«IMDEA Materials has provided a unique opportunity both to mature as a scientist as well as to contribute to the creation and growth of a research institute in Spain» Dr. Pérez-Prado was born in Asturias, Spain. She completed an MSc in Physics at the Complutense University in Madrid (UCM) in 1994.

IMDEA Materials on tv: Bioculture applied to lightning technologies

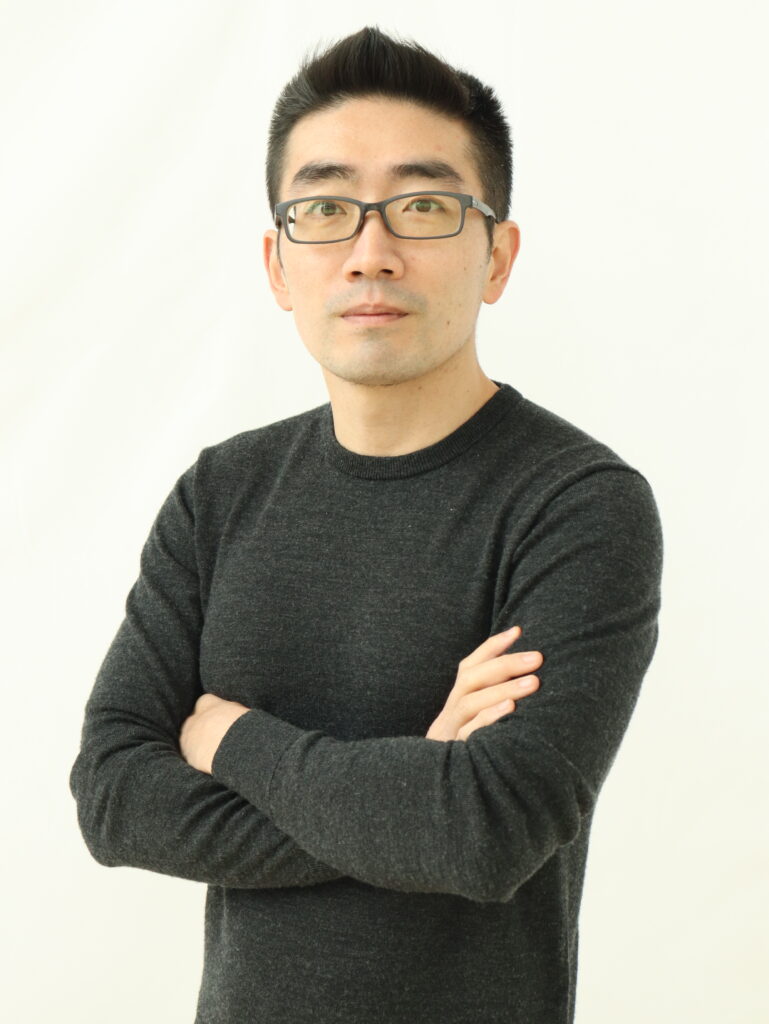

Rubén Costa explains his research line related to biological lightning in the national tv news (in Spanish only)

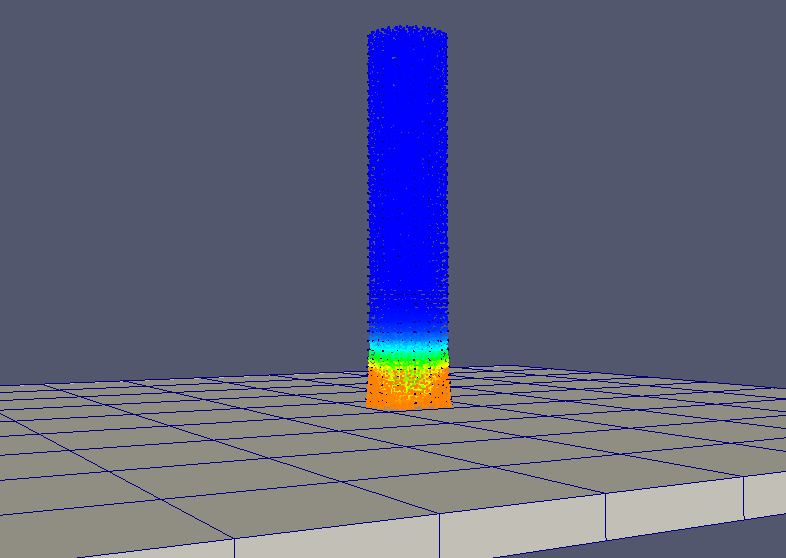

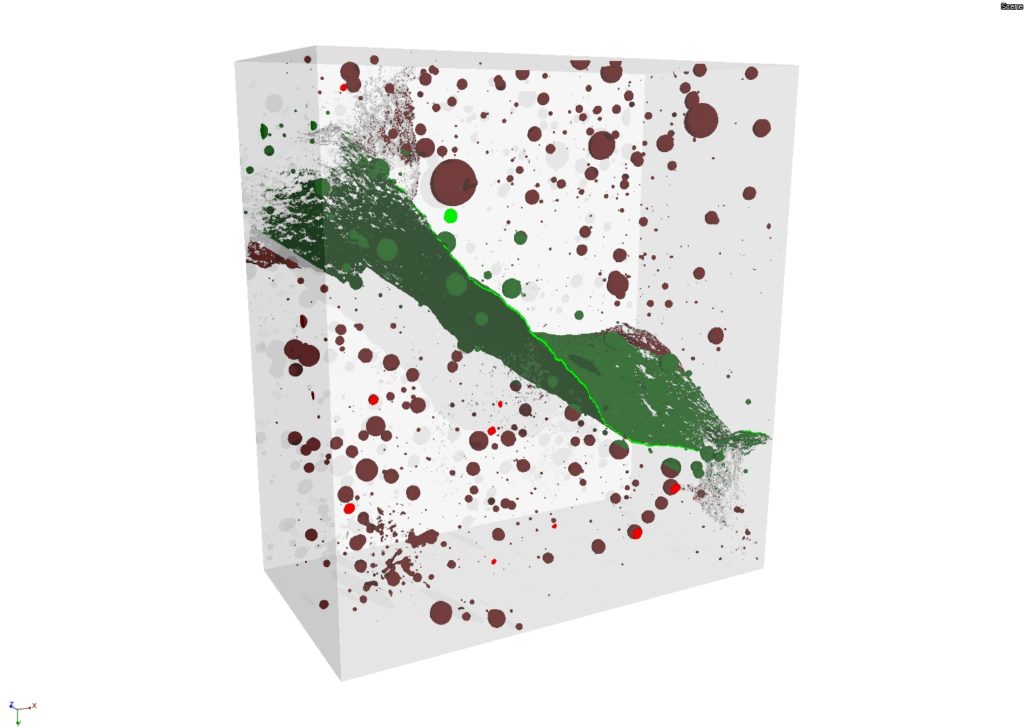

Damien Tourret: Dendritic microstructures are present in nearly every piece of metal

«Dendritic microstructures are present in nearly every piece of metal around us» Damien Tourret received an MSc in Mechanical Engineering from INSA Toulouse (France) in 2006 and a PhD in Materials Science & Engineering from École des Mines de Paris (Mines ParisTech, France) in 2009. Before

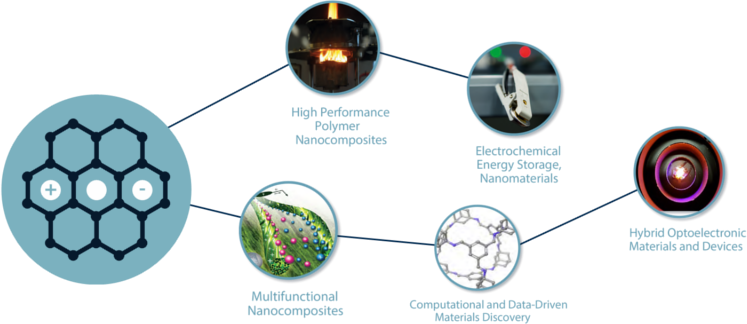

Juan José Vilatela awarded best researcher under 40 by the Madrid regional government

Juan José Vilatela, head of the Multifunctional Nanocomposites group at IMDEA Materials, has been awarded best researcher under 40 by the Madrid regional government. The award giving ceremony will take place next november 14th in Madrid (Spain).

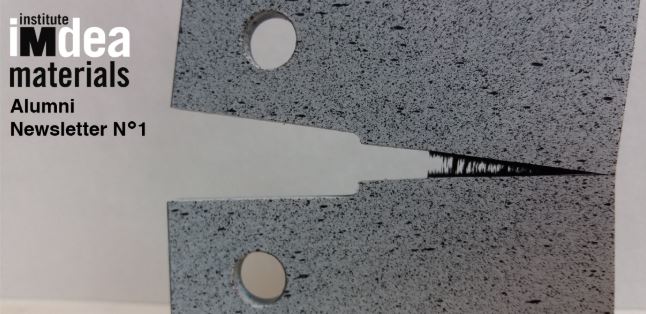

First Year Assessment of Alejandro Rodríguez, entitle “Analysis of the nucleation and growth mechanisms of fatigue cracks in Ni-based superalloys” – In the Seminar Room at 4:30 pm

Abstract: Ni-based superalloys play an extremely important role in the aerospace industry due to their outstanding strength and chemical stability at high temperature. Most demanded components employed in jet engines are manufactured with these novel materials. Several statistical studies confirm

External use of X-Ray Tomograph PHOENIX

DESCRIPTION OF THE EQUIPMENTGE (Phoenix) Nanotom 160 kV with a Hamamatsu 7942-25SK detector (2K x 2K) and tungsten and molybdenum targets, with a nanofocus X-ray source. This equipment is capable of both radiography (RX) and computed tomography (XCT) modes.Attainable resolution varies between <1

First Year Assessment of Cristina Gutierrez, entitle “Third generation γ-TiAl alloys for greener turbines: heat treatment and microstructure characterization” – In the Seminar Room at 12:00 pm

ABSTRACT The previous design of engines used for commercial aircrafts fan and turbine were driven with same shaft; new geared engines decouple fan and the low pressure turbine increasing angular velocity, and also centrifugal forces, so a change from conventional superalloy blades to lighter ones

First Year Assessment of Carmen Fernández, entitle “Rigid fluorescent protein coatings for highly efficient and stable bio-hybrid LEDs” – In the Seminar Room at 12:00 pm

Abstract Additive manufacturing (AM) is a layer by layer process that has the potential to disrupt traditional fabrication methods. It allows fast manufacturing of three dimensional pieces from metallic powders, with great exibility of design, potential for weight reduction, fast production speed

IMDEA Materials Institute Interview – Rocío Muñoz Moreno

Rocío Muñoz Moreno finished her joint PhD (IMDEA Materials and UCM III) in 2014. Then she joined the Cambridge University's Rolls-Royce UTC (University Technology Centre) as postdoc and currently, she is working in the HP 3D printing team in Barcelona as an R&D Materials System Integration

IMDEA Materials Institute Alumni Interview – Nathamar Dudamell

Dr. Nathamar Dudamell Caballero was born in Maracay, Venezuela. She completed a MSc in Metallurgy Engineering at the Central University in Caracas, Venezuela (UCV) in 2006. In 2007 she joined the ALCOA’s Aluminium Research and Development Center in Alicante site. In 2008 Dr. Dudamell Caballero

Arcadio Varona

Arcadio Varona finished his PhD at IMDEA Materials in 2016, under the supervision of Ilchat Sabirov and Teresa Pérez Prado. Later on, he joined GRUPO ANTOLIN-EUROTRIM as quality engineer. Starting this interview, would you explain us how your scientific vocation born? When and why did you take the

Nathamar Dudamell

Dr. Nathamar Dudamell Caballero was born in Maracay, Venezuela. She completed a MSc in Metallurgy Engineering at the Central University in Caracas, Venezuela (UCV) in 2006. In 2007 she joined the ALCOA’s Aluminium Research and Development Center in Alicante site. In 2008 Dr. Dudamell Caballero

Rocío Muñoz Moreno

Rocío Muñoz Moreno finished her joint PhD (IMDEA Materials and UCM III) in 2014. Then she joined the Cambridge University's Rolls-Royce UTC (University Technology Centre) as postdoc and currently, she is working in the HP 3D printing team in Barcelona as an R&D Materials System Integration

IMDEA Materials Institute Alumni Interview – Arcadio Varona

Arcadio Varona finished his PhD at IMDEA Materials in 2016, under the supervision of Ilchat Sabirov and Teresa Pérez Prado. Later on, he joined GRUPO ANTOLIN-EUROTRIM as quality engineer. Starting this interview, would you explain us how your scientific vocation born? When and why did you take the

Integrated Computational Materials Engineering

Main research lines Virtual materials design, including virtual processing and virtual testing Virtual material discovery for functional applications, through the use of DFT, cluster expansion and atomistic approaches combined with AI.Virtual processing: Integration of modelling

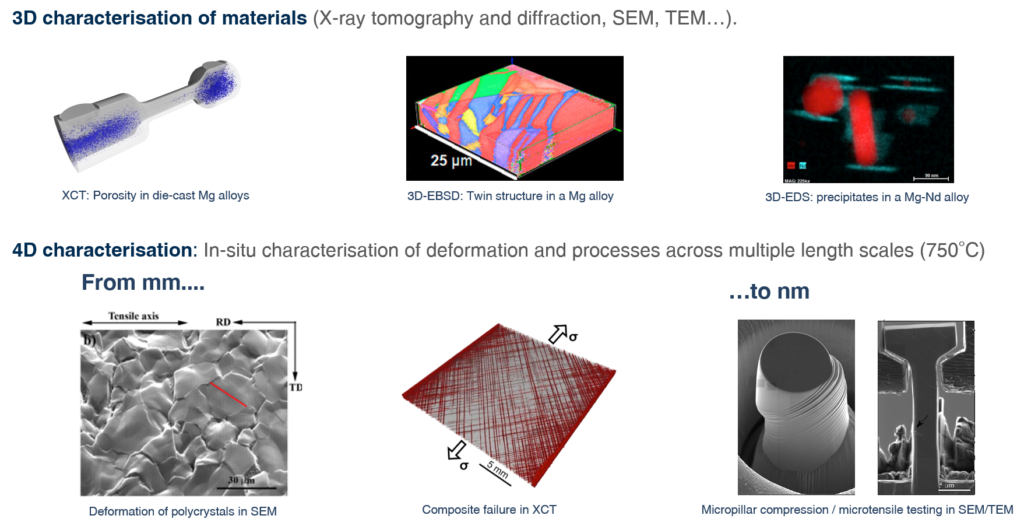

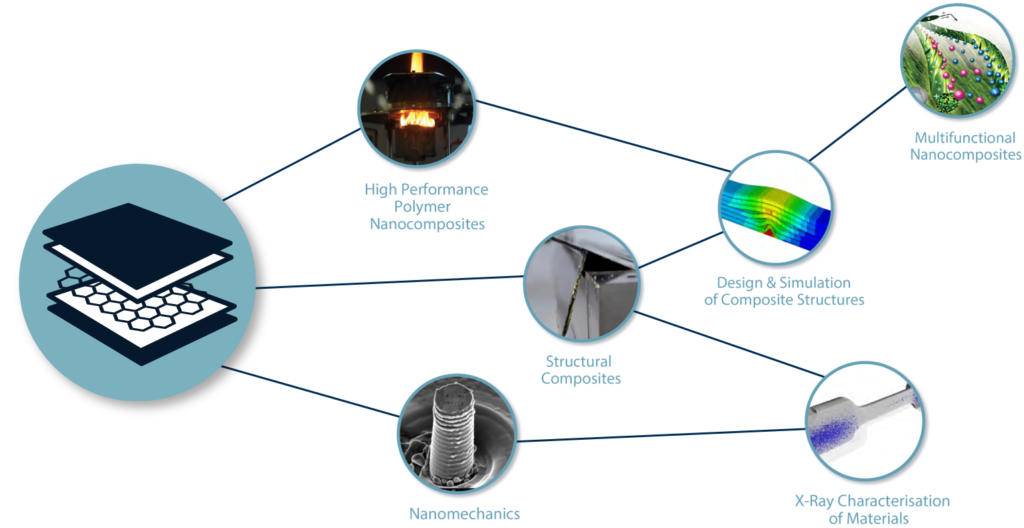

Multiscale Characterization of Materials and Processes

Main research lines Advanced material characterisation, including microstructural, chemical and crystallographic information across several length scales and using different techniques Multiscale characterisation with optical and electron microscopy, X-rays, atom force microscopy,

Advanced Manufacturing

Main research lines Industry 4.0 Virtual testing of structural composites. Analysis of the effect of manufacturing defects on structural performance.Virtual processing of structural composites including hot-forming and out-of-autoclave (injection, infusion, compression moulding).

(OPTIQPAP) OPTIMIZATION OF QP STEELS DESIGNED FOR INDUSTRIAL APPLICATIONS

The Project Commercialization of the Quenched and Partitioned (Q&P) steels to a large extent is currently limited by the lack of knowledge on their application related performance properties. The OptiQPAP project (Optimization of QP steels designed for industrial applications) addresses

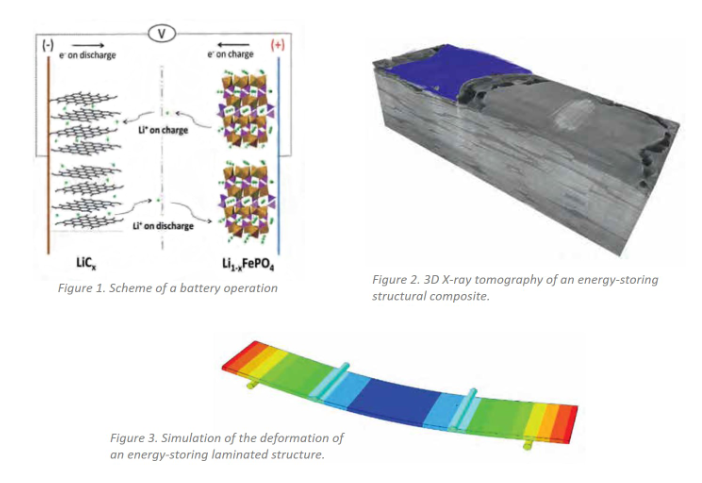

(STEM) STRUCTURAL ENERGY HARVESTING COMPOSITE MATERIALS

Structural energy harvesting composite materials Funding: European Union, Horizon 2020 Programme (Grant Agreement 678565). ERC Starting grantRegion: EuropeProject period: 2016 – 2021Principal Investigator: Dr. Juan José Vilatela (juanjose.vilatela@imdea.org)The purpose of this project is the

(MATERPLAT 2016-2017) ADVANCED MATERIALS AND NANOMATERIALS SPANISH TECHNOLOGICAL PLATFORM 2016-2017

Funding: Agencia Estatal de Investigación (Ministerio de Economía, Industria y Comptetitividad). Technological Platforms call Region: Spain Project period: 2016 – 2017 Project IP: Miguel Ángel Rodiel (miguel.angel.rodiel@imdea.org) The main purpose of the Advanced Materials and

(EQUINOX) A NOVEL PROCESS FOR MANUFACTURING COMPLEX SHAPED FE-AL INTERMETALLIC PARTS RESISTANT TO EXTREME ENVIRONMENTS

Funding: European Union, Horizon 2020 Programme (Grant Agreement 689510) Partners: National Technical University of Athens (Project Coordinator), Elastotec GmbH Elastomertechniken, Kochanek Entwicklungsgesellschaft, IMDEA Materials Institute, Technica Univerzita V Liberci, Access e.V., Open Source

(EMULATE) MULTISCALE APPROACH FOR THE SIMULATION OF THERMOMECHANICAL PROBLEMS UNDER SEVERE CONDITIONS: APPLICATION TO MACHINING

Funding: Spanish Ministry of Innovation and competitiveness (National R&D Programme for Societal Challenges) (DPI2015-67667-C3-1-R) Partners: Mondragón University, Technical University of Madrid and IMDEA Materials Institute (coordinator) Region: Spain Project period: 2016 – 2018 Principal

(HYDTCOMP) INTRALAMINAR HYBRIDIZATION, USE OF SCRAPS AND ANALYSIS OF THEIR EFFECTS. CHARACTERIZATION AND MODELING

Funding: Spanish Ministry of Innovation and competitiveness (National R&D Programme for Societal Challenges) (MAT2015-69491-C3-2-R) Region: Spain Project period: 2016 – 2018 Principal Investigators: Drs. Roberto Guzmán de Villoria (roberto.guzman@imdea.org) and Claudio Lopes

(REDISH) CROR ENGINE DEBRIS IMPACT SHIELDING. DESIGN, MANUFACTURING, SIMULATION AND IMPACT TEST PREPARATION

REDISH: CROR Engine Debris Impact Shielding. Design, Manufacturing, Simulation and Impact Test Preparation Funding: European Union, Clean Sky Joint Undertaking 2, Horizon 2020 Programme (Grant Agreement 686946) Partners: IMDEA Materials Institute (Project Coordinator) and Fundación para la

(VIRMETAL) VIRTUAL DESIGN, VIRTUAL PROCESSING AND VIRTUAL TESTING OF METALLIC MATERIALS

Virtual design, processing and testing of advanced metallic alloys for engineering applications Funding: European Union, Horizon 2020 Programme (Grant Agreement 669141). ERC Advanced grant Region: Europe Project period: 2015 – 2020 Principal Investigators: Prof. Javier Llorca

(ADVANSEAT) MODULAR CONCEPT FOR ULTRALIGH REMOVABLE ADVANCED CAR SEAT

Funding: Centre for Industrial Technological Development (CDTI, CIEN programme), Spanish Ministry of Economy and Competitiveness and Grupo AntolínPartners: National consortium led by Grupo Antolín. IMDEA Materials Institute collaborates with Grupo AntolínRegion: SpainProject period: 2015 –

(NEOADFOAM) INNOVATIVE ADDITIVES FOR FOAMS WITH IMPROVED THERMAL INSULATION AND FIRE RESISTANCE

Funding: Spanish Ministry of Economy and Competitiveness (National R&D Programme for Societal Challenges) (RTC-2015-3340-3), thematic objective "“Promotion of technological development, innovation and quality research"Partners: TOLSA S.A. (Project Coordinator), Cellmat group (University of

(ONLINE-RTM) ONLINE NDT RTM INSPECTION IN COMPOSITES

Funding: AIRBUS Operations S.L. and CDTI (CIEN 2014 programme) Region: Spain Project period: 2014 – 2017 Principal Investigator: Dr. Carlos González (carlosdaniel.gonzalez@imdea.org) ONLINE-RTM is a research collaboration between IMDEA Materials and AIRBUS Operations aiming at analysing sensor

(DIMMAT) MULTISCALE DESIGN OF ADVANCED MATERIALS

Funding: Regional Government of MadridPartners: IMDEA Materials Institute (Project Coordinator), National Centre for Metals Research (CSIC), Materials Science Institute of Madrid (CSIC), Institute For Nuclear Fusion of the Technical University of Madrid, Technical University of Madrid, Carlos III

(MAD2D) FUNDAMENTAL PROPERTIES AND APPLICATIONS OF GRAPHENE AND OTHER BIDIMENSIONAL MATERIALS

Funding: Regional Government of MadridPartners: Materials Science Institute of Madrid (CSIC) (Coordinator), IMDEA Nanoscience Institute, IMDEA Materials Institute, IMDEA Energy Institute and Autonomous University of MadridRegion: MadridProject period: 2014 – 2018Principal Investigator: Dr. Juan José

(VIRTEST) MULTISCALE VIRTUAL TESTING OF CFRP SAMPLES

Funding: Fokker Aerostructures B.V. Region: International Project period: 2014 – 2019 Principal Investigator: Dr. Claudio Lópes (claudio.lopes@imdea.org) Funded by

(ITER PCRS) STRUCTURAL ANALYSIS OF THE ITER PRE-COMPRESSION RINGS

Funding Organization: EADS CASA Espacio / F4E Region: International Project Period: 2012 – 2017 Principal Investigator: Dr.Carlos González Contact: carlosdaniel.gonzalez@imdea.org ITER (acronym of International Thermonuclear Experimental Reactor) is an international nuclear fusion research

(ENERYARN) NANOSTRUCTURED YARN COMPOSITES FOR STRUCTURAL ENERGY STORAGE

Funding: European Union, Marie Skłodowska-Curie Individual Fellowships, Horizon 2020 Programme (Grant Agreement 797176) Partners: IMDEA Materials Institute Project period: 2018 – 2020 Project Coordinador: Supervisor: Dr. Juan José Vilatela (juanjose.vilatela@imdea.org); Fellow: Anastasiia

(CONSYS) DEVELOPMENT OF A NEW TRANSITIONAL ELEMENT

(MINIMAL) CHARACTERIZATION AND MODELLING OF DISLOCATION INTERFACE INTERACTIONS IN METALLIC LAMINATES AT MULTIPLE SCALES

Funding: European Union, Marie Skłodowska-Curie Individual Fellowships, Horizon 2020 Programme (Grant Agreement 749192) Region: Europe Project period: 2018 – 2019 Principal Investigators: Supervisor: Dr. Jon Molina (jon.molina@imdea.org); Fellow: Dr. Zhilin Liu (zhilin.liu@imdea.org) The

(NAMBAT) QUEST FOR SAFE AND SUSTAINABLE BATTERIES USING NA-ION, MG AND HYBRID CONCEPTS

Funding: Ministerio de Economía, Industria y Competitividad. Retos investigación: Proyectos I+D+i Region: National Project period: 2018 – 2020 Partners: University of Córdoba (Project Coordinator), IMDEA Materials Institute Principal Investigator: Dr. Vinodkumar Etacheri

(PRECONTIAL) PRELIMINARY ANALYSIS OF TiAl CONTAINMENT

(ELAM) ULTRAFINE EUTECTICS BY LASER ADDITIVE MANUFACTURING

Funding: Ministerio de Ciencia e Innovación. M-ERA.NET Partners: DLR Institute of Materials Research (Project Coordinator), IMDEA Materials Institute, Fraunhofer Gesellschaft Zur Foerderung Der Angewandten Forschung E.V, Access e.v., Wigner Research Center for Physics, Procter & Gamble

(IMPACT TIAL) DATA DISPERSION STUDY IN IN718 AND BALLISTIC TESTS IN TiAl

Funding Company: ITP AeroPeriod: 2017 – 2018Principal Investigators: Dr. Jon M. Molina (jon.molina@imdea.org) and Dr. Ilchat Sabirov (ilchat.sabirov@imdea.org)

(NEWTOP) NEW FIRE RETARDANT ADDITIVES TO POLYMERS

Funding Company: Liaoning Jinghua New Materials Inc.Period: 2017 – 2018Principal Investigator: Dr. De-Yi Wang (deyi.wang@imdea.org)

(ALFORAMA) INNOVATIVE AL ALLOY FOR AIRCRAFT STRUCTURAL PARTS USING ADDITIVE MANUFACTURING TECHNOLOGY

Funding: European Union, Clean Sky Joint Undertaking 2, Horizon 2020 Programme (Grant Agreement 755610) Partners: Lortek (Project Coordinator), University of Leuven and IMDEA Materials Institute Region: Europe Project period: 2017 – 2020 Principal Investigator: Drs. Srdjan Milenkovic

(FIREMEC) STUDY OF THE MECHANISMS OF ACTUATION OF POLYOLS WITH FIRE RETARDANT CAPABILITIES

Funding Company: Repsol S.A.Period: 2017 – 2018Principal Investigator: Dr. De-Yi Wang (deyi.wang@imdea.org)

(SUMER) STUDY OF THE COMPREHENSIVE UTILIZATION OF MAGNESIUM SOURCES IN THE SALT LAKES DESIGN FOR FLAME RETARDANT EPOXY RESINS

Funding: Qinghai Institute of Salt LakesRegion: InternationalProject period: 2017 – 2019Principal Investigator: Dr. De-Yi Wang (deyi.wang@imdea.org)The main objet of this project is to the design and preparation of multifunctional magnesium-based nanomaterials and its application in flame retardant

(MAVIS) NEW MATERIAL SOLUTIIONS FOR THE OPTIMIZATION OF AC ROOF UNITS

Funding: Sanz ClimaRegion: SpainProject period: 2017 – 2018Principal Investigator: Dr. De-Yi Wang (deyi.wang@imdea.org)The principal aim of this project is to find new material solutions as an alternative to polyester/GF composites for climate components in vehicles. These solutions should fulfil at

(MICROMECH II) MICROSTRUCTURE BASED MATERIAL MECHANICAL MODEL FOR SUPERALLOYS

Funding: Industria de Turbopropulsores S.A.Region: SpainProject period: 2017 – 2019Principal Investigator: Dr. Javier Segurado (javier.segurado@imdea.org)The MICROMECH II project is the follow up of the Clean Sky MICROMECH project and is focused on the development of more elaborated micromechanical

(SORCERER) STRUCTURAL POWER COMPOSITES FOR FUTURE CIVIL AIRCRAFT

Funding: European Union, Clean Sky Joint Undertaking 2, Horizon 2020 Programme (Grant Agreement 738085)Partners: Imperial College (Project Coordinator), Chalmers University of Technology, KTH Royal Institute of Technology and IMDEA Materials InstituteRegion: EuropeProject period: 2017 –

(MOFMAP) TAILORED METAL-ORGANIC FRAMEWORK FROM HYBRID TO MULTIFUNCTIONAL FLAME RETARDANT POLYMER NANOCOMPOSITES

Funding: European Union, Marie Skłodowska-Curie Individual Fellowships, Horizon 2020 Programme (Grant Agreement 705365)Region: EuropeProject period: 2017 – 2019Principal Investigator: Supervisor: Dr. De-Yi Wang (deyi.wang@imdea.org); Fellow: Dr. Xiao-Lin QiThe main objective of this project is to

(CRACK-TIAL) THE HIGH TEMPERATURE FATIGUE BEHAVIOR OF A THIRD GENERATION GAMMA TiAi ALLOY FOR GREENER TURBINES

Funding: Ministerio de Ciencia e Innovación. Retos investigación: Proyectos I+D+i Region: NationalProject period: 2017 – 2019Principal Investigator: Dr. María Teresa Pérez Prado (teresa.perez.prado@imdea.org)Enhancing transport sustainability is one of the great challenges of the XXI century.

(SIMUFORM) INTERPLY FRICTION BEHAVIOUR IN FRESH COMPOSITE LAMINATES AND IMPLICATIONS IN MANUFACTURING. A COMBINED EXPERIMENTAL-SIMULATION APPROACH

Funding: FIDAMCRegion: SpainProject period: 2017 – 2019Principal Investigator: Dr. Carlos González (carlosdaniel.gonzalez@imdea.org)The main objet of the SIMUFORM project is to develop a physically based numerical methodology based on the finite element method to analize laminate inter-ply

(ACERCOM) FIBER METAL LAMINATES FOR APPLICATION IN MARINE RENEWABLE ENERGY

Funding: Spanish Ministry of Economy and Competitiveness (National R&D Programme for Societal Challenges) (RTC-2016-5076-3), thematic objective “Promotion of technological development, innovation and quality research”Partners: Arcelor Mittal (Project Coordinator), Technical University of Madrid

(DYNACOMP) DYNAMIC BEHAVIOUR OF COMPOSITE MATERIALS FOR NEXT GENERATION AEROENGINES

Funding: European Union, Marie Skłodowska-Curie actions, Horizon 2020 Programme (Grant Agreement 722096)Partners: IMDEA Materials Institute (Project Coordinator), HEXCEL, Micro Materials, Technical University of Madrid and Madri+d foundationRegion: EuropeProject period: 2016 – 2020Principal

(MAFMA) MULTISCALE ANALYSIS OF FATIGUE IN MG ALLOYS

Funding: European Union, Marie Skłodowska-Curie Individual Fellowships, Horizon 2020 Programme (Grant Agreement 795658)Partners: IMDEA Materials InstituteProject period: 2019 – 2021Project Coordinador: Supervisor: Prof. Javier Llorca (javier.llorca@imdea.org); Fellow: Anxin Ma

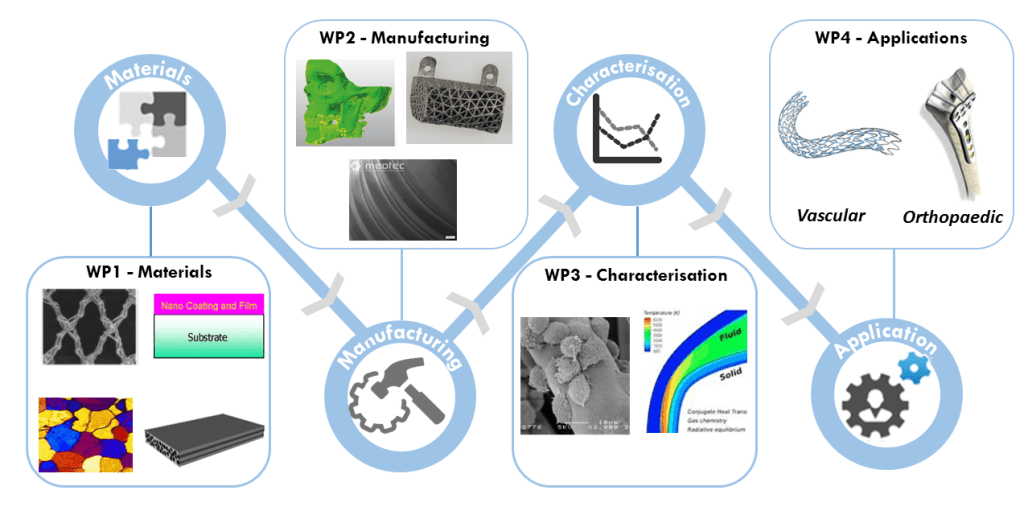

(BIOIMPLANT ITN) EUROPEAN TRAINING NETWORK TO DEVELOP IMPROVED BIORESORBABLE MATERIALS FOR ORTHOPAEDIC AND VASCULAR IMPLANT APPLICATIONS

Funding: European Union, Horizon 2020 MSCA Innovative Training Network (ITN) (Grant Agreement 813869) Partners: National University of Ireland, Galway (Project Coordinator), IMDEA Materials Institute, Boston Scientific Limited, The Queens University of Belfast (UK), RWTH Aachen (DE), Vascular Flow

(HUC) DEVELOPMENT AND VALIDATION OF A POWDER HIP ROUTE FOR HIGH TEMPERATURE ASTROLOY TO MANUFACTURE ULTRAFAN® IP TURBINE CASINGS

Funding:European Union, Clean Sky Joint Undertaking 2, Horizon 2020 Programme (Grant Agreement 821044)Region: EuropeProject period: 2018 – 2021Partners: CEIT-IK4 (Project Coordinator), IMDEA Materials Institute, Aubert & Duval SAS, Universidad del País Vasco, Interuniversitario Nazionale per la

(SAM) SUPERALLOYS FOR ADDITIVE MANUFACTURING

(ENVIDIA) VIRTUAL ENVIRONMENT FOR THE DESIGN AND MANUFACTURING OF AIRPLANE TURBINE ENGINES

Funding: Ministerio de Economía, Industria y Competitividad. Retos colaboración Region: National Project period: 2018 – 2020 Partners: ITP Aero (Project Coordinator), IMDEA Materials Institute, Universidad Politécnica de Madrid, Universidad del País Vasco Principal Investigator: Dr.

(NANOYARN) EXPLOITING LOW-DIMENSIONAL PROPERTIES OF CARBON NANOTUBES IN MACROSCOPIC YARNS FOR CHARGE TRANSFER AND STORAGE

Funding: Air Force Office of Scientific Research (AFOSR) Region: InternationalProject period: 2018 – 2021Principal Investigator: Dr. Juan José Vilatela (juan.josevilatela@imdea.org)With their intrinsic combination of toughness, conductivity, large porosity and lightweight, CNT

(PRO-CSL) PROTEIN STABILIZATION FOR LUMINESCENT SOLAR CONCENTRATORS

(VITAL) VIRTUAL TESTING OF METALLIC MATERIALS

Funding: Fonds National de la Recherche LuxembourgRegion: InternationalProject period: 2018 – 2020Partners: IMDEA Materials Institute (Project Coordinator), e-XstreamPrincipal Investigator: Supervisor Dr. Javier Segurado (javier.segurado@imdea.org); Fellow: Marco Magri

(UNIEXTEST) MECHANICAL STRENGTH OF EXPANDED JUNCTIONS

(MACHSYNCH) HIGH TEMPERATURE MINIATURE MECHANICAL TESTING RIG FOR SYNCHROTRON TOMOGRAPHY

(POPSICLE) DEVELOPMENT OF ADVANCED MATERIALS FOR LIGHTING APPLICATIONS

(NEWCPLECS) NEW CIRCULAR POLARIZED LIGHT-EMITTING ELECTROCHEMICAL CELLS

Funding: European Union, Marie Skłodowska-Curie Individual Fellowships, Horizon 2020 Programme (Grant Agreement 795905) Partners: IMDEA Materials Institute Project period: 2018 – 2020 Project Coordinador: Supervisor: Dr. Rubén Costa (ruben.costa@imdea.org); Fellow: Julio Jacinto

We are working in a paradigm swift related to lightning technologies

Rubén Costa is working in a paradigm swift related to lightning technologies, based in biological LEDs. Read more about his research line on solar windows in this article published by "El Mundo" journal (in Spanish only).

PhD Defense of Alfonso Monreal entitle ”Energy Harvesting Materials Based on Carbon Nanotube Fibre for Tough Electronics”, under the supervision of Dr. Juan José Vilatela

The PhD Defense will take place, at 12 noon, on next Friday (26th of October) in the “sala verde”, on the first floor, in the Escuela de Ingenieros de Caminos, UPM (ETSI Caminos, Ciudad Universitaria) The dissertation is entitled “Energy Harvesting Materials Based on Carbon Nanotube Fibre for

Impact of expandable graphite on flame retardancy and mechanical properties of rigid polyurethane foam

Seminar of Prof. Oana Cazacu, from the University of Florida, entitle “New models for description of plastic anisotropy of single crystals and polycrystals” – At 12:00 pm in the Seminar Room

Abstract: It is presented a rigorous framework developed for formulation of constitutive models. Based on representation theory for tensor functions and scale-bridging theorems, this framework enables the development of constitutive models that account for the influence of crystallographic

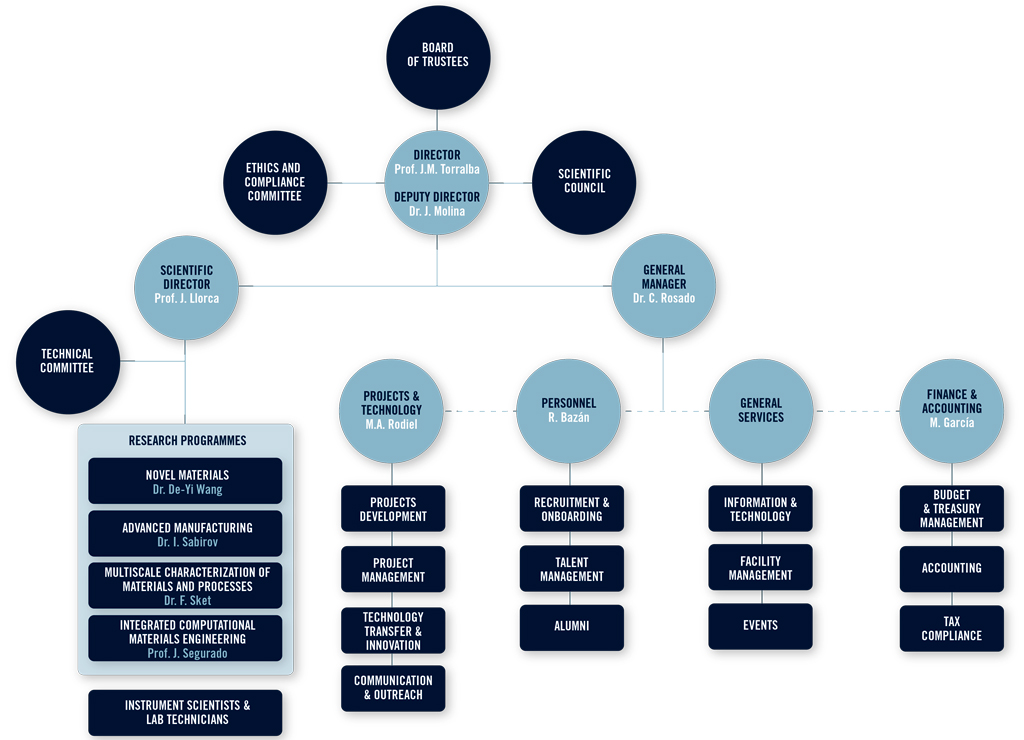

Scientific Council

The Board of Trustees and the Director are assisted in their functions by the Scientific Council, an advisory board made up by 15 scientists from all over the world with expertise in the different areas of research covered by the Institute. The tasks of the Scientific Council include the selection

Board of Trustees

The main governing body of the Institute is the Board of Trustees. The Board includes representatives of the regional government de Madrid (7), permanent trustees designated by other public research institutions (2), universities and research centers of Madrid (4), scientists with an international

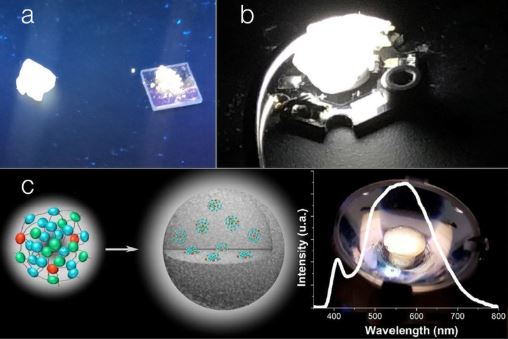

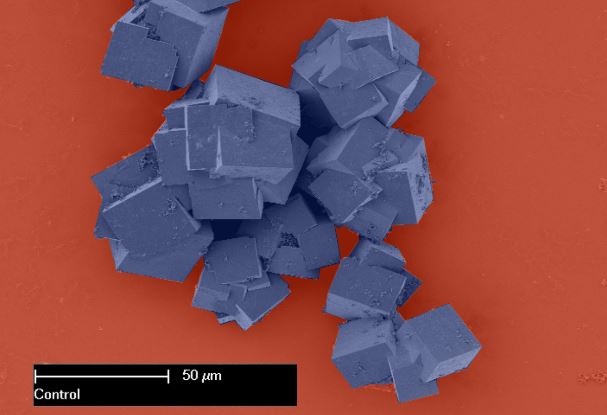

A material similar to sand that emits high quality white light for a new generation of LEDs hybrid

The high content of blue light presented by current LEDs can be harmful to the human retina, especially for children, and has a negative impact on our brain´s chemistry. Rubén Costa, researcher at the IMDEA Materials Institute of Madrid; Elena Lalinde and Jesús Berenguer, from the University of La

Madrid hosts the 55th annual technical meeting of the Society of Engineering Science (SES), the first time outside the US

We are hosting the 55th edition of the Annual Technical Meeting of the Society of Engineering Science (SES). The SES Technical Meeting is held annually to provide an interdisciplinary forum for the exchange of ideas and information among the various disciplines of engineering and the physical and

Seminar of Prof. Jesus Barrio, from the Ben-Gurion University (Israel), entitle “Rational Design of Carbon Nitride Materials by Supramolecular Preorganization of Monomers” – At 11:00 am in the Seminar Room

Abstract Over the past few years, graphitic carbon nitride (g-CN) has attracted widespread attention due to its outstanding electronic properties, which have been exploited in various applications, including in photo- and electro-catalysis, heterogeneous catalysis, CO2 reduction, water splitting,

Seminar of Prof. Irene J. Beyerlein, from the University of California at Santa Barbara, entitle “Discrete slip crystal plasticity modeling of deformation in nanolayered materials” – At 12:30 pm in the Seminar Room

Discrete slip crystal plasticity modeling of deformation in nanolayered materials Irene J. Beyerlein1, Tianju Chen2, Rui Yuan2, Caizhi Zhou2,3 1 Mechanical Engineering Department, Materials Department, University of California at Santa Barbara, Santa Barbara 93106, USA 2 Department of Materials

First Year Assessment of Venkata Sai, entitle “Nanoscale engineered electrode materials for high performance Lithium-ion batteries” – In the Seminar Room at 12:00 pm

Abstract Herein, highly ordered mesoporous pseudocapacitive electrodes for superior Li-ion storage are discussed. Hierarchical 1-D Co3O4nanorods of size ~20 nm with interfaces between the crystallites were synthesized using hydrothermal method followed by calcination. This 1D nanorods exhibited

Sino-Spanish Joint Research Center of Advanced Materials

On 15th September 2018, nine units from China and Spain (Beijing University of Chemical Technology, Beihang University, The Going Global Confederation of China Petroleum & Chemical Industry from China, the Technical University of Madrid, IMDEA Materials Institute, the Department of Innovation,

First Year Assessment of Clara Galera, entitle “AAdditive manufacturing of high strength aluminum alloys with ZrH2 addition” – In the Seminar Room at 12:00 pm

Abstract Additive manufacturing (AM) is a layer by layer process that has the potential to disrupt traditional fabrication methods. It allows fast manufacturing of three dimensional pieces from metallic powders, with great exibility of design, potential for weight reduction, fast production speed

IMDEA Crime Scene Investigation

Researchers belonging to all IMDEA institutes solved a new crime in the activity "IMDEA-CSI" as part of the European Researchers' Night Madrid 2018. More information about the event in this podcast (radio show "Por tres razones", RTVE)

Seminar of Dr. Laszlo Sturz from the Access e.V. Intzestr. (Germany), entitle “Microgravity experiments on solidification” – At 3:00 pm in the Seminar Room

Abstract: Solidification is one of the major steps in producing parts from the molten material in casting, welding or additive manufacturing. On top of process optimization and simulation to obtain good mould filling and minimized defects, the quality of the cast parts depends strongly on the

First Year Assessment de Wenliang Feng, titulado “Na-ion Hybrid Energy Storage Devices Based on Nanoengineered Electrodes” – En la Sala de Seminarios a las 12:00 am

Abstract In this study, dimension control and nanostructure design were applied in developing electrode materials for superior Na-ion storage. Firstly, hierarchical Co3O4nanorods with increased number of interfaces between individual nanocrystallites were prepared for enhancing pseudocapacitance

First Year Assessment of Maria Azzurra, entitle “Intermediate strain rate testing methodologies for composite materials characterisation” – In the Seminar Room at 12:00 am

ABSTRACT: The main objective of this work is to create a physical platform for material characterization and parameter identification at macroscale as a function of applied strain rate, understanding how the strain rate affects the damage and mechanical response of three different composite material

Ruben costa, the sole spanish researcher selected to participate in the World Economic Forum meeting in Tianjin

Rubén Costa, senior researcher at IMDEA Materials, has been recognized as one of the best scientists in the world under the age of 40 by the Word Economic Forum. He will play an important role at the Forum’s Annual Meeting of the New Champions, which is taking place in Tianjin, People’s

Development and characterization of multilayer laser cladded high speed steels

Passion to face new challenges and cross new borders is a clear sign of virtue and vocation in science

Our Scientific Director and head of the Mechanics of Materials research group, Prof Javier Llorca, explains his vision of the researcher's career in this interview (in Spanish only)

PhD Defense of Evgeny Senokos entitle ”Development of Multifunctional Flexible and Structural Supercapacitors Based on CNT Fibers”

The PhD Defense will take place, at 12 noon, on next Friday (7th of September) in the “sala verde”, on the first floor, in the Escuela de Ingenieros de Caminos, UPM (ETSI Caminos, Ciudad Universitaria) The dissertation is entitled “Development of Multifunctional Flexible and Structural

Dr. Muhammed Mehdi

Legal Status

Legal Status IMDEA Materials Institute is a non-profit independent research organization (foundation). This legal form brings together the advantages and guarantees offered by the foundation status with the flexible and dynamic management typical of a private body. This combination is necessary

Luis Arévalo

Seminar of Prof. Piaras Kelly, from the University of Auckland (NZ), entitle “Advanced Composite Materials: manufacturing quality products efficiently” – At 12:00 pm in the Seminar Room

Abstract: Advanced composite materials are now used in a wide range of industries, including aerospace, marine, construction, transport and recreational sport. The ever-increasing pressure on producing quality parts effectively and efficiently has led to many innovations over the years in

Nanostructured commercially pure titanium for development of miniaturized biomedical implants

Transparency Portal

Internal initiatives (awards)

Innovation and creativity are at the heart of IMDEA Materials and in order to encourage it amongst our researchers and technicians, Innovation Awards and Imaging Contests are celebrated every year. Innovation Awards Candidate/s have to show novel and original ideas in the form of a proof of

Alumni

Since its creation in 2007, IMDEA Materials Alumni community has done nothing but grow. Two of the pillars that define the culture of our institution, performing excellent research in materials science and engineering and transferring our knowledge and technology to the industry, are the principles

Opportunities for Postdocs

IMDEA Materials has significant experience hosting and training at postdoctoral and predoctoral levels, as shown by the participation in 16 European training programs within the Marie Skłodowska-Curie actions (2 COFUND, 5 CIG, 1 IIF, 7 IF and 2 EID) and the supervision of over 88 PhDs in

Opportunities for predocs

Open Positions

Career

Media mentions

Activities

What’s new

Visiting IMDEA Materials

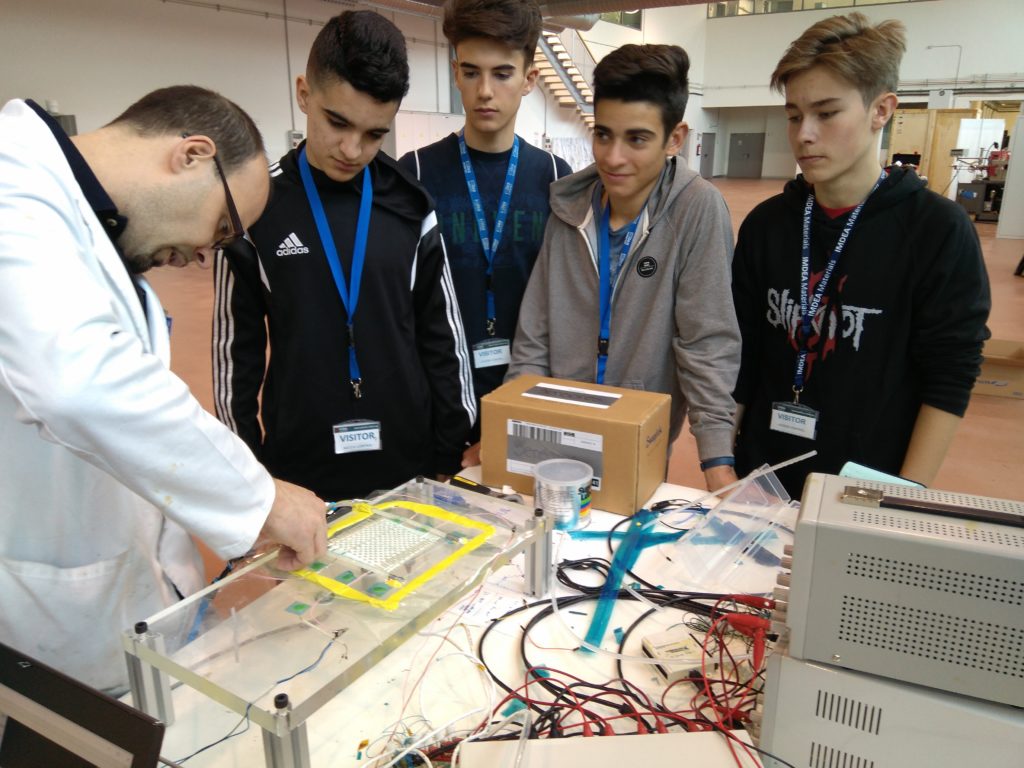

As part of the IMDEA Materials Institute commitment to inspire and encourage the interest of young talents in pursuing materials science related careers, students from secondary schools and University degrees can visit the facilities of the Institute through scheduled meetings and get a closer look

Get to know us

Supporting Initiatives

Inside & Outside IMDEA

From hosting visits of high school and university students to participating in the European Researchers Night or the World Economic Forum. At the IMDEA Materials Institute we are fully aware that being able to explain the relevance and nature of the research we do to non-specialised audiences

Outreach

MATERPLAT

Promoted by the Spanish Ministry of Science, Innovation and Universities, and Managed by the IMDEA Materials Institute, the main purpose of the Advanced Materials and Nanomaterials Spanish Technological Platform (MATERPLAT) is fostering and promoting innovation in the Advanced Materials and

Industrial collaborations

The unique scientific expertise and infrastructure of IMDEA Materials Institute enables its research groups to collaborate with national and international industry to develop innovative, high value materials. This active and effective collaboration with industry has established our centre as a key

Technology offer

The IMDEA Materials Institute is constantly developing new technologies and inventions based on the results of our R&D projects. Here you can find an on-line catalogue gathering the technological offer ready to be transferred to industry, other research insitutions, investors or

Technology

Strategic initiatives

During 2017, IMDEA Materials launched a series of strategic internal initiatives in order to further advance the research lines of the Institute and promote internal collaboration between research groups. These three initiatives comprise the design of structural fire-safe batteries, the development

External use of TEM

DESCRIPTION OF THE EQUIPMENT FEG S/TEM (Talos F200X, FEI) equipped with a chemical analysis system via energy-dispersive X-ray spectroscopy (EDS), a digital CMOS camera able to acquire images with a maximum resolution of 4×4 k, a tomography system to perform computed tomography in TEM, STEM and EDS

Scientific infrastructures

Synthesis, processing and integration of materials Microstructural and chemical characterisation Mechanical properties Simulation Functional properties Biomaterials and cell

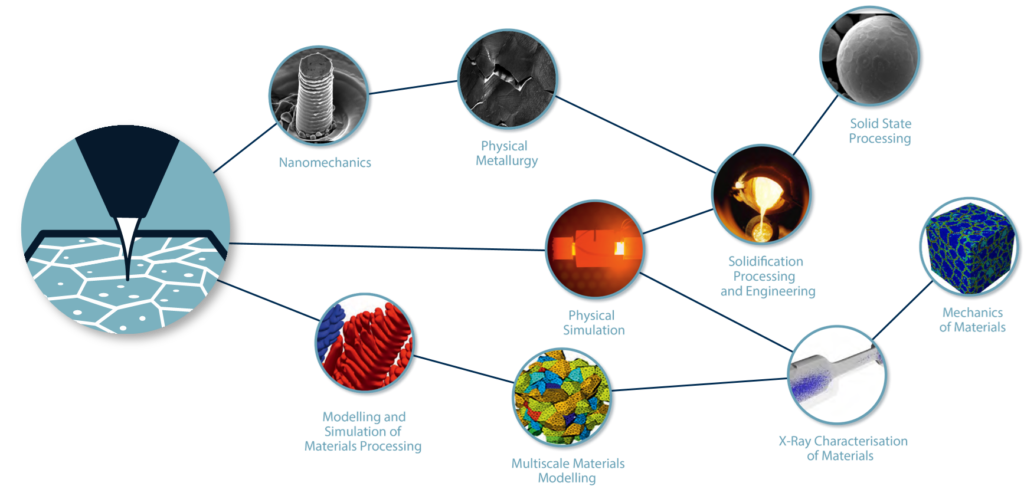

Research programmes

As a result of a high degree of internal collaboration, each research group at the IMDEA Materials Institute participates in several of our research programmes. Driven by the talent of the researchers, the research programmes combine cutting-edge fundamental oriented research in topics at the

Human Resources Excellence in Research

The Human resources strategy for researchers The ‘HR Strategy for Researchers’ supports research institutions and funding organizations in the implementation of the European Charter for Researchers and the Code of Conduct for the Recruitment of Researchers in their policies

Management and Administration

Lab Technicians

Predocs

Annual Reports

Documents

Scientific Advisory Board

Organizational chart

The Institute is run by the Director, who is the CEO and reports to the Board of Trustees (main Governing Body of the Institute). The Director has to be a scientist, appointed by the Board of Trustees under the nomination of the Scientific Council, to reinforce the academic nature of the

IMDEA Material’s strategic plan 2025

IMDEA Material’s strategic plan 2025 Follow

Mission, vision and pillars

MISSION “We do research of excellence in material science, contributing to tackle the challenges of society and fostering the sustainable development of the region of Madrid” VISION “Our vision for the future is that IMDEA Materials becomes a leading research institute, internationally

Cecilia Salvador

Andrés Ballesta

The Next Generation of Composite Materials

Goal and Vision The Next Generation of Composite Materials Programme aims at developing solutions for high performance structural composites with enhanced multifunctional capabilities such as thermal, electrical and fire resistance. The programme is focused on key aspects

Andrew Johnston

Alicia Montero

Novel Materials

Main research lines Synthesis and integration of nanomaterials (nanotubes, nanofibers, MXene, quantum dots, graphene, and hybrids) Synthesis of nanocarbon/semiconductor hybrids for photo and electrocatalysis, interaction of nanocarbons with liquid molecules, polyelectrolytes and

Research Assistant Elisa Fresta awarded with best Master Thesis Prize

Research Assistant Elisa Fresta has been awarded a Prize for one of the best Master Thesis (year 2015/2016) from the University of Turin. The thesis was developed at both the University of Turin and the University of Erlangen-Nuremberg under the supervision of Prof. Claudia Barolo and Dr. Rubén

News

Portal Team

Lab

Open positions

People

Research

10 years

The centre

We will develop the first solar window made of organic materials thanks to the BBVA Foundation

Rubén Costa and his team (below) will develop the first solar window made of organic materials thanks to a grant awarded by the BBVA Foundation. You can read here a related article published by "El Confidencial" journal (Spanish)

New nanostructured material for capacitive deionization

Researchers from our institute have developed in collaboration with IMDEA Energy a new current collector-free capacitive deionization architecture based on electrodes consisting of a porous metal oxide network interpenetrated into porous fibres of carbon nanotube. The full device has a large salt

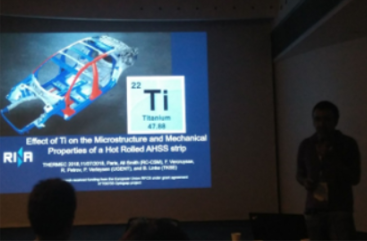

OptiQPAP participation at THERMEC 2018

The OptiQPAP consortium members have participated at the THERMEC 2018 Conference, which was held on July 8-13 in Paris. THERMEC Conference is the main international event in the area of thermo-mechanical processing of steels. The recent outcomes of the OptiQPAP project were presented in oral talks

First Year Assessment of Mario Rueda entitle “Nanoindentation impact testing methodologies for the high strain rate characterization of materials at the microscale” – In the Seminar Room at 09:30 am

Abstract: In view of the future application of polymer matrix composites for structural components subjected to impact loads, there is a need for development of experimentally calibrated constitutive models for polymers that include their inherent viscoelastic and viscoplastic behavior. These

Last June, IMDEA Materials hosted the First International Workshop on Multi-functional Nanocarbon Fibres

Last June, IMDEA Materials hosted the First International Workshop on Multi-functional Nanocarbon Fibres. The meeting gathered leading international researchers working on nanocarbons developing the next generation of functional carbon fibres and fabrics based on nanobuilding blocks. There were

PhD Defense – Zhi Li ”Ignition Delaying and Smoke Suppression Study of Fire-Retardant Polymer Composites”, under the supervision of Dr. De-Yi Wang

Time, Place, PhD thesis Title The Ph.D work is entitled as “Ignition Delaying and Smoke Suppression Study of Fire-Retardant Polymer Composites” under the supervision of Dr. De-Yi Wang. This event will be taking place at 12:00am (16th, July) in “Seminar Room” of ETS de Ingenieros de Caminos, Canales

Seminar of Dr. Lukas Helfen, from Karlsruhe Institute of Technology, entitle “Synchrotron Laminography: A Technique for In situ Observation of Damage and its Evolution Inside Engineering Materials ” – At 1:00 pm in the Seminar Room

Synchrotron Laminography: A Technique for In situObservation of Damage and its Evolution Inside Engineering Materials Lukas Helfen,1,2Mark N. Mavrogordato,3Thilo F. Morgeneyer,4T. Baumbach1 1 Institute for Photon Science and Synchrotron Radiation, Karlsruhe Institute of Technology, PO Box 3640,

Seminar of Dr. Mariana Hamer, from the University of Buenos Aires (UBA), entitle “Porphyrin-based nanomaterials: design, synthesis and applications” – At 11:30 am in the Seminar Room

Porphyrin-based nanomaterials: design, synthesis and applications Abstract The development of new nanomaterials and nanotechnology currently have a huge impact on modern science. Within this trend, a field that has taken relevance is the construction of nanometric supramolecular systems through

PhD Defense – Miguel Herraez “Computational Micromechanics Models for Damage and Fracture of Fiber-Reinforced Polymers”, under the supervision of Prof. Carlos González and Dr. Cláudio Lopes.

The PhD Defense will take place, at 12 noon, on next Friday (13th, July) in the seminar room of the Department of Materials Science at the School of Civil Engineering of UPM (ETSI Caminos, Ciudad Universitaria). The dissertation is entitled "Computational Micromechanics Models for Damage and

First Year Assessment of Verónica Fernández – Luna, entitle “Towards the understanding of FP-coating stability in Bio-LEDs” – In the Seminar Room at 12:00 pm

ABSTRACT Solid-state lighting (SSL) is one of the biggest achievements of the 20th century. It has completely changed our modern life with respect to general illumination (light-emitting diodes), flat devices and displays (organic light-emitting diodes), and small labelling systems (light-emitting

Paulo Silva Freire

Effect of solutes on the rate sensitivity in Ti-xAl-yMo-zV and Ti-xAl-yMo-zCr β-Ti alloys

High throughput analysis of solute effects on the mechanical behavior and slip activity of beta titanium alloys.

Understanding the high temperature reversed yield asymmetry in a Mg-rare earth alloy by slip trace analysis.

Effect of layer thickness on the mechanical behavior of oxidation-strengthened Zr/Nb nanoscale multilayers

Ballistic performance of hybrid nonwoven/woven polyethyelene fabric shield

Prof. Javier Llorca awarded by SOCIEMAT

Prof. Javier Llorca, Scientific Director of IMDEA Materials Institute, has received the award to the best scientific career by SOCIEMAT Javier Llorca receiving the SOCIEMAT award to the best scientific career during the CNMAT 2018 conference

PhD Defense – Mohammad Marvi-Mashhadi “Multiscale Characterization and Modelling of Polyurethane Foams”, supervised by Dr. Claudio Lopes and Prof. Dr. Javier LLorca.

The PhD Defense will take place on next Wednesday (11th, July), at 12 noon, at the "Seminar room" in the ‘’ Departamento de ciencia de Materiales, E.T.S.I. Caminos(Campus de Ciudad Universitaria,

Amalia San Román

Seminar of Dr. Vilas G. Pol, from Purdue University, entitle “Engineered Electrodes for Efficient Energy Storage and Battery Safety” – At 12:00 pm in the Seminar Room

Abstract ViPER (Vilas Pol’s Energy Research) laboratory at Purdue University focuses their research activities on the development of high capacity electrode materials, their engineering for longer cycle life and improved safety. Considering the advantages and limitations of known synthesis

The 4th review meeting

The 4th OptiQPAP progress meeting was hosted by the University of Gent (Gent, Belgium) on 15th of June, 2018. Project partners presented and discussed their research activities in frame of the OptiQPAP project within last 6 months. The future research plans and dissemination activities were updated.

Rubén Costa, awarded one of the 2018 Leonardo Grants to Researchers and Cultural Creators

Dr. Rubén Costa has been awarded one of the 2018 Leonardo Grants to Researchers and Cultural Creators by the BBVA Foundation. Leonardo Grants are intended to directly support personnal projects of researchers and cultural creators in intermediate stages of their professional careers, between 30 and

Dr. Javier García

First Year Assessment of Ismael Gómez entitle “”Algorithms and tools for detection and characterization of molecular porosity and applications thereof”” – In the Seminar Room at 12:00 pm

IMDEA Materials will host the First International Workshop on Multi-functional Nanocarbon Fibres

The First International Workshop on Multi-functional Nanocarbon Fibres, which will take place at the IMDEA Materials Institute between 27-29 June, 2018, will gather leading researchers around the globe working on nanocarbons, with a view to developing the next generation of functional carbon fibres

Dr. Muzi Li

Dr. Juan Alberto Meza

Home

Design, processing, characterisation and simulation of advanced materialsCompetitiveness through advanced knowledgeNovel materials for future applicationsYour partner to develop innovative, high value materialsDownload Previous slide Next

Clean Sky 2 visit

Past tuesday 5th of June, representatives of the Clean Sky 2 visit our Institute as part of the Engine Integrated Technology Demonstrator (ITD) annual meeting, organized by ITP Aero. Our Instutute is currently participating in 3 Clean Sky 2 projects: REDISH, (CROR Engine Debris Impact SHielding.

Seminar of Carlos M. Atienza, from the Biomechanics Institute of Valencia, entitle “3D printing technologies, new possibilities for customized products and services for TOC” – At 12:00 pm in the Seminar Room

3D printing technologies, new possibilities for customized products and services for TOC There will be first an introduction to the activities of the IBV (Valencia Biomechanics Institute), to then explain the biomechanical bases of additive manufacturing through EBV that led the IBV to work on this

CO2 Induced Synthesis of Zn-Al Layered Double Hydroxide Nanostructures towards Efficiently Reducing Fire Hazards of Polymeric Materials

Summer School & Industry Day: Additive Manufacturing

On July 23rd and 24th IMDEA Materials Institute organizes a Summer School on Additive Manufacturing and an Industry Day where prominent companies (Siemens, ITP, Renishaw, HP, LPW Technologies, Mizar Additive) will discuss the progress of the field as well as the challenges ahead. This event is

First Year Assessment of André Rittner Pires Correa entitle “A numerical approach on thermoforming simulation of UD prepregs” – In the Seminar Room at 12:00 pm

Abstract Composite materials are a serious competitor for lightweight metals used in the aerospace and automotive industry. Fast production methods like thermo-folding, diaphragm forming or stamping can produce large numbers of CFRP components in a cost efficient way. The weight saving benefits of

Success in call 2018 of Marie Skłodowska-Curie Actions Innovative Training Networks

One Marie Skłodowska-Curie Action Innovative Training Networks (ITN) has recently been awarded to our Institute, representing a 17% success rate. This new project (BioImplant ITN) will train 12 young researchers in the area of development of bioresorbable materials for orthopaedic and vascular

Mid-term report

The OptiQPAP project has successfully undergone mid-term review by the Research Fund for Coal Steel. The mid-term report of the OptiQPAP project was approved by the Committee after the evaluation that took place on April 27 at the CSM headquarters (Rome).

MINIMAL project

MINIMAL is a research endeavour which will contribute significantly towards improving analysis/predictive tools for dislocation-interface interactions in metallic nanolaminates, which have attracted application as mechanical parts in Micro Electro Mechanical Systems (MEMS). It is funded by the

Seminar of Dr. Indrat Aria, from Cranfield University, entitle “Synergistic CVD graphene and ALD alumina for permeation barrier applications” – At 1:00 pm in the Seminar Room

Abstract Permeation barrier films are critical to a wide range of applications ranging from food and medical packaging to organic electronics and photovoltaics. For some of these applications, not only low permeation values are required but also flexible and transparent. Here, I will present

Seminar of Dr. Eric Jägle, from the Max Planck Institute of Metals Research in Düsseldorf (Germany), entitle “Alloys for Additive Manufacturing, Alloys by Additive Manufacturing” – At 11:00 am in the Seminar Room

Abstract As Additive Manufacturing technologies are being adopted in more and more industries, the focus of research and development is shifting to the materials in use. On the one hand, limited processability of high-performance materials restrict the robustness of the process in some cases, while

OptiQPAP consortium will organize a Special Issue on ‘Advanced high strength steels by quenching and partitioning‘ in the open-access journal Metals

The OptiQPAP consortium members have been invited to organize a Special Issue ‘Advanced high strength steels by quenching and partitioning‘ in the open-access journal Metals, which belongs to the Q1 journals in the area of Metallurgy. The main objectives of this Special Issue are to disseminate

Annual report 2017 is out

The outcome of the research activities performed during year 2017 is summarized in this document. Information about the centre Principal Investigators, current research projects, research infrastructures as well as dissemination activities can be found in this annual report, together with scientific

Jon Molina awarded best young researcher by UC3M

Dr. Jon Molina has been awarded as one of the best young researchers by Carlos III University of Madrid (UC3M). The full information of this award can be found in this link (in Spanish only)

Large surface area lends superpowers to ultra-porous materials

Some materials are special not for what they contain, but for what they don’t contain. Such is the case with metal-organic frameworks (MOFs) – ultra-porous structures that are being developed for a variety of future applications from fire-proofing to drug-delivery. Read the whole article in HORIZON

Seminar of Prof. Marisol – Martín González, from the Instituto de Micro y Nanotecnología, entitle “Nanoengineering thermoelectrics to improve their efficiency: some examples” – At 12:00 am in the Seminar Room

Short summary of her group Functional Nanoscale Devices for Energy Recovery Group (FINDER) (Instituto de Micro y Nanotecnología) Their research is focused on the optimization of thermoelectric devices via nanostructuration. A thermoelectric device is able to transform temperature differences into

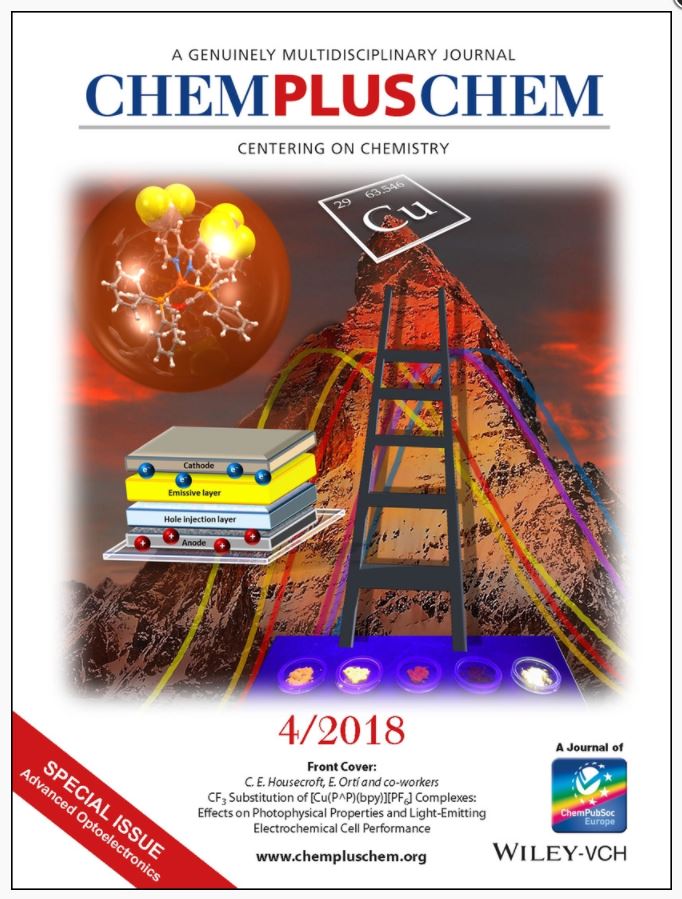

Optoelectronics special issue

A special issue organized by our colleague Rubén Costa on new materials and approaches for optoelectronics is free to read in ChemPlusChem through May! Check it out under this link: https://onlinelibrary.wiley.com/toc/21926506/83/4

Seminar of Dr. Thomas Bieler, from the department of Physical Metallurgy, Grain Boundaries, Crystal Plasticity from IMDEA Materials, entitle “The challenge of finding critical resolved shear stress values for meso-scale modeling of titanium alloys” – At 12:00 am in the Seminar Room

Short bio: Professor Thomas R. Bieler earned a B.A. in Applied Mechanics at University of California at San Diego in 1978 followed by a M.S. In Ceramic Engineering at University of Washington (Seattle) in 1980. He worked for five years at Sandia National Laboratory in Livermore on high rate

IMDEA Materials Institute opens its doors to the future of scientific research in “4ºESO+Empresa”

Last week we participated in the program "4ºESO + empresa", through which high school students of the Lourdes School made an approach to an adult work environment and thus better understand the world of work.

Bio-inspired engineering of boron nitride with iron-derived nanocatalyst toward enhanced fire retardancy of epoxy resin

Studies on intumescent flame retardant polypropylene composites based on biodegradable wheat straw

7th Edition of the IMDEA Materials Imaging Contest

On March1 16th, the Director and Deputy Director of the Institute gave the awards to the winners of the 2017 edition of the IMDEA Materials Imaging Contest.

CIMNE – IMDEA Materials Workshop

On April 13, a bilateral technical meeting was held between the International Centre for Numerical Methods in Engineering (CIMNE) and the IMDEA Materials Institute. Twelve researchers from both institutions attended the workshop, which took place at IMDEA Materials’ facilities in Tecnogetafe, with

Role of lignin nanoparticles in UV resistance, thermal and mechanical performance of PMMA nanocomposites prepared by a combined free-radical graft polymerization/masterbatch procedure

VIII Conference with Science in the School – Circulo de Bellas Artes

On March 6 and 7 we will participate in the VIII Conference with Science in the School, organized by Circulo de Bellas Artes and FUHUMER. Our colleagues Juan Pedro Fernandez, Maria Azurra, Jose Sanchez and Jaime Castro will do their best to bring science closer to citizens!

Seminar of Prof. Efstathios I. Melts, from the Department of Materials Science and Engineering of the University of Texas at Arlington, entitle “The Quest for New Materials: Interface-engineered Materials” – At 12:00 am in the Seminar Room

ABSTRACT Atomic interface structures provide a unique opportunity to design new materials that can provide promising solutions to future technological demands. This talk presents an overview of two diverse areas of activity at the Surface and Nano Engineering Laboratory at the University of Texas,

Energy storage in structural composites by introducing CNT fiber/polymer electrolyte interleaves

The paper entitled "Energy storage in structural composites by introducing CNT fiber/polymer electrolyte interleaves" is available for download at Scientific Reports journal. This is a recent work by the multifunctional nanocomposites group, headed by Dr. Juan José Vilatela. This work presents a

Nearly 30% success rate in call 2017 of Marie Skłodowska-Curie Actions Individual Fellowships

3 Marie Skłodowska-Curie Actions Individual Fellowships have recently been awarded to our Institute, and 2 more are on the reserve list. That represents nearly a 30% success rate. Our new fellows will work in top-notch areas such as nanostructured yarn composites for structural energy storage, new

International Women and Children in Science Day at IMDEA Materials Institute

Last Tuesday, February 8, IMDEA Materials opened the doors to children of the Community of Madrid to have the opportunity to know the great work done by women scientists and transmit them the enthusiasm they have in science. In the following link you can see a brief explanation of the activities

Seminar of Prof. Jiacheng Wang, from the Shanghai Institute of Ceramics, Chinese Academy of Sciences (CAS), entitle “Emerging Materials for Electrocatalysis” – At 11:30 am in the Seminar Room

Abstract Platinum-based materials are highly active as the electrocatalysts both in hydrogen evolution reaction (HER) and oxygen reduction reaction (ORR) in fuel cells, but high cost limits its wide applications. In this talk, the reporter summarized the recent research progress of designing and

Is ultra-fast processing the next revolution for steel production?

Researchers of our Institute collaborate with an international consortia to develop an ultra-fast processing process for steels. This approach is energetically more efficient than current methods. You can learn more about this technique in this article (Spanish only)

3rd review meeting

The 3rd OptiQPAP progress meeting was held on 24th of January, 2018, at the CTM headquarters (Manresa, Spain). The meeting was organized by Toni Lara. Project partners presented and discussed their research activities in frame of the OptiQPAP project within last 6 months, as well as

PhD Defense – Yetan Pan “Synthesis of nano-flame retardant and its use as a promising substitute of antimony trioxide in flame retardant flexible poly(vinyl chloride)”, supervised by Dr. De-Yi Wang.

The PhD Defense will take place on next Tuesday (23rd, January), at 12 noon, in the Sala Verde (first floor) in the Escuela de Ingenieros de Caminos, UPM The link below shows the address of the

ALFORAMA 1st consortium meeting in Ordizia

The First ALFORAMA Technical Committee Meeting took place on the 18th of January 2018 and was hosted by the Coordinator of the Consortium IK4-LORTEK in Ordizia, Spain The ALFORAMA partners reviewed the progress made across the different work packages addressing topics such as definition of

New project supported by the Center for Nanoscale Materials at Argonne National Laboratory

The Center for Nanoscale Materials at Argonne National Laboratory will support the research project entitled "Atomistic simulations of precipitate-strengthening for optimum design of light alloys for green transport", who will be carried out by Prof. J. LLorca, Dr. I. Papadimitrou and Mr. Gustavo

First Year Assessment of Can Fu entitle “Design and study of multifunctional flame retardant polyester fabric” – In the Seminar Room at 12:00 pm

ABSTRACT Poly(ethylene terephthalate) (PET) is extensively used in the production of fibers and films and now increasingly used as container material for soft drink due to its outstanding characteristics of high strength, good flexibility, and thermal stability, but their uses are limited by their