials such as composites, polycrystals or cellular materials, depends on their actual microstructure. Computational homogenization is a powerful tool that allows to link macroscopic behavior with microstructure by solving a boundary value

Seminar of Prof. José A. Rodríguez-Martínez – “A general overview on multiple necking and fragmentation problems in ductile solids subjected to high strain rates” – April 19th 2017, Seminar Room at 12:30 pm

Seminar: "A general overview on multiple necking and fragmentation problems in ductile solids subjected to high strain rates" Understanding the fragmentation of ductile solids and structures subjected to high velocity impacts or blast loadings has importance in aerospace industry, military

σ-Hammett parameter: a strategy to enhance both photo- and electro-luminescence features of heteroleptic copper(I) complexes

A virtual test lab for structural composite materials

You can read our view on advanced simulation tools for Fibre-Reinforced Polymers in JEC Magazine (Issue #111 - March 2017, pp. 110 - 111)

Fire protection of films, fabrics and foams achieved through surface nano-structuring

Schedule of Presentation: 11:30-12:30 on 4th April 2017 Jenny Alongi University of Milan, Department of Chemistry jenny.alongi@unimi.it Polymer flammability represents a major limitation to their employment and thus to the development of most polymer-based advanced materials. Environmental and

CRASHING II project

The CRASHING II project is the follow up of the Clean Sky CRASHING project and is focused on the modelling and simulation of the crashworthiness of and aircraft front fuselage using numerical composite material models developed in the initial project. The cabin model will be simulated in different

Seminar of Prof. Raúl Sánchez-Martín – “Introduction to Machine Learning with Python: Image Processing and Recognition” – April 4th 2017, Seminar Room at 5:00 pm

ABSTRACT: Machine learning, an important part of artificial intelligence, has made a huge impact on many different areas (baking, logistic, telecommunications, etc.) during the last years. Following this trend, there are clear indications that this data-driven technique will play a fundamental role

PhD Defense – Xiaomin Zhao “Halogen-Free Phosphorus-Containing Flame Retardant Epoxy Composites”

The PhD Defense will take place next Monday, April 3rd, at 11:00 am, in the room “Puig Adam” of the Industrial Engineering, School of UPM (c/José Gutiérrez Abascal, 2) ABSTRACT Epoxy resins are widely applied in transportation, aerospace, electrical and electronic (EE) industrial sectors

“A good scientist should be able to motivate and inspire the next generation of researchers”

An interview of Dr. Vinodkumar Etacheri, head of the Electrochemical Energy Storage group at IMDEA Materials Institute (Madri+d, in Spanish only)

Juan José Vilatela joins the Editorial Board of Scientific Reports

Dr. Juan José Vilatela, Senior Researcher at IMDEA Materials, joins the Editorial Board of Scientific Reports. Scientific Reports is an online, open access journal from the publishers of Nature. It publishes scientifically valid primary research from all areas of the natural and clinical sciences.

A yarn like sensor for composites

J. Carlos Fernández-Toribio There is a clear evidence that composites are an increasing field of interest. Thus, the demand for composites end products has reached 22.2$ billion in 2015 . This is due to their low weight and high mechanical resistance. Therefore, lighter structural parts can be

Seminar Prof. Jorge Alcalá – “Multi-scale mechanistic interpretations to indentation experiments across the material length scales: from continuum to atomistic” – Seminar Room (12:00)

Abstract We provide a fundamental contact mechanics background to the interpretation of spherical indentation experiments performed in polycrystalline aggregates, single crystalline units, thin films, and minute material scales comprising an atomistic ensemble. A central issue under examination is

Metals Winter Meeting 2017 (Seminar Room – 9:45 am)

METALS WINTER MEETING 2017 PROGRAM 9:45 Arrival and welcome Session I Chairman: Carmen Cepeda 10:00 Marcos Jiménez “Fatigue behaviour of INCONEL 718 under cyclic conditions” 10:15 Deng Xiangxing “Development of innovative materials for the cutting sector" 10:30 Marta

First Year Assessment of Jaime Castro entitle “Dual Scale Flow during Vacuum Infusion of Composites Experiments” – 11:00 am at the Seminar Room

Abstract LCM techniques such as RTM and VARI still require to be enhanced in order to disseminate their use in the industry. In situ VARI experiments were carried out using synchrotron X-ray computed tomography (SXCT) to study the mechanisms of microfluid within a fibre tow. A bundle of two tows of

Teresa Pérez Prado elected Board Member of the Spanish Society for Materials (SOCIEMAT)

Dr. Teresa Pérez Prado, Senior Researcher at IMDEA Materials, has been elected Board Member of the Spanish Society for Materials (SOCIEMAT). The mission of the Spanish Society for Materials (SOCIEMAT) is to foster and disseminate the important research and development efforts carried out in Spain in

(ECOPVC) ECO-FRIENDLY FIRE RETARDANT PVC NANOCOMPOSITES

Funding: China Scholarship CouncilRegion: InternationalProject period: 2013 – 2017Principal Investigator: Dr. De-Yi Wang (deyiwang@imdea.org)The study of fire retardancy in PVC is a very important topic nowadays due to its huge industrial application. ECOPVC project aims to develop a series

Training course DIMMAT: “Economic-business basic concepts”

The next training course “Economic bussines basic concepts” will be held at the Seminar Room, on March 2nd, 2017. The programme offered is suitable for pre-doctoral and post-doctoral researchers. · Place: IMDEA Materials Institute (Seminar room) Date: March 2nd, 2017 Time: 10:00 – 12:00 Attached

IMDEA Materials coordinates the Advanced Materials and Nanomaterials Spanish Technological Platform

Driven by the Spanish Ministry of Economy, Industry and Competitiveness (MEIC), Technological Platforms are public-private team-work structures led by the industry, in which all the stakeholders of the Science-Technology-Innovation Spanish system interested in a given technological field, work

PhD Defense – Raul Sanchez “Micromechanics of Magnesium and Its Alloys Studied by Nanoindentation”

The PhD Defense will take place next Monday, February 20, at 12:00 in the "Aula de Grados" building "Padre Soler", in Carlos III University (Campus Leganes).

Seminar of Dr. Elías Cueto – “A Manifold Learning Approach to Data-Driven Computational Elasticity and Inelasticity”

University of Zaragoza Abstract Standard simulation in classical mechanics is based on the use of two very different types of equations. The first one, of axiomatic character, is related to balance laws (momentum, mass, energy, ...), whereas the second one consists of models that scientists have

Seminar of Dr. Efim Borukhovich – “Incorporating elastoplastic models in phase field”

Royal Institute of Technology (KTH), Stockholm, Sweden Abstract: In material science modeling, phase field is the method of choice when morphology of the observed system is to be modeled. This full field approach is able to capture the microstructure of interest regardless of its complexity. The

First Year Assessment of José Antonio Santiago entittle “Enhanced Diamond-Like Carbon coatings and tribomechanical properties via innovative sputtering processes”

Abstract: Diamond-like Carbon (DLC) coatings have been recognized as one of the most valuable engineering materials for various industrial applications including manufacturing, transportation, biomedical and microelectronics. Among its many properties, DLC stands out for good frictional behaviour

Review—Single-Walled Carbon Nanohorn-Based Dye-Sensitized Solar Cells

1st review meeting

The 1st OptiQPAP progress meeting was held on 24th of January at the CSM headquarters (Rome, Italy). The meeting was organized by Dr. Ali Smith. Project partners presented and discussed their research activities in frame of the OptiQPAP project within first 6 months. The research plans for the next

Recruitment process is closed

The recruitment process to cover 2 research assistants positions (Early Stage Researchers) within the DYNACOMP project is now closed. The selected candidates are Maria Azzurra (Master’s degree in Materials Engineering by the University of Salento in Italy) and Mario Rueda (Master of

Summer school on composite materials

Composite materials are nowadays extensively used in applications where outstanding mechanical properties are necessary in combination with weight savings.Their increased use has presented new challenges to engineers, largely due to the highly complex failure mechanisms of composite materials but

Dr. Aude Simar – Friday, January 27th 2017 – Seminar: Improving the damage resistance of 6xxx series aluminum alloys by friction stir processing – towards an ERC project

Université Catholique de Louvain. UCL - iMMC - IMAP

On the Role of Alloy Composition and Sintering Parameters in the Bimodal Grain Size Distribution and Mechanical Properties of ODS Ferritic Steels

A. García-Junceda, M. Campos, N. García-Rodríguez, J.M. Torralba. On the Role of Alloy Composition and Sintering Parameters in the Bimodal Grain Size Distribution and Mechanical Properties of ODS Ferritic Steels. Metallurgical and Materials Transactions A 47, 5325–5333,

Seminar of Prof. José Luis Tirado (University of Cordoba): “Recent advances and challenges in Li- and post-Li- ion batteries”, January 23th at 1:00 pm

Abstract: Univalent Na- and multivalent (Ca, Mg, Al)- ion batteries have recently emerged as potential candidates to replace Li-ion batteries in some applications. Their elemental natural abundance, homogeneous geographic distribution and high volumetric capacities in some cases, could be useful

Seminario del Prof. José Manuel Baena “3D printing of medical devices and bioprinting of tissues”, 25 de enero a la 1:00 pm

Abstract: MSc. José Manuel Baena, research associate "Advanced therapies: differentiation, regeneration and cancer" IBIMER,CIBM, Universidad de Granada. Founder of BRECA Health Care, pioneer in 3D printed custom made implants for orthopedic surgery, and REGEMAT 3D, the first Spanish bioprinting

Seminar of Prof. José Manuel Baena: “3D printing of medical devices and bioprinting of tissues”, January 25th, 1:00 pm

Abstract: MSc. José Manuel Baena, research associate "Advanced therapies: differentiation, regeneration and cancer" IBIMER,CIBM, Universidad de Granada. Founder of BRECA Health Care, pioneer in 3D printed custom made implants for orthopedic surgery, and REGEMAT 3D, the first Spanish bioprinting

Seminar of Dr. Marta Serrano (CIEMAT, Head of the Division of Materials of Energy Interest), January 23th at 12:00 pm

Abstract: The next evolution for commercial nuclear reactors include the design of fast nuclear reactors as a sustainable nuclear energy production system. The operating conditions for this Gen IV reactors are much more aggressive than the ones for operating light water reactors, in terms of neutron

Seminar of Dr. Marta Serrano (CIEMAT, Head of the Division of Materials of Energy Interest), January 23th at 12:00 pm

Abstract: The next evolution for commercial nuclear reactors include the design of fast nuclear reactors as a sustainable nuclear energy production system. The operating conditions for this Gen IV reactors are much more aggressive than the ones for operating light water reactors, in terms of neutron

José Agustín Hobson

Seminario – Prof. Damien Tourret “Solidification of alloys across length and time scales” (16 de Enero 12:30)

The processing path of a structural material controls the development of its microstructure, and the formation of defects that ultimately dictate its properties and performance. From a fundamental standpoint, complex solidification microstructures, such as dendrites, arise from a subtle interplay

Weak interface dominated high temperature fracture strength of carbon fiber reinforced mullite matrix composites

Towards stable porous crystalline phases of molecular belts

María Dolores Martín

Modelling and simulation of tow-drop effects arising from the manufacturing of steered-fibre composites

Manganese dioxide decoration of macroscopic carbon nanotube fibers: From high-performance liquid-based to all-solid-state supercapacitors

Bioinspired polydopamine-induced assembly of ultrafine Fe(OH)3 nanoparticles on halloysite toward highly efficient fire retardancy of epoxy resin via an action of interfacial catalysis

A Multi Material Shell Model for the Mechanical Analysis of Triaxial Braided Composites

Garcia-Carpintero, A.; Herraez, M; Xu, J; Lopes, CS; Gonzalez, C

María Teresa Nieto Valeiras

Nerea Rodríguez

Ilchat Sabirov

Research Interests Physical simulation of metallurgical processes (rolling, forging, casting, welding, joining of dissimilar materials, etc.) Mechanical and functional properties of metallic materials Processing-microstructure-properties relationship Refractory materials Academic

Implementation of single-walled carbon nanohorns into solar cell schemes

Symposium on New steels for applications under extreme conditions

Metallurgical and Materials Transactions A A. García-Junceda, M.J. Santofimia. Symposium on New steels for applications under extreme conditions. Metallurgical and Materials Transactions A 47, 5271–5271, 2016. DOI: 10.1007/s11661-016-3766-2

Micro-macro mechanical relations in Palmetto wood by numerical homogenisation

Source(s): IMDEA Materials, Composite Structures E. I. Saavedra, S. Haldar. Micro-macro mechanical relations in Palmetto wood by numerical homogenisation. Composite Structures 154, 1-10, 2016. DOI: 10.1016/j.compstruct.2016.06.050

First Year Assestment: Hugo Mora – Development and characterisation of advanced coatings on nanostructured titanium for biomedical applications

Ti-based materials are one of the most important materials used in biomedical engineering. Recently, commercially pure (CP) Ti has attracted significant attention of research community due to its full biocompatibility with human body, and there is an ongoing demand to improve its mechanical

ITN 2016 – Coordinators Info Day

IMDEA Materials, as coordinator of the DYNACOMP network, attended an information day for ITN actions organized by the Research Executive Agency (REA) past 12/12/2012 in Brussels (Belgium). During the event, the REA (funding agency of the DYNACOMP project) provided detailed

First Year Assessment – Xiangxing Deng: Development of Innovative Materials for the Cutting Sector

Traditional hard metals based on WC/Co system are currently the most important hard metals due to their high hardness, mechanical impact strength and wear resistance, which always take the largest share of the global cutting market. Interest in the field of alternative binders in hard metals has

Moisés Zarzoso

Energy dissipation during delamination in composite materials – An experimental assessment of the cohesive law and the stress-strain field ahead of a crack tip

Source(s): IMDEA Materials, Composites Science and Technology M. Jalalvand, G. Czél, J. D. Fuller, M. R. Wisnom, L. P. Canal, C. D. González, J. LLorca. Energy dissipation during delamination in composite materials - An experimental assessment of the cohesive law and the stress-strain field ahead of

Strengthening mechanisms in nanostructured Al/SiCp composite manufactured by accumulative press bonding

Source(s): IMDEA Materials, Metallurgical and Materials Transactions A S. Amirkhanlou, M. Rahimian, M. Ketabchi, N. Parvin, P. Yaghinali, F. Carreño. Strengthening mechanisms in nanostructured Al/SiCp composite manufactured by accumulative press bonding. Metallurgical and Materials Transactions A

1ª Entrega de Premios de Innovación de IMDEA Materiales.

Lugar: Auditorio (13.00 hrs.) Organización: Instituto IMDEA Materiales. Fecha: Wednesday, 14 December, 2016

New incorporation – Alberto Jesús Palomares

Position: Research Assistant Research: Micromechanics of intermetallic materials Contact: alberto.palomares(AT)imdea.org

Seminar – Prof. Rigoberto Burgueño "Integration of materials science and structural engineering for the design of advanced materials systems"

New incorporation – Yetang Pang

Position: Research Assistant Research: Fire Retardant Polymeric Materials Contact: yetang.pang(AT)imdea.org

Seminar – Prof. Thomas R. Bieler "Interdependent Modeling and Characterization to Identify Effects of Slip Transfer at Grain Boundaries in Heterogeneous Deformation"

New incorporation – Yang Lingwei

Position: Research Assistant Research: Nanoscale metal-ceramic multilayers Contact: yang.lingwei(AT)imdea.org

Seminar – Dr. Pablo Antolín "New developments for locking problems in Isogeometric Analysis: nearly-incompressibility and solid shells"

New incorporation – Wenzhou Chen

Position: Research Assistant Research: DFT/MD calculation of phase change materials Contact: wenzhou.chen(AT)imdea.org

Seminar – Prof. Sylvain Drapier "Challenges and expectations from modeling infusion-based processes for structural composites"

IMDEA Materials awarded two new Airbus R&D contracts

IMDEA Materials Institute has been awarded two new R&D contracts by Airbus Operations. The first one (ECURE) is focused on developing electrically-curable epoxy resins for bonding and repairing composite materials. The second project (NONCIRC) aims at assessing the potential of using

Seminar – Dr. Raghavendra Adharapurapu "Industry Perspective on ICME Modeling Approaches for Superalloys"

New incorporation – Alfonso Monreal

Position: Research Assistant Research: Production and properties of thermoset nanocomposites Contact: alfonso.monreal(AT)imdea.org

Phd Defense- Joaquim Vilà Bramon

Contract awarded with Abengoa Research

IMDEA Materials Institute has been awarded a R&D contract with Abengoa Reseach to develop a simulation platform to perform virtual design, virtual processing and virtual testing of engineering materials to reduce the time necessary to develop and introduce new materials into the market. See VMD

Seminar – Dr. Kostas Danas "Magnetorheological elastomers and elasto-plastic metallic materials: from micro-deformation mechanisms to instabilities"

New incorporation – Dr. Belén Alemán

Position: Research Associate PhD: Complutense University of Madrid, Spain Research: Synthesis of advanced materials based on carbon nanotube fibres Contact: belen.aleman(AT)imdea.org

Seminar – Prof. Victor M. Orera – "Tailoring microstructures and interfaces for improving functionalities in ceramics"

New incorporation – Miguel de la Cruz

Position: Laboratory Technician Contact: miguel.delacruz(AT)imdea.org

Seminar – Prof. Arnaud Weck " Ductile fracture studies using artificial microvoids in metals and polymers"

Success in the final FP7 calls

IMDEA Materials Institute is achieving great success in the last calls of the 7th Framework Programme. To date, our researchers have secured 6 R&D projects belonging to different lines of this programme: MICROMECH project (Clean Sky I JTI (Joint Technology Initiative)) MODENA, ICMEG and

Phd Defense – Francisca Martínez

New Airbus Operations contract awarded

IMDEA Materials Institute has been awarded a new R&D contract by Airbus Operations to design composite shields against high energy impact of an open-rotor blade on the new NSA (New Single Aisle) aircraft fuselage concept. See BLADE IMPACT project description

Seminar – Prof. Philippe Boisse " "Simulations of composite reinforcement forming processes"

New incorporation – Dr. Hyung-Jun CHANG

Position: Research Associate Grenoble INP, France / Seoul National University, South Korea Research: Multiscale plasticity Contact: hyungjun.chang(AT)imdea.org

Seminar – Prof. Juan Pou – "Laser spinning: a new technique for nanofiber production"

1st workshop on graphene and 2D materials proved to be a great success

IMDEA Materials Institute hosted the 1st international workshop on graphene and 2D materials past Tuesday 16th of July. The event gathered together some of the most reputed researchers working in the field (see event programme), who presented the latest findings and advances to an audience of

Phd Defense – Ehsan Naderi Kalali "Multifunctional Layered Double Hydroxide (LDH) Based Epoxy Nanocomposites"

High performance environmentally friendly fire retardant epoxy nanocomposites

Dr. De-Ti Wang and Prof. Javier LLorca will carry out a research project in collaboration with the China Scholarship Council (China) to develop high performance fire retardant, halogen-free epoxy nanocomposites by means of molecular design and advanced chemical

Seminar – Dr. Jose Maria Ulloa "Photonic devices based in III-V semiconductors" / Dr. Gonzalo Fuentes: " AlN microcantilevers " / Dr. Javier Martinez: "Graphene electronic devices"

Final year project on carbon nanotube growth receives regional award

Carbon nanotube growth on conventional engineering materials

Seminar – Dr. Vinodkumar Etacheri "Nanoscale Engineering and Electrochemical Approaches to Next-Generation Energy Storage"

Screening of phase transformation kinetics of Ti alloys

Drs. Yuwen. Cui and Javier Segurado will carry out a research project in collaboration with the China Scholarship Council (China) to develop a high throughput diffusion multiple technique for screening of phase transformation kinetics in Ti alloys, which will be used

Advances in Materials and Processing Technologies 2015 conference (14-17 December 2015)

New incorporation – Prof. Mauricio Terrones

Position: Visiting Scientist (01/07/2013-31/07/2013) Penn State University, USA / Shinshu University, Japan Research: Synthesis and Properties of Novel Nanocarbons Link to the researcher profile

Seminar – Prof. Julián J. Rimoli “A concurrent multi-scale model for the thermomechanical response of ceramics”

Seminar – Juan Carlos Fernández – "Infiltration of CNT fibers in liquids: chemo-electro-mechanical sensing"

New incorporation – Prof. Xiaoma Tao

Position: Proffesor Guangxi University, China Research: DFT/MD of thermoelectric/phase change materials

Seminar – Prof. Sybrand van der Zwaag “Computational guidance of the development of new creep steels and that of polymer-PZT composites for sensing and energy harvesting”

New incorporation – Dr. Yong Lu

Position: Lecturer Xiamen University, China Research: Mg alloys

Seminar – Zhi Li – "Study on Delaying Ignition Time and Smoke Suppression behaviors of Flame-retardant Polymers”

Madrid, world hub of light metals

In order to significantly reduce environmental burdens, lightweight metals and alloys play an increasingly important role because of their high specific strength and stiffness, corrosion resistance, and recyclability. Among them, magnesium (Mg), aluminum (Al), and titanium (Ti) alloys are widely

I IMDEA Conference, Science, Industry and Society

New incorporation – Daniel Rodriguez Galán

Position: Research Assistant Polytechnic University of Madrid, Spain Research: Multiscale Plasticity Contact: daniel.rodriguez@imdea.org

Science week Madrid 2015

IMDEA Materials participates in ITER project

ITER (acronym of International Thermonuclear Experimental Reactor) is an international nuclear fusion research and engineering project, which is currently building the world's largest experimental tokamak nuclear fusion reactor at the Cadarache facility in the south of France. The ITER project

Seminar – Dr. Noemí Encinas "“To Wet or Not to Wet. Liquid-repellent Coatings”

Nanostructured Al alloys with improved properties

Dr. Ilchat Sabirov will carry out a research project in collaboration with Ufa State Aviation Technical University (Ufa, Russia) on Nanostructured Al alloys with improved properties. See NANOAL project description

Seminar – Evgeny Senokos – "Development of Multifunctional All-solid-state Supercapacitor Based on Carbon Nanotube Fibers”.

New generation of eco-benign fire retardants

Dr. De-Yi Wang, head of the High Performance Nanocomposites group of IMDEA Materials Institute, has been awarded a prestigious Marie Curie Action: "Career Integration Grant" (CIG) to carry out a four-year research project on design and processing of eco-benign multifunctional fire

Seminar – Prof. Miguel Bañares "Operando Raman methodology to understand structure-performance relationships in catalysis"

New incorporation – Luis Carlos Herrera Ramírez

Position: Research Assistant University Carlos III of Madrid, Spain Research: Nano-Architectures and Materials Design Contact: luis.herrera@imdea.org

Seminar – Alfonso Monreal – “Energy Harvesting Materials Based on Carbon Nanotube Fibre for Tough Electronics”

New incorporation – Mónica Prieto de Pedro

Position: Research Assistant Complutense University of Madrid, Spain Research: Computer simulation of dislocations Contact: monica.prieto@imdea.org

Research initiation fellowships presentations (2nd call)

R&D contract between IMDEA Materials and TOLSA

TOLSA S.A. and IMDEA Materials Institute have recently signed a R&D contract to carry out a study on the performance of sepiolite based additives in fire retardant systems. This one year project is led by Dr. De-Yi Wang, head researcher of the High Performance Nanocomposites group.

Seminar – Chuangyun Wang – "A high-throughput diffusion-multiple study on titanium alloys”

Seminar – Juan José Torres – "“Mechanisms of air removal and void development in Out-of-Autoclave processing of composites”

New incorporation – Prof. Ignacio Romero

Position: Visiting Scientist Research: Computational Solid Mechanics PhD: Berkeley, University of California, USA Contact: ignacio.romero@imdea.org

Phd Defense – Irene de Diego

Guanglong Xu has been awarded with a CALPHAD scholarship

Guanglong Xu has been awarded with a CALPHAD scholarship as a PhD student to give presentation at the coming international conference CALPHAD XLII to be held at San Sebastian (Spain) next May 26-31.

Seminar – Dr. Laura Cabana "Carbon nanotube – inorganic hybrids: from synthesis to application"

New incorporation – Dr. Carmen Cepeda

Position: Research Associate University of Alicante, Spain Research: Al and Mg nanocomposites Contact: carmen.cepeda@imdea.org

Highest grade for Silvia Hernandez´s PhD thesis

Silvia Hernandez defended her PhD thesis entitled “Cure, Defects and Mechanical Performance of Fiber-Reinforced Composites” on March 11th at the Civil Engineering School of the Technical University of Madrid (UPM). Her work was awarded the highest grade by the PhD committee. Dr.

Seminar – Dr. Silvia Marchesan "Twists of chirality for the self-assembly of short peptide nanomaterials".

New incorporation – Marcos Angulo

Position: Laboratory Technician Contact: marcos.angulo@imdea.org

Seminar – Dr. Yongjun Su "’Microstructure and Mechanical Properties of Large Size Ti-43Al-9V-Y Alloy Pancake Produced by Pack Forging’’

New incorporation – Alejandro Garcia Carpintero

Position: Research Assistant Carlos III University of Madrid, Spain Research: High Energy Impact on Aeronautical Composite Structures Contact:

Advances in Materials and Processing Technologies 2015 conference

New Incorporation – Hossein Ehteshami

Position: Research Assistant Bahonar University of Kerman, Iran Research: Multiscale Modelling of Nanostructured Titanium Contact: hossein.ehteshami@imdea.org

Seminar – Prof Marc Anderson "materials science of nanoporous metal oxides and their applications in energy, sensors and water treatment"

Nanoscale hybrids for hydrogen production through water splitting using sunlight

A consortium of European universities, research centres and companies, led by IMDEA Materials Institute, is working on the production of new, more efficient hybrids composed of nanocarbons (e.g. graphene) and inorganics (metal oxides) that can produce hydrogen by water splitting using sunlight.

Seminar – Prof. Krishnaswamy Ravi-Chandar "PREDICTIVE MODELING OF DEFORMATION AND FAILURE IN DUCTILE MATERIALS"

New Incorporation – Alicia Moya

Position: Investigador Predoctoral Complutense University of Madrid, Spain Research: Nanohybrids for Photocatalysis Contact: alicia.moya@imdea.org

Seminar – Balaji Selvarjou – "Triaxiality Effects in Magnesium: Crystal Plasticity Modeling”

New Incorporation – Dr. Dong-Wook Lee

Position: Research Associate PhD: Texas Tech University, EEUU Research: Mesoscale Modeling of Microstructure Contact: dongwook.lee@imdea.org