On October 6, BIOMET4D held the first meeting of its Stakeholder Advisory Board (SAB) in which board members were updated on the project's current status and its progress over the past year. All of the SAB members were present for the meeting, including Ana María Zambrano López from APERTCRAS,

DELIGHTED project’s latest results presented

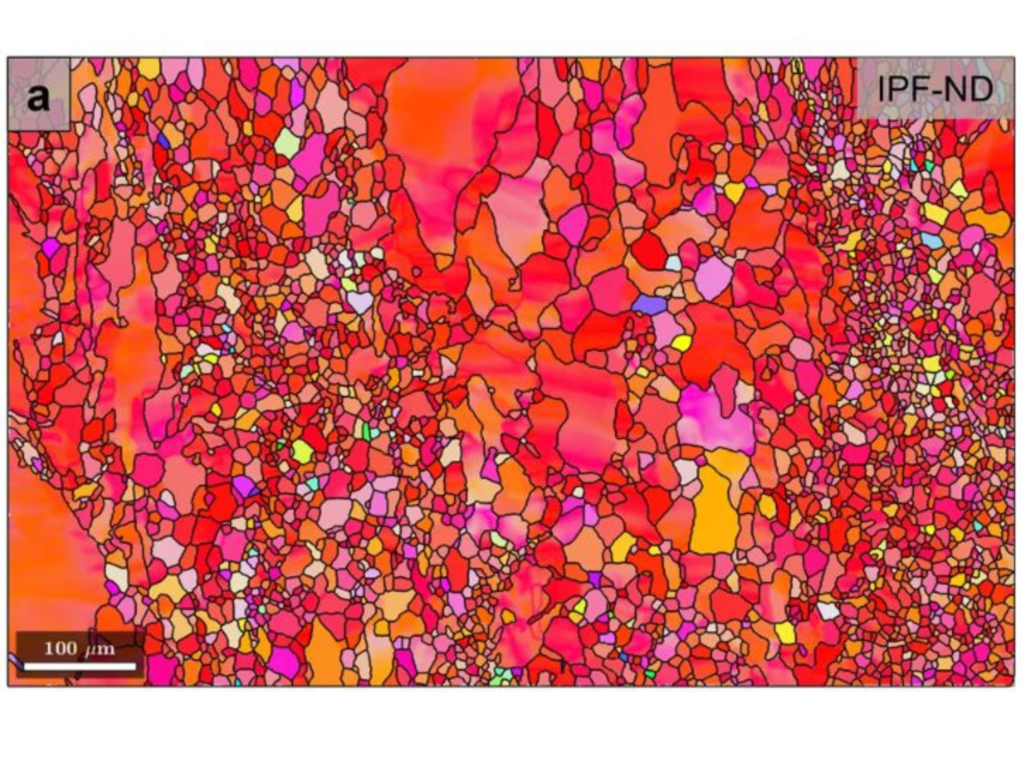

The DELIGHTED consortium continues to disseminate the project results. Andrea Gómez Fernandez from IMDEA Materiales gave a talk about the effect of aging on microstructure and mechanical properties of Fe-30Mn-9Al-1C steel on macro- and microscales at EUROMAT 2023 Congress in Frankfurt am Main,

IMDEA Materials Institute seeks a new generation of biodegradable implants to improve clinical results

IMDEA Materials researcher Guillermo Domínguez is developing new zinc alloys to manufacture biodegradable cardiovascular stents with better performance than those currently on the market. The ultimate goal of this work is to obtain a zinc alloy to be used in additive manufacturing techniques,

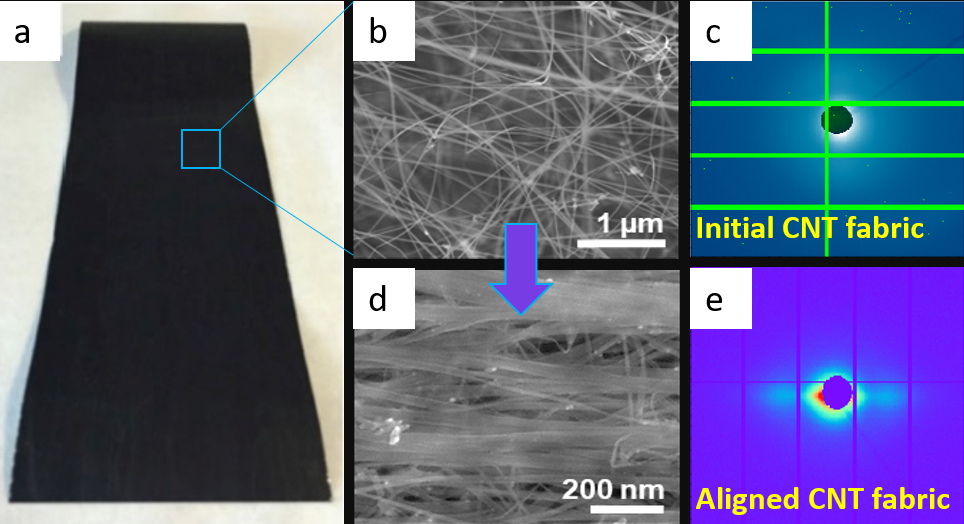

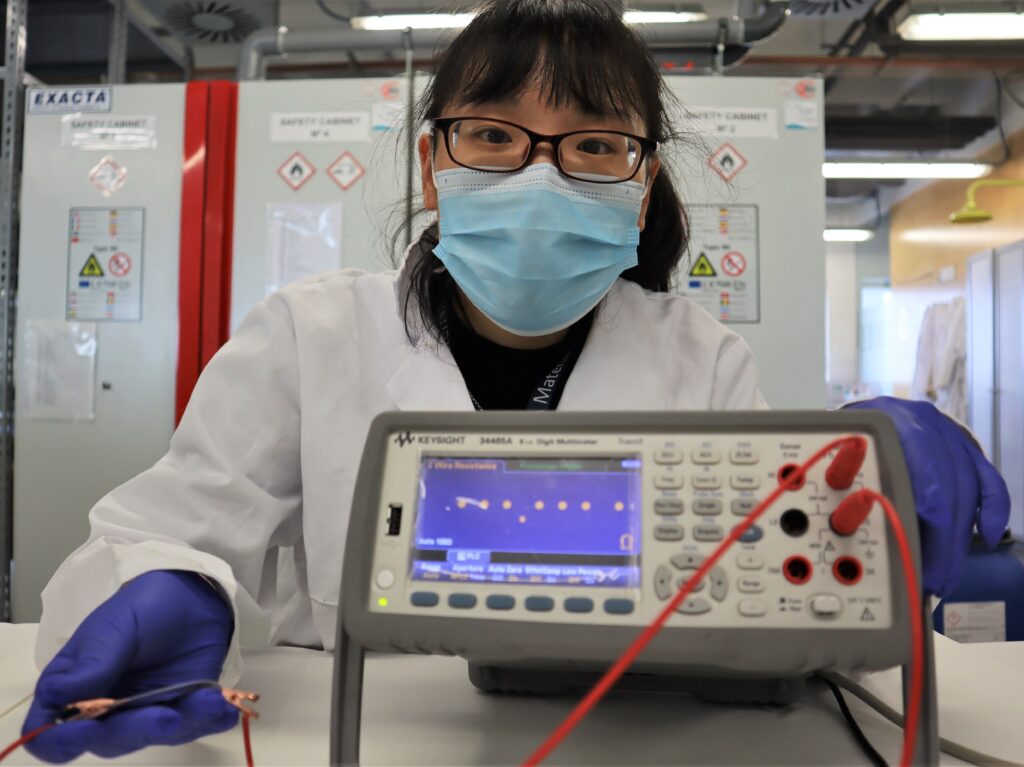

The results of the ENERYARN MSCA IF on multifunctional CNT fabrics featured by the European Commission

In the MSCA IF ENERYARN project, Dr. Anastasiia Mikhalchan worked on the development of CNT yarn-stretching strategies and new ways of studying energy-storing composite materials. The new methods addressed the alignment problem. Using them, the researchers team demonstrated that fabrics made of

REDISH project: results highlighted by the European Commission and used to evaluate how european research contributes to ACARE’s Flightpath 2050 roadmap

The results of the REDISH project have been highlighted by the European Commission in the 'Results in Brief' section at the CORDIS website. The project consortium, composed by IMDEA Materials and FIDAMC, applied a coupled experimental-numerical development approach to a number of possible

The OptiQPAP results are presented at the EUROMAT 2019 Congress

The OptiQPAP members continue to actively disseminate the outcomes of the project. The researchers from TU DELFT have participated at the EUROMAT 2019 Congress in Stockholm on September 1-5, 2019. The EUROMAT is the premier international congress in the field of materials science and technology in

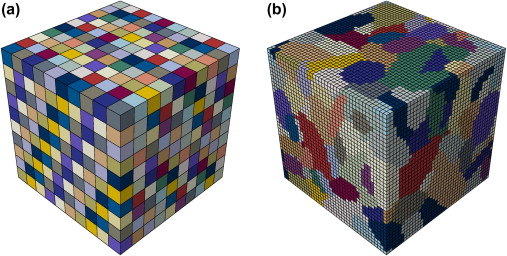

Synchronous parallel Kinetic Monte Carlo: Implementation and results for object and lattice approaches

Martin-Bragado, Ignacio; Abujas, J.; Galindo, P. L.; Pizarro, J.

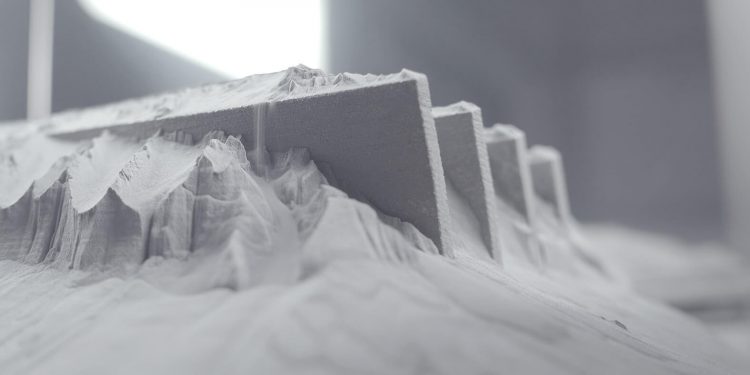

Printed Organs, Custom Scalpels, and Other Medical Applications of 3D Printing

KateStudio/Shutterstock Pedro Jesús Navarrete Segado, IMDEA MATERIALES One of the technologies that has had the most impact on advances in medicine in recent years has been 3D printing. In the 90s it began to be used in the production of dental implants and personalized prostheses, surprising

IMDEA Materials researchers unravelling the mysteries of twin nucleation in magnesium alloys

Twinning, a phenomenon where crystals develop mirror symmetry across a twin plane during deformation, holds significant importance in the mechanical behaviour of materials. Recently, researchers from IMDEA Materials Institute, Prof. Javier LLorca, Dr. Valentín Vassilev-Galindo and Biaobiao Yang,

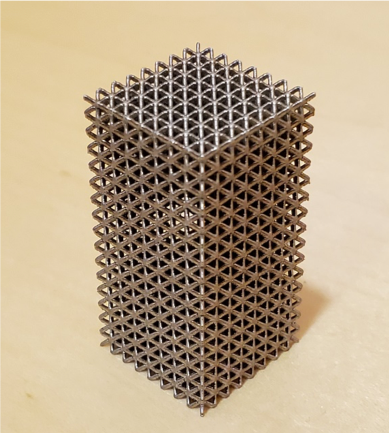

FYA of Sergei Zorkaltsev entitled “Towards Machine Learning Guided Design of Porous Metal Structures”– March 22nd, 2024.

Abstract: Porous metals are increasingly important in technology. Due to their tunable me- chanical properties, they are promising candidates in various emerging applications such as metallic scaffolds for load-bearing bones, lightweight structures for trans- port technologies, electrodes for

FYA of Arley García entitled “Design and Scaling of Novel Hard Coatings Deposited by Hipims for High-Speed Milling”– March 20th, 2024.

Abstract: The high standards and requirements demanded in high-speed machining (HSM) applications some examples are the precise manufacturing of microelectronics circuits or biomedical devices - comprise a delicate control of the tool preparation as well as coatings design and finish, which are

(METALIA) ENABLING TECHNOLOGIES FOR THE IMPLEMENTATION OF ARTIFICIAL INTELLIGENCE IN THE ADDITIVE MANUFACTURING VALUE CHAIN OF NEW METAL ALLOYS

Project details Funding: Proyectos Líneas Estratégicas – Transmisiones 2023.Project coordinator (AEI): CATECProject coordinator (CDTI): EgileProject period: 01/01/2024 – 31/12/2027 IMDEA Materials' researchers Dr. Federico SketDr. Jon M.

FYA of Qi Chen entitled “Biobased flame-retardant polymer electrolyte for lithium battery”– March 19th, 2024.

Abstract: The applications of Li-ion batteries (LIBs) vary widely from the transport sector (viz. electric vehicles, aircraft, robotics, drones, etc.) to battery energy storage technologies supporting and strengthening the power grid to mitigate the problem of intermittency of renewable energy

Seminar by Prof. Morten Willatzen from the Beijing Institute of Nanoenergy and Nanosystems, Chinese Academy of Sciences, entitled ‘Triboelectric Nanogenerators and Quantum-Mechanical Modeling of Contact Electrification’. Scheduled for March 20th, 2024

Abstract A general theory of triboelectric nanogenerators (TENGs) is presented for an arbitrary geometric setup consisting of two electrodes, a fixed dielectric, and a moving dielectric [1]. The two dielectric materials have opposite charges. Optimization of power output is computed for a general

DELIGHTED consortium celebrated final meeting

On February 6, 2024, the DELIGHTED consortium held its final meeting. The partners presented and discussed the latest results from the characterization of the developed steel grades within the framework of the DELIGHTED project. A manufactured prototype of a vineyard tractor cabin, ready for

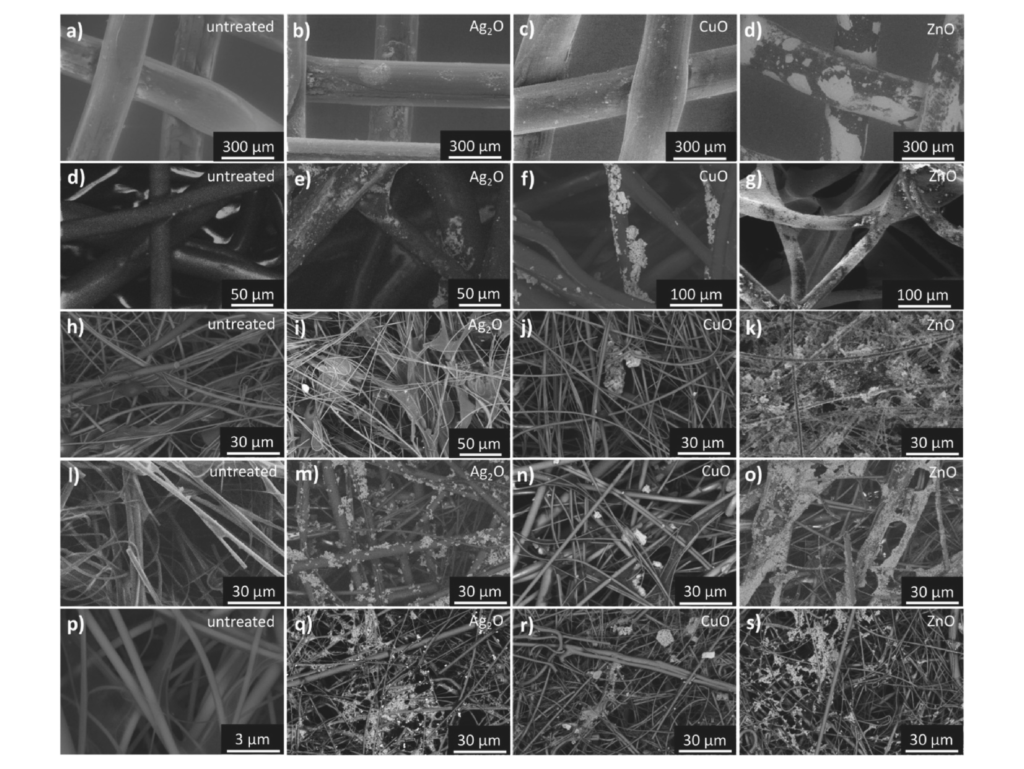

Promising new study significantly reduces risk of airborne bacterial infections caused by air filtration systems

A novel nanoparticle spray coating process has been shown to all-but eliminate the growth of some of the world’s most dangerous bacteria in air filtration systems, significantly reducing the risk of airborne bacterial and viral infections. That’s the principal finding of a recently published

Floatech, the disruptive Madrid-based startup, to build pilot plant for the production of its next-generation silicon anodes.

Floatech, the Madrid-based startup and spin-off of IMDEA Materials Institute, has secured investor backing to establish a pilot plant for the production of 100% silicon anodes intended for lithium-ion batteries (LIBs). The funding will enable Floatech to construct an advanced pilot plant in the

Seminar of Camila Aguiar Teixeira, from Karlsruher Institute of Technology (KIT) Germany, entitled “Measuring twinning stress of CoCrFeNiMn high entropy alloy by in situ micromechanical testing”. Next November 29th, 2023, at 4:30 pm.

Abstract: The equiatomic CoCrFeMnNi high entropy alloy (HEA) and its derivatives have attracted attention fromscientific community due to their mechanical properties, also at cryogenic conditions. Extensivemechanical twinning is mainly responsible for their outstanding mechanical response under

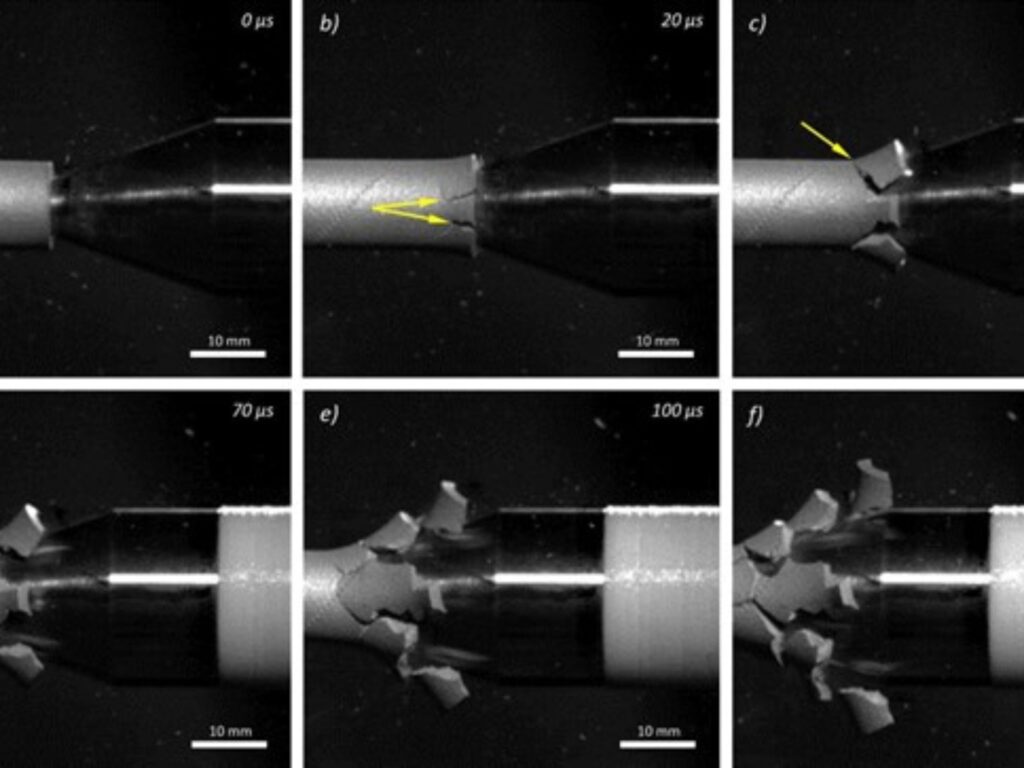

New experimental technique developed to analyse the protection of 3D printed metal structures

Scientists from the Universidad Carlos III de Madrid (UC3M) and IMDEA Materials Institute have developed a new experimental technique in fragmentation tests to evaluate the energy absorption capacity in the event of impact of metallic structures manufactured using 3D printing. This technique,

What is the most used material in the world and the least researched?

José Manuel Torralba, IMDEA MATERIALES We live in a world of steel. It's so common that we use it as a metaphor for everyday life. Some people have nerves of steel, and the biceps of many muscular young individuals are made of ship steel. What is not a metaphor is that steel is everywhere we

Seminar of Prof. K. Jimmy Hsia, from Nanyang Technological University (Singapore), entitled “Overcoming the adhesion paradox with shape memory polymers”. Next October 23rd, 2023.

Abstract: Animals such as geckos can climb vertical walls or even move about upside down on ceilings. Such locomotion requires strong and ubiquitous adhesion between their feet and various surfaces, yet easy detachment when needed. However, current smart adhesives made of elastomers suffer from

FYA de Miguel Hernández titulado: “Development of an autonomous laboratory for the preparation and characterization of nanocomposite materials”. El día 4 de octubre, a las 12:00 hr, en la sala de Seminarios.

Resumen: Nanocomposite materials based on a polymer matrix and nanomaterials (as Graphene Nanoplateletes, 2D clays or Metal Organic Frameworks) acting as additives are an exciting type of materials that bring the opportunity to create plastics with better properties (mechanical, thermal,

Seminar of Prof. Nik Chawla (from Purdue University), entitled “Unraveling the Construction of Honeycomb in the Apis mellifera Using Time-Resolved X-ray Microscopy (XRM)”– next October 11th, 2023.

Abstract: Honeycomb has fascinated humans for millennia. It is a naturally engineered structure that serves as storage for the bees, a place for the queen to lay eggs, rear their brood, among a multitude of additional functions. Even though honeycomb construction has been studied, results have

“The possibility of seeing what no one has seen before in what everyone has already looked at”: Prof. Javier LLorca is awarded the National Research Prize in Engineering and Architecture

The possibility of seeing what no one has seen before in what everyone has already looked at. That is a large part of what drives Prof. Javier LLorca to continue his pioneering work after nearly four decades among the best in Spanish science and research. Scientific Director of IMDEA Materials

FYA of Nabil Abomailek entitled “From aerosols to aerogels: A study on aggregation and gelation of floating 1D nanoparticles”. – September 29, 2023.

Abstract: Floating Catalyst Chemical Vapor Deposition (FCCVD) is a method for the synthesis of 1D nanoparticles, i.e., nanotubes and nanowires, in the aerosol phase. Specifically, 1-D nanoparticles grow on the surface of spherical catalyst nanoparticles while floating through a gas reactor. An

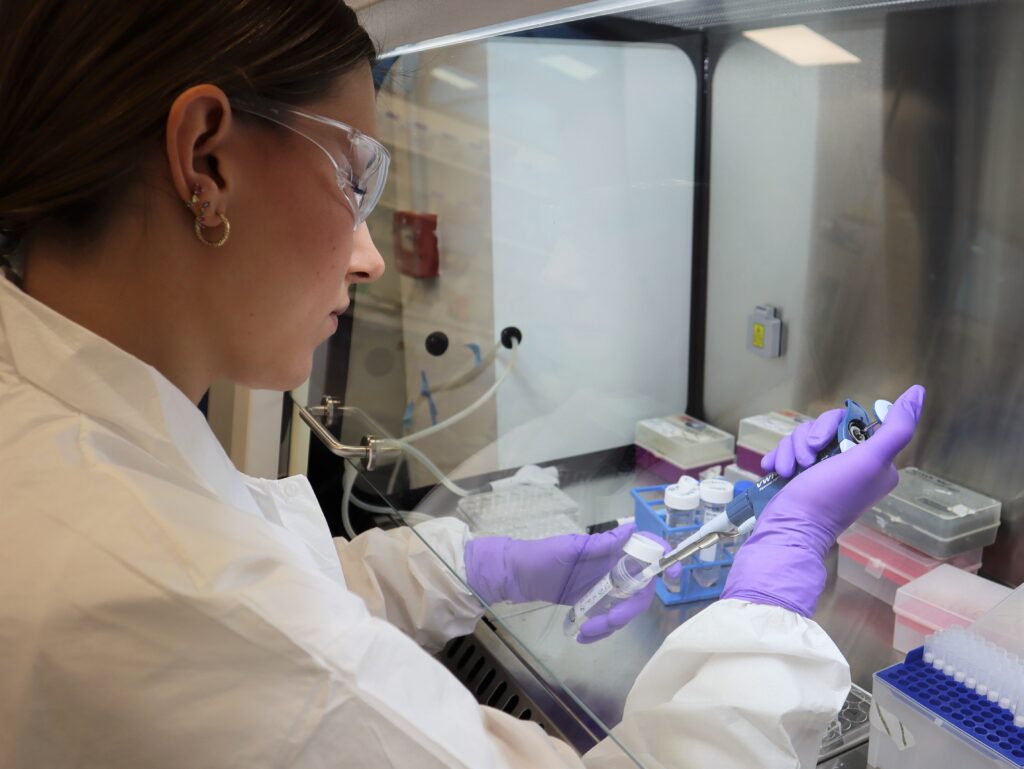

The DITTCe project: how IMDEA Materials Institute has joined the fight against cancer

Tomorrow, September 24th, World Cancer Research Day is celebrated. To commemorate this important day, IMDEA Materials Institute speaks with Dr. Mónica Echeverry, principal investigator of the DITTCe project. This project, led by the Technical University of Madrid (UPM), aims to develop an

FYA of Jingyi Zhang, entitled “Carbon Allotropes Inspired Acoustic and Mechanical Metamaterials” – September 22, 2023.

Abstract: Systems with broken continuous symmetry in ideal lattices cannot be rectified through rearrangement or deformation. Topological metamaterials featuring nontrivial, artificially induced phase transitions have emerged as pivotal constituents for engineering these topological defects,

Meet IMDEA Materials Institute Research Initiation Fellow Enrique Dios Lázaro

Each year, IMDEA Materials Institute offers three-month Research Initiation Fellowships, or Summer Scholarships, to final year master’s and undergraduate students studying courses related to engineering and materials science. Today, we’re getting to know one of this year’s fellows, Enrique Dios

IMDEA Materials looks to tackle growing number of bone replacement surgeries with stronger, longer lasting implants

Researchers at IMDEA Materials Institute are working to ensure that future bone replacement implants are more durable and offer a greater service life than ever before. The research, which is being undertaken through the European Union-funded M3TiAM project, is designed to meet the needs of an

BIOMET4D Dissemination Activities

Here you can find a review of the principal events and dissemination activities related to the BIOMET4D project. BIOMET4D researcher Dr. Jon Molina delivers keynote at AAMS2023 IMDEA Materials Institute Deputy Director, Dr. Jon Molina, has delivered a keynote presentation at the Alloys for

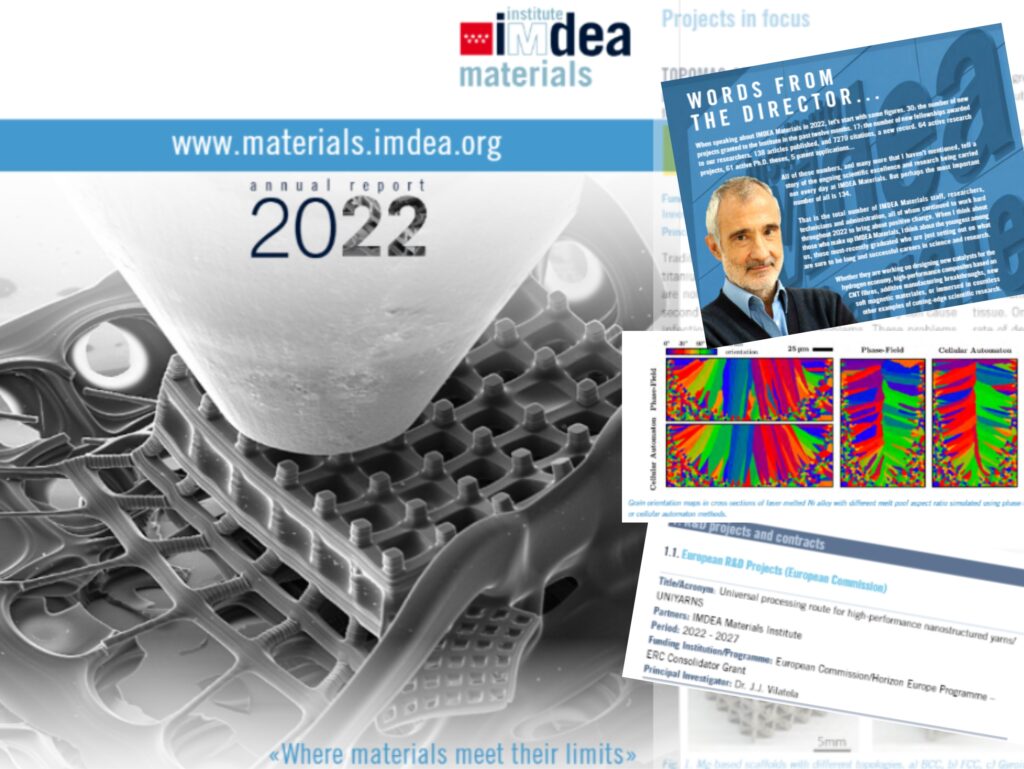

Year in Review – IMDEA Materials Institute is pleased to launch its 2022 Annual Report

MDEA Materials is delighted to announce the launch of our 2022 Annual report, available now for download. This annual report is designed to give you an overview of the Institute and main achievements in 2022. You will also find a description of the current Research Programmes, highlighting

Unveiling Breakthroughs: DELIGHTED Project’s Latest Findings Presented at THERMEC 2023 Conference

The dissemination activities of the outcomes of the DELIGHTED project are ongoing. Researchers from consortium members the Max-Planck Institute for Iron Research, IMDEA Materials Institute and the University of Ghent presented the latest DELIGHTED results at the THERMEC 2023 Conference in Vienna,

(DITTCE) IMPLANTABLE DEVICE FOR BRAIN TUMOR TREATMENT USING ELECTRICAL FIELDS

Project details Funding: Projects on Strategic Lines 2022.Project coordinator: Universidad Politécnica de MadridProject period: 01/12/2022 – 30/11/2025 IMDEA Materials' researchers Dra. Mónica Echeverry RendónDr. Javier LLorca Martínez Abstract The main objective is to develop

The secrets and science behind Damascus swords, long famed for their strength and beauty

José Manuel Torralba, IMDEA MATERIALES y Ilchat Sabirov, IMDEA MATERIALES Damascus steel swords were legendary for their great strength, durability and their "almost eternal" edge. They could cut silk as well as shatter a rock. Sultan Saladin impressed Richard the Lionheart at a sword exhibition.

The world’s first scalable and continuous surface modification process for magnesium alloy wires

Researchers from IMDEA Materials Institute and German medical equipment manufacturer Meotec GmbH have developed the world's first industrially scalable surface modification process for bioabsorbable magnesium alloy wires. The findings, as reported in two recently published scientific papers (see

Floatech eyes industrial-scale manufacturing of silicon anodes with its first pilot plant

Floatech, a Madrid-based spin-off of IMDEA Materials Institute, plans to open its first pilot plant for the manufacture of silicon anodes this year. Silicon anodes will be vital for the next generation of lithium ion batteries (LIBs) that will power the electric vehicles of the future. The

The future of regenerative medicine meets the present at IMDEA Materials Institute

By Blanca Martínez and Andrés Gerlotti Currently, those suffering from bone or cartilage damage can opt for metal implants for treatment, prostheses that last approximately fifteen years. But now that patients are living longer, they need implants that can function for the rest of their

Seminar of Dr. Miroslav Zezevic, from “Los Alamos National Laboratory” (USA), entitled “Large Strain Crystal Plasticity Gradient Model Based on FFTs: Formulation, Implementation and Application.”. March 8th, at 12:30 pm, in the Seminar Room.

Abstract: Robust and efficient full-field crystal plasticity models (based on finite element or FFT methods) have been developed over the past decades, and were extensively used for simulating and understanding different material phenomena at the macro- and mesoscales. On the other hand,

IMDEA Materials Institute Alumni in Focus – Sergio Sadaba

IMDEA Materials Institute alumni and Senior Computer-Aided Engineering (CAE) Project Engineer, Dr. Sergio Sadaba, believes researchers could finally be reaching a tipping point in the development of nuclear fusion reactor technology. Dr. Sadaba, who was at IMDEA Materials for more

Safer helmets and more comfortable running shoes: optimized 3D-printed metamaterials

This Saturday, February 11, is the International Day of Women and Girls in Science. To mark the occasion, IMDEA Materials is showcasing the work of three of our female researchers. In this, the second of three articles, we talk to predoctoral researcher Lucia Cobian about the European MOAMMM

Stopping brain tumor growth via electric fields using remotely powered, implantable devices

- IMDEA Materials Institute will play a key role in a new project aimed at designing and manufacturing new implantable devices for brain tumor treatment. - Glioblastoma is the deadliest form of brain cancer. It has a 5-year survival rate of less than 10%. Current treatments are both expensive and

Prof. Javier Segurado receives “Consolidation of Research Activity” award from the UPM

Prof. Javier Segurado, leader of IMDEA Materials' Multiscale Materials Simulation research group, recently received the "Consolidation of Research Activity" award from the Technical University of Madrid. Prof. Segurado received this award in recognition of the "impact and number of his scientific

(OPE – IMDEA MATERIALS 2023 – 2024) EUROPEAN PROJECT OFFICE IMDEA MATERIALS INSTITUTE 2023 – 2024

Project details Funding: Preparación y gestión de proyectos europeos 2022 Project coordinator: IMDEA Materials. Project period: 01/01/2023 – 31/12/2024 IMDEA Materials' responsible Miguel Ángel Rodiel Abstract The Office of European Projects of Institute IMDEA Materials (OPE - IMDEA

(CARDIOBOOST-CM) BIOINGENIERÍA DE CÉLULAS SATÉLITE DE MÚSCULO ESQUELÉTICO COMO NUEVA ESTRATEGIA DE DIFERENCIACIÓN A CARDIOMIOCITOS Y REGENERACIÓN CARDIACA

Project details Funding: Biomedicina 2022 - Comunidad de Madrid Project coordinator: Centro Nacional de Investigaciones Cardiovasculares Carlos III (CNIC) Project period: 01/01/2023 – 31/12/2027 IMDEA Materials' researchers Dr. Jennifer Patterson Abstract Relevance. Heart failure is a

(NATURE) CONSOLIDATION AND STUDY OF BEHAVIOR UNDER HYDROGEN

Project details Funding: Strategic Projects Focused on the Ecological Transition and Digital Transition 2021. Ministry of Science and Innovation (MCIN/AEI); European Union "Next GenerationEU"/ PRTR.Project coordinator: Universidad Carlos III de MadridProject period: 01/12/2022 –

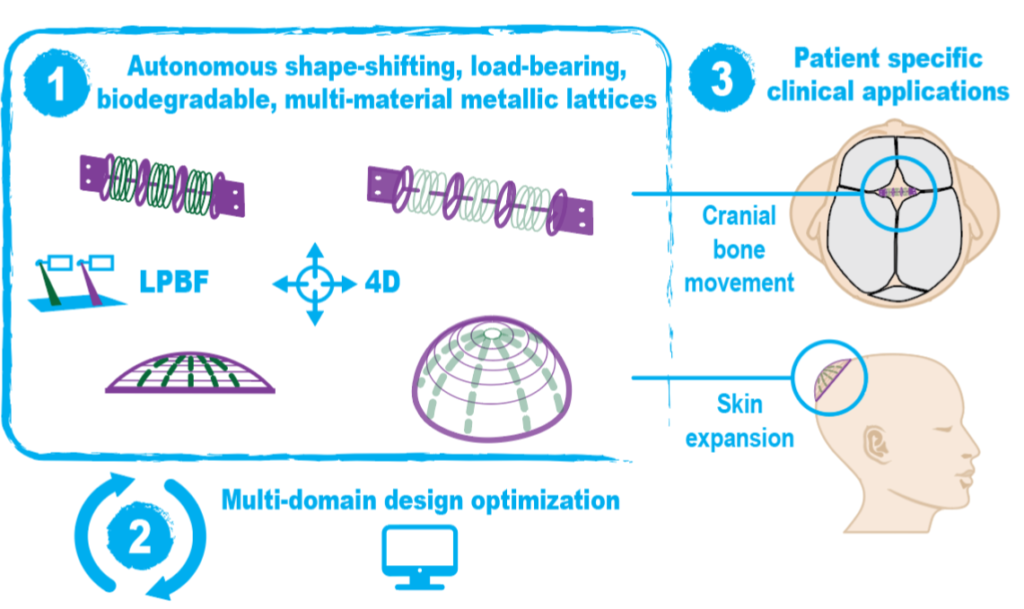

Reinventing 4D medical printing for intelligent, next-generation biomedical implants

IMDEA Materials Institute and the Technical University of Madrid (UPM) recently celebrated the first Open Innovation and Industrial Workshop, marking the 18-month point of the iMPLANTS-CM project. The main objective of iMPLANTS-CM, funded by the Community of Madrid, is the development of a new

First Year Assessment of Wen Ye, entitled“High-performance Flame-retardant Microspheres (FRMs) via Controllable Core-Shell Structure: Preparation, Characterization and Mechanisms» – November 11th, 2022 – 09:00 am (online)

Abstract:A novel series of FRMs was synthesized by suspension polymerization which had coreshell structure and complete spherical morphology. The core material is composed of a variety of flame-retardant components, some phosphate ester flame-retardant such as BDP, RDP, TPP etc. (or several of them)

IMDEA Materials and the UPM put additive manufacturing and the biomedicine of the future on show

Professor Andrés Díaz Lantada and Dr. Jon Molina-Aldareguia, of the Technical University of Madrid (UPM) and IMDEA Materials Institute, have highlighted the “significant advances” made in 4D printing, shape-morphing materials and medical devices thanks to the iMPLANTS-CM project. Their comments

IMDEA Materials developing sensor technology to detect fires before they start

Researchers at IMDEA Materials Institute are working on fire safety systems that can detect and warn of the risk of fire danger before a fire breaks out. Fire alarms generally operate by detecting the presence of smoke, open flame, and/or higher-than-normal levels of carbon monoxide. Such

First Year Assessment of Mingyang Zhang, entitled “Fire safety enhanced electrolytes for lithium ion batteries: materials, methods, and mechanism» –October 27th, 2022 – 12:00 hr.

Abstract: The development of advanced composite solid-state electrolytes (CSSEs) is considered to be one of the most promising directions for achieving breakthroughs in lithium battery technology. To enhance overall performance of electrolytes, such as mechanical properties, electrochemical

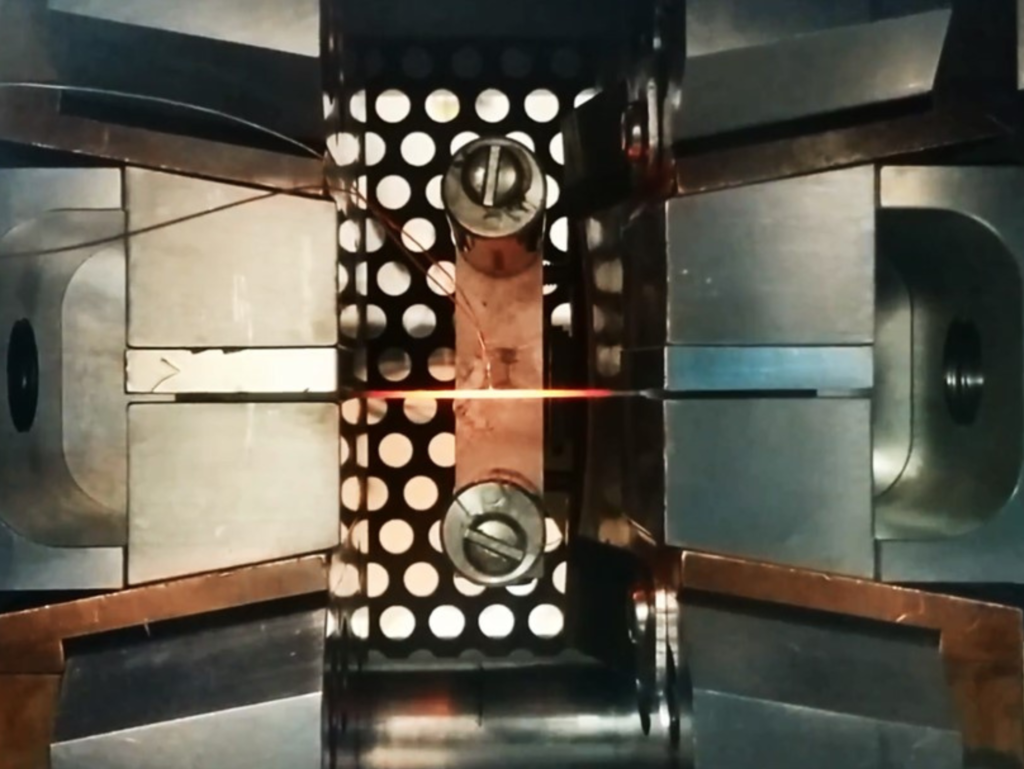

Seminar of Prof. Jose A. Rodríguez-Martínez from the department of Continuum Mechanics and Structural Analysis from the University Carlos III of Madrid, entitled “Dynamic plastic localization and fragmentation of porous printed metals: impact experiments and multiscale modeling”. October 24th, at 12:00 in the Seminar Room.

ABSTRACT: Understanding damage, localization and fracture in ductile solids and structures subjected to high velocity impacts or blast loadings has importance in aerospace industry, military applications, civil engineering and geophysical applications. Meteoric cratering, explosive behavior of

(PORMETALOMICS) POROUS METAL GENOMICS FOR TAILORING MECHANICAL PROPERTIES OF LIGHT-WEIGHT 3D-PRINTED ARCHITECTURES

Project details Funding: International Collaboration Projects PCI2022-1. Ministry of Science and Innovation (MCIN/AEI); European Union "Next GenerationEU"/ PRTR.Project coordinator: IMDEA Materials.Project period: 01/09/2022 – 31/08/2025 IMDEA Materials' researchers Dr. Maciej

IMDEA Materials joins the effort to construct a more sustainable future through 3D printing

An international group of researchers is out to prove that the wide-scale use of metal 3D printing in steel manufacturing can reduce energy consumption in the steel construction sector by up to 30%. That’s the goal of the recently launched, Resource-Efficient Steel Construction Using Additive

IMDEA Materials Institute Alumni in Focus – Olben Falcó

Given IMDEA Materials Institute only opened its doors in 2007, there haven’t yet been many opportunities for multiple generations of the same family to join its ranks. One of the rare exceptions, however, can be found in the case of former postdoctoral researcher Dr. Olben Falcó Salcines. Dr.

IMDEA Materials Institute Alumni in Focus – Bárbara Bellón

Dr. Bárbara Bellón has seen first-hand just how quickly IMDEA Materials’ International Reputation has grown in recent years. Bellón, who is currently working at the Max Planck Institute for Iron Research in Düsseldorf, completed her PhD at the Madrid-based research centre from 2015-2020. Since

EXCELLENCE UNIT MARÍA DE MAEZTU 2018

The objective is twofold. Firstly, to promote the quality of Spanish scientific research by recognising the best centres and units that stand out for the relevance and impact, at international level, of the research results obtained during the previous reference period. In addition to the

(BIOMET4D) Smart 4D BIOdegradable METallic Shape-shifting Implants for Dynamic Tissue Restoration

Project details Funding: Horizon Europe. EIC Pathfinder Open 2021 (Project No 101047008)Project coordinator: IMDEA MaterialsProject period: 01/07/2022 – 30/06/2026 IMDEA Materials' researchers Dr. Jennifer PattersonDr. Jon Molina-AldareguiaDr. Javier

Seminar of Dr. Jesús Ordoño, from IGTP, entitled “Lactate as a novel signal for cardiac tissue engineering and regenerative medicine”. July 26th, at 12:00 in the Seminar Room.

Abstract:The increasing prevalence of cardiovascular diseases on the world population urge the development of efficient new therapies for the reestablishment of the cardiac function. The heart has a very limited regenerative ability, and so lost cardiomyocytes cannot be replaced, thus causing

IMDEA Materials Institute Alumni Interview – Alicia Moya Cuenca

Dr Alicia Moya Cuenca was born in Cuenca, Spain. She joined IMDEA Materials in 2013, where she completed her PhD thesis entitled “Hybrid systems based on metal oxide and nanocarbons: electronic properties and applications for photocatalysis” under the supervision of Dr. Juan J. Vilatela. Afterwards,

About us

Who we are Mission, vision and pillars Code of ethics Organizational chart The IMDEA Materials Institute, one of the seven Madrid Institutes for Advanced Studies (IMDEA), is a public research centre founded in 2007

Year in Review – IMDEA Materials Institute is pleased to launch its 2021 Annual Report

IMDEA Materials is delighted to announce the launch of our 2021 Annual report, available now for download. This annual report is designed to give you an overview of the Institute and main achievements in 2021. You will also find a description of the current Research Programmes, highlighting

“A breath of fresh air”: IMDEA Materials celebrates International Women in Engineering Day

IMDEA Materials Institute has highlighted the importance of the participation of more women in the country's next generation of engineers. June 23 marks the International Day of Women in Engineering, a day with the aim of highlighting the role of female engineers in a sector that, like other

Materials science at “the tip of the spear” in confronting environmental challenges

IMDEA Materials is celebrating World Environment Day 2022 with a focus on the institute’s key role in improving industrial sustainability and reducing carbon emissions. Advances in the technology of lithium-ion battery production, the development of lightweight alloys and superalloys, the reuse

MSCA Fellow Series: Breaking new ground in phase diagram calculation

As a Marie Sklodowska-Curie Actions (MSCA) postdoctoral fellow, Dr. Sha Liu has helped the IMDEA Materials Institute to become a reference in the calculation of phase diagrams of metallic alloys for engineering applications. Dr. Liu, 31, joined IMDEA Materials in 2018 and has been working on

Seminar of Dr. Monsur Islam from the Institute for Microstructure Technology, Karlsruhe Institute of Technology, entitled “3D shaping of carbon to engineered living carbon materials”. May 31st, at 12:00 in the Seminar Room.

Abstract: Carbon microelectromechanical system (carbon MEMS) has emerged as a technique alternative to silicon-based MEMS technologies in the last two decades. Although carbon-MEMS allows for the fabrication of 3D carbon microstructures useful for several applications, complex architectures are

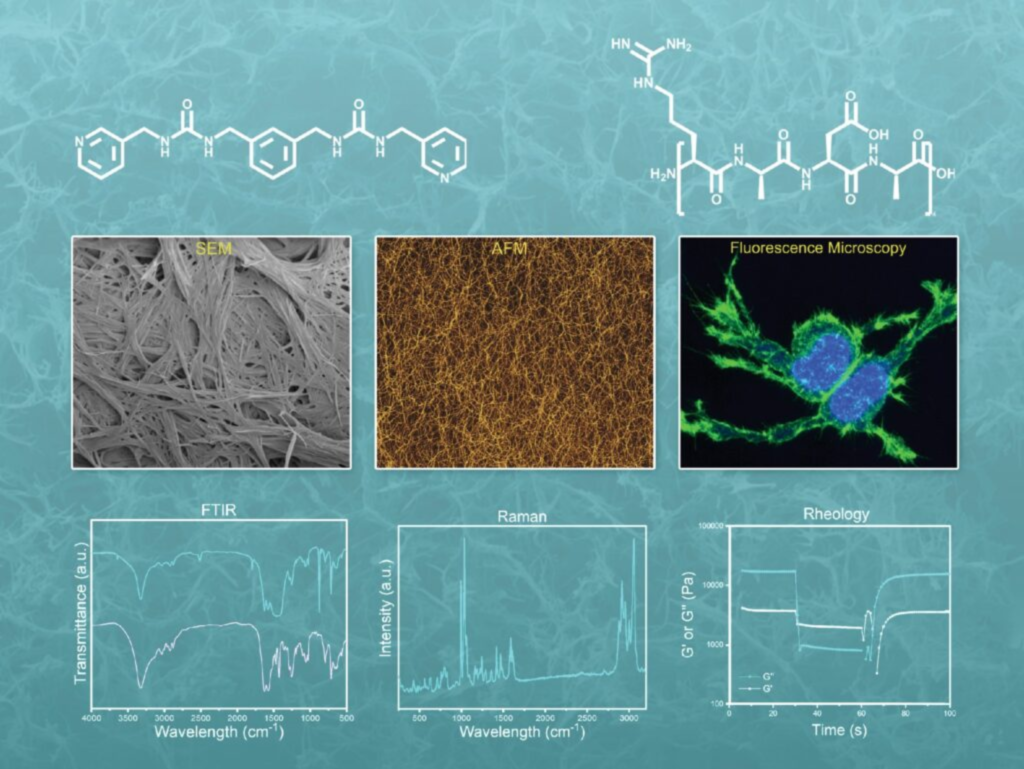

Scientific Highlight: Novel supramolecular hydrogels for biomedical applications

Hydrogels can be formed from polymers or from small molecules, from either natural or synthetic sources. Further, they can be classified by the types of bonds that form the hydrogel network – either covalent or non-covalent. Supramolecular hydrogels, particularly those formed from the

First Year Assessment of María Dolores Martin, entitled “Microstructure-Topology-Mechanical Properties relationship of 3D printed Mg-based scaffolds for biomedical applications (TOPOMAG-3D)” – 18th of March, 2022 – 12:00 pm

Abstract: Magnesium and its alloys are promising biodegradable metal scaffolds for potential bone regeneration applications, such as bioabsorbable implants. However, for this to be possible, further developments are necessary. On the one hand, Mg tends to corrode at a high rate, leading to

(MIMMOSA) MICRO/MACRO-MODELING OF SOLIDIFICATION IN ADDITIVE MANUFACTURING

Funding: Ministerio de Ciencia e Innovación. Proyectos de Colaboración Internacional - 2021Region: SpainProject period: 2022 – 2024Supervisor: Dr. Damien Tourret (damien.tourret@imdea.org); Fellow: Rouhollah Tavakoli (rouhollah.tavakoli@imdea.org)Metal Additive Manufacturing (AM) has an enormous

How time flies when you’re having fun: 15th anniversary of the IMDEA Institutes!

The Madrid Regional Government celebrated the fifteenth anniversary of the creation of the Madrid Institutes for Advanced Studies (IMDEA) on 25 February at the Real Casa de Correos. The event was attended by the directors, researchers and staff of the IMDEA Institutes and by the Director General of

Int. Day of Women and Girls in Science 2022: “Being a woman in science”, by Mónica Echeverry

If a day is commemorated, it is because something special has happened or will happen. Since 2016, the 11th of February has a different nuance. Each year brings a louder voice that reminds us that science is one, universal and does not discriminate against race, age, condition and much less

Seminar of Prof. Jaime Marian, visiting scientist at the IMDEA Materials, entitled “Elasto-plastic stochasticity: the role of atomic level fluctuations on mesoscale deformation properties in metals”. February 15th at 12:00 pm in the Seminar Room.

Abstract: Materials deformation is ultimately controlled by physical processes at the atomic scale. In many cases, these processes are controlled by fluctuations characterized by highly stochastic behavior. While we have learned to subsume this stochasticity into continuum laws that describe

IP portfolio

The IMDEA Materials Institute is constantly developing new technologies and inventions based on the results of our R&D projects. Here you can find an online catalogue gathering the technological offer ready to be transferred to industry, other research institutions, investors or

Seminar of Dr. Jaime S. Sanchez from the University of Technology (Sweden), entitled “All-Electrochemical Graphene Composite Multilayers Deposited on Carbon Fibers and 3D-Foams for Energy Storage” – January 27th, at 12:00 pm in the Auditorium.

Abstract: Major breakthroughs in batteries would require the development of new composite materials, with a precisely controlled nanoscale architecture. These materials can be synthesized directly on the electrodes using electrochemical methods, allowing sequential deposition, high structural

IMDEA Materials Institute Alumni Interview – Eva Moreno

Dra. Eva Moreno was born in Toledo, Spain. She joined IMDEA Materials in 2009, where she completed her PhD thesis entitled “Formability of ultra-fine grained metallic materials” under the supervision of Dr. Ilchat Sabirov. Afterwards, she found a position as a metallurgist in the materials

First Year Assessment of Andrea Gómez, entitled “Microstructural design in lightweight steels” – 14th of December, 2021 – 3:00 pm.

Abstract Pollution is a problem that affects us, and every day is more necessary to take into account the reduction of emission to environment. One of the proposal to reduce the pollution is decreasing the weight of automobiles. To reach this objective, it is necessary to develop new materials much

Seminar of Prof. Bianchi Mendez from the Materials Physics Department of “Universidad Complutense Madrid”, entitled “Nano-heterostructures based on wide bandgap semiconducting oxides: Synthesis and optical properties ” – 26th of November, at 11:00 am in the Auditorium.

Abstract: Wide band gap (WBG) oxides are currently attracting a lot of attention due to both their versatility in achieving a nanostructured architecture as well as from their capability of interacting with the ultraviolet radiation. In this talk, I will present our latest results concerning the

First Year Assessment of Mohib Mustafa, entitled “Nonlinear full-field simulation of lattice materials”– 24th of November, 2021 – 12:00 pm

Abstract: This report identifies key ingredients necessary for developing a robust numerical framework capable of performing full-field simulations of polymer base lattice materials. Direct simulation of components manufactured out of lattice materials is not deemed suitable on account of high

IMDEA Materials creates first spin-off to manufacture revolutionary battery electrodes for electric vehicles.

With the centre’s support, researchers from our group on Multifunctional Nanocomposites have launched a company to produce silicon electrodes for batteries for electric vehicles and portable electronic devices. It all started more than three years ago when the group, led by Juan José Vilatela,

First Year Assessment of Jorge Valilla, entitled “Physical and thermodynamic simulation of Functionally Graded Materials” – 4th of October, 2021 – 4:30 pm.

On Friday, 4th of October, Jorge Valilla will present his FYA entitled "Physical and thermodynamic simulation of Functionally Graded Materials". It will be a fully remote (zoom) event, at 4:30 pm: https://us02web.zoom.us/j/86733563907 Abstract: With the up and

IMDEA Materials and 3D printing of metamaterials for structural applications

Additive manufacturing, or 3D metal printing, allows to build ultralight and resistant structures with geometries that are impossible to achieve using conventional machining and processing techniques, including complex structures named “lattice”. These are three-dimensional constructions,

Flexible batteries for integration in car interior roof, boot and flooring components

Grupo Antolín, a worldwide supplier of technological solutions for car interiors, works with IMDEA Materials and IMDEA Energy Institutes in the development of flexible Lithium-ion batteries that can be integrated in interior components of vehicles. The objective is to develop Lithium-ion batteries

First Year Assessment of Isabel Gómez, entitled “Synthesis and Characterization of inorganic nanowires via Floating Catalyst Chemical Vapour Deposition” – 25th of June at 12:00, 2021.

Abstract: The work presented is the result of a year studying the growth of inorganic nanowires by floating catalyst chemical vapour deposition (FCCVD) with the objective of applying this technique to the synthesis of metal oxide nanowires. The differences between substrated-CVD and FCCVD

First Year Assessment of Lucia Cobian, entitled “Experimental-Numerical Analysis of Polymer Based Lattice Materials Fabricated with Additive Manufacturing” – 24th of June, 2021.

ABSTRACT: Lattice materials are materials constituted by the repetition of small cells composed of structural units as bars, beams or shells, which form a lattice. The cell geometry can be designed to have an outstanding macroscopic response such as very high specific stiffness or energy

IMDEA Materials researchers in the “Ranking of the World´s Top 2% Scientists”

The University of Standford just published its "Ranking of the World Scientists: World´s Top 2% Scientists". The ranking, which analyses data from Scopus like the number of articles published, the career-long citation impact up until the end of 2019 and the citation impact during the single calendar

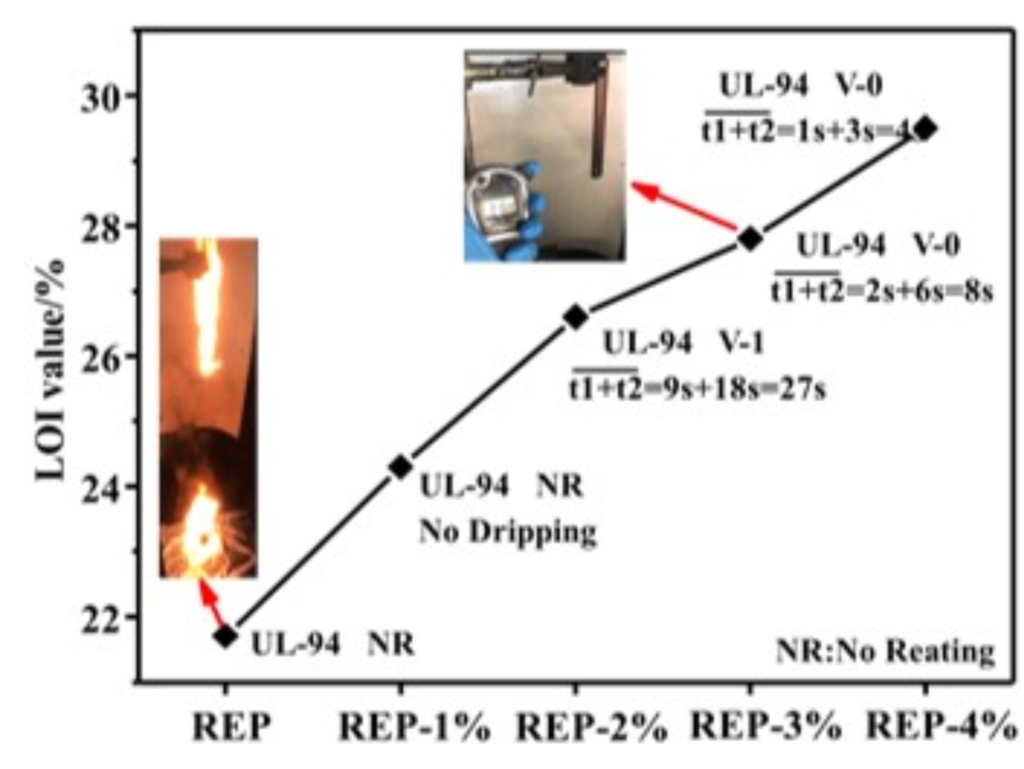

Scientific Highlight: Fire retardant reprocessable epoxy-based composites

IMDEA Materials has developed a technology to produce Reprocessable Epoxy Resin (REP) composites with excellent fire retardancy and re-processability. Compared with pure epoxy resin with a Limited Oxygen Index (LOI) of 21.7 % and no rating in vertical burning test (UL-94), recyclable epoxy resin

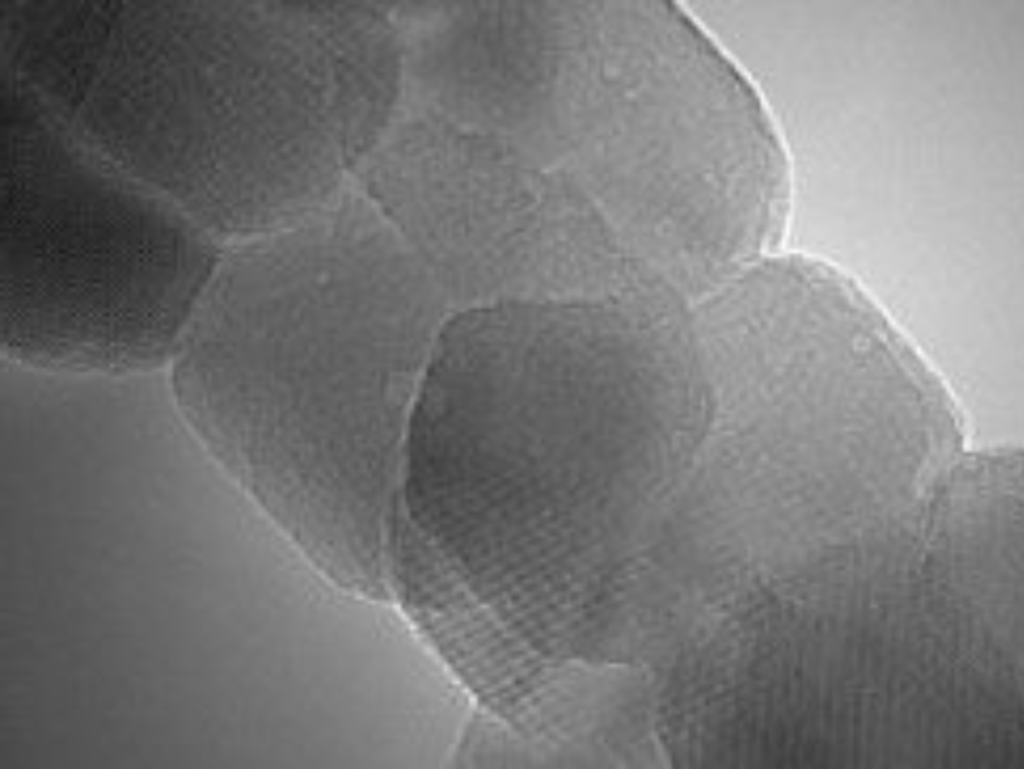

Scientific Highlight: Defect-engineered electrodes for long-range electric vehicles

Although secondary Li-ion batteries are widely used for electrochemical energy storage, low energy (100-300 Wh kg-1) and power density (250-400 W kg-1) are limiting their applications in several areas including long-range electric vehicles. This is mainly due to the use of graphite anodes with

IMDEA Materials Institute Alumni Interview – Saeid Loftian

Dr. Saeid Loftian was born in Iran. He joined IMDEA Materials in 2010, where he completed his PhD thesis entitled "High-Temperature Mechanical Behavior of Al/SiC Nanoscale Multilayers" under the supervision of Dr. Jon Molina and Prof. Javier LLorca. The thesis was awarded with the best PhD Thesis

First Year Assessment of Andres Sierra, entitled “Microstructural design in novel stainless steels via quenching and partitioning to improve their mechanical properties” – 12 of March, 2021.

Abstract: The quenching and partitioning (Q&P) process is a relatively new heat treatment (2003) aimed at the creation of a multi-phase microstructure of tempered martensite and stabilized retained austenite. This microstructure enhances the mechanical properties of the steel, achieving an

First Year Assessment of Alvaro Méndez, entitled “Harder and tougher AlTi(B)N coatings deposited by HiPIMS for high temperature applications” – 1st of February, 2021, at 12:00.

Abstract: A novel series of multilayered nanocomposite materials based on the AlTiN system with high Al content and the addition of B as the successful element for obtaining the amorphous phase are presented. The coatings were grown using co-deposition reactive HiPIMS from an alloyed TiAl(X)

Scientific Highlight: AI-guided smart manufacturing of structural composites

Manufacturing in the EU is crucial, given that it is one of the main drivers in innovation, job creation and sustainable growth. It involves almost 2,000,000 companies that provide approximately 28.5 million jobs. Therefore, its impact is significant in terms of economic share, with it being ~18% of

Quo Vadis Biogenic Phosphors?

LED professional journal publishes an article about the research approach being carried under the ARTIBLED project in its December issue (page 64). More articles will follow showing the results of the project.

ITP Aero and IMDEA Materials develop a pioneer R&D program to simulate 3D manufacturing processes

ITP Aero and IMDEA Materials collaborate in an R&D program named ENVIDIA, whose goal is the development of software capable of simulating the production of aeronautic components by additive manufacturing technologies. The activities in this program began in mid 2018, with the objective of

First Year Assessment of Xiaolu Li, entitled “Highly-sensitive Flame-retardant Smart Sensor for Early Warning Fire Detection to Polymer-based Materials” – 23th of November at 2:30 pm

Abstract Fire hazard is one of the major disasters that threaten public safety seriously. Once a fire occurs, the fire will spread quickly along some flammable materials, which bring much difficulty to control the fire. The fire hazard will cause casualties, considerable property loss and medical

PhD Defense of Yunfu Ou entitled “Hybrid FRP/CNT veil hierarchical composites with enhanced interlaminar properties and integrated multifunctionalities” – November 20th, 2020.

The PhD Defense will take place the 20th of November, at 12:00. The asistance will be remote. The dissertation is entitled "Hybrid FRP/CNT veil hierarchical composites with enhanced interlaminar properties and integrated multifunctionalities" Abstract: While FRP composites are extensively

MSCA Fellow Series: Enhancing mutual alignment and stress-transfer in multiyarn CNT fabrics

"We developed a method to enhance mutual alignment and stress-transfer in multiyarn CNT fabrics, which is a critical step for scaling up the CNT fabrics manufacturing process and further industrial implementation." Dr. Anastasiia Mikhalchan graduated from the Saint-Petersburg State University of

Scientific Highlight: Dynamic behavior of composites: Coupling tests and simulations

The use of polymer-based composite materials in aircraft structures has increased consistently in the last decades and today they represent up to 50% in weight for wings, fuselage sections and tail surfaces in the latest generation of commercial aircrafts. However, the use of such composites in

Scientific Highlight: Simulation of multiphysical coupled problems in mechanics of materials

There are situations in which the mechanical response of a material is coupled with relevant physical phenomena occurring in parallel. Some examples are chemomechanical problems in which mechanical fields interact with the evolution of the local composition, as it happens during the deformation

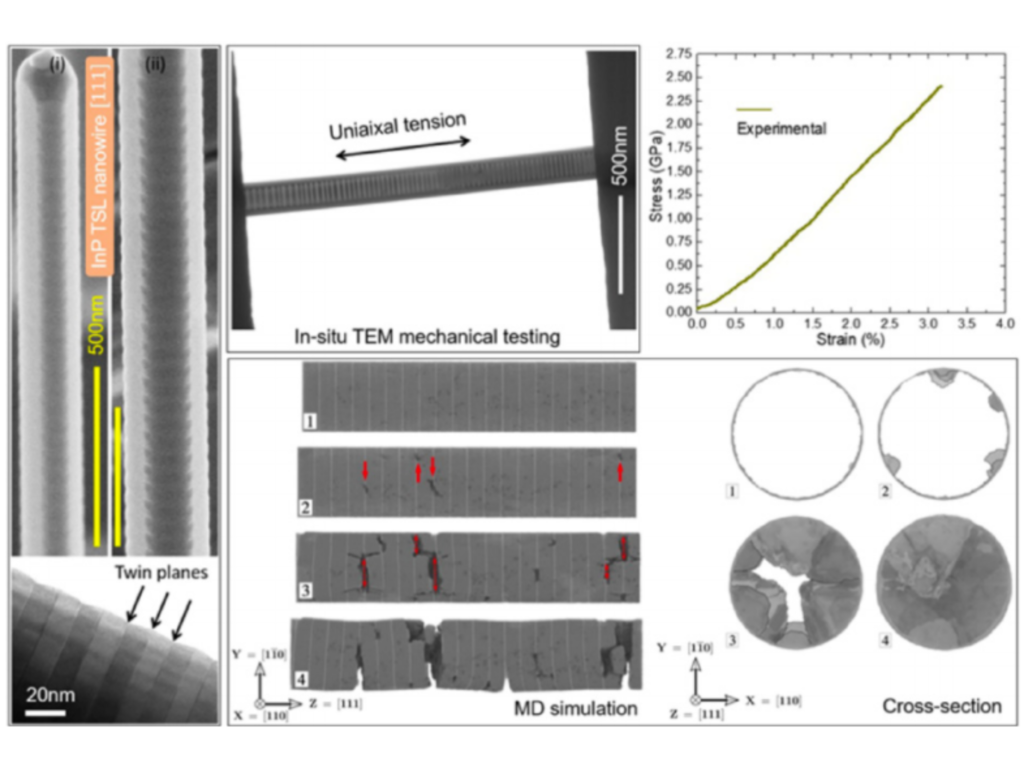

Scientific Highlight: Mechanical behavior of InP twinning superlattice nanowires

It has been shown that InP semiconductor nanowires carry charge and excitons efficiently and also exhibit very high optical efficiency. Their mechanical properties are extremely important, as mechanical strain strongly influences the electric, optical and magnetic properties. However, this

Year in Review – IMDEA Materials is pleased to launch its 2020 Annual Report

We are delighted to announce the launch of the IMDEA Materials 2020 Annual Report, available now for download. This annual report is designed to give you an overview of the Institute and main achievements in 2020. You will also find a description of the current Research Programmes

(DELIGHTED) DESIGN OF LIGHTWEIGHT STEELS FOR INDUSTRIAL APPLICATIONS

Intranet The project Triggered by environmental issues, the EU market has a strong interest in development of low-cost and lightweight heavy gauge steels for various applications. The austenitic Fe–Al–Mn–C quaternary alloys have recently been attracting tremendous attention, as they can

(ENLIGHTED) MULTISCALE DESIGN OF MG ALLOYS WITH HIGH STRENGTH AND DUCTILITY FOR SUSTAINABLE TRANSPORT

Proyectos I+D+i -Modalidades «Retos Investigación» y «Generación de Conocimiento»Proyecto PID2019-111285RB-I00 financiado por MCIN/AEI /10.13039/501100011033Region: NationalProject period: 2020 – 2023Principal Investigator: Teresa Pérez Prados (teresa.perez.prado@imdea.org)Increasing transport

Year in Review – IMDEA Materials is pleased to launch its 2019 Annual Report

We are delighted to announce the launch of the IMDEA Materials 2019 report, available now for download. This annual report is designed to give you an overview of the Institute and main achievements in 2019. You will also find a description of the current Research Programmes highlighting R&D

IMDEA Materials opens a Technology Transfer and Innovation Unit

As part of our strategic plan 2020-2025, we have recently opened a Technology Transfer and Innovation Unit (TTIU) to promote and support the commercial exploitation of the R&D results obtained within our projects. The head of the TTIU, Dr. Javier Rubio, joined the Institute on the 1st of March

Seminar of Dr. Laurent Capolungo from Los Alamos National Laboratory , entitle “Twin transmission across grain boundaries in Mg” – 9th of March, at 12:00 pm, in the Seminar room

Abstract Transmission of mechanical twins across grain boundaries in Mg is a mechanism that can facilitate intergranular crack propagation by providing a path to cracks along along the twin interface. Clearly, understanding twin transmission requires us to understand twin

The OptiQPAP project celebrates its final consortium meeting

The IMDEA Materials Institute has hosted the final face-to-face OptiQPAP project meeting. Partners have presented the latest results of their research within frame of the project. Preparation of the remaining deliverables, final project report and further dissemination of the OptiQPAP outcomes were

Madrid regional government, proud of the IMDEA Institutes

Ignacio Aguado, Deputy presisent of the Madrid region, has shown his satisfaction about the results achieved by the 7 IMDEA Institutes since their creation about ten years ago. The Madrid regional government funds around 50% of the budget of all IMDEA Institutes.

First Year Assessment of Thomas Isensee , entitled “Three-dimensional needle network model for dendritic growth with fluid flow” – 17th of January, in the Seminar Room at 12:00 pm

Abstract: In metals and alloys, complex solidification microstructures, such as dendrites, arise from a subtle interplay between phenomena occurring at much different scales: from atom attachment kinetics to macroscopic transport of heat and species in the different phases. As such, solidification

Seminar of Dr. Michalis Agoras from University of Thessaly (Greece), entitle “Homogenization Methods For Elasto-Viscoplastic Composites” – December 18th at 12:00 pm, in the Seminar room

ABSTRACT In this work, following Agoras et al. [1], we develop a homogenization procedure for particulate composites with elasto-viscoplastic constituents. By employing a standard time-discretization scheme for the local stress rate, we show that the associated

First Year Assessment of Juan Luis de Pablos , entitled “Formulation, implementation and statistical analysis of material models for metals subjected to high strain rates and high temperature” – 26th of September, in the Auditorium at 12:00 pm

Abstract The commercial aviation industry is a field of innovation and vanguard technology application, in which competitiveness is a critical need. As a consequence, new materials and techniques take place continuously with the purpose of creating a significant advantage in relation to other

First Year Assessment of Alba Martínez , entitle “Integration and properties of carbon nanotube fiber electrodes and new electrolytes in dye-sensitized solar cells” – In the Seminar Room at 12:00 pm

Abstract: Dye-Sensitized Solar Cells (DSSCs) are a promising alternative to Si solar cells, with efficiencies of 14% under sunlight and 28.9% under ambient light. DSSCs’ components can separately be optimized. One of the major challenges is replacing Pt-counter-electrode (CE), due to its

(FOTOART-CM) NUEVA GENERACIÓN DE MATERIALES MULTIFUNCIONALES PARA FOTOSÍNTESIS ARTIFICIAL

Funding: Regional Government of MadridPartners: IMDEA Energy Institute (Coordinador), Materials Science Institute of Madrid (CSIC), IMDEA Nanoscience Institute, IMDEA Materials Institute, Autonomous University of Madrid and Institute of Catalysis and Petrochemicals (CSIC)Region: MadridProject

(SYMMETRY) SHAPE MEMORY METAMATERIALS FOR ENERGY ABSORPTION

Funding: Ministerio de Ciencia, Innovación y Universidades. Proyectos: Explora Ciencia/Explora TecnologíaRegion: NationalProject period: 2018 – 2020Principal Investigators: Ignacio Romero Olleros(ignacio.romero@imdea.org)Artificially engineered lattice structrures, also known as metamaterials, are

(MUVITCAPCOM) MULTISCALE VIRTUAL TESTING CAPABILITY FOR COMPOSITES

Funding: Air Force Office of Scientific Research (AFOSR). U.S. Air Force Defense Research Sciences Program.Region: InternationalProject period: 2019 – 2022Principal Investigator: Claudio Faria Lopes (claudiosaul.lopes@imdea.org)The AFRL (Air Force Research Laboratory) and IMDEA Materials are at the

Seminar of Dr. Ysmael Verde from “TECNM México”, entitle “Doped carbon nanostructures for electrochemical energy devices” – September 13th at 11:00 am, in the Seminar Room

Abstract: Carbon nanotubes, graphene and graphene oxides have been under development due to their suitable properties to be applied in electrochemical energy devices such as supercapacitors, batteries and fuel cells. Recently, carbon nanostructures doped with heteroatoms have demonstrated to play

Seminar of Zhouwen Zhao from Michigan State University, entitle “Critical Resolved Shear Stresses (CRSS) of Hexagonal Titanium from Nanoindentation Optimization” – July 18th at 1:00 pm, in the Seminar Room

Abstract: Titanium and its alloys are important engineering materials due to their low density, high strength, and good bio-compatibility. The study of critical resolved shear stress (CRSS) values of basal, prismatic, and pyramidal ⟨c + a⟩ slip systems has been a hot topic in the community as

Seminar of Dr. Enzo Liotti from the University of Oxford, entitle “In-situ x-ray imaging studies of solidification” – July 2nd at 12:30 pm, in the Seminar Room

I Abstract Synchrotron x-ray–based imaging techniques, such as radiography and tomography, have reached sufficient spatio-temporal resolution that they are now used almost routinely to investigate solidification in technologically important systems such as steel, Ni, Al, and other alloy

(QPINOX) DEVELOPMENT OF NEW MARTENSITIC STAINLESS STEELS FOR AUTOMOTIVE LIGHTWEIGHT STRUCTURAL APPLICATIONS

Funding: European Union, Research Fund for Coal and Steel (Grant Agreement: 847195)Partners: RINA CONSULTING - Centro Sviluppo Materiali SPA (Project Coordinator), IMDEA Materials Institute, Technische Universiteit Delft, ACERINOX EUROPA SAProject period: 2019 – 2022Principal Investigator: Dr.

First Year Assessment of Mewin Vincent , entitle “Quest for high performance Mg and Mg-Li/Na ion hybrid concepts” – In the Seminar Room at 12:00 pm

Abstract Magnesium batteries are superior to all the known battery systems owing to its substantially larger volumetric capacity, environmental benignity, electrochemical stability and lower cost. This study is focused on the improving the electrochemical characteristics of Magnesium based

(CINEMA) CREATING AN INFRASTRUCTURE FOR THE NUMERICAL EXPLORATION OF METALLURGICAL ALLOYS

Funding: European Union, Marie Skłodowska-Curie Individual Fellowships, Horizon 2020 Programme (Grant Agreement 842795)Region: EuropeProject period: 2019 – 2021Principal Investigator: Supervisor: Dr. Javier Segurado (javier.segurado@imdea.org); Fellow: Dr. Damien TourretManufacturing has

CAPSUL

Software details Software authors Javier Segurado, Javier LLorca, Sergio Lucarini, Aitor Cruzado, Sarra Haouala, Vicente Herrera Intellectual Property Rights Copyright © 2012-2021 Fundación IMDEA Materiales and Universidad Politécnica de Madrid. All rights

(FOTOFUEL) SOLAR FUELS PRODUCTION CHALLENGES EXCELLENCE NETWORK

Funding: Spanish Ministry of Innovation and competitiveness (National programme for the promotion of excellence in scientific and technical research) (ENE2014-52280-REDT)Partners: IMDEA Energy Institute (Coordinator), Institute of Catalysis and Petrochemistry, Institute of Chemical Research of

20% success rate in call 2018 of Marie Skłodowska-Curie Actions Individual Fellowships

2 Marie Skłodowska-Curie Actions Individual Fellowships have recently been awarded to our Institute, and 2 more are on the reserve list. That represents a 20% success rate. Our new fellows will work in top-notch areas such as the numerical exploration of metallurgical alloys and inducing doping in

Technology & projects department

We count with a dynamic and professional team to support our researchers and partners in the following tasks: Attract funding Full support on competitive proposals preparation, including partner's search and contracts

Seminar of Dr. Christian Leinenbach from EMPA (Swiss Federal Laboratories for Materials Science & Technology), in Zurich, entitle “Microstructure control during laser additive manufacturing – what possibilities do we have?” – At 15:30 pm, in the Seminar Room

Abstract: During the last couple years, laser-based additive manufacturing (AM) technologies such as laser powder bed fusion (LPBF) and directed energy deposition (DED) have evolved from a mere prototyping technology to a real production technology that allow building parts with intricate 3D

Transversal training

Besides on-the-job technical training, IMDEA Materials Institute is committed to train the Institute’s staff in “soft” or transversal skills. Those competences are relevant to a broad range of occupations and sectors (academic research or teaching career, specialization in a given field or a career

Seminar of Prof. Kostas Danas, from The Ecole Polytechnique (Paris), entitle “Microstructured Magnetorheological Elastomers and Instabilities” -At 12:00 pm in the Seminar Room

Absract: Magnetorheological elastomers (MREs) are ferromagnetic particle impregnated rubbers whose mechanical properties are altered by the application of external magnetic fields. In addition, these composite materials can deform at very large strains due to the presence of the soft polymeric

Privacy Policy

Privacy policy The purpose of this “Privacy Policy” is to advise users of the general terms and conditions governing the collection and treatment of personal data by IMDEA Materials Institute.In accordance with REGULATION (EU) 2016 / 679 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 27 april

New grant from the European Research Council

Ruben Costa, head of the research group on Hybrid Optoelectronic Materials and Devices, has been awarded a Consolidator grant by the European Research Council. These grants allow ambitious top scientists to establish or strengthen their teams in Europe and be truly creative in their research. Ruben

First Year Assessment de Xaquín Rodiles titulado “Molecular and chirality control of CNTs synthesized via FCCVD process”– En la Sala de Seminarios a las 12:00 hr

ABSTRACT Carbon nanotubes (CNTs) have been a focus of nanomaterial research over the past two decades, due to their wide range of potential applications. In recent years, studies have shown a high degree of molecular control of CNTs in terms of number of layer, morphology and alignment, as well

Mauricio Terrones: Do something you like and that motivates you on a daily basis

«I strongly believe that it is important that everybody do something they like and motivate on a daily basis» Mauricio Terrones (Mexico DF, 1968) is a Physics Engineer by the Iberian-American University of Mexico City, did his PhD under the supervision of the former Nobel Laureate Harry Kroto and

Damien Tourret

«Dendritic microstructures are present in nearly every piece of metal around us» Damien Tourret received an MSc in Mechanical Engineering from INSA Toulouse (France) in 2006 and a PhD in Materials Science & Engineering from École des Mines de Paris (Mines ParisTech, France) in 2009. Before

First Year Assessment of Clara Galera, entitle “Additive manufacturing of high strength aluminum alloys with ZrH2 addition” – In the Seminar Room at 12:00 pm

Abstract Additive manufacturing (AM) is a layer by layer process that has the potential to disrupt traditional fabrication methods. It allows fast manufacturing of three dimensional pieces from metallic powders, with great exibility of design, potential for weight reduction, fast production speed

Damien Tourret: Dendritic microstructures are present in nearly every piece of metal

«Dendritic microstructures are present in nearly every piece of metal around us» Damien Tourret received an MSc in Mechanical Engineering from INSA Toulouse (France) in 2006 and a PhD in Materials Science & Engineering from École des Mines de Paris (Mines ParisTech, France) in 2009. Before

First Year Assessment of Carmen Fernández, entitle “Rigid fluorescent protein coatings for highly efficient and stable bio-hybrid LEDs” – In the Seminar Room at 12:00 pm

Abstract Additive manufacturing (AM) is a layer by layer process that has the potential to disrupt traditional fabrication methods. It allows fast manufacturing of three dimensional pieces from metallic powders, with great exibility of design, potential for weight reduction, fast production speed

IMDEA Materials Institute Interview – Rocío Muñoz Moreno

Rocío Muñoz Moreno finished her joint PhD (IMDEA Materials and UCM III) in 2014. Then she joined the Cambridge University's Rolls-Royce UTC (University Technology Centre) as postdoc and currently, she is working in the HP 3D printing team in Barcelona as an R&D Materials System Integration

IMDEA Materials Institute Alumni Interview – Nathamar Dudamell

Dr. Nathamar Dudamell Caballero was born in Maracay, Venezuela. She completed a MSc in Metallurgy Engineering at the Central University in Caracas, Venezuela (UCV) in 2006. In 2007 she joined the ALCOA’s Aluminium Research and Development Center in Alicante site. In 2008 Dr. Dudamell Caballero

Nathamar Dudamell

Dr. Nathamar Dudamell Caballero was born in Maracay, Venezuela. She completed a MSc in Metallurgy Engineering at the Central University in Caracas, Venezuela (UCV) in 2006. In 2007 she joined the ALCOA’s Aluminium Research and Development Center in Alicante site. In 2008 Dr. Dudamell Caballero

Rocío Muñoz Moreno

Rocío Muñoz Moreno finished her joint PhD (IMDEA Materials and UCM III) in 2014. Then she joined the Cambridge University's Rolls-Royce UTC (University Technology Centre) as postdoc and currently, she is working in the HP 3D printing team in Barcelona as an R&D Materials System Integration

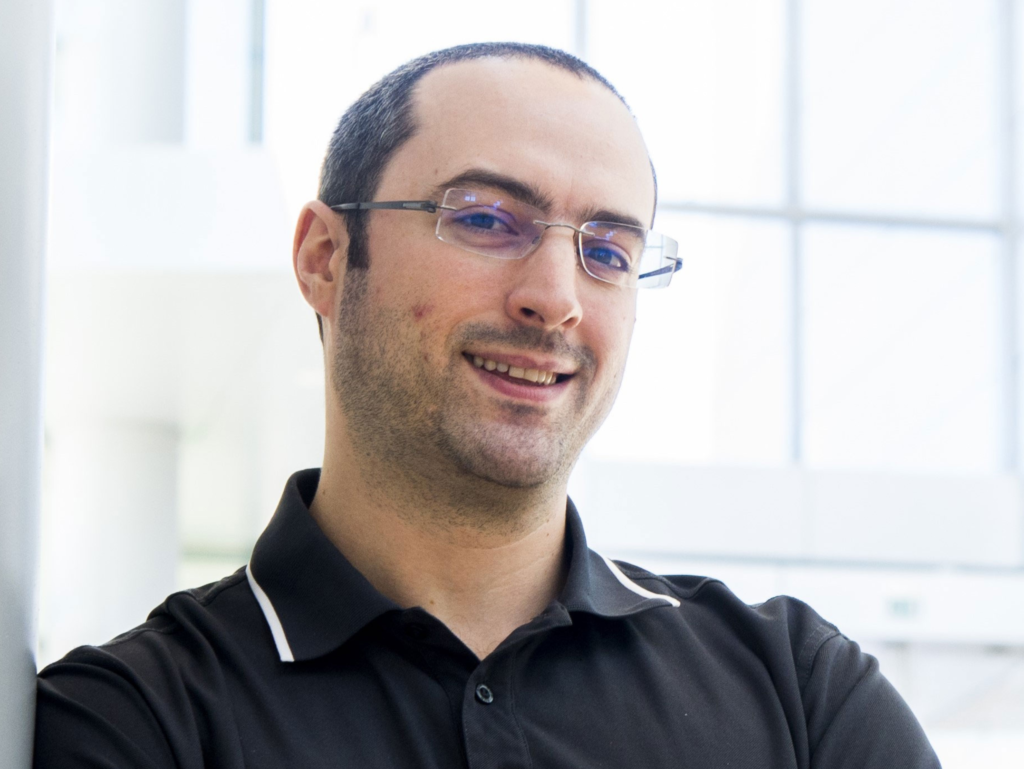

Multiscale Characterization of Materials and Processes

Main research lines Advanced material characterisation, including microstructural, chemical and crystallographic information across several length scales and using different techniques Multiscale characterisation with optical and electron microscopy, X-rays, atom force microscopy,

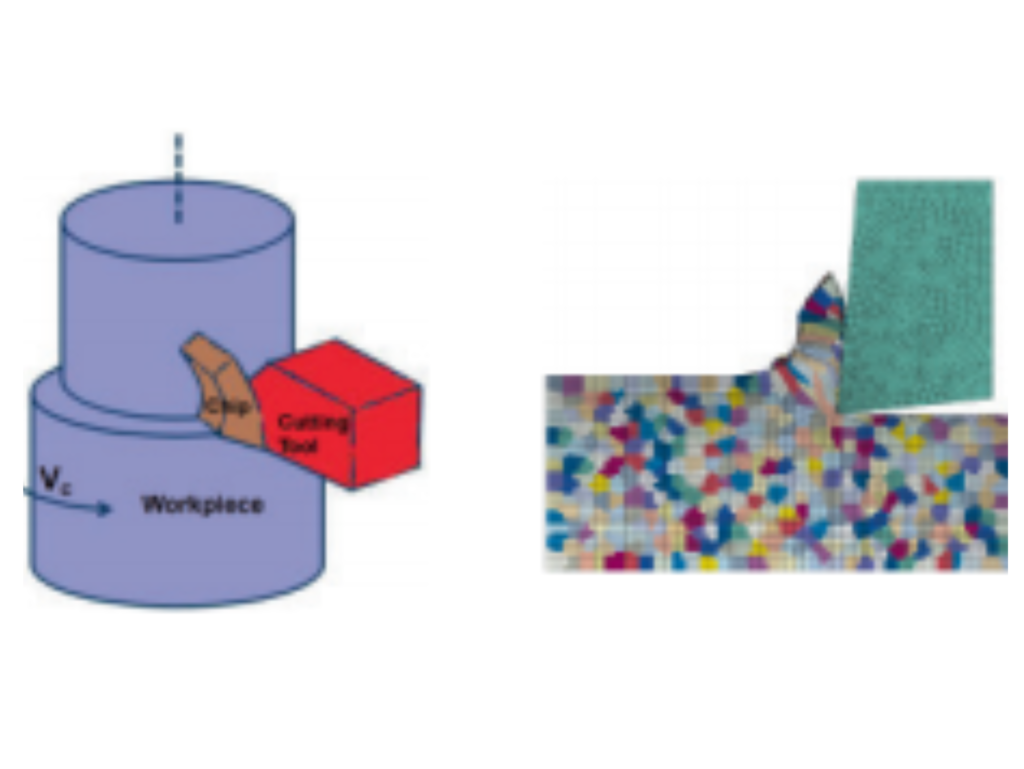

(EMULATE) MULTISCALE APPROACH FOR THE SIMULATION OF THERMOMECHANICAL PROBLEMS UNDER SEVERE CONDITIONS: APPLICATION TO MACHINING

Funding: Spanish Ministry of Innovation and competitiveness (National R&D Programme for Societal Challenges) (DPI2015-67667-C3-1-R) Partners: Mondragón University, Technical University of Madrid and IMDEA Materials Institute (coordinator) Region: Spain Project period: 2016 – 2018 Principal

Seminar of Prof. Jesus Barrio, from the Ben-Gurion University (Israel), entitle “Rational Design of Carbon Nitride Materials by Supramolecular Preorganization of Monomers” – At 11:00 am in the Seminar Room

Abstract Over the past few years, graphitic carbon nitride (g-CN) has attracted widespread attention due to its outstanding electronic properties, which have been exploited in various applications, including in photo- and electro-catalysis, heterogeneous catalysis, CO2 reduction, water splitting,

Seminar of Prof. Irene J. Beyerlein, from the University of California at Santa Barbara, entitle “Discrete slip crystal plasticity modeling of deformation in nanolayered materials” – At 12:30 pm in the Seminar Room

Discrete slip crystal plasticity modeling of deformation in nanolayered materials Irene J. Beyerlein1, Tianju Chen2, Rui Yuan2, Caizhi Zhou2,3 1 Mechanical Engineering Department, Materials Department, University of California at Santa Barbara, Santa Barbara 93106, USA 2 Department of Materials

First Year Assessment of Clara Galera, entitle “AAdditive manufacturing of high strength aluminum alloys with ZrH2 addition” – In the Seminar Room at 12:00 pm

Abstract Additive manufacturing (AM) is a layer by layer process that has the potential to disrupt traditional fabrication methods. It allows fast manufacturing of three dimensional pieces from metallic powders, with great exibility of design, potential for weight reduction, fast production speed

Technology offer

The IMDEA Materials Institute is constantly developing new technologies and inventions based on the results of our R&D projects. Here you can find an on-line catalogue gathering the technological offer ready to be transferred to industry, other research insitutions, investors or

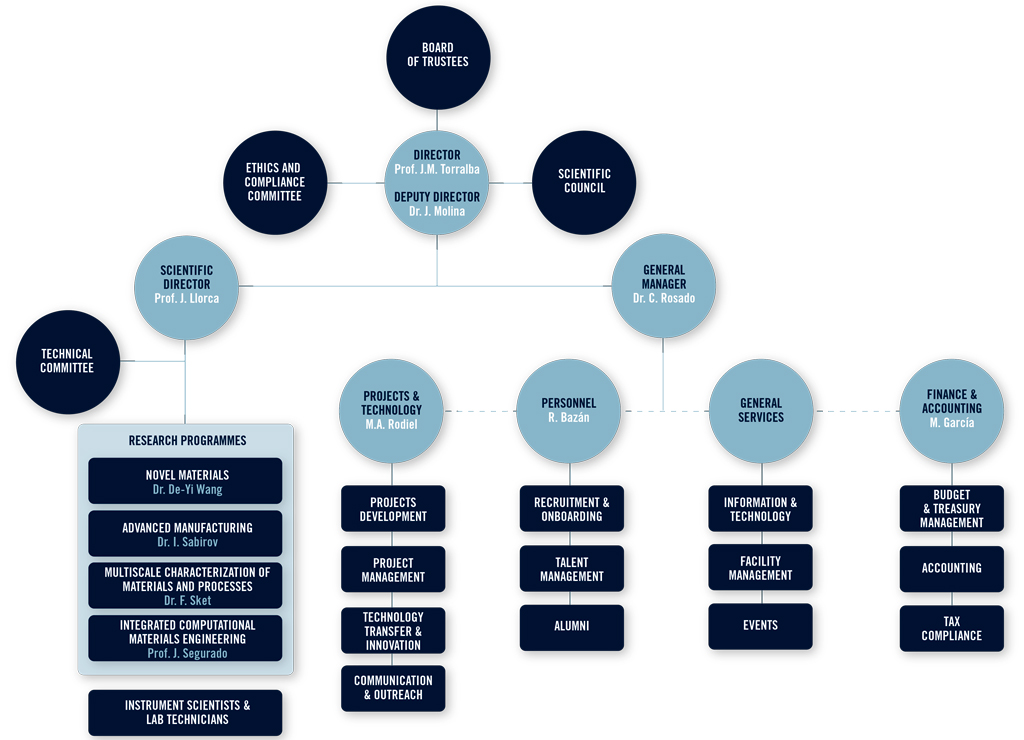

Organizational chart

The Institute is run by the Director, who is the CEO and reports to the Board of Trustees (main Governing Body of the Institute). The Director has to be a scientist, appointed by the Board of Trustees under the nomination of the Scientific Council, to reinforce the academic nature of the

First Year Assessment of Mario Rueda entitle “Nanoindentation impact testing methodologies for the high strain rate characterization of materials at the microscale” – In the Seminar Room at 09:30 am

Abstract: In view of the future application of polymer matrix composites for structural components subjected to impact loads, there is a need for development of experimentally calibrated constitutive models for polymers that include their inherent viscoelastic and viscoplastic behavior. These

Home

Design, processing, characterisation and simulation of advanced materialsCompetitiveness through advanced knowledgeNovel materials for future applicationsYour partner to develop innovative, high value materialsDownload Previous slide Next

Seminar of Prof. Efstathios I. Melts, from the Department of Materials Science and Engineering of the University of Texas at Arlington, entitle “The Quest for New Materials: Interface-engineered Materials” – At 12:00 am in the Seminar Room

ABSTRACT Atomic interface structures provide a unique opportunity to design new materials that can provide promising solutions to future technological demands. This talk presents an overview of two diverse areas of activity at the Surface and Nano Engineering Laboratory at the University of Texas,

Nearly 30% success rate in call 2017 of Marie Skłodowska-Curie Actions Individual Fellowships

3 Marie Skłodowska-Curie Actions Individual Fellowships have recently been awarded to our Institute, and 2 more are on the reserve list. That represents nearly a 30% success rate. Our new fellows will work in top-notch areas such as nanostructured yarn composites for structural energy storage, new

First Year Assessment of Can Fu entitle “Design and study of multifunctional flame retardant polyester fabric” – In the Seminar Room at 12:00 pm

ABSTRACT Poly(ethylene terephthalate) (PET) is extensively used in the production of fibers and films and now increasingly used as container material for soft drink due to its outstanding characteristics of high strength, good flexibility, and thermal stability, but their uses are limited by their

First Year Assessment of Jing Zhang entitle “Metal organic frameworks (MOFs) derived hierarchically nanomaterials as multifunctional fire retardant for polymer nanocomposites” – In the Seminar Room at 12:00 pm

Abstract Fire hazards including the generation of heat, smoke and toxic vapor, cost a great number of lives and damage properties. Compared with natural polymers, the high flammability and the widespread use of synthetic polymers lead to serious safety and environmental problems. Therefore, methods

First Year Assessment of Andrea Fernández entitle “Recycling of composites by recovering carbon fibres of cured prepregs, and their re-use in hybrid laminates” – In the Seminar Room at 12:00 pm

Abstract: Recycling of composites by recovering carbon fibres of cured prepregs, and their re-use in hybrid laminates by Andrea Fernández Gorgojo The applications of composite materials are rapidly growing in several sectors. For example, in the aeronautical sector, composites can account for up

Research Initiation Fellowships of Juan Manuel Moreno entitle “Optimization of electrolyte conductivities containing flame retardant. A computational experimentally-guided approach based on Genetic Algorithms combined with Machine Learning techniques (GAML)” – At 4:00 pm in the Seminar Room

Abstract Flame retardants are going to be such an important component in future Lithium-based batteries. However, these flame retardants have a major problem: they decrease the conductivity values of electrolytes. During this project we have been trying to use some new optimization techniques

First Year Assessment of Pablo García entitle “The fatigue behavior of advanced high-strength steels processed via quenching and partitioning” – In the Seminar Room at 12:00 pm

ABSTRACT The increasingly demanding environmental and safety goals imposed to the automotive industry have fostered fierce competition to develop new multi-phase steel types that are stronger, tougher, more formable, and fatigue-resistant. Among the various approaches in study, steels processed via

Seminar of Prof. Javier García Martínez entitle “Design, Fabrication and Commercialization of new catalysts engineered at the nanoscale” – At 10:00 am in the Seminar Room

DESIGN, FABRICATION AND COMMERCIALISATION OF NEW CATALYSTS ENGINEERED AT THE NANOSCALE J. García-Martínez Laboratorio de Nanotecnología Molecular, Dpto. Química Inorgánica, Universidad de Alicante, Ap. 99, E-03690 Alicante, Spain. www.nanomol.es; Rive Technology, Inc., 1 Deer Park Drive, Monmouth

ALFORAMA at Strategic Workshop on Additive Manufacturing

ALFORAMA participated in the European Strategic Approach on Additive Manufacturing that took place on 15th November 2017 in Oeiras, Portugal. The workshop was organised by the European Federation for Welding, Joining and Cutting and AM-motion project. The event

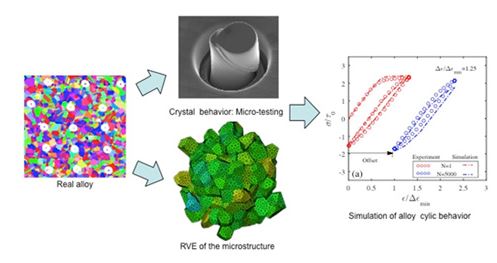

Modelling superalloy behaviour to improve aircraft engine design

The MICROMECH project, part of the Sustainable and Green Engines (SAGE) Integrated Technology Demonstrators (ITD) of Clean Sky, has successfully developed a multi-scale computational tool to predict the mechanical behaviour of the Ni-based superalloys used in the hottest parts of aircraft engines.

Seminar of Prof. Maurice Collins – “An Overview of Naturally derived polymers for Medical and Fibre applications” – Seminar Room at 1:00 pm

Maurice N Collins Stokes Laboratories, Bernal Institute, University of Limerick Abstract The first part of the talk deals with the hyaluronic acid biopolymer. Hyaluronic acid (HA) is a glycosaminoglycan that is found in extracellular tissue in many parts of the body. It is a material of increasing

Seminar of Prof. Luis Cueto-Felgueroso – “Stick–slip dynamics of flow-induced seismicity on rate and state faults”, 12:00 pm at the Seminar Room.

Stick–slip dynamics of flow-induced seismicity on rate and state faults Luis Cueto-Felgueroso Departamento de Ingeniería Civil: Hidráulica, Energía y Medio Ambiente Universidad Politécnica de Madrid luis.cueto@upm.es ABSTRACT Changes in pore pressure due to the injection or extraction of fluids from

Seminar of Dr. Markus Stricker – “Glissile junctions: Insights from discrete dislocation dynamics and development of a continuum model” -Seminar Room, 12:00 am

Glissile junctions: Insights from discrete dislocation dynamics and development of a continuum model Markus Stricker Karlsruhe Institute of Technology The understanding of the mechanisms governing plastic deformation of metals is the understanding of dislocation motion from single dislocations to

Seminar of Dr. Pedro B. Coto – “Intramolecular Singlet Fission: Insights from Quantum Dynamical Simulations” – Seminar Room, 10:30 am

Intramolecular Singlet Fission: Insights from Quantum Dynamical Simulations Pedro B. Coto Friedrich-Alexander Universität Erlangen-Nürnberg, Institut für Theoretische Physik und Interdisziplinäres Zentrum für Molekulare Materialien (ICMM), Staudtstraße 7/B2, Erlangen, 91058, Germany Email:

IMDEA Materials Institute takes part in “Graphene Market Place” organised by Airbus

The past 4th of May, IMDEA Materials Institute took part in the “Graphene Market Place” event, organised by Airbus in Getafe (Madrid), which counted with the participation of the 2010 Physics Nobel Prize, Konstantin Novoselov. Novoselov gave a talk in which besides explaining the simple exfoliation

Seminar of Prof. José A. Rodríguez-Martínez – “A general overview on multiple necking and fragmentation problems in ductile solids subjected to high strain rates” – April 19th 2017, Seminar Room at 12:30 pm

Seminar: "A general overview on multiple necking and fragmentation problems in ductile solids subjected to high strain rates" Understanding the fragmentation of ductile solids and structures subjected to high velocity impacts or blast loadings has importance in aerospace industry, military

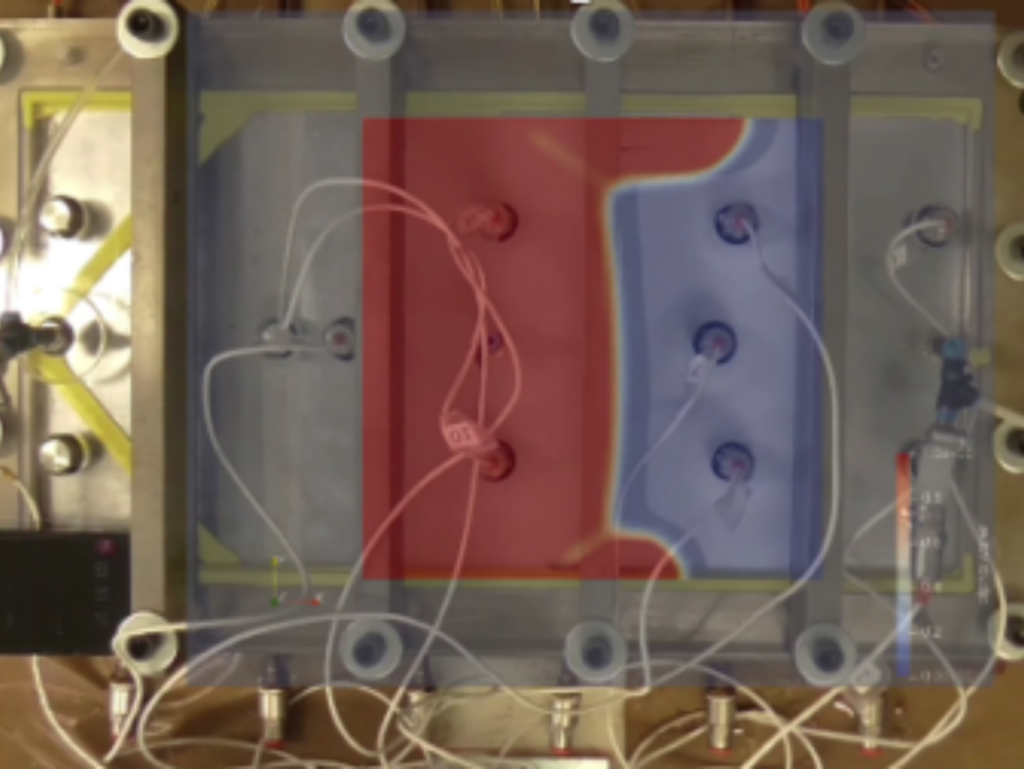

First Year Assessment of Jaime Castro entitle “Dual Scale Flow during Vacuum Infusion of Composites Experiments” – 11:00 am at the Seminar Room

Abstract LCM techniques such as RTM and VARI still require to be enhanced in order to disseminate their use in the industry. In situ VARI experiments were carried out using synchrotron X-ray computed tomography (SXCT) to study the mechanisms of microfluid within a fibre tow. A bundle of two tows of

Seminar of Dr. Elías Cueto – “A Manifold Learning Approach to Data-Driven Computational Elasticity and Inelasticity”

University of Zaragoza Abstract Standard simulation in classical mechanics is based on the use of two very different types of equations. The first one, of axiomatic character, is related to balance laws (momentum, mass, energy, ...), whereas the second one consists of models that scientists have

ITN 2016 – Coordinators Info Day

IMDEA Materials, as coordinator of the DYNACOMP network, attended an information day for ITN actions organized by the Research Executive Agency (REA) past 12/12/2012 in Brussels (Belgium). During the event, the REA (funding agency of the DYNACOMP project) provided detailed

Nanoscale hybrids for hydrogen production through water splitting using sunlight

A consortium of European universities, research centres and companies, led by IMDEA Materials Institute, is working on the production of new, more efficient hybrids composed of nanocarbons (e.g. graphene) and inorganics (metal oxides) that can produce hydrogen by water splitting using sunlight.

Hexagonal Lithium under ambient conditions

The Metal Physics group, led by Dr. Teresa Pérez-Prado, has succeeded in stabilizing a Li phase with a hexagonal closed packed (hcp) structure at room temperature and 1 atm by the application of pressure to Mg-Li alloys. At atmospheric pressure, pure Li and Li-Mg alloys undergo a bcc to hcp

High temperature nanomechanical testing: …or the art of compressing pancakes…

Researchers at IMDEA Materials Institute and members of the ESTRUMAT, programme have implemented new high temperature nanomechanical testing techniques. The objective is two-fold. On the one hand, these techniques are necessary to study size effects in the mechanical properties of materials,

HIGHRATE project

This project will study high strain rate mechanical behavior of novel Advanced High Strength Steels (AHSS). The results of these investigations will greatly contribute to understanding of mechanical behavior of the AHSS and help to reduce the dimensions of the AHSS components used in the automotive

Watching Metals Alive

Researchers at IMDEA Materials Institute are investigating the in-situ deformation of metallic materials using a tensile testing micromachine coupled to a scanning electron microscope (Fig. 1a). This device allows to analyze in real time, the deformation, recrystallization and fracture mechanisms

Carbon nanotube “stitches” strengthen composites

The newest Airbus and Boeing passenger jets flying today are made primarily from advanced composite materials such as carbon fiber reinforced plastic (extremely light, durable materials that reduce the overall weight of the plane by as much as 20 percent compared to aluminum-bodied planes). Such

When will it break?

In recent years, large spills from oil pipelines and tankers, leaks from nuclear reactors and the constant need for lighter, stronger, and safer materials in the transportation industry illustrate how breaks or cracks (fracture) can have detrimental effects in terms of health and safety, the

An IMDEA Materials Institute poster awarded at the European Congress Aerodays 2011

The results presented are part of two doctoral theses that are being carried out at the IMDEA Materials Institute within the framework of various research projects. On the one hand, Marcos Rodriguez presented a new methodology of micromechanical characterization of composite materials which is being

Design allowables for Ni-based superalloys

As part of the European project MICROMECH, carried out in collaboration with Industria de Turbopropulsores (ITP), the following results have been obtained Development of a new methodology for experimental characterization at the micro scale. This methodology is based on micropillar compression as

Computational modeling of Magnesium alloys

By comparison with other metals such as Aluminum or Steel, Magnesium alloys present the remarkable advantage of having a very high specific strength. They are thus becoming increasingly relevant to industries within the automotive or aerospace sectors, as the incorporation of these alloys in

Airbus entrusts IMDEA Materials the design of advanced shields against high-velocity ice impact

Airbus is already planning its A30X next generation aircraft to replace the A320, the standard Airbus jet airliner for short- to medium-range routes. The aircraft manufacturer has been evaluating new configurations through the European Union-funded Nacre (New Aircraft Concepts Research) project,

FASENOVA. – New metallic materials by compression and shear

The objective of this research project, funded by the EXPLORA program of the Spanish Ministry of Science and Innovation (MICINN) is to evaluate the possibility of stabilising, under ambient conditions, high pressure metallic phases by the simultaneous application of compression and shear. The good

Prof. Javier LLorca receives the prestigious ERC Advanced Grant

Prof. Javier LLorca, Director of IMDEA Materials Institute, has obtained the prestigious ERC Advanced Grant from the European Union. Prof. LLorca will receive € 2.5 million along the next 5 years to develop multiscale modeling strategies to carry out virtual design, virtual processing

IMDEA Materials starts PilotManu project

PilotManu is an European project funded by the 7th Framework Programme of the European Union. PilotManu will upscale of the current mechanical alloying technological facility into a powder manufacturing pilot line by further developing existing IPR-covered results owned by the consortium related to

(MAAXIMUS) MORE AFFORDABLE AIRCRAFT STRUCTURE LIFECYCLE THROUGH EXTENDED, INTEGRATED, & MATURE NUMERICAL SIZING

Funding: European Union, 7th Framework Programme (Cooperation, Transport Theme)Region: InternationalProject period: 2008 – 2016Partners: Consortium of 58 partners from 18 countriesPrincipal Investigator: Dr. Carlos González (carlosdaniel.gonzalez@imdea.org)A Collaborative Research project funded by

(CRASHING) CHARACTERIZATION OF STRUCTURAL BEHAVIOUR FOR HIGH FREQUENCY PHENOMENA

Funding: European Union, Clean Sky Joint Undertaking, 7th Framework Programme (CS-GA-2013-632438) Region: Europe Project period: 2014 – 2016 Principal Investigator: Dr. Claudio Saul Lopes (claudiosaul.lopes@imdea.org) The use of composite materials as principal structural elements in an

(NFRP) NANO-ENGINEERED FIBER-REINFORCED POLYMERS

Funding Organization: Marie Curie Action-CIG, 7th Framework ProgrammeRegion: EuropeProject Period: 2013 – 2017Principal Investigator: Dr. Roberto Guzmán de VilloriaFiber-reinforced polymers (FRP’s), stronger per unit of weight than steel or aluminium, are highly demanded for high-performance

(CARINHYPH) BOTTOM-UP FABRICATION OF NANOCARBON-INORGANIC HYBRID MATERIALS FOR PHOTOCATALYTIC HYDROGEN PRODUCTION

Partners: IMDEA Materials Institute, Westfälische Wilhelms Universität Münster, Thomas Swan & Co Ltd., University of Cambridge, Friedrich-Alexander-Universität Erlangen-Nürnberg, INSTM, INAEL Electrical Systems and EMPAFunding Organization: European Union, 7th Framework Programme (Cooperation,

(SIMUCOMP) ADVANCED NUMERICAL SIMULATIONS OF INTER- AND INTRALAMINAR FAILURES IN COMPOSITE

Funding: ERA-Matera+, 7th Framework Programme Region: Europe Project period: 2010 – 2013 Principal Investigator: The research consortium is led by IMDEA Materials Institute and includes Université de Liège (Belgian University), CENAERO (Belgian Research Center), Centre de Recherche Public Henri

(SINTONIA) UNMANNED SYSTEMS ORIENTED TO NULL ENVIRONMENTAL IMPACT

Funding: CDTI (CENIT 2009 Programme) and National Consortium Region: IndustrialProject period: 2010 – 2011Partners: National consortium of companies (CESA, Sener, Indra, Aernnova, ARESA, among other companies of the aerospace sector) and several research organizations.Principal Investigator: Drs.

(FIRERESIST) INSIGHTS INTO THE DEVELOPMENT OF ECO-FRIENDLY AND EXCELLENT FLAME RETARDANT POLYMER NANOCOMPOSITES

Funding Organization: Spanish Ministry of Science and Innovation (Fundamental Research) Industrial Sector: Electronics, packaging, etc Project Period: 2011 – 2013 Principal Investigator: Dr. Aravind Dasari Unsatisfactory flame performance with eco-friendly materials is a major obstacle for